Happens every time. You're deep in an aisle, the foreman's breathing down your neck, and your Yale MPB040 just quits. No warning, no sputter—just a 4,000 lb paperweight.

Before you start tearing off covers or cursing the dealer who sold you this glorified hand truck, take a breath. Ninety-nine percent of the time, it's not some deep-state secret only their magic "Service Master" laptop can solve. It’s one of three things: power, electrical, or hydraulics. Just like the yellow iron I fix every day.

I've seen guys waste a whole shift chasing ghosts when the fix was staring them in the face. The key is quick, dirty triage. Don't just start swapping parts like a dealer tech. Think like the machine. What does it need to move? Juice from the battery, a signal from the controls, and pressure in the lift cylinder. That's it. It’s not a finicky JCB AdBlue system.

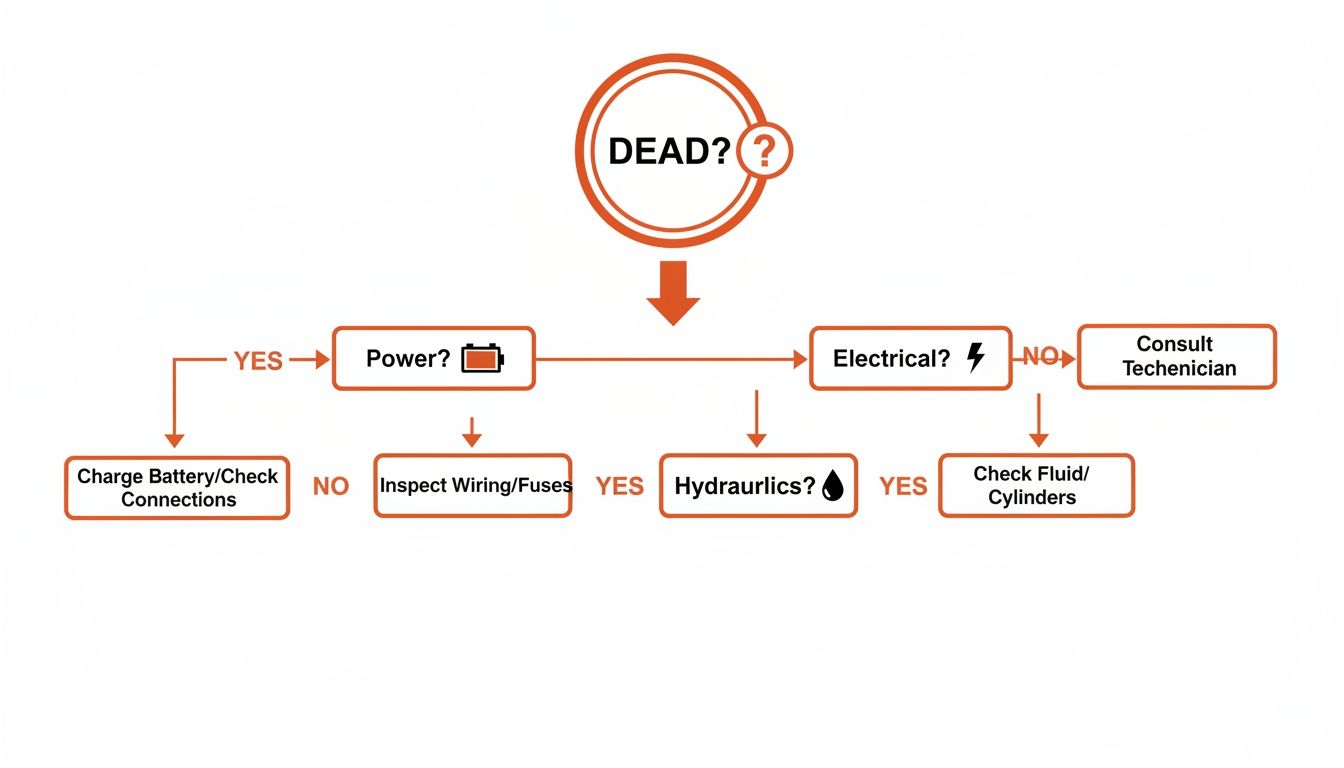

This flowchart is your battle plan. It's the path to follow when you're standing over a dead machine and the clock is ticking.

This forces you to check the obvious stuff first, saving you from chasing phantom electrical faults when the E-stop is just popped.

The 5-Minute Triage Checklist For A Dead Pallet Jack

Forget the manual. Before I even grab a multimeter, I run through this list. It’s the stuff that gets overlooked in a panic. This table gets you to the problem without turning a single screw.

| Symptom | Most Likely Culprit | First Action To Take |

|---|---|---|

| Absolutely no lights, no sounds, nothing. | Total power loss. | Check the big red E-stop button. Then, unplug and re-seat the main battery connector. |

| Jack stutters, then dies completely. | A loose connection or a critically low battery. | Wiggle the battery connector. Look at the Battery Discharge Indicator (BDI) for any flashing lights. |

| Lights on the display, but no movement. | A safety interlock or an electrical fault. | Make sure the tiller arm is in the operating range (not straight up or down). |

| You can hear a click, but the jack won't lift or drive. | The main contactor is trying to engage but can't. | This screams "weak battery." It has enough juice for the display but not the motors. |

This initial check takes less than five minutes and solves more than half of your "dead jack" problems without opening a toolbox.

Key Takeaway: The battery is the heart of this machine. No power, nothing else matters. Start simple. Power is always your prime suspect.

It's no surprise that technicians report over 60% of downtime in electric pallet jacks stems from battery-related problems, from failure to charge to sudden power loss during a lift. Industry surveys show fleet managers pinpoint battery degradation after 1,500-2,000 charge cycles as the main culprit, especially in busy warehouses. You can read the full research about these findings to see how widespread the issue is.

If these simple checks don’t bring it back to life, then you can start digging deeper into the electrical and hydraulic systems, which we’ll cover next.

Diagnosing The Electrical Gremlins

Okay, so the battery's solid, but the jack's still dead or acting possessed. Time to hunt the gremlins in the wiring. Electrical faults are the bane of modern equipment, just like the finicky electronics on a JCB. The dealer would love for you to believe you need their special laptop to figure this out, but that’s a load of bunk.

The machine itself will tell you what’s wrong; you just have to know how to listen.

Before you touch a multimeter, use the performance modes as a quick-and-dirty diagnostic tool. Can you still switch between "turtle" and "rabbit" mode? If you can, the main controller is getting power and is at least partially awake. If it's stuck or unresponsive, your problem is probably further upstream, closer to the key switch or the main contactor.

Decoding Jerky Movements And Sensor Failures

One of the most common complaints I hear is a jerky, stuttering ride. The operator will describe it as "hiccuping." This isn't a random glitch. Nine times out of ten, that stutter is the cry for help from a failing Hall Effect sensor in the throttle.

This little sensor tells the controller how much juice to send the drive motor. When it goes, it sends a choppy, unreliable signal. The controller gets confused, and you get that jerky motion.

You can often confirm this is the problem without any tools:

- The Sweet Spot Test: Try to drive the jack very, very slowly. If you find a "sweet spot" where it runs smooth, but it hiccups as you apply more power, the sensor is almost certainly your culprit.

- The Coasting Test: Get it moving and let go of the throttle. If it coasts to a smooth stop, the motor and brake are likely fine. The problem is isolated to the "go" signal.

Glitches in the electrical system, especially with the SEM and MOSFET traction controller, are behind roughly 25% of the Yale MPB040 troubleshooting cases we see. They can bring this 4,000 lb pallet jack to a dead stop and kill its maneuverability in tight aisles. One industry report found that 42% of electrical downtimes were directly linked to Hall Effect sensor wear after about 8,000 hours of use. You can learn more about these specific pallet jack component findings to see just how common this failure really is.

Field Tip: Don't let a dealer talk you into a whole new controller for a jerky ride. The Hall Effect sensor is a small, cheap part. At Flat Earth Equipment, we keep these on the shelf because we know they're a frequent failure point that shouldn't cost you a grand to fix.

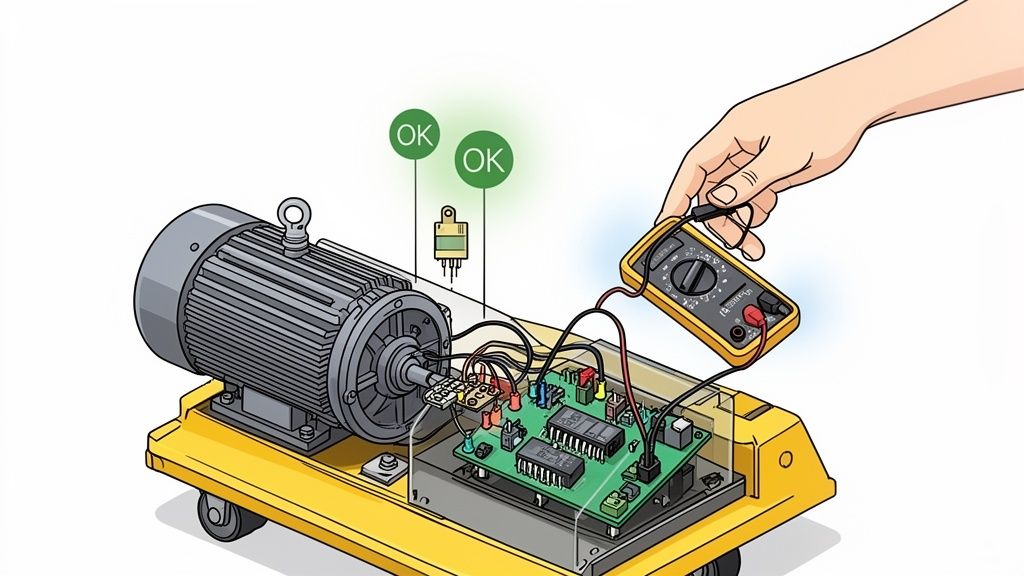

Basic Wiring Checks With Your Multimeter

If the jack is completely dead but you’ve confirmed good battery voltage, grab the multimeter. We're not diving into complex schematics; we're hitting the common points of failure that cause a total blackout.

Set your multimeter to DC Volts. Key on. Follow the power from the battery to the jack's brain.

- Check Power at the Contactor: Put your leads on the two large posts of the main contactor. You should see full battery voltage (around 24V). If not, you have a bad cable or loose connection between the battery and contactor.

- Check Power After the Contactor: Have someone activate the throttle. You should hear a solid "clunk." Now check for voltage on the other side of the contactor. If you have 24V going in but nothing coming out when it clunks, the contactor itself is shot.

- Inspect the Fuses: You’ll find low-amperage control fuses near the controller. Pull them one by one and check for continuity. A blown fuse can be a symptom of a bigger problem, but replacing it might get you moving again for now.

These simple voltage checks are the foundation of any real Yale MPB040 pallet jack troubleshooting. They quickly tell you if power is even making it to the components that make the jack move, saving you from a costly, unnecessary service call.

Tackling Hydraulic Headaches And Lift Failures

So, the drive system checks out, but your Yale MPB040 won't lift a feather. You've officially moved from electrical gremlins to hydraulic headaches. A pallet jack that can't lift is just a heavy skateboard, but don't let it intimidate you. The hydraulic system is simpler than you think, and most of its problems are things you can sort out right on the warehouse floor.

The usual suspects are almost always the same: bad fluid, a worn-out pump, or a leaky seal. We're talking basic nuts-and-bolts diagnostics—a welcome change from chasing voltage drops.

Differentiating A Weak Lift From A Total Failure

First, understand what the machine is telling you. Is it trying to lift but struggling, or is there no response when you hit the lift button? The answer points you in two different directions.

A weak or spongy lift—where the forks slowly rise but crumble under a real load—almost always points to a pure hydraulic problem. This could be:

- Low or Contaminated Fluid: The lifeblood of the system. If it's low, the pump sucks air. If it's dirty, it chews up seals and clogs valves.

- Internal Seal Leak: A seal inside the lift cylinder is shot, letting fluid bypass the piston. The pump works its heart out, but the pressure can't build.

- Failing Lift Pump: The pump itself could be worn out and unable to generate the pressure needed.

On the other hand, a total failure to lift, where you hear nothing but a click (or not even that), might not be hydraulic at all. If the lift motor isn't even trying to spin, your problem is likely electrical. You could be looking at a bad lift contactor, a faulty lift button, or a wiring issue between the controller and the pump motor.

Spotting The Obvious Signs Of Hydraulic Trouble

Before you break out the wrenches, do a walk-around. Hydraulics leave clues. Look for that tell-tale sheen of hydraulic fluid on the floor or coating the lift cylinder. A small leak can drain enough fluid over time to cause lift problems and suck air into the system.

Pop the cover and check the fluid level. It should be clean and clear, not milky or full of gunk. Milky fluid is a dead giveaway that water got into the system, which will destroy a pump in short order.

Field Tip: I've seen guys waste hours chasing a "no lift" problem only to find the pressure relief valve was stuck open. Before you condemn the pump, make sure the manual lowering lever isn't jammed. It happens more than you think.

Hydraulic lift failures are the second most common headache with the Yale MPB040, directly sideline its solid-state hoist control and its ability to handle 4,000 lb loads. Looking at the bigger picture, industry data shows that hydraulic leaks or pump stalls pop up in 32% of service reports for similar pallet jacks. These issues are often traced back to contaminated fluid or worn seals after about 5,000 hours of use. You can dive deeper into these pallet jack service trends at Lectura Specs.

Real-World Damage And Pressure Spikes

Remember, these jacks live a hard life. I once worked on a unit where an operator slammed the forks straight into a dock plate. That impact sent a massive pressure spike through the system and blew out a primary hose fitting. It wasn't a slow leak; it was a catastrophic failure from a single moment of carelessness.

Always inspect the hydraulic lines for physical damage, especially if you know the jack has taken a hard hit. A crushed hose or a cracked fitting is an easy diagnosis, but you'll miss it if you're only looking at the pump and cylinder. Proper Yale MPB040 pallet jack troubleshooting means looking at the whole picture.

Solving Battery And Charger Issues: The Real Downtime Killer

Let's get straight to it. Forget the fancy diagnostics. If your Yale MPB040 is acting up—jerking, dying mid-shift, or refusing to lift—I'll bet you a case of beer the problem is in your 24V battery system. More than half the problems I see trace right back to this black box.

A dead battery is easy. A weak or dying battery? That's the real villain. It tricks you into thinking you have a bad controller, a faulty sensor, or a shot hydraulic pump. The machine gets just enough juice to power up the display but chokes the second you ask it to do real work.

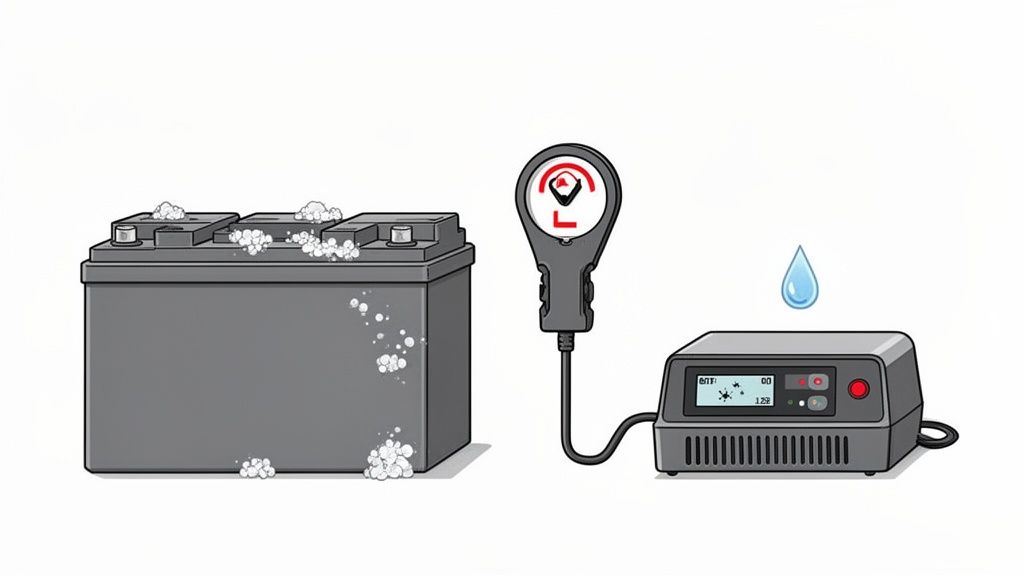

Don't Trust The Resting Voltage

Every rookie makes this mistake. They slap a multimeter on the battery, see 24 volts, and declare it "good." That's useless. A battery at rest tells you nothing. You have to put it to work.

To do a real test, check the voltage under load.

- Connect your multimeter to the main battery terminals. You should see a resting voltage between 24V and 25.5V on a fully charged battery.

- While watching the meter, hit the lift button and raise the forks.

- Observe the voltage drop. If it plummets below 21V-22V, your battery is on its last legs. It can't deliver the amperage needed, even if it looks fine at rest.

This simple load test is the most critical part of any Yale MPB040 pallet jack troubleshooting. It immediately tells you if you're dealing with a power supply issue or something else.

My Two Cents: I've seen brand-new controllers swapped out because a tech didn't do a proper load test. They chased an electrical ghost for days, all because the battery was too weak to close the main contactor properly. Don't be that guy. Test under load, always.

The Unseen Killers: Sulfation And Water Levels

That "smart" charger the dealer sold you isn't as smart as it thinks. It can't fix a battery that's been neglected. Two things will murder a flooded lead-acid battery faster than anything: sulfation and low water.

Sulfation is a buildup of lead sulfate crystals on the plates. It happens when a battery is left discharged. These crystals act like an insulator, preventing the battery from accepting or delivering a full charge. The tell-tale signs are longer charging times and drastically reduced run times.

Checking the water level is even more basic, but it's often ignored. If the water level drops below the top of the lead plates, that part of the plate is exposed to air and is permanently damaged. It’s a five-minute check that can save you thousands.

- Weekly Check: Pop the caps and look inside. The electrolyte should cover the plates by about a half-inch.

- Use Distilled Water Only: Tap water is full of minerals that will kill the battery.

- Fill After Charging: Add water after the battery is fully charged. Charging causes the water level to rise, and filling it beforehand can cause a messy, acidy overflow.

A healthy battery is the foundation of a reliable machine. If you're constantly fighting power issues, you may want to investigate more robust options. You can learn more about industrial battery chargers that are built for the demanding environment of a warehouse. Proper maintenance prevents those infuriating mid-shift power losses that bring the whole operation to a standstill.

Sourcing Parts Without The Dealer Markup

Alright, you’ve done the hard work. You’ve traced the wires, tested the battery, and you know exactly which component has given up the ghost. Now comes the part that grinds every operation to a halt: getting the actual replacement.

The dealer will happily sell you a new controller or a hydraulic pump, but it’ll come with a three-day wait and a price tag that feels like a punch to the gut. That's not how we keep the wheels turning.

Waiting on a dealer is like being stuck in a forced regen cycle on a piece of heavy equipment—the machine is down, the clock is ticking, and you're completely powerless. We don't play that game. This is your playbook for bypassing the gatekeepers and getting the right part, right now.

Finding The Exact Part Number Yourself

First things first, you need the part number. Don't bother calling the dealer to ask for it; they’ll play dumb or try to sell you the whole assembly. Instead, get your hands dirty and pull the number directly off the failed component.

Most major parts on the Yale MPB040—like the controller, contactors, and pump motor—will have a manufacturer's plate or a stamped number on them. It might be caked in grease, but it’s there. Grab a rag, some brake cleaner, and a flashlight.

- Controllers: Look for a sticker or plate on the main housing. It’ll often have the brand (like Curtis or ZAPI) and a specific model number. That’s your golden ticket.

- Sensors and Solenoids: These smaller parts can be tricky. The numbers are often tiny and etched into the plastic or metal body. A phone camera with the zoom cranked up can be a huge help here.

- Hydraulic Components: Pumps and valves usually have a metal tag riveted to the body. Get that number.

Once you have that OEM number, the game changes completely. You’re no longer asking for a "Yale pallet jack part." You're searching for a specific component from the original manufacturer.

Why We Stock The Parts That Fail

Here’s the thing about warehouse equipment—it has predictable failure points. Just like JCBs have their electronic quirks, these Yale units always break the same parts: Hall Effect sensors, lift contactors, lowering valve coils, and hydraulic seals. The dealer knows this, too, but their business model relies on selling you a service call, not just a $50 part.

That’s why we do things differently at Flat Earth Equipment. We stock the high-failure items because we know you needed them yesterday. We’ve seen enough error codes to know which solenoid to stock. We’ve replaced enough throttle assemblies to keep Hall Effect sensors on the shelf, ready to ship same-day. We’re not just parts-pullers; we’re technicians. We stock what we know you need to fix a specific problem.

The Bottom Line: The dealer sells parts. We sell uptime. There’s a massive difference. We’re not interested in locking you into a proprietary system; we want to give you the components to solve the problem and get back to work.

Bypassing The Gatekeepers And Getting It Done

You’ve got the part number. You’ve found a supplier who respects your time. Now you’re in control. A quick search with that OEM number will often reveal multiple sources, giving you the power to compare price and availability.

To help you connect the dots without paying for a diagnostic fee, here is a quick-hit guide that links common symptoms directly to the parts you should be looking for.

Common Failure Points And Part Solutions

| Problem Symptom | Component To Check Or Replace | Why It Is The Fix |

|---|---|---|

| Jack is jerky or stutters | Throttle Potentiometer / Hall Effect Sensor | This sensor sends a choppy signal to the controller, causing erratic motor commands. |

| Won't lift, but you hear a "clunk" | Lift Contactor or Pump Motor Brushes | The contactor is closing, but worn brushes prevent the motor from getting the amperage it needs to spin. |

| Lifts but slowly drifts down | Hydraulic Cylinder Seal Kit | Internal seals are worn, allowing hydraulic fluid to bypass the piston and release pressure. |

| Dead stop, likely with an error code | Lowering Valve Coil / Cartridge | This common electrical failure prevents the hydraulic lowering valve from closing properly. |

This isn't about being cheap; it's about being smart and efficient. Waiting a week for a part that should have been on a shelf is a failure of the system, not a failure of your equipment.

For any parts you can't find or questions you have, you can get technician-led support by contacting us directly. We speak your language.

Knowing When to Call For Backup (and Avoid a Bigger Mess)

The goal is always to get the machine running yourself, but a good tech knows when to put the tools down. Pride has no place when you're staring down a problem that’s way bigger than your toolkit. There are some very clear red flags that signal it's time to stop before you turn a simple repair into a catastrophic failure.

This isn’t about giving up. It's about making the smart call to bring in a specialist while you keep the rest of your operation moving. A bent frame from a collision or a wiring harness that’s been fried to a crisp aren't jobs for the warehouse floor. These are "stop work" situations, plain and simple.

Drawing the Line

Knowing your limits is what separates a pro from a liability. If you see any of the following, it’s time to pick up the phone:

- Major Frame Damage: Is the chassis visibly bent? Do you see cracked welds? If so, the jack's structural integrity is gone. Using it is a massive safety risk, and it’s not something you can just hammer back into place.

- A Fried Wiring Harness: I'm not talking about a single frayed wire here. If you see melted connectors or large sections of burnt, brittle wiring, you’re looking at a massive electrical short that demands a full harness replacement.

- Catastrophic Hydraulic Leak: A small drip is one thing. A gusher that's dumping fluid all over the floor is a whole different beast. This usually points to a burst hose or a cracked pump housing—a major, messy repair.

Trying to be the hero on these jobs can be unsafe and will absolutely end up costing you more in the long run. There's no shame in calling for backup when you're out of your depth; the real shame is causing an accident or a five-figure repair bill because you didn't.

Attempting to weld a cracked frame without the right gear or chasing a major electrical short without a full schematic is just asking for trouble. This isn't just about the machine; it's about your own safety and the safety of everyone around you. For a refresher on the basics, our guide on workshop and equipment safety covers the essentials every good technician lives by. Sometimes, the smartest move is to make a strategic retreat and fight another day.

Frequently Asked Questions

You've run through the diagnostics, but some questions always pop up when you're out on the floor. Here are the straight answers to the most common things I hear when a Yale MPB040 pallet jack decides to act up.

How Do I Read The Error Codes Without The Dealer Laptop?

Forget waiting on a tech with a fancy laptop. The jack tells you exactly what’s wrong using the Battery Discharge Indicator (BDI). It’s a simple system where the light flashes in a specific sequence to spell out an error code.

For example, a super common code like AL 04 (which points to a lowering valve fault) will show up as a distinct pattern of flashes. Don't overthink it—just watch the BDI, write down the pattern, and you've got your starting point. The machine is talking directly to you, saving you a hefty service call fee.

What Does The AL 04 Code Mean?

When you see an AL 04 code flashing, the jack is telling you there’s a problem in the lowering valve circuit. I'd bet money that nine times out of ten, the coil on the lowering valve solenoid has given up the ghost. It's one of the most common failure points on these pallet jacks.

A dealer will try to sell you the entire valve assembly, which is just absurd. The coil is a small, separate part you can swap out in about five minutes with a couple of wrenches. It's a classic $50 fix for a problem they'll gladly bill you $500 for.

Can I Bypass A Faulty Sensor To Get Moving?

Listen, I’m all for a field-expedient fix to get a pallet jack out of a busy aisle and back to the shop. But you have to be smart about it. Sure, you can bypass a tiller position sensor to get it moving in a pinch, but you’re also disabling a critical safety feature. Think of it as a last-ditch effort, not a real repair.

Field Wisdom: A jumper wire is a diagnostic tool to get a dead machine back to the maintenance bay. It is not a replacement part. Don't let someone run it for a full shift like that—fix the actual problem.

Why Does My Jack Keep Shutting Off Randomly?

Intermittent shutdowns are the absolute worst, aren't they? This is almost always an electrical gremlin, usually a loose connection or a component that's failing under heat or vibration. Your first move should be to check the main battery connector. Give it a good wiggle; if the jack cuts out, you've found your problem.

If that’s not it, start tracing the wiring to the key switch and the main contactor. A wire that’s frayed and hanging on by just a few strands will cause exactly this kind of phantom shutdown. It’s tedious work, but a careful visual inspection and a "wiggle test" along the main harness will uncover the issue more often than not.

When you've figured out what's wrong and need the right part without getting the runaround from a dealer, Flat Earth Equipment has you covered. We keep the coils, sensors, and contactors that commonly fail in stock so you can get back to work fast. Find exactly what you need at https://flatearthequipment.com.