When your JCB 535-125 hydraulics go on strike, your first thought is probably a five-figure dealer bill. Before you make that call, stop. Most of the time, the problem is something simple you can fix right where it sits, with the tools in your truck. This ain't about fancy theory; this is about getting back to work.

The first thing you do, every single time, is check the hydraulic fluid level and pull the main filter. I'm not kidding. A huge percentage of hydraulic failures I see in the field come down to these two basic checks. Nail the fundamentals before you even think about calling for help. It'll save you a tow bill and a week of waiting for a "technician" to do the same thing.

Your First-Response Hydraulic System Check

The job is dead in the water. The boom is frozen, the forks won't tilt, and every minute you're not moving material is money burning. Before you even think about calling the dealer to hear about their two-week backlog, let's walk through the first checks you should perform right there in the dirt.

Forget the black magic of electronics for a minute. We're starting with the lifeblood of the machine: the hydraulic fluid. You'd be amazed how many guys skip this and go straight to panicking about the pump.

Start with the Basics: Fluid and Filters

The most common gremlin causing intermittent hydraulic cutout is also the easiest to fix: low hydraulic fluid. When that level drops, the pump starts sucking air. Air in a hydraulic system is poison—it causes cavitation, which sounds like marbles rattling around in your pump, and leads to the erratic pressure that makes your functions die mid-lift.

Don't just glance at the sight glass. The machine needs to be on level ground with the boom fully retracted and lowered for an accurate reading. Pull the dipstick, wipe it clean on a rag (not your pants), and get a proper measurement. If it's low, top it off with the correct spec oil—no substitutions.

Field Tip: I've seen countless machines towed to the shop only to find they were two gallons low on hydraulic fluid. The dealer happily charges a grand for that. A five-minute check can save you that bill and a week of downtime. It's the first thing you should do, every single time.

This isn't just an anecdote. A 2023 analysis of 150 JCB 535-125 units found that over 40% of sudden hydraulic cutouts were traced directly back to fluid levels dropping below the minimum mark. This simple oversight led to an average of 4.2 hours of lost work per incident.

Inspecting the Hydraulic Filter

After confirming your fluid level is correct, the next stop is the main hydraulic filter housing. A clogged filter starves the system just as effectively as low fluid. But it also tells a story.

When you pull that filter, don't just toss it. Cut it open and inspect the pleats. This simple step can give you a crucial diagnosis on the health of your entire system before you waste time and money chasing phantoms.

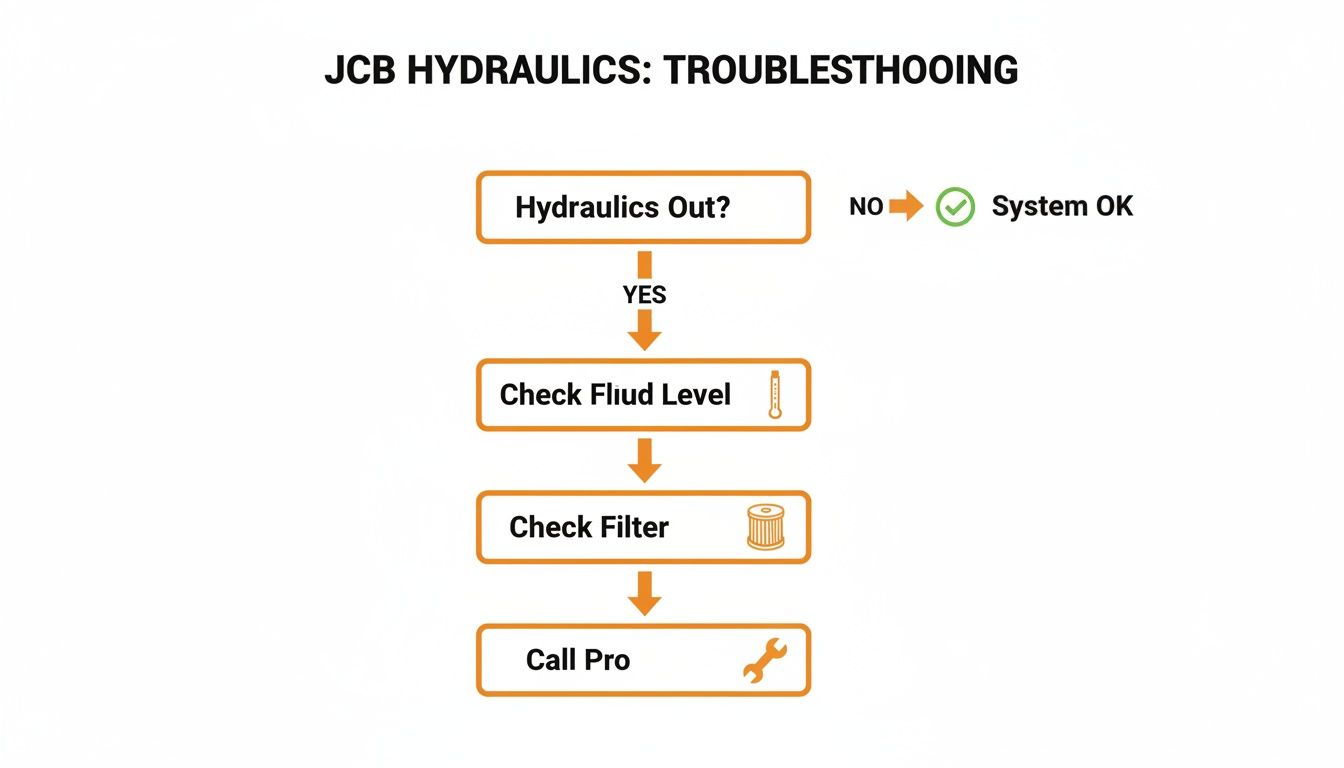

This flowchart maps out the critical first steps: verify the problem, check the fluid, then inspect the filter before you even think about calling the dealer.

Here's a quick rundown of what you're looking for inside that filter:

- A "glitter" or fine metallic sheen: This is bad news. It means a major component, likely the pump or a motor, is coming apart internally. Game over, time for a big job.

- Dark, burnt-smelling fluid: This indicates the oil has been cooked, losing its lubricating properties. You've got an overheating problem somewhere.

- Sludge or milky fluid: This is a clear sign of water contamination.

If the filter is just dirty with normal debris, replace it with a quality filter. Don't cheap out here—a good filter is your system's only defense. Flat Earth Equipment has the filters you need, without the dealer markup.

Initial Hydraulic System Checkpoints

| Symptom | Most Likely Cause | Field Check / Action |

|---|---|---|

| All Functions Weak or Slow | Low Hydraulic Fluid or Clogged Filter | Check dipstick on level ground, boom down. Inspect and replace the main hydraulic filter. |

| Intermittent Function Cut-Out | Low Hydraulic Fluid / Air in System | Verify fluid level is correct. Top off with spec oil. Cycle functions to bleed air. |

| Loud Pump Noise (Whining/Rattling) | Air in System (Cavitation) or Blocked Suction Line | Check fluid level immediately. Inspect suction hose and filter for restrictions. |

These initial checks are your frontline defense. They're the bedrock of good troubleshooting that keeps you independent, productive, and in control of your machine. Remember to always prioritize your well-being on the job; for essential guidelines, review our machine inspection and operational safety tips.

Hunting Down Electrical Gremlins in the System

Alright, so the fluid is clean and the filter isn't sparkling with metal shavings. That's good news. It likely means you haven’t grenaded a major component. Now we pivot from the greasy side of the machine to the finicky one—the electronics. JCBs are notorious for this stuff.

More often than not, the problems that shut down a JCB 535-125 aren't purely hydraulic anymore. They're a tangled mess of wires, sensors, and the machine's overprotective brain, the ECU, that listens to all of them. This is where the dreaded Regen cycle can stop you dead in your tracks, all thanks to a faulty sensor.

This is where the dealer loves to plug in their "Service Master" laptop and hit you with a massive quote for a new harness and three different control modules. Let's use our eyes and a bit of common sense first.

Starting in the Operator's Seat

Your first stop is right there in the cab with you: the joystick. Every single command you give the hydraulics flows through that stick and its wiring harness. After thousands of hours of use, that harness gets flexed, rubbed, and tugged on constantly. It's one of the most common failure points I see causing intermittent JCB 535-125 hydraulic functions cutting out.

Go ahead and peel back the rubber boot at the base of the joystick. Look for chafed or shiny wires where the harness bends sharply or rubs against the console frame. The insulation wears thin, the copper wire corrodes, and pretty soon, you’ve got a short that kills the signal. Sometimes, all it takes is wiggling this harness while a buddy tries to operate the functions to see it flicker back to life.

Field Tip: Don't just look for obviously broken wires. Check the connectors for that dusty green corrosion that screams water got in. A little dab of dielectric grease on these connections during routine service can prevent a world of headaches down the road.

If the joystick wiring looks solid, your next culprit is often the seat switch. This simple safety device is the bane of many an operator's existence. If the ECU doesn't get a clear signal that you're firmly planted in the seat, it assumes the machine is unoccupied and locks out all hydraulic functions. A broken wire or a failed switch here can perfectly mimic a catastrophic hydraulic failure.

Decoding Fault Codes Without the Dealer Laptop

Modern JCBs will throw a fault code for a stiff breeze, and most of them are just noise. The dash might light up like a Christmas tree, but only a handful of codes are actually critical for diagnosing hydraulic cutouts. The dealer’s Service Master software will give them a hundred different readings, often leading to a "replace-everything" strategy that drains your wallet.

You don't need their proprietary gear to get the gist of it. Pay close attention to any codes related to these systems:

- Joystick Position Sensor: These codes point directly to your control inputs, often confirming a wiring issue or a failed sensor inside the joystick itself.

- Boom Angle Sensor: If this sensor is on the fritz, the machine's stability control system gets confused. It might think the boom is at an unsafe angle and cut power to prevent a tip-over, even if the boom is on the ground.

- Seat Switch Circuit: A fault code here is a dead giveaway. It’s the machine telling you the ECU isn't seeing the "operator present" signal it needs to enable the hydraulics.

These sensors and switches are the machine's eyes and ears. When they start lying to the ECU, the brain makes bad decisions. Your job is to figure out which sensor is the liar. Flat Earth Equipment has the sensors you need to bypass the dealer's wait times.

And don't forget the absolute basics of any electrical diagnosis: a good battery and clean, tight connections. A weak battery can cause voltage to sag under load, making sensors act erratically and throwing all sorts of phantom fault codes. If you're constantly chasing electrical gremlins, it might be time for new batteries and a look at some reliable heavy-duty battery chargers to keep them properly maintained. This simple step can save you countless hours of frustration.

Putting Pressure Gauges on the Hydraulic System

Alright, the easy checks are out of the way. You've gone through the fluids, pulled the filter, and given every wire harness a good wiggle. If your machine is still a glorified paperweight, it's time to stop guessing and start measuring. This is where we break out the tools and find out what’s really happening inside those hydraulic lines.

Forget the dealer's laptop for a minute. A good set of pressure gauges tells the unvarnished truth every single time.

We're not trying to rebuild a pump in the dirt with a pocket knife here. The goal is targeted testing. Pinpoint the exact component that failed so you know exactly what to order from a supplier like Flat Earth Equipment instead of just throwing expensive parts at the problem.

Tapping into Main and Standby Pressure

First thing's first: we need to see what the pump is doing at idle and when you demand work from it. The JCB 535-125 uses a variable displacement piston pump, which is a smart piece of engineering. It only produces the flow and pressure needed for the job, saving fuel but adding some complexity when things go south.

You'll need to find the main test port, usually a small, capped fitting on the pump itself or the main valve block. Safety is paramount here: clean the area around the port meticulously before you even think about cracking it open. The last thing you want is to introduce a spec of dirt into the heart of your hydraulic system.

Once your gauge is connected securely, fire up the machine and let it idle. This initial reading is your standby pressure.

Pro Tip from the Field: A healthy JCB 535-125 should show a standby pressure around 350-450 PSI. If you're seeing zero, the pump isn't stroking at all. If it's sky-high, something is already demanding pressure when it shouldn't be.

Now, have someone hop in the cab. Have them carefully operate a function until it bottoms out—for example, holding the boom lift all the way up or tilting the forks fully. This "dead-heads" the circuit and forces the pump to deliver its maximum output. This reading is your main relief pressure.

Interpreting What the Gauges Tell You

Those numbers on your gauge are the machine's vital signs. They tell a story if you know the language.

- Low Standby and Low Main Pressure: If both readings are way below spec, the pump is your prime suspect. It's either worn out and can't build pressure, or its internal controller has failed.

- Good Standby but Low Main Pressure: This points away from the pump and straight toward your main relief valve. The valve is likely weak or stuck partially open, dumping pressure back to the tank long before it hits the required system pressure of around 3,500 PSI.

- Fluctuating or Erratic Pressure: A needle bouncing all over the place often signals air in the system. It could also mean a failing load-sensing controller on the pump is sending chaotic signals.

Here’s a quick-glance table for what those pressure readings probably mean.

| Pressure Reading | What It Likely Means | Your Next Move |

|---|---|---|

| Below 250 PSI at idle | Pump is not stroking or is severely worn. | Check the pump's controller for electrical faults or prepare for a pump replacement. |

| Pressure won't exceed 2,000 PSI under load | Main relief valve is weak or stuck. | Locate and inspect the main relief valve cartridge on the main valve block. |

| Pressure jumps around erratically | Air in the system or a faulty load-sense signal. | Re-check fluid levels and hunt for leaks on the suction side of the pump. |

The Load-Sensing Circuit Mystery

This is the final piece of the pressure puzzle and a common culprit. The load-sensing circuit is a small signal line running from the valve block back to the pump. Its job is to whisper to the pump, telling it exactly how much flow and pressure is needed for the function you're commanding.

If there's a leak in this line or the signal is weak, the pump never gets the message to ramp up. The machine will feel sluggish and weak. Under a heavy load, it might not have the guts to perform the function at all, leading to the dreaded JCB 535-125 hydraulic functions cutting out.

This failure mode often tricks technicians into thinking the main pump is shot when it’s really just a faulty signal. While testing this circuit is more advanced, a careful visual inspection of the signal lines for obvious damage or leaks is a smart next step if your main pressures are acting strange.

The Usual Suspects: Common JCB Failure Points

After you've spent enough years with your knuckles busted open on these machines, you stop being surprised. You start seeing the same patterns, the same parts giving up the ghost, over and over again. The JCB 535-125 is a solid telehandler, but it's got its weak spots, just like any other piece of yellow iron.

When you're troubleshooting JCB 535-125 hydraulic functions cutting out, there's a short list of usual suspects I check long before I start worrying about a catastrophic failure. These are the components that get cooked, clogged, or confused, and they account for the vast majority of problems you'll face. The dealer loves to shotgun parts at a problem; we're going to be smarter than that.

This isn't just theory. This is my field-tested hit list. Knowing these common failure points will save you days of downtime and thousands in labor, because you can have the parts on hand before the machine even goes down.

Hydraulic Solenoids: The Sticky Culprits

Think of the hydraulic valve block as the nervous system for your hydraulics. If that's the case, the solenoids are the individual nerve endings. Each one is just a small electromagnet that opens and closes a valve spool, directing oil to a specific function like lifting, tilting, or extending the boom. They are, by far, one of the most common things to go wrong.

After thousands of heat cycles and constant vibration, two things tend to happen: the electrical coil inside can burn out, creating an open circuit, or the valve spool itself gets gummed up with contaminated oil and just refuses to move.

A failing solenoid usually shows its hand in a few classic ways:

- One specific function stops working. If your boom extends but won't retract, the problem is almost certainly the retract solenoid.

- The function is intermittent. The solenoid might work when cold but conk out as the machine heats up and the coil's internal wiring expands.

- You get that "dead" joystick feel. When you move the joystick for that function, you feel nothing. No slight change in engine load, no faint hydraulic whine—just... nothing.

You can quickly confirm a bad coil with a multimeter by checking for resistance. If it reads as an open circuit (OL), the coil is toast. If the coil checks out electrically but the function is still dead, you've likely got a mechanically stuck spool inside. Don't wait on the dealer's backorder list for a simple solenoid. A supplier like Flat Earth Equipment keeps these on the shelf, turning a week-long headache into an afternoon fix.

Pressure Sensors: The Electronic Liars

Modern JCBs are covered in sensors that feed information back to the ECU. The problem is, these sensors live in a brutal world of heat, pressure, and vibration, and eventually, they start to lie. A bad pressure sensor can trick the ECU into thinking the system is overloaded, causing it to cut hydraulic power as a safety measure. It's the same kind of nonsense that triggers a Regen cycle at the worst possible time.

I've personally seen a faulty $80 sensor convince a dealer technician that a machine needed a $7,000 hydraulic pump. The laptop told him the pressure was dangerously high, but the sensor was just feeding it bad data. Always trust your mechanical gauges over what the screen tells you.

The symptoms of a bad pressure sensor are often maddeningly vague. The machine might work fine under a light load but cut out the second you pick up something heavy. It might throw a generic "hydraulic system pressure" fault code that sends you on a wild goose chase through the whole system.

Internally Collapsed Hoses: The Hidden Blockage

Now this one is sneaky. From the outside, a hydraulic hose can look perfectly fine—no leaks, no bulges, no abrasions. But over time, the inner lining of the hose can delaminate and collapse inward. This creates a flap that acts like a one-way check valve, and it’s a nightmare to diagnose if you don't know what you're looking for.

This hidden blockage can starve a cylinder of oil, making a function incredibly slow or weak in one direction. It can also cause massive pressure spikes that lead to other components failing downstream. If you have a single function that has gotten progressively weaker and you've already ruled out solenoids and the cylinder itself, that hose is your prime suspect. Finding it is simply a matter of tracing the lines for that specific circuit and swapping them out.

Your Field Toolkit and Knowing When to Call for Backup

Having the right tools in your truck is the difference between a quick fix and a thousand-dollar tow bill. When you're staring down a JCB 535-125 that’s decided to quit, being prepared is your best defense against the dealer's expensive "solutions." This isn’t about hauling a whole shop out to the job site, but about having the essential kit to figure out what's really going on.

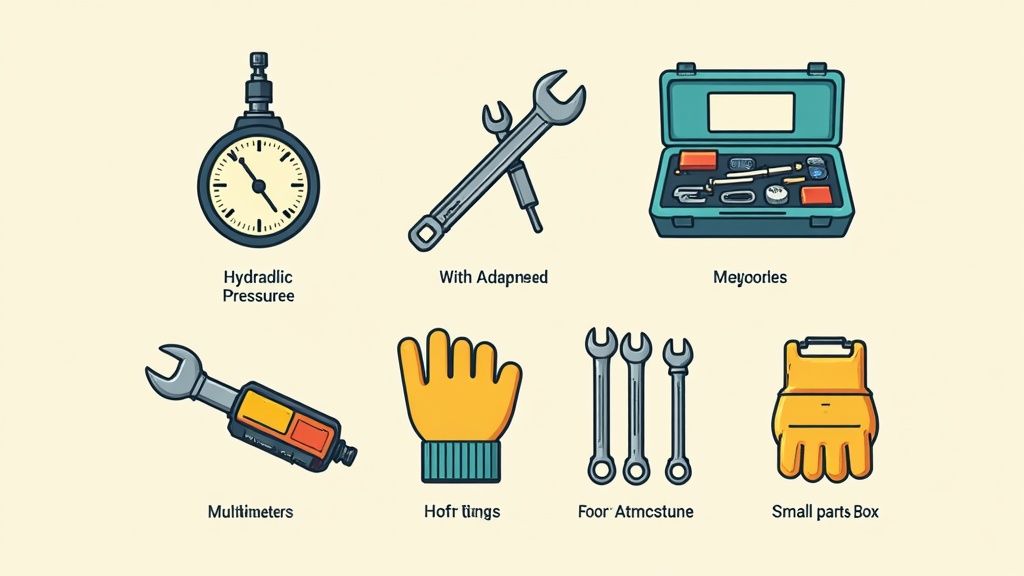

You can't fight what you can't measure. The absolute cornerstone of your field toolkit is a solid set of hydraulic pressure gauges. Get yourself a kit with a few different pressure ranges, especially a high-pressure gauge that can handle at least 5,000 PSI. Make sure it comes with a grab bag of JIC, ORFS, and metric test-point adapters; JCB loves to mix and match fittings just to keep you on your toes.

Assembling Your Diagnostic Arsenal

Beyond the hydraulics, your electrical diagnostic tools are just as critical. The electronics on these machines are finicky at best, and a simple multimeter is your best friend out there. It’s what you’ll use to hunt down a dead solenoid coil or a shorted wire in a joystick harness. Don't leave the yard without it.

Here’s a no-nonsense list of what should be in your field kit:

- Hydraulic Pressure Gauge Kit: This is non-negotiable. It's the only way to know what the pump and relief valves are actually doing.

- Digital Multimeter: For checking voltage, continuity, and resistance on every sensor and solenoid you can get your hands on.

- Basic Hand Tools: A good set of metric and standard wrenches and sockets is obvious. You’ll specifically need larger sizes for hydraulic fittings and valve block bolts.

- Jumper Wires with Alligator Clips: Perfect for safely bypassing a suspect seat switch or pressure sensor for a quick diagnostic test.

- Infrared Temp Gun: A great, cheap tool for spotting an overheating component, like a relief valve that's stuck open and constantly bypassing hot oil.

You don't need the dealer’s "Service Master" laptop to do good work. In fact, that laptop is often a crutch that leads to lazy diagnostics. Your gauges and your multimeter will tell you the truth, without the five-figure price tag.

Knowing When to Wave the White Flag

I’m the first to advocate for fixing it yourself, but there’s a line. Being a good tech also means knowing your limits and recognizing when a problem is bigger than a field repair. Pushing past that point is how you turn a simple component failure into a total system contamination that costs a fortune to clean up.

Here are the situations where you swallow your pride and make the call:

- Metal Shavings in the Filter: If you cut open that hydraulic filter and it looks like a glitter bomb went off inside, stop immediately. A pump or motor has failed catastrophically, sending shrapnel through the entire system.

- Major Structural Damage: A cracked boom section or a bent cylinder rod isn't a field patch job. That requires specialized heavy fabrication and line boring to fix correctly and safely.

- Deep ECU or Wiring Harness Issues: If you've got multiple, unrelated electrical faults popping up and the main harness shows signs of widespread damage or corrosion, it's time for a specialist.

When you hit one of these roadblocks, it's smarter and cheaper in the long run to bring in a dedicated hydraulic specialist or a tech with the right equipment. For honest advice on when to tackle a job yourself versus calling for backup, you can always get in touch with our team of technicians who have seen it all. Working smart is what keeps you running, not just working hard until something breaks even worse.

Field Notes: Answering Common JCB Hydraulic Questions

When you're out in the field, you start to see the same problems pop up again and again. You also hear the same questions. When your JCB telehandler quits, you don’t have time to thumb through a textbook. You need quick, practical answers to get that machine running without having to call the dealer and listen to their hold music.

Here are a few of the most common scenarios I run into and the straight-shooting answers you need when your machine is down and the clock is ticking.

Why Do My Hydraulics Work Cold but Cut Out When Warm?

This is a classic symptom, and it almost always points to one of two things. As the hydraulic oil gets up to operating temperature, its viscosity drops—it gets thinner. This thinner fluid will expose a weak pump or a worn internal seal leak that was being masked by the thicker, cold oil.

The second likely culprit is electrical. A solenoid coil can be on its last legs, and as it heats up, the fine copper windings inside expand. This expansion can create a temporary open circuit, instantly killing power to that function. First, check that your hydraulic cooler is clean and the fan is working properly. If they are, you're almost certainly looking at a worn pump or a failing solenoid.

Can a Bad Seat Switch Really Stop Everything?

Absolutely. It’s one of the most common culprits for a machine going completely dead hydraulically, and it’s a pure safety interlock. The ECU on the JCB 535-125 needs to see a constant "operator present" signal from that switch to enable any hydraulic functions.

If the switch fails, the wiring gets sliced, or the connector gets corroded, the ECU assumes nobody is in the seat and locks everything out. It’s an easy thing to check. You can temporarily bypass it by jumping the two wires in the connector to confirm it’s the problem, but never leave it that way. A seat switch is a cheap, simple fix for an issue that can completely shut down your operation.

Never permanently bypass a safety switch. It’s there for a good reason. A new switch is a tiny investment to prevent a catastrophic accident. Get the right part and fix it correctly.

My Boom Lifts but Won't Extend—Is My Pump Bad?

This is actually great news. If one function works (lift) but another doesn't (extend), your main hydraulic pump is almost certainly fine. A working function proves the pump is delivering pressure to the valve block. This means your problem is isolated specifically to the boom extend circuit.

This scenario screams "solenoid." The most likely cause is the telescope function solenoid on your main hydraulic valve block. You're probably dealing with a burnt-out coil, a valve spool that's physically stuck with debris, or a simple wiring problem between your joystick and that specific solenoid.

Grab your multimeter and check for voltage at the solenoid's connector while someone tries to extend the boom. If you've got power there, the solenoid or the valve cartridge itself is your problem. This is a targeted, straightforward repair that should keep you out of the dealer's shop.

When you've diagnosed the problem and need the right part without the runaround, Flat Earth Equipment offers the sensors, solenoids, and filters you need to bypass the dealer wait times. We stock the components that fail most often, so you can skip the backorder list and get your JCB 535-125 back to work. Find your parts at https://flatearthequipment.com.