When you're out in the mud and a Toyota 8FGU25 forklift is down for an oil change, the last thing you need is a parts runaround from some dealer desk jockey. You need the right oil filter, and you need it now. The main Toyota OEM part numbers are 90915-20004 and 90915-YZZF1, the standard fit for that tough-as-nails 4Y engine. This guide is your cheat sheet—the direct cross-reference numbers to get that machine off the lowboy and back to work, no dealer laptop required.

Your No-Nonsense Oil Filter Cross Reference

Forget wasting half a day on hold with the dealer's parts counter or digging through internet forums full of guys who've never turned a wrench. We're giving you the field-tested numbers that we know for a fact will work. The mission is simple: find the right filter, confirm it's not some cheap knock-off, and get it on the machine without the usual headache. It's about bypassing the dealer wait times and their inflated prices.

That Toyota 8FGU25 is a solid piece of iron, but its 4Y engine is only as good as the maintenance it gets. A clean oil filter isn't a suggestion—it's the only thing keeping that engine from eating itself alive in the grit and grime of a real job site. Slapping on a cheap or incorrect filter is just asking for a seized engine, something the dealer is more than happy to charge you a fortune to fix.

Finding The Right Part Number Fast

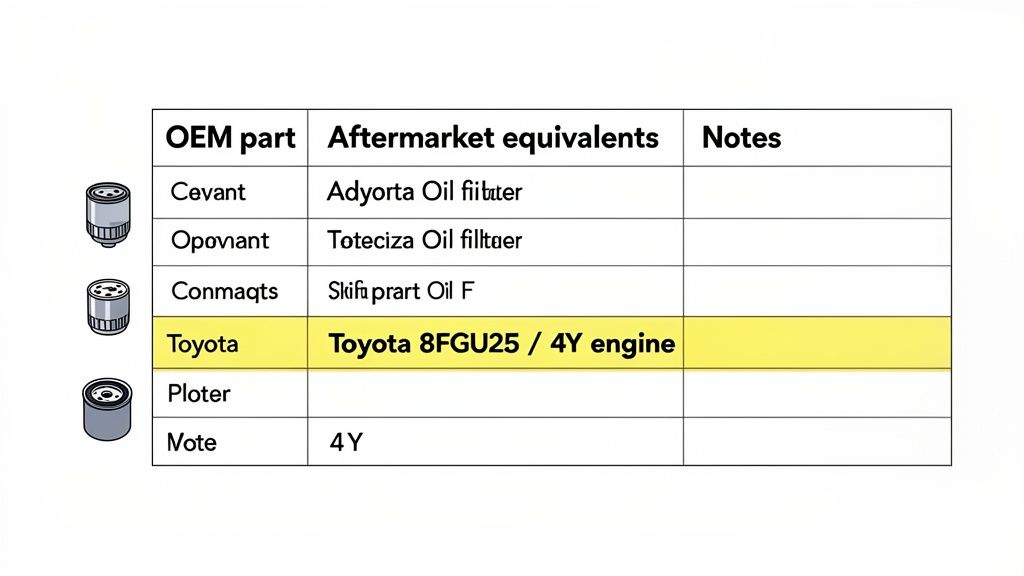

For a quick check, these are the numbers you need written in the cab. This table gives you the OEM numbers and the aftermarket equivalents that real mechanics trust.

Quick Lookup Toyota 8FGU25 Oil Filter Numbers

| Part Number Type | Part Number | Notes |

|---|---|---|

| Primary Toyota OEM | 90915-20004 |

Original equipment part number. |

| Alternate Toyota OEM | 90915-YZZF1 |

Superceded number, widely used and cross-referenced. |

| WIX Aftermarket | 51348 |

Popular and reliable aftermarket choice. |

| NAPA Gold Aftermarket | 1348 |

Same as the WIX 51348, just rebranded for NAPA. |

| Baldwin Aftermarket | B1405 |

Heavy-duty filter option. Built for yellow iron. |

Keep these numbers in your phone, and you'll always be able to find a filter that fits, whether you're at a parts store or ordering online to avoid the dealer tax.

This isn’t guesswork; it’s about having the right intel. The OEM part number 90915-YZZF1 became the go-to cross-reference for a reason. It fits a whole fleet of equipment, not just the 8FGU25. By 2010, parts distributors were moving over 500,000 units of this filter annually in the U.S. alone. It's everywhere.

Out here, you don't get paid to wait for a parts truck. Having a solid cross-reference list means you can get a filter from anywhere and know it's the right one. This isn't like fighting with a finicky JCB DEF sensor; this is a simple fix. It’s about keeping the machine running, not waiting on a dealer.

Here at Flat Earth Equipment, we stock the sensors, solenoids, and filters you need to bypass the dealer delays entirely. We have what you need to keep your equipment operational and earning its keep.

Why The Right Filter Is Your First Line Of Defense

Forget the dealer’s slick brochure for a second. An oil filter isn’t just another part; it's cheap insurance against a catastrophic engine failure that'll have your machine hauled off to the shop. For that 4Y engine, the filter is the only thing standing between clean oil and the metal shavings and job-site grit that will destroy it from the inside.

It's the engine's kidney. It’s working nonstop to pull out the trash that grinds away at bearings and scores cylinder walls. A cheap filter is like trying to run a backhoe with a failing kidney—it won't be long before the whole system shuts down. Just like a bad sensor can trigger a derate and a forced regen, a bad filter will stop you dead.

The Real Cost Of A Bad Filter

Using a mismatched filter is a gamble where the house always wins. The immediate risk is a bad seal, which leads to a leak that can drain your oil and seize the engine before you can even shut it off. But the slow death is worse.

Here’s what we see when guys use the wrong filter:

- Pressure Drop: A restrictive filter starves critical parts of oil, and the pressure plummets. That's a fast track to a spun bearing.

- Bypass Valve Failure: A cheap filter’s bypass valve will pop open way too early, letting unfiltered, gritty oil run straight through your engine. It’s the same as having no filter at all.

- Contaminant Overload: Low-grade filter media gets clogged in no time, losing its ability to trap anything. This just grinds down every moving part inside that 4Y.

The kid at the parts counter might say, "It looks close enough." But "close enough" is how a $300 PM job turns into a $7,000 engine rebuild. The math just doesn't work.

This isn’t about parts; it’s about uptime. A machine sitting dead isn't making you money. That’s the real-world consequence the dealer’s service manual, locked behind their "Service Master" laptop, doesn't talk about. Every decision, right down to the filter, impacts whether that machine is working or waiting. To learn more about our commitment to providing field-tested parts, you can read about the philosophy behind Flat Earth Equipment and why we put reliability above everything else.

The Definitive Aftermarket Cross Reference List

You’re in the middle of a job, covered in grease, and the last thing you need is a parts hunt. The dealer will sell you their "official" filter with a markup that'll make your eyes water, but you and I know that quality aftermarket filters get the job done just as well—if not better. Forget their catalogs and long wait times. This is the list you need to get a reliable filter from anywhere.

We’re not talking about what might fit. This is a list of verified, field-tested equivalents for the Toyota 8FGU25 oil filter. We’ve included notes where they matter, because in a tight engine bay, a few millimeters is the difference between a clean install and a busted knuckle.

This simple decision tree shows the only question that matters.

The takeaway is brutally simple: either you use a verified part and protect your iron, or you roll the dice and risk a catastrophic failure.

Toyota 8FGU25 Aftermarket Oil Filter Cross Reference

Forget squinting at blurry catalog pages. Here's a quick-lookup table of the most reliable aftermarket filters confirmed to fit the Toyota 4Y engine. These are the parts we trust and see on yellow iron every day.

| Brand | Part Number | Fitment Notes |

|---|---|---|

| WIX | 51348 |

The go-to industry standard. Solid construction and reliable media. |

| NAPA Gold | 1348 |

Identical to the WIX 51348, just in a different box. |

| Baldwin | B1405 |

Heavy-duty can. A top choice for dusty, demanding environments. |

| Fleetguard | LF3349 |

A premium option from Cummins known for excellent filtration. |

| Donaldson | P550162 |

Another heavy-duty player with solid performance and availability. |

| Fram | PH3614 |

Widely available, but check for the heavy-duty version if available. |

| Purolator | L10241 |

A common and reliable filter you can find at most auto parts stores. |

This isn't an exhaustive list of every filter that might screw on, but a curated list of proven performers. Stick with these, and you won't have to worry.

Top-Tier Aftermarket Brands

These are the brands we trust. They're built for the pressures and contamination of a real industrial engine, not some grocery-getter. When you're looking for a Toyota 8FGU25 oil filter cross reference, start here.

- WIX

51348: A solid, all-around performer. The can is tough, the media is reliable. It's one of the most common aftermarket options you can find. - NAPA Gold

1348: This is the same filter as the WIX51348. If your local NAPA has this on the shelf, grab it. - Baldwin

B1405: Baldwin filters are built for yellow iron. This is a great choice for machines running in dusty hellscapes. - Fleetguard

LF3349: Often considered a premium filter, Fleetguard (by Cummins) provides excellent filtration. A top-tier choice if you can get it.

Other Reliable Cross References

Sometimes your go-to brand isn't on the shelf. These part numbers are also confirmed fits for the 4Y engine, giving you more options to get back to work without waiting on the dealer.

- Donaldson

P550162 - Fram

PH3614 - Purolator

L10241

Don't let anyone tell you that only an OEM filter will protect your engine. That's a sales pitch, not a fact. A verified filter from a reputable aftermarket brand will keep that 4Y running strong, and it’ll keep more money in your pocket.

At Flat Earth Equipment, we stock the parts that keep you independent from the dealer's service bay. We believe in arming technicians with the right information and the right parts to get the job done on their own terms.

How To Verify You Have The Right Filter In Hand

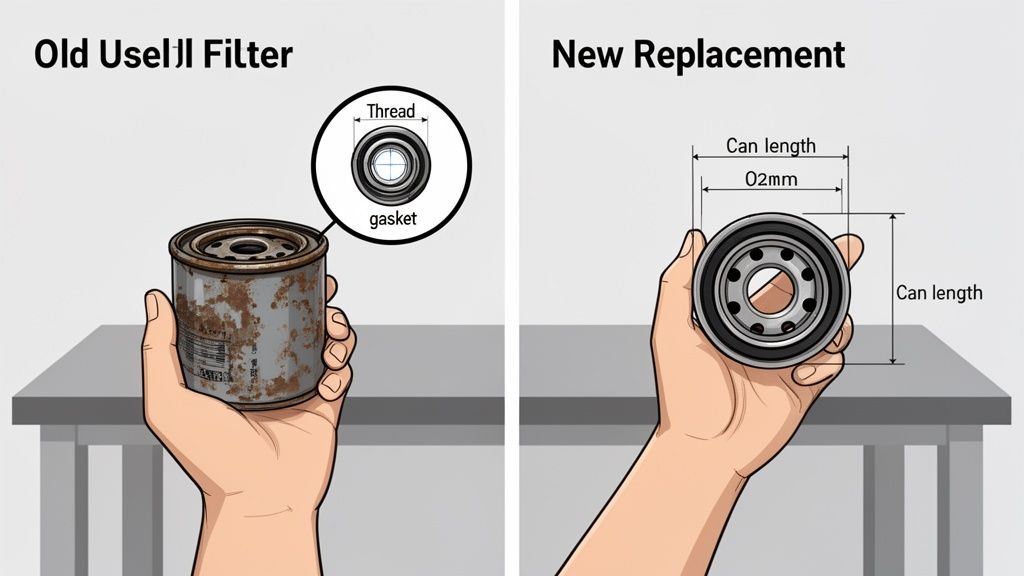

Getting the right part number is half the battle. The real test comes when you pull the new filter out of the box and hold it next to the crusty, oil-soaked one you just fought to get off the engine.

Don't just trust the box—trust your eyes. Installing a filter that "looks close enough" is a rookie mistake that leads to catastrophic failures.

Before you even think about spinning on that new filter, run a quick side-by-side inspection. This isn't some fussy procedure—it's the five-second check that separates a professional from a liability. It saves you from blowing a seal, losing oil pressure, and turning a simple PM into an engine rebuild.

The Field Mechanic's Verification Checklist

When that new filter arrives, grab the old one and put them base-to-base. Here's exactly what to check to make sure your Toyota 8FGU25 oil filter cross reference paid off.

- Check the Gasket: Is the new gasket the same diameter as the old one? A smaller gasket won't seal, and a larger one can get pinched, creating a massive leak the second the engine turns over.

- Compare the Threads: Look inside. The thread pitch and diameter must be identical. If you try to force on a filter with the wrong threads, you'll strip the engine's filter mount—a nightmare repair you don't have time for.

- Verify Can Dimensions: Make sure the new filter's can is roughly the same height and diameter. A filter that's too tall might not clear other components in the tight engine bay.

In the field, there are no do-overs. You verify your parts before they go on the machine. That discipline is what keeps your equipment running and prevents the kind of expensive, time-wasting screw-ups that get you sent back to the shop with your tail between your legs.

This simple habit of double-checking your parts is what separates the pros from the parts-changers. It’s about preventing problems before they start and keeping that machine on the job, making money.

Field Installation Guide For The 8FGU25

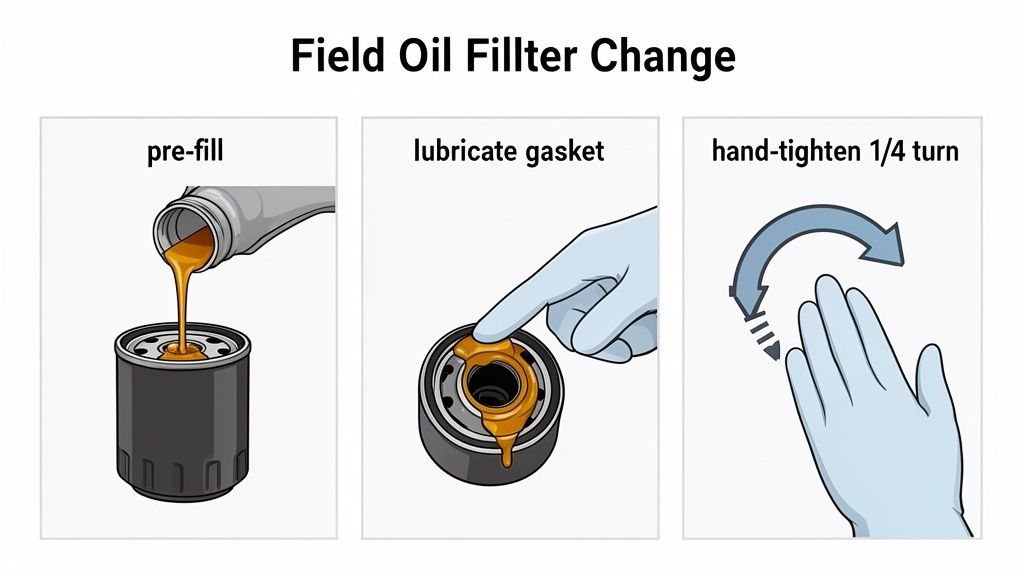

Changing an oil filter seems simple, but screwing it up in the field leads to nasty spills and seized engines. This isn't the textbook procedure—this is about the real-world steps that save you from headaches when you're on uneven ground with dirt kicking up. We're not in a clean shop.

Sure, the dealer’s service bay has a level concrete floor. Out here, you’ve got gravel and mud. A clean job is a safe job, so take a minute to wipe down the filter housing before you spin the old one off. That keeps grit from getting into clean oil passages where it can do real damage.

The Technician's Walkthrough

There's a reason this process is muscle memory for experienced techs. Every step prevents a specific, expensive failure. Skip one, and you're asking for a callback or a seized engine.

Pre-Fill the New Filter: Never install an oil filter dry. Pour fresh engine oil into the new filter until it's about two-thirds full. This prevents a dry start, making sure the engine gets immediate lubrication. That brief moment of oil starvation is when serious wear happens.

Lubricate the Gasket: Dip a finger into clean oil and run a thin film over the new filter’s rubber gasket. A dry gasket will bunch up, tear, or fail to seal. The result? A massive leak as soon as oil pressure builds. This is non-negotiable.

Hand-Tighten Plus a Quarter Turn: Spin the new filter on by hand until you feel the gasket make contact with the engine block. Once it’s snug, grab a filter wrench and give it just another quarter to a half turn. That's it. Over-tightening crushes the gasket and makes removal a nightmare next time.

Don't be the guy who strips the threads on a filter mount because you tried to gorilla-tighten it. The hand-tight-plus-a-quarter-turn rule exists for a reason—it works every single time. It creates the perfect seal without damaging the equipment.

Most mistakes are born from rushing. Stripped threads are from cross-threading or over-tightening. Leaks? Nearly always a dry or damaged gasket. Do it right, do it once, and get on with your day.

For more on keeping your work area secure, check out our guide on job site safety protocols.

Service Intervals and the True Cost of Neglect

That owner's manual? It was written for a perfect world. It recommends an oil and filter change every 500 hours for the 4Y engine, but out here, the real world is filled with dust, grit, and brutal conditions. That 500-hour interval is a starting point, not a rule.

If your 8FGU25 lives in a clean warehouse, sure, stick close to that number. But if it’s on a dusty construction site, you’d be a fool not to cut that interval in half. Contaminants are the enemy, and a clogged filter stops protecting your engine long before that hour meter rolls over.

Adjusting Intervals for the Real World

Stretching an oil change to save a few bucks is the definition of short-sighted. That filter is the only thing keeping abrasive particles from turning your engine oil into liquid sandpaper.

Letting it go too long is a recipe for disaster:

- Accelerated Engine Wear: Dirty oil grinds away at bearings and rings.

- Reduced Oil Pressure: A clogged filter restricts flow, starving critical components.

- Catastrophic Failure: Eventually, something gives. A spun bearing or a scored cylinder means a complete engine rebuild.

You're not saving money by skipping maintenance; you're just deferring a much bigger payment. A $40 filter and an hour of your time today prevents a $7,000 engine replacement and weeks of downtime tomorrow. It’s the same logic as replacing a bad DEF sensor before it triggers a forced regen that stops the whole job site.

The data backs it up. In markets like the U.S. and Canada, where Toyota owns 32% of the cushion tire forklift segment, properly maintained filters are proven to reduce engine wear by 35%. When changed on schedule, this alone slashes repair costs by $450 on average per forklift, per year. Dig into the numbers yourself with these industrial maintenance findings-Truck-Components/Tune-Up-Kits-and-Planned-Maintenance-Kits/Planned-Maintenance-Kit/p/380012-020-06) and see the real cost of neglect.

Smart PM isn't about following a book; it’s about protecting your iron and maximizing uptime. Don’t let a cheap filter take down an expensive machine.

Questions Straight From The Shop Floor

You're halfway through a PM, covered in grease, and questions pop up. Forget the clean-hands, by-the-book answers from the dealer's service desk. Here are the real answers to the questions we get every day from techs in the field working on the Toyota 8FGU25.

Can I Just Slap a Car Oil Filter On My Forklift?

Don't do it. Seriously. Yes, a car filter might thread on, but it's not built to handle the constant high hydraulic pressures and brutal cycles of a forklift engine.

Forklift-specific filters are engineered for industrial abuse:

- Beefier Cans: The outer casing is thicker to keep from bursting under pressure spikes.

- Industrial Bypass Valves: The bypass valve is calibrated for an industrial engine, not a commuter sedan. The wrong one will starve the engine of oil.

- Tougher Filter Media: The filter material is designed to capture the kind of gunk you find on a job site—hydraulic dust, fine metal shavings, and soot.

Putting the wrong filter on is the fastest way to blow the can out, dump all your oil, and seize the engine. It's a cheap shortcut to a catastrophic failure.

What’s the Big Deal If I Use Some Unverified, Off-Brand Filter?

You're gambling with a piece of equipment that costs tens of thousands of dollars. An unverified, cheap knock-off filter is a huge risk. It might not seal right, it could have the wrong bypass pressure, or the filter media could be garbage that lets contaminants flow right to your bearings.

This leads to two bad outcomes. The immediate one is an oil leak that could drain an engine in minutes. The slower, more painful death is the long-term, accelerated wear from dirty oil that grinds down your engine from the inside. Always stick to a verified Toyota 8FGU25 oil filter cross-reference from a supplier who knows their iron.

How Do I Know If My Oil Filter Is Clogged or Failing?

The obvious red flags are a drop in engine power, low oil pressure readings, or an engine that starts sounding rough. If it gets really bad, the engine will overheat.

But you should never wait for these signs. That’s like waiting for the DEF light to start flashing before you do anything. The whole point of PM is to change the filter before it becomes a problem. That's how you stop these issues before they ever start.

Tired of the dealer runaround and their laptop locking you out? Flat Earth Equipment has your back. We ship the sensors, solenoids, and filters you need to stay in the field. Find what you need at https://flatearthequipment.com.