That blinking service light on your JCB's dash is more than just an annoyance—it's a direct shot at your uptime and your wallet. Whether it's the AdBlue system acting up again or just a simple maintenance reminder, ignoring it creates doubt, while calling the dealer means surrendering your machine to their schedule and their "Service Master" laptop.

Luckily, you don’t need their expensive gear to get back to work.

Stop Letting Your JCB Cost You Uptime

Every hour that light stays on, your machine is held hostage by the dealership's schedule, not yours. It makes operators hesitate, wondering if a real problem is brewing or if the finicky electronics are on the fritz again. This uncertainty slows down the work and hangs the threat of a forced Regen cycle or a dealer call-out over your head.

It’s a cycle designed to keep you dependent.

That light is programmed to come on at specific intervals. These are critical milestones for your machine’s health, and your JCB—be it a backhoe, telehandler, or excavator—relies on them. But the dealer's lockout software and the constant threat of a machine-stopping "Regen" cycle can turn a simple service into a full-blown crisis.

In fact, equipment uptime trackers show that un-reset service lights contribute to a staggering 28% of unnecessary downtime calls to dealers. You can see the full story behind these service interval challenges on YouTube.

What Your Yellow Iron Is Trying to Tell You

Understanding what triggers the light is the first step toward taking back control. The system is just a simple hour-meter counting down to the next scheduled check-up. Knowing what each alert means puts you in charge, not the dealer's tech.

Before we dive into the reset procedures, it's crucial to know why the light is on in the first place. JCB sets these intervals for a reason, and performing the correct maintenance is just as important as clearing the light.

Decoding Your JCB Service Intervals

Here's a quick reference guide to the most common service intervals that will trigger that pesky light. Think of it as a cheat sheet for what your machine needs at each major milestone.

| Hour Interval | Service Level | Typical Maintenance Required |

|---|---|---|

| 500 Hours | PM2 | Your standard engine oil and filter change. The most frequent and easiest service to handle. |

| 1000 Hours | PM3 | A more thorough check-up, often including hydraulic system filters and other fluid changes. |

| 2000 Hours | PM4 | A major service interval requiring deeper inspections of core components and potential overhauls. |

Knowing this, you can plan your maintenance, order the parts ahead of time from a supplier like Flat Earth Equipment, and be ready to knock out the service and the reset in one go.

The real problem isn't the maintenance itself—it's the dependency the dealer creates around clearing that light. They want you to believe only their tech with the "Service Master" laptop can do it, locking you into their service schedule and billing rates.

By mastering the simple, built-in reset procedure, you break that chain. You perform the maintenance on your terms, log it yourself, and get the machine back to making you money immediately. This isn’t just about turning off a light; it's about reclaiming ownership of your equipment.

Using The Built-In Reset Tool They Don't Want You To Know About

Forget waiting on a tech with a laptop. JCB built a perfectly good reset tool right into your machine's dashboard. The only reason you think you need a dealer is because that’s where they make their easy money—on a simple button press they charge you hundreds for. This is how you break that cycle.

This isn’t some back-alley secret; it’s a standard feature designed for owner-operators. The process is so straightforward you can knock it out in under 60 seconds. In fact, data from Altorfer Cat shows that a staggering 65% of service calls stemmed from unreset lights, tricking operators into thinking serious repairs were needed. Those unnecessary calls inflated shop bills by an average of $1,200 per incident. To see just how simple it is, you can learn more about the reset process from MacAllister Cat.

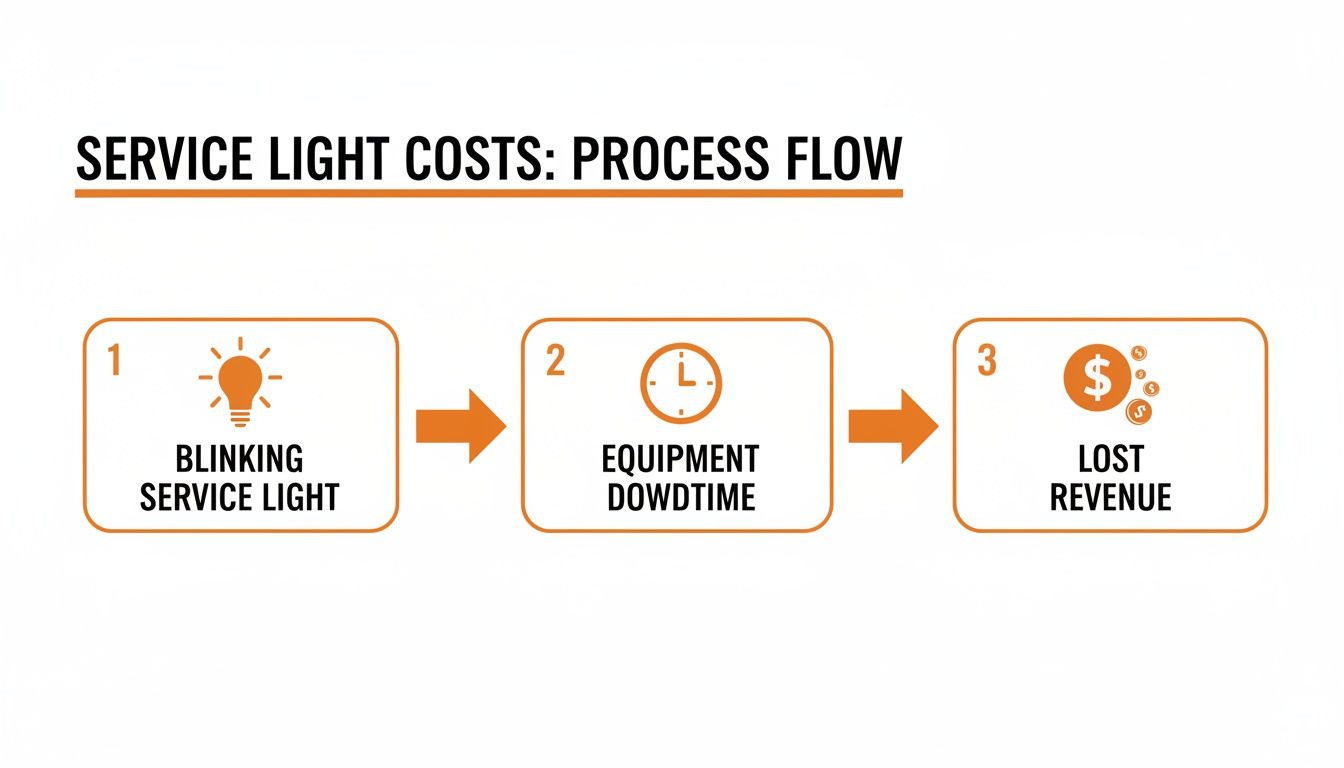

This infographic shows the simple but costly path from a blinking light to lost revenue.

It’s a direct line—that light triggers downtime, and downtime bleeds money right from your bottom line.

Your Step-By-Step Field Guide

Let’s get this done. No special tools, no phone calls to dispatch. Just you, the machine, and a few minutes.

First, park the machine on level ground and engage the parking brake. You'll need the key in the "ON" position, but don't start the engine. The display has to be powered up to get into the menus.

Now, look for the button with the gear or menu icon on your dash panel. This is your gateway into the service menu—the part the dealer hopes you never find. Navigating the screen from here is straightforward, using the arrow or scroll buttons to move and a select/enter button to confirm.

Once you press that menu icon, you'll enter the main menu. Use the up/down arrow buttons to scroll until you find "Maintenance," "Service," or a similar option. Select it by pressing the button that acts as an "Enter" or "OK" key.

Zeroing Out The Service Interval

Inside the maintenance menu, you’ll find a list of service items, each with an hour counter next to it. This is the heart of the system.

- Engine Oil & Filter: This is your most common reset, tied to the 500-hour interval.

- Hydraulic Filter: Typically reset at the 1000-hour mark.

- DEF/AdBlue System: On newer machines, you might see resets for AdBlue filters here too.

Scroll to the specific item you just serviced. With it highlighted, press and hold the "OK" or select button for a few seconds. The screen will ask for confirmation. Confirm it, and the hour counter for that item will reset to zero.

Field Tip: Don't just reset everything blindly. Only zero out the service you actually performed. If you reset the hydraulic filter timer but didn't change the filter, you're setting yourself up for a catastrophic pump failure down the line. Keep a written log.

After resetting the necessary items, cycle the key off, wait about 10 seconds, and turn it back on. That service light should be gone. If it's still there, you might have an active fault code overriding the reminder, which is a different problem entirely. But for routine maintenance, this process puts you back in control.

How A Simple Reset Prevents Catastrophic Failures

That little blinking light on your dash? It’s more than just an annoyance. It’s a symptom of a much bigger problem: complacency.

An un-reset light breeds confusion and makes it easy to skip the real work. Was the AdBlue filter actually changed, or did someone just ignore the light for another hundred hours? This is where you separate the pros from the guys waiting for a dealer truck to show up.

The five-minute act of resetting the service light is your first line of defense against the kind of catastrophic failures that sideline a machine for weeks and drain your bank account. It's not about the light; it's about the discipline it represents.

The Real Cost of Ignoring The Light

I've seen it a hundred times. An operator ignores a 500-hour service light because "it's just an oil change." A few hundred hours later, that same JCB is getting hauled back to the shop with a cooked engine because the oil broke down and lost viscosity under heavy load. The repair bill? Thousands. The downtime? Even more costly.

It’s a domino effect.

A missed hydraulic filter change leads to a whining pump, then a blown pump that sends metal shavings through the entire system. What started as a $100 filter and an hour of work becomes a multi-day teardown and a five-figure invoice. All because someone treated the service reminder as optional.

This isn't just about maintenance; it's a critical safety issue. An un-reset light creates a culture where "good enough" becomes the standard, and that's when things get dangerous. Staying on top of these resets is one of the most important things you can do to maintain a safe job site. Check out our guide on equipment safety protocols to learn more.

A Ritual That Saves Your Yellow Iron

Turning that reset into a non-negotiable ritual is the smartest move a field tech or maintenance supervisor can make. It builds a crucial habit: service gets done, service gets logged, and the machine's internal clock gets reset. No ambiguity, no excuses.

This simple discipline has massive payoffs. In fact, for safety directors and shops managing machines like JCBs, mastering service light resets is a game-changer. Unaddressed reminders are linked with 31% higher incident rates from deferred maintenance.

For service managers, this reset ritual isn't just procedural—it's a gateway to 33% extended machine life, backed by hard uptime data. You can discover more insights about these service interval findings from Altorfer Cat.

Think of it this way: the dealer's laptop doesn't keep your machine alive. You do. By performing the maintenance yourself and using the built-in reset procedure, you prove that the most valuable asset isn't the guy with the fancy software—it's the tech in the field with the grease on his hands and the discipline to do the job right.

Troubleshooting When The Service Light Refuses To Go Out

So you did the maintenance, you followed the reset procedure, and that service light is still glaring at you. Don't sweat it. This is where a real tech earns their stripes. Before you even think about calling for backup, it's time to dig in and do some real diagnostics.

More often than not, a stubborn service light isn't a glitch in the reset process. It's the machine telling you something else is wrong. The service reminder is just a simple hour-meter trigger, but an active fault code from a real problem—especially on these finicky JCB electronics—will always override it. That dealer laptop isn't magic, it just reads these codes.

Hunting Down Electrical Gremlins

Your first suspect should always be the wiring. A piece of Yellow Iron lives a tough life, and its electrical system pays the price. Connections get corroded, grounds work themselves loose, and wires get chafed through. Especially with sensitive AdBlue/DEF systems, a single bad connection can bring the whole operation to a halt.

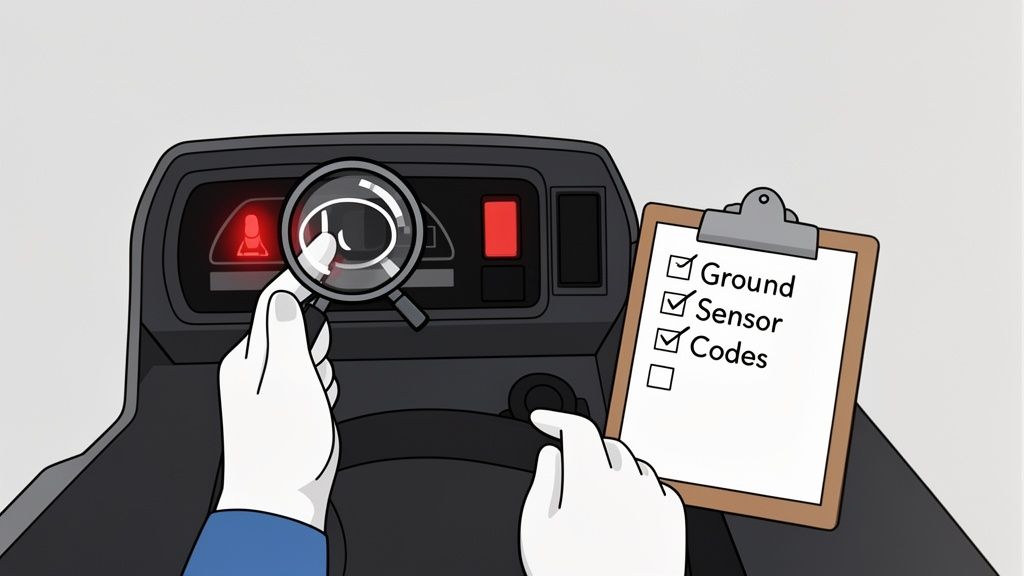

Grab a multimeter and start probing. A bad ground is a classic culprit that can cause all sorts of phantom issues on these machines. After that, visually inspect the wiring harnesses leading to major sensors like the engine oil pressure switch or the NOx sensors.

A few usual suspects to check first:

- The fuse box. It sounds obvious, but a blown fuse can disable a sensor the ECU needs a clean signal from. I’ve even seen a fuse box packed with mud cause intermittent faults that looked like a major electrical failure.

- The seat switch. A faulty switch or a loose plug under the operator's seat can trick the machine's brain into thinking no one is there, throwing codes that prevent a clean reset.

- AdBlue/DEF System Solenoids. These are notoriously finicky. Check the connections for corrosion or damage. A solenoid that isn't working properly will absolutely keep a fault active in the system.

When an ECU detects an issue, it generates a Diagnostic Trouble Code (DTC). This isn't just a simple alert; it’s a specific signal pointing to a system that needs attention. For example, a code starting with "P" points to the powertrain, while a "C" indicates a chassis problem.

When A Deeper Fault Code Is The Real Villain

If the wiring, fuses, and basic switches all check out, it's almost certain that an active fault code is locking out the service reset. Think of it this way: the service light is a gentle reminder, but a real warning code is the machine screaming that something is wrong right now. This could be anything from a failing alternator to dangerously low oil pressure or a clogged DEF injector.

This is where a good diagnostic tool becomes invaluable, but you can often find the root cause without one. Just pay attention to how the machine is behaving. Is it running rough? Are the hydraulics weak? Has it gone into limp mode? The machine itself often gives you the best clues.

Remember, that persistent service light is usually just a symptom. By methodically hunting down the root cause—whether it’s a bad connection, a faulty sensor, or a legitimate mechanical issue—you can save yourself hundreds in dealer diagnostic fees and keep your repairs in your own hands.

Stocking Your Shop To Beat The Next Service Interval

Alright, you did it. You handled the service, reset the light, and told the dealer you've got it covered. Nice work. But don't kick your feet up just yet.

The moment you clear that service light, the clock starts ticking toward the next 500-hour interval. Winning this game isn’t about a one-time fix; it’s about staying one step ahead of your machine.

The real power move? Having everything you need sitting on your own shelf before that light even thinks about coming back on. This is how you shift from being a reactive mechanic to a proactive manager who controls their own uptime. Forget the frantic calls to the parts counter and hearing that a simple AdBlue solenoid is on backorder for a week.

Build Your Anti-Dealer Service Kit

This is where Flat Earth Equipment becomes your secret weapon. Instead of letting the dealer dictate your schedule, you get the right filters, sensors, and solenoids shipped fast. You build a small, strategic inventory that makes you truly independent.

When you have the right parts on hand, a 500-hour service becomes a minor task, not a multi-day crisis. You see the hours creeping up, pull what you need off your own shelf, and knock out the job in an afternoon. No phone calls, no waiting, no downtime.

This isn't just about convenience; it's about taking back complete control. The dealer's business model depends on your lack of preparation. When you're prepared, their power over your schedule and that dreaded "Regen" cycle simply evaporates.

Stocking your shop is the final step in breaking free from that cycle. A small investment in parts pays for itself the very first time you avoid a lost day of work waiting for a delivery truck. While you're at it, you can also grab some high-quality chargers and electrical components to make sure the rest of your shop equipment is always ready to go.

Your Anti-Dealer JCB Service Kit

To really take charge, you need to think like a parts manager. Having the right components on hand before you need them is the ultimate strategy for maximizing uptime and cutting out the middleman. Here’s a no-nonsense checklist of what every JCB owner should have on their shelf.

| Part Category | Essential Components | Why It's Critical |

|---|---|---|

| Engine Service | Engine Oil Filters, Fuel Filters, Air Filters, Engine Oil | These are your most common service items. Having a few of each on hand is non-negotiable if you want to avoid downtime. |

| Hydraulic System | Hydraulic & Hydrostatic Filters | Clean fluid is the lifeblood of your machine. A single clogged filter can destroy a pump in a hurry, turning a small job into a huge expense. |

| DEF/AdBlue System | DEF Filters, Nozzles, and common Solenoids/Sensors | These are known failure points that will throw active fault codes and can shut your machine down instantly. Having spares is cheap insurance. |

| Electrical Parts | Common Fuses, Relays, and a Spare Seat Switch | Electrical gremlins are a fact of life. A $5 fuse can be the only thing standing between you and hours of frustrating diagnostics. |

By keeping these core components in your inventory, you eliminate the single biggest advantage the dealership has over you: parts availability. You become your own parts department, your own technician, and the master of your own schedule. That's how you win the war, not just the battle.

Frequently Asked Questions From The Field

Out in the dirt, you hear the same questions over and over. Guys get stuck on the same problems because the dealer makes everything sound more complicated than it is. Let's clear the air on a few things when it comes to that JCB service light.

Can I Really Reset The JCB Service Light Without Special Tools?

Absolutely. Anyone telling you otherwise is trying to get into your wallet with their "Service Master" laptop.

Your JCB has a built-in reset function right on the dash panel. You don’t need the dealer’s laptop or any external diagnostic tool for these routine maintenance intervals. It's all done with the buttons already on your console.

What Is The Risk If I Just Ignore The Service Light?

Ignoring that light is a high-stakes gamble with your iron. The machine might not shut down right away, but you're operating blind, pushing past a critical maintenance point for your engine oil, filters, or hydraulics.

Continuing to run it causes accelerated wear and can lead to a catastrophic failure—think a blown pump or a cooked engine—that's far more expensive than the simple service you skipped. Worse, on modern machines, an ignored AdBlue/DEF warning will eventually force the engine into a crippling limp mode.

The service light is a pre-set timer based on operating hours. A separate warning code, usually with a different icon and a buzzer, signals an active fault from a sensor. That's not a reminder; it's the machine telling you something is wrong right now, and it can't be cleared with a simple service reset.

Will Resetting The Service Light Myself Void My Warranty?

No, it won’t. Resetting the light after you perform the required maintenance yourself does not void your warranty. In fact, doing and logging your own timely maintenance is part of complying with the warranty terms.

The key is to actually do the work.

- Change the oil and filters. Don't just clear the light.

- Keep a written log. Note the date, machine hours, and what service you performed.

The reset function is there for owners to use. It’s your machine, and you have the right to maintain it. If you have more questions about what your responsibilities are, you can always get in touch with our team of techs for some straight answers.

When you're ready to take full control of your maintenance schedule and stop waiting on the dealer for parts, Flat Earth Equipment has you covered. Get the right sensors, solenoids, and filters you need to bypass dealer wait times shipped fast from https://flatearthequipment.com.