When that parking brake pedal hits the floor, or your telehandler starts that slow, expensive creep on a hill, you’re looking at a JCB Telehandler Parking Brake Pad Replacement 15/920284. This isn't some checkbox on a safety form; it's the only thing stopping tons of yellow iron from turning into a runaway nightmare. This guide cuts the crap and shows you how to do the job right, out in the mud where the work actually gets done.

That Parking Brake is the Only Thing Saving Your Drivetrain

Let's get this straight: the parking brake on your JCB is not a suggestion. It’s the last line of defense holding that machine on a slope, protecting your crew, your site, and your job. Ignoring worn pads is asking for a disaster.

Once those pads are shot, you're putting insane stress on the drivetrain. That slow creep you feel isn't just an annoyance; it’s the sound of your transmission and axles getting hammered. Trust me, the dealer bill for a new transmission is a hell of a lot more than a set of brake pads and an hour of your time.

Spotting a Worn-Out Brake

You won't get a "Check Engine" light for this. No fancy sensor is going to tell you the pads are gone. This is old-school mechanic work—it's about feel, sound, and common sense. Here's what to look for when you're out in the dirt:

- A "Spongy" Pedal: The pedal travels way too far before you feel any bite.

- Machine Creep: The biggest red flag. You park on a slight grade, and the machine starts rolling. This is dangerous, period.

- Grinding: Hear metal-on-metal when you hit the brake? You're past due. You’ve ground the friction material down to nothing.

Waiting for the dealer to schedule you in between their high-dollar warranty jobs isn't an option when you’re down. This is where you take control. Getting the right parts, fast, is what keeps you running. A supplier like Flat Earth Equipment is your ally against the dealer monopoly. Skip their wait times and get your iron back to work.

The real problem is a failing parking brake is a silent killer. It murders your productivity and opens you up to a massive safety liability. It’s a simple fix that prevents catastrophic failures, and every real tech needs to treat it seriously.

In the world of heavy iron, the JCB Telehandler Parking Brake Pad 15/920284 is critical, especially on workhorses like the JCB 456 and 456E wheeled loaders. These pads are built for extreme pressure. A proper replacement can boost machine uptime by up to 35% when you need it most.

Before you turn a wrench, use your head. Review your job site safety protocols. Take a minute to check our no-nonsense guide on equipment safety.

JCB 15/920284 Brake Pad Specs and Compatibility

Getting the right part number is half the battle. This table cuts through the noise so you know you're ordering the right part for your machine.

| Specification | Detail | Field Notes |

|---|---|---|

| Part Number | 15/920284 | The OEM number. Don't get screwed by a look-alike part that doesn't fit. |

| Dimensions (LxWxH) | 137.5mm x 82mm x 11mm | These dimensions matter. The wrong size means uneven wear or a caliper that won't fit. Don't guess. |

| Compatible Models | JCB 456, 456E, various telehandlers | Used all over the place, but primarily on the 456 series loaders. If you're not sure, check your machine's serial number before you order. |

| Material | High-friction composite | Built for holding force. Cheap aftermarket junk uses garbage material that glazes over and fails when you need it most. It's not worth the risk. |

| Kit Contents | Varies by supplier | Some kits are just pads. Good kits include new retaining pins and clips. Replace the damn hardware. It's cheap insurance against a seized pin down the road. |

Double-check this info against your machine's serial number. It saves you the headache of a second trip for parts and more downtime.

The Right Tools for a Job in the Dirt

You're not doing this in a clean dealer bay. You're in the mud, the ground's uneven, and it's probably about to rain. Your toolkit needs to be lean and mean because driving back to the shop is downtime you can't afford. This isn't about having a shiny Snap-on box; it's about having the right tools to beat the machine into submission.

First, safety. A telehandler will kill you without thinking twice. You need heavy-duty jack stands—not the cheap garbage from the auto parts store. Get stands rated for double the weight you're lifting. Use a solid hydraulic jack and chock the wheels that are staying on the ground. Never trust hydraulics to hold up a machine this heavy.

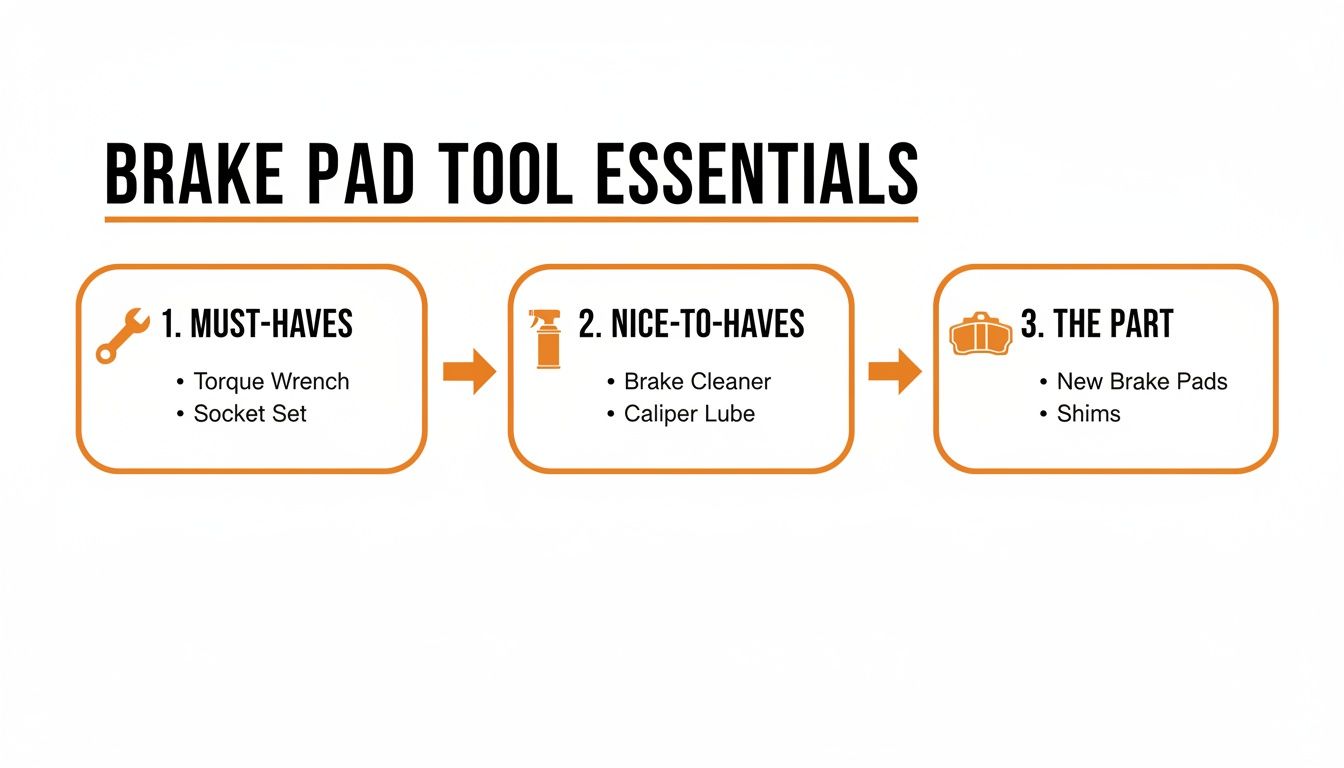

Must-Haves vs. Nice-to-Haves

Space on the service truck is gold. When I'm packing for a JCB Telehandler Parking Brake Pad Replacement (15/920284), this is the gear that makes the cut.

The Absolute Essentials:

- Heavy-Duty Sockets & Breaker Bar: Get the right metric sizes for the caliper bolts and guide pins. A long breaker bar is your best friend for cracking loose bolts baked on by heat and rust.

- Torque Wrench: Not optional. "Good-n-tight" is how you get callbacks. Torque those bolts wrong, and you're looking at brake drag or a caliper falling off.

- Large C-Clamp or Piston Spreader: That piston won't retract itself. A big C-clamp will get it done if you don't have a dedicated brake tool.

- Wire Brush & Brake Cleaner: Don't you dare slap new pads on a dirty caliper. A few minutes with a wire brush and brake cleaner will get rid of the gunk that causes pads to bind and wear unevenly.

I’ve seen more brake jobs fail from pure laziness than from bad parts. If you don't clean the guide pin bores and the surfaces where the pad ears sit, you're just setting yourself up for a callback in a hundred hours.

Now, the "nice-to-haves" that make the job less of a fight. A good set of pry bars for wrestling old, seized pads out of the caliper. A can of penetrating oil for those rusty bolts. You can do the job without them, but they’re the difference between a four-hour fight and a one-hour win.

What a Quality 15/920284 Pad Looks Like

Finally, the part itself. A cheap knock-off pad will cost you more in the long run. When you get your 15/920284 kit from a real supplier like Flat Earth Equipment, you'll see the difference.

The friction material is dense and uniform, not flaky. The backing plates are thick and stamped right, so they fit without rattling. A cheap pad just turns to dust, glazing over and losing its grip. Don't risk it.

The Brake Pad Swap: No Dealer Laptop Required

Alright, let's get dirty. This is where the real work happens, far from the dealer's clean floors and diagnostic software. We're doing a full JCB Telehandler Parking Brake Pad Replacement 15/920284 in the field, with nothing but good tools and real-world know-how. The whole point is to get this machine working without begging a dealer to plug in their laptop and "unlock" a function.

First, secure the machine. Find the flattest ground possible, chock the wheels, and get your jack and stands under a solid frame point. Safety first. Once the machine is stable and the wheel is off, you can finally see the parking brake assembly. It’s usually caked in grime, so prepare for a fight just to get access.

This breakdown shows what you'll need for the job, from the absolute must-haves to the nice-to-haves that make life easier.

Having this stuff ready before you start is what separates a smooth job from an all-day curse-fest.

Getting the Old Pads Out

Crack the caliper mounting bolts loose with a long breaker bar. They're almost always seized. Don't pull them all the way out yet.

Next, push the caliper piston back to make room for the new, thicker pads. Forget proprietary dealer tools; a big C-clamp or piston spreader works perfectly. Use the old inner pad against the piston and slowly tighten the clamp to press it back into its bore. Go slow—you don't want to damage the seal.

With the piston retracted, remove the caliper bolts and slide the caliper off the rotor. The old pads should come out, but they're often frozen in with rust. A pry bar will persuade them.

Prepping the Caliper for New Pads

This is what separates a pro from a parts-changer. Before you even touch the new pads, you have to clean everything. Use a wire brush and brake cleaner to scrub the caliper, especially where the new pad ears will sit.

Focus on the guide pins and their bores. Pull them out, clean off all the old, gummy grease, and scrub the bores clean. Any binding here will cause the brake to drag, generating heat and cooking your new pads.

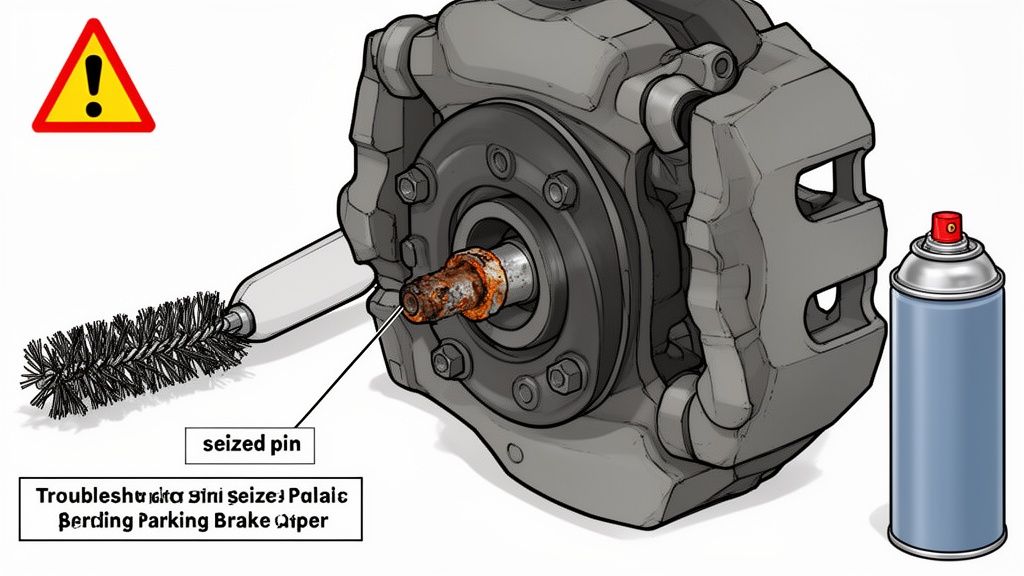

The most common shortcut is skipping the guide pins. Don't. A seized pin is the #1 cause of premature brake failure. It takes five extra minutes to prevent. Lube them with high-temp brake grease before re-installing.

Installing the 15/920284 Pads and Final Torque

With everything clean, it’s time for new parts. The 15/920284 brake pads should slide into the bracket without a fight. If you have to force them, you missed a spot cleaning.

Slide the caliper back over the rotor. Pro tip: put a small dab of anti-seize on the caliper mounting bolt threads. It won’t affect the torque, but it'll make the next guy's job—probably you again—a lot easier.

Now, grab your torque wrench. This isn't optional. The caliper bolts need to be torqued to JCB’s spec. You'll find it in the service manual, but a good rule of thumb for this hardware is around 120-140 ft-lbs. Under-torquing is dangerous; over-torquing stretches the bolts and leads to failure.

These aren't just any pads. They go into machines making up 42% of the European material handling market, designed to handle immense torque up to 25,000 Nm. That's a critical factor reducing accident risks by a documented 40%. You can get more details on these vital JCB style brake pads from htsspares.com.

Once torqued, pump the brake pedal a few times to seat the piston. That's it. You just did a dealer-level repair without their precious laptop.

Verifying Your Work With a Real-World Brake Test

Alright, new pads are in, caliper's torqued. Job done? Not a chance. Bolting on parts is half the battle. Making sure the repair will actually hold is what separates a real tech from a parts-changer. This isn't about paperwork; it's about making sure that machine doesn't roll away and kill somebody.

First, bed-in the new pads. The surface of new pads and the rotor aren't a perfect match yet. Bedding them in creates a uniform layer of friction material on the rotor for maximum stopping power. Don't skip this.

Drive the machine slowly in first gear and gently apply the parking brake a few times. You're not trying to lock it up; you just want to create enough heat and friction to mate the surfaces. After a few gentle applications, do a couple of firmer ones. This takes five minutes and makes a huge difference in brake performance and pad life.

The Essential Brake Adjustment

Now, dial in the adjustment. This is critical. You need the brake to fully engage for holding power, but it has to fully disengage when released. A dragging brake will cook your new pads, overheat the drivetrain, and suck the life out of the machine.

Find the adjustment mechanism on the linkage or cable. You're looking for the sweet spot.

- Too Loose: The pedal feels spongy, and the brake won't hold on a hill.

- Too Tight: The brake drags, creating constant heat and wear. You'll smell it.

Adjust it so there's just a tiny bit of slack before engagement. Apply and release the brake, then spin the wheel by hand (if it's lifted) or listen for drag as you drive slowly. It should spin free.

A dragging brake is a silent killer. It won't throw a code. The operator might not notice it until the pads are smoked and the rotor is warped. Take the extra ten minutes and get the adjustment perfect.

The Real-World Incline Test

Forget testing on flat ground. The only test that matters is on a hill.

Find a safe incline—nothing crazy—and park the machine on it. With the engine running and the transmission in neutral, apply the parking brake firmly.

Now, take your foot off the service brake. The machine should not move. Not one inch. Let it sit for a minute. If it holds solid, your JCB Telehandler Parking Brake Pad Replacement 15/920284 was a success. If it creeps, go back and check your adjustment.

A solid brake means a safe machine. That's the bottom line. This level of diligence is a core part of any good forklift safety program, ensuring equipment is always ready for the job.

Troubleshooting Seized Parts and Junk Components

You did everything right, hit every torque spec, and the damn thing is still dragging. Welcome to the real world, where a perfect job on paper turns into a field nightmare. The most common problems aren't complex; they're the result of rust, grime, and cheap parts.

Maybe the caliper piston fought you every millimeter. Or the new pads are dragging, threatening to cook themselves before the day is out. These aren't signs you need the "Dealer Laptop"; they're signs you need to look closer at the basic hardware.

Seized Guide Pins: The Hidden Killer

If your brake drags after a pad swap, nine times out of ten, it’s a seized guide pin. These pins let the caliper slide freely, ensuring even pressure. But when they get gummed up with old grease and rust, the caliper gets stuck.

The result? The outer pad does all the work while the inner one barely touches. This is how you burn through new pads in a hundred hours. You have to pull those pins, hit them with a wire wheel, and clean the bores until they shine. It's the only way.

Never trust a part that feels "off." If a cheap pad doesn't slide into the bracket easily, or if the backing plate looks thinner than the OEM part, send it back. You're just buying yourself a future problem.

The Problem With Cheap Friction Material

This is why getting quality parts matters. A proper JCB Telehandler Parking Brake Pad Replacement 15/920284 from a supplier like Flat Earth Equipment uses OEM-spec friction material. Cheap knock-offs use a garbage compound that glazes over after a few heat cycles.

Glazed pads lose all their grip. The surface becomes smooth and hard as glass, giving you that terrifying spongy pedal with no holding power. You’re right back where you started, but now you’ve wasted hours on junk parts.

The modern JCB 15/920284 parking brake pad is about reliability. These 137.5mm x 82mm x 11mm pads have logged over 500 million braking cycles worldwide. Their design cuts unplanned downtime by up to 52% in tough environments like Australian mining fleets. Find out more about how these quality JCB parts boost uptime on kuduparts.com. This isn't just a part; it's insurance against doing the job twice.

Straight Answers to Questions from the Field

Out in the dirt, time is money and guessing is a fast way to lose both. You'll run into the same questions on these jobs. Here are the straight answers to what I hear most from other techs. My goal is to get you through the job without second-guessing yourself.

How Often Should I Inspect the Pads?

Forget the service manual's "perfect world" recommendation. If that telehandler is running in a dusty quarry or slogging through mud, you have to be more aggressive.

I tell my crew to put eyes on those pads every 250 hours, or anytime it's in for another service like a hydraulic filter change. A quick visual check is all it takes. Five minutes now can save you from a catastrophic failure later.

The biggest mistake is rushing the cleaning. Built-up grime on the caliper and guide pins will cause the new pads to bind and wear ridiculously fast. Take the extra five minutes. Clean everything with a wire brush and brake cleaner. It makes all the difference.

Do I Replace One Side or Both?

This comes from guys used to working on trucks. A JCB telehandler parking brake is a single caliper system—not a set of wheel brakes. The 15/920284 is a complete kit with both pads for that one assembly, which is usually mounted right on the drivetrain. You're servicing the entire parking brake unit in one shot.

Is Bleeding the Brake System Necessary?

Good news: no. As long as you don't crack open any hydraulic lines, you won't have to touch a bleeder screw. Retract the caliper piston using a C-clamp without disconnecting the hydraulic hose. This saves a ton of time and mess. If you stick to just swapping the pads, it's a purely mechanical job. No air gets in, and you're done faster.

If you run into a weird issue or have questions about a specific model's quirks, you need a solid parts expert to call. For those tough questions on your particular machine, you can always reach out to a specialist through the Flat Earth Equipment contact page.

When you’re stuck in the field and the dealer is weeks out, you need parts you can trust from people who understand urgency. Flat Earth Equipment stocks the high-quality JCB 15/920284 parking brake pads you need and ships them fast, so you can kill downtime and get back to work. Don't let the dealer hold you hostage—get the right parts now at https://flatearthequipment.com.