When your JCB Telehandler dashboard lights up with an AdBlue fault, here's the quick and dirty difference between a pump and an injector failure: a dead pump usually means a hard stop, killing your power almost instantly, while a clogged injector leads to a slow, frustrating decline into limp mode. Getting that distinction right in the field is the first step to beating the dealer's timeline and getting your machine back on the job, without ever needing their damn laptop.

Understanding Your JCB Telehandler AdBlue System

That blinking light and derate warning are coming from the Selective Catalytic Reduction (SCR) system—JCB's answer to Tier 4 emissions mandates. It’s a finicky setup designed to inject Diesel Exhaust Fluid (DEF), or AdBlue, into the hot exhaust gas, a process that converts harmful Nitrogen Oxides (NOx) into harmless nitrogen and water.

The theory is simple. But on a real job site filled with dust, vibration, and temperature swings, it’s a constant source of headaches. Two components bear the brunt of this abuse: the DEF pump and the injector.

The Heart and the Valve of the System

Think of the SCR circuit like a simple fuel system. The DEF pump is the heart, responsible for pressurizing the AdBlue from the tank and sending it down the line. The injector is the valve, a precision nozzle that sprays a fine mist of that fluid into the exhaust stream at exactly the right moment.

When one of them fails, the entire emissions control sequence falls apart. The ECU throws a fault code, triggering a countdown to a forced engine derate or a full-on "regen" cycle that stops you dead in your tracks.

Field Technician's Takeaway: A fault in the AdBlue system isn't just an emissions problem; it's a productivity killer. The machine doesn't care if the engine runs perfectly—if the SCR system isn't happy, it will shut you down. The dealer loves this, because it means a service call for them.

Key Differences Between Pump and Injector Roles

This simple comparison breaks down the job of each component. Knowing their distinct functions is critical before you start troubleshooting.

| Component Role | AdBlue (DEF) Pump | AdBlue (DEF) Injector |

|---|---|---|

| Primary Function | Pressurizes and circulates DEF | Sprays a measured dose of DEF |

| Analogy | The system's "heart" | The system's "control valve" |

| Failure Impact | No DEF flow to the injector | Incorrect or no DEF spray pattern |

| Typical Problem | Motor burnout, internal leaks | Clogging from DEF crystallization |

Pinpointing which part is giving you grief is the difference between a quick field fix and waiting days for a dealer tech with a laptop. If you’ve already run basic checks and are still stumped, Flat Earth Equipment offers the sensors, solenoids, and filters you need to bypass the dealer wait times.

Pump vs. Injector Failure: Reading the Telltale Signs From the Cab

Before you even grab a wrench, your JCB is screaming what’s wrong. The trick is learning to listen. The difference between a failed AdBlue pump and a clogged injector isn't just in the parts—it’s in how the machine dies on you. Getting this diagnosis right from the cab saves hours of guesswork and avoids a tow bill.

A total pump failure is usually a sudden, hard stop. One minute you're working, the next your power vanishes as the ECU detects zero DEF pressure and throws the machine into a severe derate. It’s an immediate, project-stopping event. You won't be limping this one back to the trailer.

An injector failure, on the other hand, is a slower, more agonizing death. It often starts with an intermittent fault light that flickers on under heavy load, then disappears. The machine might feel sluggish, slowly losing power over hours or even days as the injector gets progressively more clogged with crystallized AdBlue. This is the slow bleed that kills your productivity.

Reading the Dashboard Warnings

The lights on the dash are your first clue, but they don't tell the whole story. The dealer wants you to believe only their expensive diagnostic laptop can translate these warnings, but a little field instinct goes a long way.

- Solid Warning Light with Immediate Power Loss: This almost always points to the pump. The system expects a certain pressure (around 5 bar or 72 PSI) within seconds of startup. When it sees nothing, it triggers a critical, non-negotiable fault.

- Flashing Warning Light with Gradual Derate: This is classic injector behavior. The system is still seeing some pressure from the pump, but the NOx sensors downstream are reporting that the exhaust isn't getting clean enough. The ECU assumes the injector isn't delivering the right dose and slowly pulls back engine power.

- Fault Code Behavior: A pump failure will typically log a "DEF Pressure Low" or "Pump Circuit Open" code that stays locked in. An injector fault might start as an "SCR Efficiency Low" or "NOx Conversion Fault" code that only appears intermittently at first.

The Field Mechanic's Rule: A sudden, catastrophic power loss is the pump screaming for help. A weak, lazy machine that gets worse over time is the injector whispering that it’s choking to death.

Engine Performance and Audible Clues

Beyond the lights, pay attention to how the engine feels and sounds. A struggling AdBlue system changes the machine's behavior long before it throws a hard fault.

A complete pump failure is like cutting a fuel line—the engine just falls on its face. There’s no warning, just an immediate and total loss of performance as the machine protects itself. You might even hear a faint electrical hum from the pump that suddenly goes silent upon failure.

Conversely, a failing injector often leads to rough running or surging under load. Because the DEF isn't being sprayed correctly, the exhaust aftertreatment can't keep up, leading to inconsistencies that you can feel right in the operator's seat.

Getting this right is crucial. Our data shows that AdBlue pump failures, often from motor burnout or internal leaks, account for 35-45% of all AdBlue system faults in these machines. Injector malfunctions, usually from crystallization, follow closely behind, making up about 25-35% of the issues. You can explore more about AdBlue system failures to get a deeper understanding of the causes.

To help you make the call from the cab, we put together this quick reference table.

Symptom Breakdown: Pump vs. Injector Malfunction

Use this table to quickly compare operational symptoms and dashboard alerts to determine if you're dealing with a failing AdBlue pump or a faulty injector.

| Symptom or Indicator | Points to Pump Failure | Points to Injector Failure |

|---|---|---|

| Power Loss | Instant and severe | Gradual and progressive |

| Warning Light | Solid, constant light | Often starts as intermittent or flashing |

| Machine Behavior | Hard stop, no "limp along" | Sluggishness, poor response under load |

| Audible Cues | Pump hum may stop abruptly | No distinct sound, just poor performance |

This initial diagnosis will point you in the right direction, helping you decide whether to start testing pressure at the pump or pull the injector for a physical inspection.

Toolbox Diagnostics: How to Test Your Pump and Injector

Don't get stuck waiting for a dealer tech to show up with his Service Master laptop just to tell you what you already suspect. When your JCB telehandler throws an AdBlue fault, you need answers fast, and the reality is you can diagnose a bad pump or injector with a few common tools. It's all about knowing what to look for right there in the dirt.

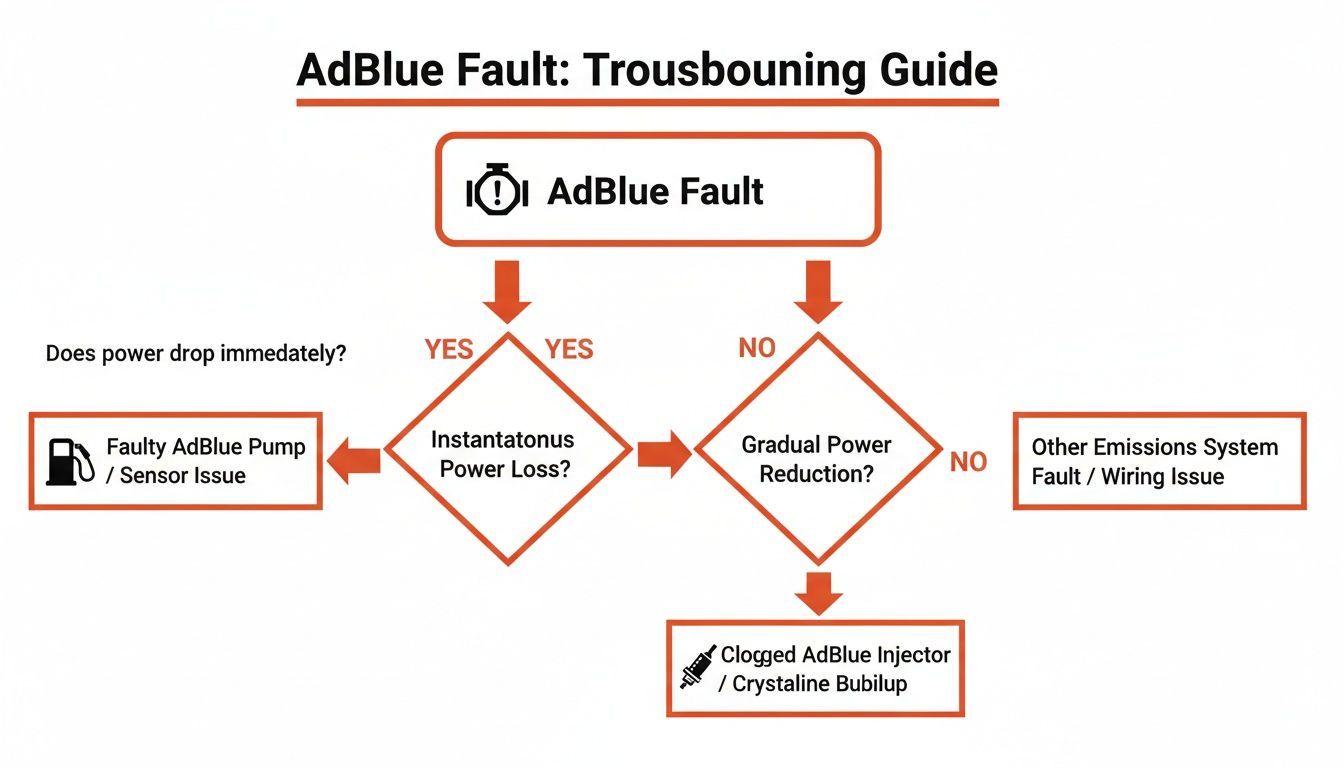

This simple decision tree can help you visualize the diagnostic path based on how the machine is behaving.

As the chart shows, a sudden, immediate power loss usually points straight to a pump failure. If the power loss has been slow and gradual, your first suspect should be the injector.

Electrical Checks with a Multimeter

Before you crack open any fluid lines, grab your multimeter. These quick electrical tests can often isolate the problem in less than five minutes, telling you whether a component is dead or if you have a bigger wiring headache.

Testing the Pump Motor: Find the electrical connector on the DEF pump. Disconnect it and probe the wiring harness side for voltage with the key on. You should read either 12V or 24V, depending on your telehandler's system. If you've got voltage there, the pump motor is likely the issue. No voltage? You're chasing a blown fuse or a break in the wire somewhere upstream.

Checking the Injector Solenoid: Unplug the injector's electrical connector and set your multimeter to ohms (Ω). Probe the two pins on the injector itself. The exact resistance value isn't as important as what you don't see. An open circuit (infinite resistance) or a dead short (zero resistance) means the internal solenoid coil is fried.

These two checks are your first line of defense. They confirm if the parts are electrically sound before you dig any deeper.

Field Mechanic’s Insight: I’ve seen more JCB AdBlue issues caused by a chafed wire or a corroded connector than most people would believe. Never, ever skip the basic electrical checks. They can save you the cost of a new pump or injector you didn't need.

Pressure and Flow: The Definitive Pump Test

If the electricals check out but you’re still getting a low-pressure code, it's time for the definitive test: checking pressure and flow. This will tell you in plain terms whether the pump is actually moving fluid. You don't need a fancy gauge set for this—just a bucket and an extra set of hands.

First, safety. AdBlue is corrosive, so put on gloves and eye protection. With the machine off, find the DEF line coming out of the pump module.

- Step 1: Place a drain pan or bucket underneath the pump assembly.

- Step 2: Slowly and carefully crack the fitting on the pump's outlet line. A small amount of fluid will likely drip out, which is normal.

- Step 3: Have a helper cycle the key to the "on" position but don't start the engine. The pump will prime for several seconds.

- Step 4: Watch the fluid flow from the cracked fitting. You’re looking for a strong, steady stream of AdBlue. If all you get is a weak dribble or nothing, the pump is shot.

A healthy pump pushes fluid with noticeable force. If it passes this test, your problem isn't the pump—it's likely a blockage downstream, which leads us right to the injector.

The Injector Visual Inspection

The final step is a visual check of the injector nozzle. The number one killer of these injectors is DEF crystallization. This white, chalky crust builds up over time and completely blocks the spray pattern, starving the SCR catalyst of the AdBlue it needs.

Removing the injector is usually simple. It's typically held in the exhaust decomposition tube with one or two small bolts. Once it's out, inspect the tip carefully.

What to Look For:

- White Crystal Buildup: Any significant amount of crusty white residue on the nozzle is a dead giveaway.

- Blocked Orifices: The nozzle has tiny holes designed to create a fine mist. If they're clogged with crystals, the injector can't do its job.

- Signs of Leakage: Look for fluid trails around the base where the injector seals against the exhaust pipe.

Don’t fall into the trap of just cleaning it. Scraping off the crystals is a temporary fix, at best. The internal damage that caused the clog is already done, and it will just plug up again soon. If you see heavy crystallization, the only reliable fix is a replacement.

Once you’ve confirmed the faulty part, ordering a precision-fit injector or pump from a trusted supplier like Flat Earth Equipment gets you the right component without the dealer wait times.

Sourcing the Right Parts to Get Back to Work Fast

You’ve done the dirty work, run the tests, and you know exactly what’s wrong with your JCB's AdBlue system. The next "logical" step for many is a call to the dealer’s parts counter. But we all know what that means: paying a steep markup and waiting—sometimes for days—while your machine sits idle. When you're trying to keep a project on schedule, that's not a solution; it's another problem.

So, let's talk about the real fix. You're looking at a crystallized injector or a pump with a fried motor. Can you salvage them? The short answer is hell no. Don't even waste your time trying.

Why a Quick Fix Is No Fix at All

Some guys will tell you to pull the injector and go at it with a pick or some solvent. Sure, you might chip away that white crust and get it to spray again for a few hours, but you’re just slapping a bandage on a much bigger problem. Crystallization is a symptom of internal contamination or wear; that injector will plug up again, probably before the end of the next shift.

The same logic applies to a weak pump. If the motor is struggling to build pressure, it’s already on its last legs. There’s no rebuilding these sealed units in the field. A temporary fix is a guaranteed repeat failure, which means you'll be doing the exact same job twice.

Technician’s Bottom Line: When an AdBlue pump or injector fails, it’s done. The only lasting repair is a complete replacement. Trying to "save" a failing component is the fastest way to get stranded again tomorrow.

Bypassing the Dealer Bottleneck

Here’s the truth the dealer won't tell you: you don’t need them. Relying on their parts network means you’re on their schedule, not yours. This is where you can take back control.

Sourcing a high-quality, direct-fit replacement AdBlue pump or injector from a dedicated parts supplier is the only way to turn a project-stopping failure into a manageable repair. You need a part that matches OEM specs without the OEM price tag and, more importantly, without the lead time. This is about getting the right component shipped directly to your site so you can swap it out and get back to making money. Forget about hauling the machine to the dealer's shop or paying for their field mechanic’s travel time.

Having a reliable source for these critical emissions parts is non-negotiable. It transforms what could be a multi-day disaster into a one-day fix.

Get the Right Part Shipped Today

This is where Flat Earth Equipment makes all the difference. You need someone who stocks the specific AdBlue pumps and injectors for your JCB telehandler and can get them out the door fast. No backorders, no "we'll call you when it's in"—just the part you need, right when you need it.

This approach puts you back in the driver's seat. You diagnose the issue, you order the replacement, and you install it on your terms. Instead of losing two or three days of productivity, you're back up and running in a matter of hours. This is how you beat the system and keep your profits from evaporating while you wait on a part.

With access to a huge inventory of precision-fit parts, you can easily find the components you need to fix your JCB AdBlue system faults. Check out the extensive catalog of industrial parts at Flat Earth Equipment and see how quickly you can get your yellow iron back in the fight.

Analyzing the True Cost of AdBlue System Downtime

A dead machine is a black hole for your profits. It's not just about the cost of a replacement AdBlue pump or injector; it’s the ripple effect of lost man-hours, blown deadlines, and an entire crew standing around burning daylight. When your JCB telehandler goes down, the clock starts ticking on your bottom line. Every minute counts.

The real financial hit from a JCB telehandler AdBlue fault comes down to downtime, and that’s where the difference between a pump and an injector failure gets real clear, real fast. You have to weigh the initial parts cost against the hours of lost productivity.

Pump Failure: The Hard Stop

A complete AdBlue pump failure is a hard stop. The machine detects zero DEF pressure and immediately slams into a severe derate or a total shutdown. There is no limping back to the yard; your telehandler is out of action right where it sits, often in the worst possible spot.

This kind of failure brings the entire operation to a grinding halt. You're not just losing the operator's time; you’re losing the productivity of every single worker who relied on that machine to lift, move, or load. A pump failure is a project killer, plain and simple.

Injector Failure: The Slow Bleed

A clogged or failing injector is sneakier but just as destructive. The machine might start with an intermittent fault, slowly losing power over hours or even days. You might try to work through it, but you're operating at a fraction of your normal efficiency, burning more fuel and putting more strain on the operator.

This slow bleed of productivity is a silent killer. It doesn't feel as dramatic as a hard stop, but the accumulated lost hours can be just as damaging—if not more so—by the time you finally decide to pull the machine from service.

The Gritty Reality of Downtime: The dealer will tell you to wait for their tech and their laptop. Meanwhile, you have a framing crew that can't get materials to the second floor, a concrete crew waiting for rebar, or a loading operation that's completely stalled. That's not a service call; it's a financial liability.

Breaking Down the Financial Damage

Let's put some real numbers to this. A replacement part is one thing, but the cost of waiting is another beast entirely. Industry data gives us a clear picture of what downtime looks like for these specific AdBlue system faults. On average, downtime due to pump failures ranges between 8 to 16 hours per incident. In contrast, injector issues typically cause 4 to 12 hours of lost time.

When you factor in the average replacement costs—around $800 to $1,200 for a pump and $600 to $1,000 for an injector—the true expense becomes clear. You can discover more about JCB telehandler specifications and operational data to see how these systems integrate.

To truly understand the impact, let's consider a modest crew of four at a loaded rate of $60/hour per person.

- Pump Failure (12 hours downtime): 12 hours x 4 crew members x $60/hr = $2,880 in lost labor alone.

- Injector Failure (8 hours downtime): 8 hours x 4 crew members x $60/hr = $1,920 in lost labor.

This math doesn't even touch project penalties, equipment rental costs for a temporary replacement, or the damage to your reputation for missing a deadline. Sourcing your own parts from a supplier like Flat Earth Equipment for a rapid, in-field repair delivers a massive ROI. The cost of an overnighted part is nothing compared to the thousands of dollars you bleed every hour your yellow iron is down.

Field-Tested Tips for Preventing AdBlue System Failures

The best repair is the one you never have to make. Out in the field, prevention isn’t just some buzzword—it's the difference between hitting your deadline and having a multi-thousand-dollar paperweight sitting in the mud. These finicky JCB AdBlue systems will look for any excuse to shut you down, but a few simple habits can keep them running straight.

It all starts and ends with the DEF fluid itself. Using anything other than pure, fresh DEF from a sealed container is just asking for a breakdown. That half-used jug that’s been sitting open in the back of your truck for a month? It’s contaminated. That’s how crystallization begins, and that white crust is exactly what kills pumps and injectors.

Your Daily Pre-Start Inspection

Before you even turn the key, take thirty seconds for a walk-around. You don't need a laptop for this, just your eyes. This simple routine can catch a small issue before it triggers a costly derate.

- Check the Lines and Fittings: Look for any dampness or that tell-tale white, chalky residue around the DEF lines, the pump housing, and the injector. A tiny leak today becomes a catastrophic failure tomorrow.

- Inspect the Injector Nozzle: Take a quick look at where the injector enters the exhaust. If you see white crystals building up on the outside, you can bet the inside is even worse.

- Glance at the Tank Cap: Make sure the AdBlue tank cap is clean and sealed tight. Dirt and dust are the sworn enemies of this system; letting them into the tank is like pouring sand into your engine.

This isn’t about being picky; it’s about recognizing that these systems have zero tolerance for the everyday grit and grime of a real job site.

Field Mechanic’s Wisdom: Every single time I’ve been called out for a major AdBlue system failure, it started as something small that got ignored. A leaky fitting, a dirty fill-up—these are the things that snowball into project-stopping downtime.

The Cheapest Insurance Policy You Can Buy

Beyond the daily checks, there’s one piece of preventative maintenance that is absolutely non-negotiable: changing the AdBlue filter. This little filter is the only thing standing between your expensive pump and injector and any crud that gets into the tank.

For the price of a couple of bucks and ten minutes of your time, you’re buying an insurance policy against a catastrophic failure. Skipping it is just lazy. Running a clean system and staying vigilant with your inspections are the fundamentals of keeping your yellow iron earning.

To build a comprehensive maintenance culture, you can review essential heavy equipment safety procedures that reinforce these habits. It's these simple routines that separate the pros from the guys always waiting on a service truck.

Common Questions About the JCB AdBlue System

Out on the job, questions come up fast, and you need answers even faster. There’s no time to flip through a manual or wait on hold with a dealer. Here are the straight answers to the most common problems we see with these JCB AdBlue systems in the field.

Can I Just Keep Topping Off the AdBlue Tank?

Whatever you do, don't let that tank run dry. That's a surefire way to burn out your pump. The pump actually relies on the DEF fluid itself for cooling and lubrication. When it runs dry, it overheats and fails—it’s really that simple. A good rule of thumb is to always top it off before it dips below a quarter tank.

What Happens if I Put Diesel in the AdBlue Tank?

This is a catastrophic, system-killing mistake. Diesel fuel will absolutely destroy the entire SCR system: the pump, the lines, the injector, and the catalyst. If this happens, do not turn the key. The whole system has to be drained and professionally flushed, and even then, you're almost certainly looking at replacing major components.

A single splash of diesel in the DEF tank is a multi-thousand-dollar mistake that will take your machine out of service for days, if not weeks. There is no easy fix for this.

Can I Drive with the AdBlue Warning Light On?

You can, but the clock is ticking. As soon as that light comes on, the machine's ECU starts a countdown. First, you'll notice it derates the engine power. Ignore it long enough, and it will eventually force a complete shutdown or simply refuse to start again. Ignoring that light isn't an option; it's a direct threat to your uptime. Your only move is to find the underlying JCB AdBlue system fault and fix it. Think of the light as the final warning before the machine takes control away from you.

When you've pinpointed the problem and need the right part without the dealer games, Flat Earth Equipment has the precision-fit AdBlue pumps, injectors, and filters to get you back to work. Get your yellow iron earning again with parts shipped fast right to your job site.