When your JCB flashes a P0087 code, it's not a suggestion—it's a shutdown notice. Your machine is starving for fuel, and the Engine Control Unit (ECU) has thrown it into limp mode to save its own hide. While a few things can cause this mess, my money is almost always on a failed Suction Control Valve (SCV) first.

Decoding The P0087 Code And Why It Derates Your Machine

That light on the dash and the sudden power loss mean one thing: your fuel rail pressure dropped below the magic number the ECU needs to run right. This isn't a polite request; it's a hard stop. The ECU slams the brakes on engine power to keep you from grenading the high-pressure pump and your injectors.

You’re left with a machine that stumbles, fights to start, or won’t turn over at all. The job site grinds to a halt, and every minute you're down is cash flying out of your wallet. The dealer will tell you to haul it in, hook it up to their precious laptop, and wait. I say forget that. We can nail this down right where it sits.

The Achilles' Heel Of The JCB Fuel System

The P0087 fault code has been a thorn in our side since common rail fuel systems became the norm. In the US, it's a huge headache for diesel truck guys, but it's just as real in our yellow iron. The code, which means Fuel Rail/System Pressure Too Low, plagues everything from Ford Powerstrokes to JCB telehandlers. A lot of the time, the data shows a huge gap between the fuel pressure the ECU is screaming for and what it's actually getting. You can read more about the widespread impact of this code on Suncentauto.com.

While clogged fuel filters or a weak lift pump can throw the code, my money is on the Suction Control Valve first. Think of the SCV as the gatekeeper for your high-pressure fuel pump. It’s a little solenoid that meters out exactly how much low-pressure fuel gets into the high-pressure side.

The SCV does all the real work, constantly twitching to meet the engine's demands. Because it’s a moving part and hates bad fuel, it’s usually the first thing to crap out.

This constant work, plus the questionable quality of job site fuel, makes the SCV a prime suspect. Crap like dirt, water, or the waxy gunk from cold-weather diesel can make the valve’s tiny plunger stick or wear out. An electrical failure in the solenoid coil is another common one I see, leading to it acting crazy or just giving up the ghost completely.

Before you even think about calling a lowboy or scheduling a dealer visit that's two weeks out, you need to understand the SCV. It’s the key to a fast, accurate field diagnosis that gets your machine—and your paycheck—moving again.

Matching P0087 Symptoms To Likely Causes

Sometimes the machine gives you clues before the code even pops. Use this table to match what you're seeing in the field to the most likely culprit. It'll help you narrow your focus before you even bust out the tools.

| Symptom On Your JCB | Top Suspect | Secondary Suspect |

|---|---|---|

| Engine cranks but won't start | Suction Control Valve (SCV) | Failed Lift Pump |

| Hard starting, especially when cold | Sticking SCV Plunger | Clogged Fuel Filters |

| Engine stumbles or hesitates under load | SCV Electrical Failure | Fuel Rail Pressure Sensor |

| Sudden loss of power with P0087 code | Failed SCV | High-Pressure Pump Failure |

| Runs rough at idle but smooths out at high RPM | Contaminated Fuel / Dirty SCV | Minor Fuel Line Air Leak |

| Black smoke from exhaust with low power | Leaking Injector(s) | SCV (unable to control pressure) |

This table isn't gospel, but after years of fighting this yellow iron, I can tell you these matchups are right more often than not. Start with the top suspect and save yourself a headache.

Assembling Your Field Diagnostic Toolkit

Forget waiting on a service truck or paying dealer labor rates just to tell you what's wrong. You can beat this P0087 code in the field if you have the right gear in your truck. We're not talking about the dealer's magic "Service Master" laptop; we're talking about real-world tools that get you answers on the ground.

First, the basics. A solid set of metric sockets and wrenches is non-negotiable. For the SCV on a 3CX or a Loadall, you’ll probably need a good set of Allen keys (hex sockets) or maybe some small Torx bits to get the valve off the high-pressure pump. And grab some pliers for those damn harness clips JCB loves so much.

Gear That Gives You The Upper Hand

Hand tools are just the start. If you want to nail this diagnosis and not just throw parts at it, you need a few key pieces of diagnostic gear. These are the tools that let you see what the ECU sees—and more importantly, call its bluff if it's wrong.

- Digital Multimeter: This is your best friend, so don't get a cheap one. We'll use this to check the resistance of the SCV's coil, which is a dead giveaway for an electrical failure. A good meter also lets you chase down opens or shorts in the harness as it gets cooked by engine heat and vibration.

- Diesel Fuel Pressure Test Kit: The dash says pressure is low, but is it? Hooking a mechanical gauge to the low-pressure side (before the high-pressure pump) tells you if the lift pump is doing its job. You need to see at least 5-7 PSI from a healthy lift pump. Anything less, and you found a problem before you even touched the SCV.

- OBD-II Scanner: You need a scanner that can read live data. Seeing the ECU command 20,000 PSI while the sensor only reads 4,000 PSI is the smoking gun that points right to a fuel delivery failure.

I keep my multimeter charged and ready to go. A dead battery on your most important tool is a rookie mistake that costs you hours. A good power source is key, and you can learn more about keeping your gear juiced up with the right heavy-duty battery chargers.

The Must-Haves For The Job

Beyond the main tools, a few cheap things make this job cleaner and way easier.

A can of brake cleaner is perfect for blasting the crap away from the high-pressure pump before you open the system. You’ll also want a bunch of clean, lint-free rags. Contaminating a common rail system is an expensive mistake you don't want to make.

And my personal favorite: a telescoping magnetic pickup tool. Trust me, you will drop one of those tiny SCV mounting bolts into the abyss of the engine bay. This thing turns a 30-minute search-and-rescue mission into a 10-second fix. It's all about being prepared to win the fight on-site.

Pinpointing SCV Failure On The Job Site

Alright, time to get dirty. Forget what the dealer says about needing their laptop. We can get undeniable proof of a bad Suction Control Valve right here in the field with a few smart checks. This is my exact process from years of fighting the P0087 code on everything from 3CX backhoes to Loadall telehandlers.

First, I always do a visual inspection. It costs nothing and can save you a ton of grief. Get your eyes on the SCV and its wiring. Look for the obvious stuff: wires rubbed raw from vibrating against the block, connectors packed with mud, or pins pushed back into the plug. These machines live a rough life, and the wiring is often the first victim.

Getting Real Answers With A Multimeter

If the wiring looks good, grab the multimeter. This is where you stop guessing and start knowing. Unplug the harness from the SCV—key OFF—and set your meter to Ohms.

Probe the two pins on the SCV itself. On a healthy JCB SCV, you want to see a reading between 2 and 3 ohms. If you see a high number, like 5 ohms or more, or if it reads "OL" (open loop), that solenoid's coil is fried. It's junk. No fixing it; it's a clear-cut replacement.

This resistance check is one of the fastest ways to condemn a bad SCV. The meter doesn't lie.

Don't just stop at the valve. Check the harness side, too. A busted wire between the ECU and the SCV will give you the same P0087 headache, but a new valve won't fix it. A little extra time with the meter here confirms the whole circuit is solid.

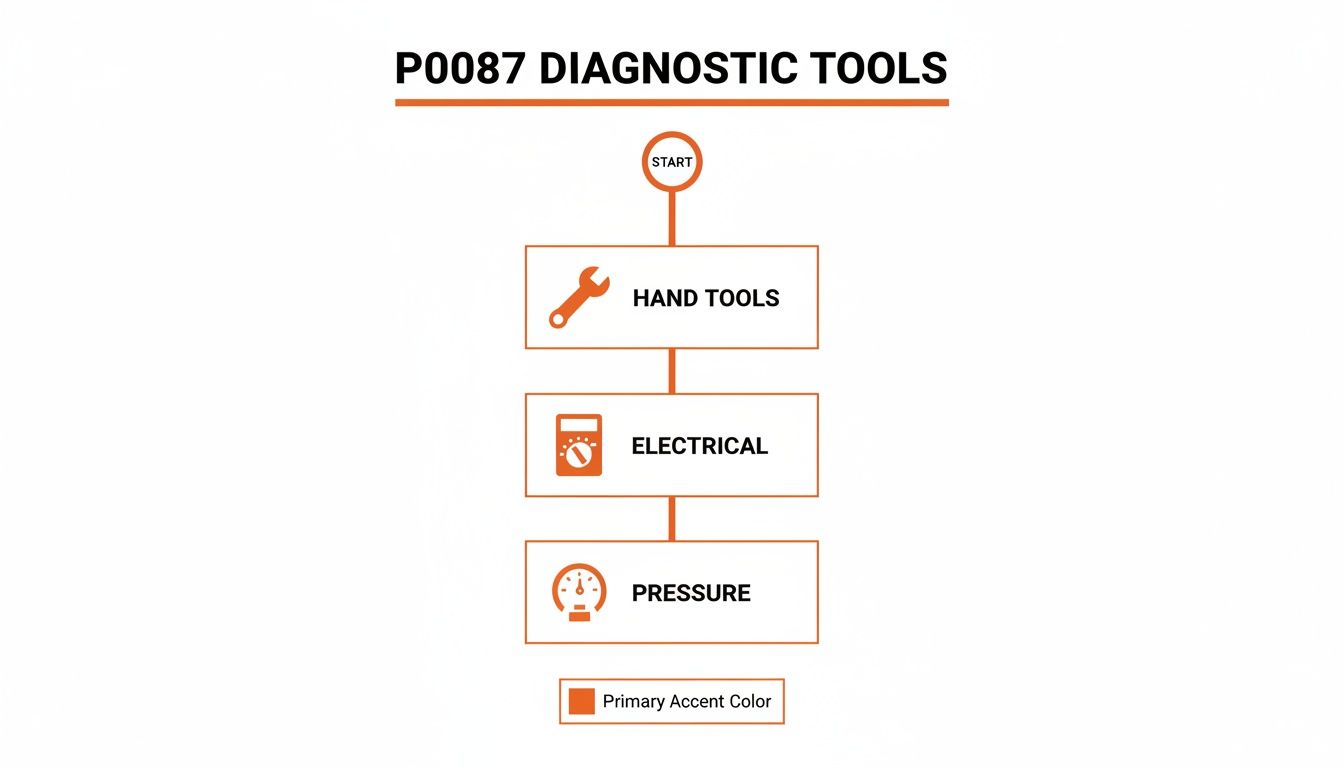

This diagnostic flowchart lays out the simple but effective tool progression for tackling a P0087 code in the field.

As you can see, a logical, tool-based approach—starting with basic inspection and moving to electrical and pressure tests—is the most efficient way to isolate the fault.

The Old School Tap Test

Sometimes the failure isn't electrical, it's mechanical. The little plunger inside the SCV gets sticky from bad fuel or tiny bits of junk. If your resistance check was good, try this old trick: the 'tap test'.

With the engine running (if it will), take the plastic handle of a screwdriver or a small dead-blow hammer and give the body of the SCV a few firm taps. Don't go nuts and break it, just enough to maybe jar that sticky plunger loose.

If the engine suddenly smooths out or the stumble goes away, even for a second, you've found your problem. A sticking valve is an unreliable valve, and it needs to be replaced.

Using Live Data As Your Smoking Gun

The final piece of evidence comes from your OBD-II scanner. Plug it in, start the machine (or at least key-on), and go to the live data stream. You're looking for two things:

- Commanded Fuel Rail Pressure: This is what the ECU wants.

- Actual Fuel Rail Pressure: This is what the sensor is seeing.

On a healthy machine at idle, these two numbers should be almost identical. When you see a huge gap—like the ECU is commanding 20,000 PSI but the actual pressure is struggling to hit 4,000 PSI—that's your smoking gun. The ECU is calling for pressure, but the system can't deliver.

When you see that data after getting a good resistance reading on the SCV, it points right to a valve that is mechanically broken. It’s failing its one and only job.

Field data backs this up. Diagnosis of the SCV in JCBs and similar diesel systems for P0087 often reveals it as the culprit in about 22% of low fuel rail pressure failures. Some reports show that P0087 issues can cause up to 35% downtime in JCB models like the 3CX, often traced back to an SCV coil with resistance way outside the healthy 2-3 ohm range. You can watch a detailed breakdown of these common failure points on YouTube.

By following these steps—visual, electrical, mechanical, and data-driven—you gather all the proof you need. You're not just swapping parts and praying. You’re making a confident diagnosis and getting your yellow iron ready to earn its keep again. This is how you beat the P0087 code on your own terms.

Replacing The SCV And Fuel Filters The Right Way

Alright, you did the legwork and proved the SCV is the bad guy. Time to stop diagnosing and start turning wrenches. This is your no-bull guide to swapping that valve and getting back to work, but we're going to do it right.

The number one rule when you crack open a common rail fuel system is CLEANLINESS. I can't say this enough. One grain of sand in that high-pressure pump can cost you thousands, turning a simple job into a nightmare. This isn’t the time to rush.

Before you put a wrench on anything, grab your brake cleaner or compressed air. Clean the hell out of the whole area around the SCV and the high-pressure pump. Get rid of every bit of dust, grease, and mud.

The SCV Swap Procedure

With the area spotless, you can get to the replacement. The job itself is easy, but your attention to detail is what separates a pro from a parts-changer.

- Bleed Off Fuel Pressure: Even with the machine off, there’s serious pressure in the system. Carefully and slowly crack a fuel line fitting loose—with a rag over it—to bleed it off. Never skip this. High-pressure diesel spray is no joke.

- Disconnect The Harness: Unclip the electrical connector from the old SCV. Look at it one last time for any corrosion you might have missed.

- Pull The Old Valve: Use the right Allen or Torx socket to remove the mounting bolts. They can be tight, so use a good tool to avoid stripping them. Gently twist and pull the old valve straight out of the pump.

Pro Tip: Have your new SCV ready, still in its clean plastic bag. The second the old valve comes out, wipe the pump's mounting surface with a clean, lint-free rag. Immediately install the new SCV and its O-rings. The less time that pump is open to the air, the less chance you have of contaminating it.

When you install the new valve, lube the O-rings with a little clean diesel fuel and make sure they're seated right. Torque the mounting bolts to spec—don't just guess. Overtightening can wreck the new valve or the pump housing.

Don't Mess Up The Most Important Part

Here’s where guys screw up. They replace the SCV but leave the old, dirty fuel filters. That's just asking for the same problem to happen again. Bad fuel and clogged filters are what kill SCV valves in the first place.

While the fuel system is open, you MUST replace both the primary and secondary fuel filters. Skipping this just gives your brand-new SCV a short, miserable life. It's cheap insurance against a comeback.

In fact, data from 2010-2025 shows P0087-related SCV valve failures have surged by 45% in commercial diesels, largely due to poor fuel quality. Simply changing filters annually reduces these incidents by a massive 60%.

SCV Replacement Field Checklist

Follow this checklist for a clean, successful SCV valve and filter swap every time.

| Action Step | Technician's Tip | Required Tool Or Part |

|---|---|---|

| Area Prep | Clean the HP pump & SCV area with brake cleaner or air. | Brake Cleaner, Compressed Air |

| Pressure Release | Loosen a fuel line fitting slowly with a rag over it. | Line Wrench, Rag |

| Disconnect | Unplug the electrical connector and inspect the pins. | Small Flathead Screwdriver |

| Removal | Remove mounting bolts and gently pull the old SCV out. | Allen or Torx Socket Set |

| Immediate Install | Wipe the surface and install the new SCV immediately. | New SCV, Clean Lint-Free Rag |

| Torque | Lubricate O-rings and torque new bolts to spec. | Torque Wrench |

| Filter Swap | Replace BOTH primary and secondary fuel filters. | Filter Wrench, New Filters |

| Prime System | Use the hand primer pump until it becomes firm. | Hand strength |

| Final Check | Start the engine, let it idle, and check for any leaks. | Your eyes and a flashlight |

Sticking to these steps prevents contamination and ensures the repair holds up.

Priming The System To Avoid A False Code

Once it's all back together, you have to prime the fuel system right. If you don't, trapped air in the lines can act just like a P0087 code, sending you down the same rabbit hole.

Most JCBs have a manual priming pump near the fuel filter housing. Pump it until you feel solid resistance. That tells you the filter is full and you've pushed most of the air toward the high-pressure pump.

Now, crank the engine. It might take longer than usual to start as that last bit of air gets pushed through the rail and injectors. Once it fires, let it idle and check for any leaks around your new SCV and filters.

Before you send it back to work, run through your standard startup procedures as detailed in our heavy equipment safety guidelines. A good prime and a quick safety check mean the job is truly done.

Troubleshooting When The SCV Isn't The Problem

So, you did everything right. You put in a new SCV, fresh filters, and bled the system perfectly. You fire it up, and for a minute, it runs great. Then you hear it—that damn beep. P0087 is back, and the engine falls on its face.

Don't throw your wrench yet. While the SCV is the problem probably 70% of the time, that leaves a solid 30% chance something else is wrong. This is where we separate the parts-changers from the real techs. Time to dig deeper.

When a new SCV doesn't fix it, the next logical place to look is before the high-pressure pump. The SCV can only control the fuel it's given. If it's being starved, the symptoms are identical.

Is Your Lift Pump Pulling Its Weight?

First suspect is the lift pump, or transfer pump. Its only job is to suck fuel from the tank and feed the high-pressure pump with a steady, low-pressure supply. If that pump is weak, the high-pressure side never stands a chance.

You need to put a gauge on it. Find the test port on the low-pressure circuit, usually around the fuel filter housing. A healthy lift pump on a JCB should give you a steady 5 to 10 PSI at crank or idle.

If you’re seeing 1 or 2 PSI, or the needle is bouncing around, that pump is probably shot. It’s not just about pressure, either—it’s about volume. A pump can make decent pressure at idle but can't deliver the flow needed under load.

I've seen pumps test fine sitting still but fall flat the second you try to track or lift. It's a classic sign of a worn-out lift pump that can’t keep up with demand.

Chasing Down Restrictions and Bad Sensors

If the lift pump pressure is good, your problem is likely a restriction between the tank and the pump, or you have a sensor feeding the ECU bad info.

- Clogged Fuel Tank Pickup: That pickup tube in the tank has a screen on the end. Over the years, that screen can get plugged with algae, rust, or whatever sludge is in the bottom of your tank. It’s a messy job, but you may need to pull the whole pickup assembly to inspect and clean it.

- Collapsed Fuel Line: Squeeze all the flexible fuel lines between the tank and the engine. They can look fine but collapse internally, creating a restriction that chokes off fuel flow. They should feel firm, not soft and mushy.

- Failing Fuel Rail Pressure Sensor: This is the sensor that's ratting out your system and throwing the P0087 code. If the sensor itself is bad, it can send a false low-pressure signal to the ECU, triggering a derate even when the pressure is fine. Swapping it is often easier than testing, but make sure you’ve ruled everything else out first.

The Worst-Case Scenario: The High-Pressure Fuel Pump

If you’ve checked everything else and you're still stuck, you have to face the elephant in the room: the high-pressure fuel pump (HPFP) itself could be failing. This is the heart of the common rail system, and it’s an expensive, bitch of a repair.

Before you condemn it, there’s one last sign. Pull your new fuel filter back out and cut it open. Dump the contents into a clean pan. If you see fine, glitter-like metal shavings, it’s game over.

Those metal particles are the guts of your high-pressure pump grinding itself into your entire fuel system. At this point, it's not just a pump. You're replacing the pump, all the injectors, the fuel rail, and flushing every single line. It's a surgically clean job that can’t be rushed—and it’s the one repair that will make you wish it had just been the SCV valve. When you're facing a job this big, get your parts from a trusted source like Flat Earth Equipment to avoid the dealer's brutal markup.

JCB P0087 And SCV Valve Common Questions

Out here, covered in grease with a deadline breathing down your neck, you don't have time for a textbook. You need straight answers to the questions rattling around your brain while you stare down this stubborn P0087 code. Here are the quick-and-dirty answers I give guys on the job every day.

This isn't dealer-speak. This is what you need to know to get the iron moving again.

Can I Just Clean My Old SCV Valve Instead Of Replacing It?

I get this one a lot. In a pinch, can you try to clean it? Sure. If you're a hundred miles from nowhere and just need to limp the machine back to the yard, a blast of brake cleaner might dislodge a piece of grit and get you moving. But I never, ever recommend it as a permanent fix.

The failure is rarely just about dirt. More often, the electrical coil inside is starting to break down, or the internal seals are worn out from millions of cycles. Cleaning can't fix a weak coil or a worn seal.

For the cost of a new SCV from a place like Flat Earth Equipment versus the risk of being stranded on-site again next week, replacement is the only smart move. Don't be cheap now just to pay for it with more downtime later.

How Do I Prevent The P0087 Code From Coming Back?

Prevention is all about two things: fuel quality and religious maintenance. These common rail systems are princesses, and they hate dirty diesel.

- Fuel Source: Always buy your diesel from a high-volume station. Fuel that sits in a tank collects water and junk.

- Filter Schedule: Stick to a strict fuel filter replacement schedule. Don't stretch it. If you're working in a dusty hellscape, change them more often than the manual says.

- Fuel Additives: Use a quality diesel fuel additive, especially in the winter. It keeps the system clean, lubes the pump and injectors, and prevents gelling.

An ounce of prevention is worth a pound of cure, a tow bill, and a screaming foreman.

Can A Bad SCV Valve Force My JCB Into A Regen Cycle?

This is a great question because it connects the fuel system to that other nightmare: the emissions system. A bad SCV doesn't directly trigger a regen, but it sure as hell makes it worse. It's an accomplice to the crime.

When your SCV is failing, it can't maintain proper rail pressure. This leads to poor fuel atomization and incomplete combustion. What does that create? A whole lot of extra soot.

That soot goes right into your exhaust and plugs up the Diesel Particulate Filter (DPF) way too fast. The ECU sees the DPF filling up and screams for more frequent, and often more problematic, regen cycles. That's the last thing you need when you're trying to get a job done.

Fixing the root fuel pressure issue by replacing the SCV is a critical step in getting that whole cursed emissions system to finally behave. If you run into other complex electrical issues or have specific questions about your machine's setup, it's always good to reach out to a knowledgeable parts team who deals with this stuff day in and day out.

When you’re done fighting and ready for a part that fits right and ships fast, Flat Earth Equipment has the SCV valves, sensors, and filters you need to put the P0087 code in your rearview mirror for good. Get the right part, get back to work, and leave the dealer out of it. Visit us at https://flatearthequipment.com to get what you need.