You’ve got a JCB throwing a P0087 code. That means your fuel system is being starved, leading to a gut-wrenching loss of power or a machine that just won't start. More often than not, this points directly to a failing Suction Control Valve (SCV), the little gatekeeper that regulates fuel flow to the high-pressure pump.

Getting a handle on this problem fast is the difference between a quick field fix and hauling the whole damn machine back to the shop.

What a P0087 Code Really Means for Your JCB

Let's skip the textbook definition. You're on site, your JCB suddenly loses all its muscle, the screen flashes, and the engine derates. You’re dead in the water. That P0087 code is the machine screaming that its high-pressure fuel system is choking.

The common rail system on your JCB engine is a finely tuned instrument. It needs a very specific amount of fuel pressure to work right. When the Engine Control Module (ECM) sees the actual pressure in the fuel rail fall way below the commanded pressure, it throws the P0087 fault and slams the machine into limp mode to protect itself.

This isn’t some random electronic gremlin. It’s a real-world mechanical problem that grinds your operation to a halt, costing you time and money.

Operator Complaint vs. Engine Reality

You know your iron better than anyone. What you feel in the operator's seat or see from the ground tells a story about what’s happening in the engine bay. This table bridges that gap, helping you connect the dots faster.

| Symptom You See On Site | What's Actually Happening In The Engine |

|---|---|

| Engine struggles to start, or won't start at all | The high-pressure pump isn't getting enough fuel to build the minimum pressure required for injection. |

| Machine is gutless and has no power under load | Fuel pressure drops dramatically when you demand more power, starving the injectors and preventing a complete burn. |

| Black smoke billowing from the exhaust | Incomplete combustion from low fuel pressure and poor atomization. The engine is getting air but not enough properly pressurized fuel. |

| Rough, sputtering idle or engine stalling | The Suction Control Valve (SCV) may be sticking, causing erratic and unstable fuel delivery to the rail. |

Knowing these connections helps you move from "it's acting weird" to "I bet it's the SCV" without waiting for a tech to plug in the dreaded Dealer Laptop.

The Usual Suspect: The SCV Valve

Nine times out of ten, the villain in this fuel pressure drama is the Suction Control Valve (SCV). You might also hear it called a spill valve or fuel metering unit. Think of it as the bouncer standing between your low-pressure lift pump and your very expensive high-pressure pump. Its one and only job is to precisely control how much fuel gets into the high-pressure side.

When it gets clogged with debris, worn out from millions of cycles, or the internal solenoid starts giving up, it can't do its job. It might stick open and flood the pump, or—more likely with a P0087—it sticks closed and starves it.

Either way, the result is the same: the fuel rail pressure plummets, the ECM panics, and your workday is officially on hold.

The P0087 code has become a notorious headache for fleet managers across major markets, especially where JCB holds a significant portion of the backhoe loader market share. This code triggers when the engine control module detects fuel pressure dropping below spec, a problem that has spiked downtime in rental fleets since the adoption of common rail injection systems. Discover more insights about P0087 causes on kbb.com.

Diagnosing the SCV Valve in the Field

Alright, let's get our hands dirty. Before you even think about cracking a fuel line or ordering a single part, we need to do some real diagnosis right where the machine sits. The dealer wants you to believe you need their magic laptop to figure this out, but that’s not the whole story. A good multimeter and a basic scan tool are all a real tech needs to condemn a faulty Suction Control Valve.

First things first, put your tools down and just use your eyes. JCB wiring harnesses are notorious for rubbing through on brackets and frame rails. Pop the hood and trace the two-wire harness going to the SCV on the high-pressure fuel pump. Look for the obvious stuff—chafing, melted insulation, or pinch points. Unplug the connector and check for that green crust of corrosion or any backed-out pins. These simple visual checks can save you hours of headaches down the road.

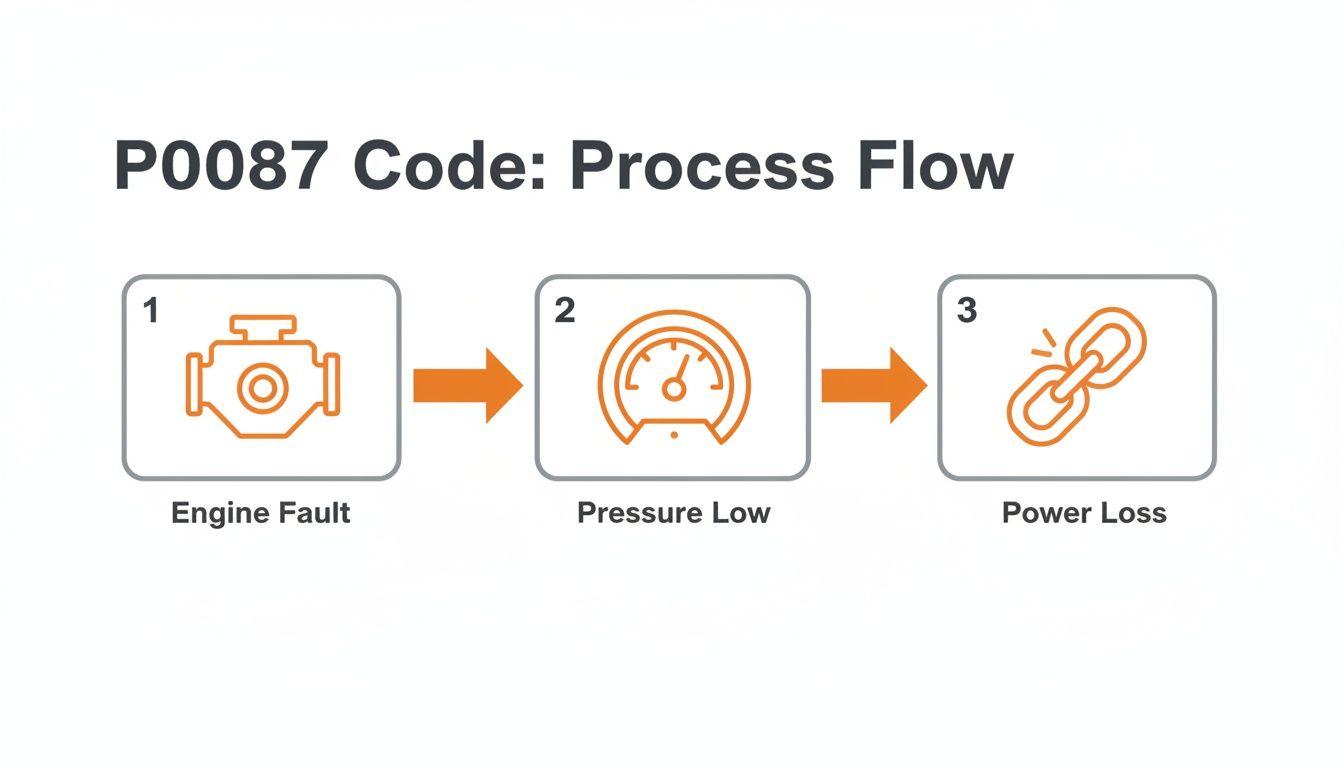

The whole P0087 situation can be broken down into a pretty simple chain of events, starting with the fault and ending with the power loss you feel in the operator's seat.

This flowchart really spells it out: the low-pressure condition directly causes that frustrating power loss that stops your job site cold.

Reading the Live Data

If the wiring looks good, it's time to plug in your scanner. You don't need the dealer's expensive Service Master; any generic OBD-II tool that can read live data will do the job. We're only interested in two key Parameter IDs (PIDs):

- Commanded Fuel Rail Pressure: This is what the ECM wants to see. It’s the target pressure based on what the engine is doing.

- Actual Fuel Rail Pressure: This is the real-time reading from the sensor on the fuel rail. It’s what the system is actually delivering.

At idle on a warm engine, you should see these two numbers tracking each other pretty closely, usually somewhere in the 4,000 to 6,000 PSI range. Now, have someone safely put the machine under a bit of a load—raise the boom or curl the bucket. Both commanded and actual pressure should jump up fast, sometimes as high as 18,000-20,000 PSI or more.

If you see the commanded pressure spike but the actual pressure just lags way behind or even drops, you've found your fuel delivery problem. That’s a classic symptom of a failing SCV that just can't respond fast enough to what the ECM is asking for.

A sticky or leaking Suction Control Valve is the prime suspect for a reason. In diesel common rail systems like those found in JCB engines, SCV failures are linked to a staggering 52% of all low rail pressure incidents. This valve is the gatekeeper, and when contaminants clog its solenoid, it simply can’t meter fuel correctly, causing that massive pressure drop under load that triggers the P0087 code. You can learn more about how widespread this issue is by reviewing research on the P0087 code.

The Multimeter Never Lies

The final field test is a simple resistance check. It's a quick, definitive way to prove the SCV's internal solenoid is either electrically sound or completely shot. Remember to always prioritize safety when working near fuel systems; our guide to job site safety protocols is a good refresher if you need it.

With the key off and the SCV connector unplugged, set your multimeter to Ohms (Ω). Touch your probes to the two pins on the SCV itself. You're looking for a resistance reading typically between 2.0 and 4.0 Ohms. The exact spec can vary slightly by model, but it should be right in that ballpark.

- Reading is in spec: The solenoid coil is likely fine electrically. Your problem might be mechanical (the valve is sticking) or somewhere else in the fuel system.

- Reads "OL" (Over Limit) or infinite resistance: The coil is open. The valve is junk. Time to order a new one.

- Reads close to zero Ohms: The coil is shorted out. The valve is junk. Order a replacement.

This whole test takes less than five minutes and doesn't require any special software. It’s what separates the real technicians from the parts-changers—using basic electrical principles to find the root cause. If the SCV fails this simple test, you can be damn sure you've found your culprit without ever having to call the dealer.

Replacing a Faulty SCV Valve on Your Own Terms

You’ve done the work, you’ve run the tests, and the verdict is in—the Suction Control Valve is toast. Now it’s time to stop diagnosing and start turning wrenches. Waiting for the dealer to send a field tech is a losing game that costs you hours, if not days. This is a job you can handle right where the machine sits, getting your iron back to earning its keep in a fraction of the time.

This isn't a complex, engine-out repair. It’s a straightforward parts swap that turns a major headache into a minor inconvenience, provided you do it right. Having a quality replacement from Flat Earth Equipment on your service truck means you’re already ahead of the game.

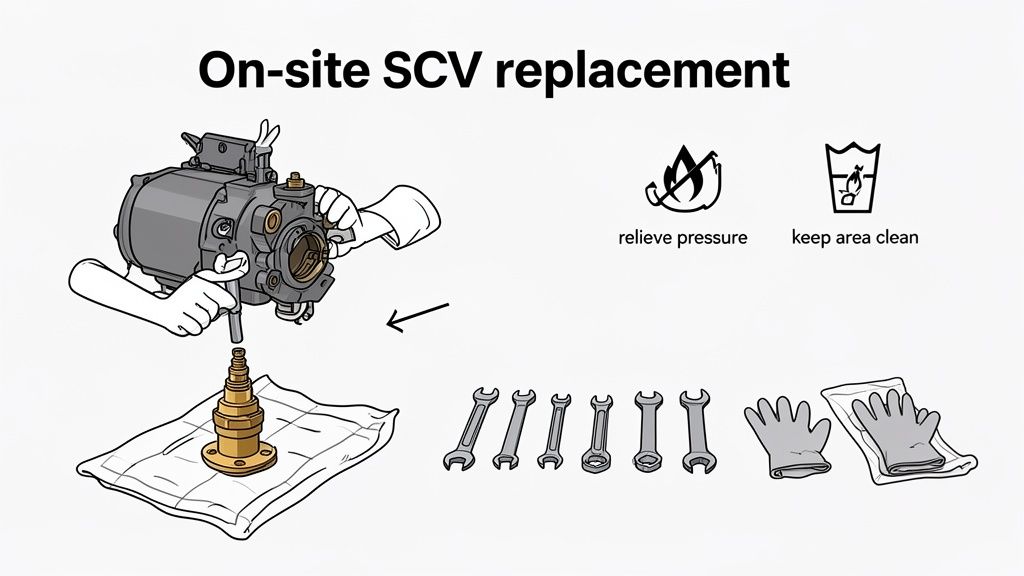

Gathering Your Gear for the Job

You don’t need a rolling Snap-on shrine to get this done. The tools required are the basics you already have in your service truck. No proprietary JCB tools, no dealer-specific nonsense.

Here’s your bare-bones list:

- Basic Socket Set: You'll typically need smaller metric sockets for the mounting bolts and bracketry.

- Wrenches: A set of combination wrenches is always a good idea for tight spots.

- Torx or Allen Keys: The SCV is often held in with Torx or Allen head bolts, so have a good set handy.

- Clean Rags or Shop Towels: Contamination is the mortal enemy of a common rail fuel system. You can never have too many clean rags.

- Brake Cleaner or Electrical Contact Cleaner: Essential for cleaning the mounting surface and electrical connector.

- Safety Glasses: A non-negotiable. Diesel fuel in your eye is a bad day.

That’s it. This entire job is about precision and cleanliness, not specialized equipment.

Safety First: Bleed the Pressure

Before you put a wrench on a single bolt, you have to deal with the pressure cooker you’re about to open. Common rail systems operate at pressures that can cut through skin and cause a fatal injection injury. Don't be a hero; take this step seriously.

First, make sure the machine is shut down, the key is in your pocket, and the battery is disconnected. This prevents any chance of the system trying to prime or build pressure while you're working. The residual pressure in the rail will bleed down on its own after about 5-10 minutes, but it’s never a bad idea to crack a fitting very slowly on the low-pressure side to be certain. Just wrap it in a rag to catch any spray.

Contamination is the fastest way to kill a brand new SCV or, even worse, your high-pressure pump. One speck of dirt can score the plunger or clog the valve, putting you right back where you started. Work clean. It’s not a suggestion; it’s a requirement.

The Swap: Step-by-Step

With the pressure bled and the area prepped, it's time for surgery.

Locate the SCV on the back of the high-pressure fuel pump. It's a small cylindrical solenoid with a two-wire electrical connector. Carefully disconnect the wiring harness and move it out of the way. Before removing the bolts, use compressed air and brake cleaner to blow away all the dirt and grime around the valve.

Once it's spotless, remove the mounting bolts—usually just two of them. The valve should pull straight out. You might need to give it a gentle twist to break the seal of the O-ring. Have a clean rag ready to immediately cover the opening in the pump to prevent anything from falling in.

Before installing the new valve from Flat Earth Equipment, take a moment to inspect it. Make sure the new O-rings are in place and lightly lubricate them with some clean diesel fuel or assembly lube. This ensures it seats correctly without tearing the seal.

Carefully insert the new SCV into the pump, making sure it slides in smoothly. Hand-tighten the bolts first to ensure it's seated properly, then torque them down to spec. Don't go crazy—these are small bolts. Reconnect the electrical plug, making sure it clicks securely into place. Finally, clear your old codes with your scanner, and you're ready to get back to work.

While you’re thinking about job site protocols, it’s a good time to review your forklift safety procedures too. Check out this guide on comprehensive forklift safety to keep your crew sharp.

Ruling Out Other P0087 Gremlins

Look, the Suction Control Valve is guilty most of the time, but that doesn't mean it's the only problem. A good technician never assumes. Before you condemn that SCV and place an order with Flat Earth Equipment, you need to run down the other gremlins that can throw a P0087 code. Wasting time and money on the wrong part is the dealer’s game, not ours.

The whole point of this diagnostic workflow is to be thorough but efficient. We're going to start with the simple stuff and work our way up, ruling out the easy fixes before digging into more serious mechanical failures. This process will save you from a costly misdiagnosis and get that machine back in the fight.

Start With The Low-Hanging Fruit: Fuel Filters

I can't tell you how many times a P0087 code ended up being nothing more than a set of completely clogged fuel filters. Seriously, before you even think about plugging in a scanner, get your eyes on the filters—both the primary water separator and the secondary final filter.

If that primary bowl is full of water and gunk, you’ve likely found a major contributor. Drain it and see what comes out. A plugged filter is like trying to breathe through a coffee stirrer; the lift pump simply can’t push enough fuel through to supply the high-pressure side.

For the cost of a couple of filters, it's the cheapest and easiest first step in any JCB P0087 diagnosis. Always start here. It might just be your lucky day.

Checking The Low-Pressure Lift Pump

If the filters look good, the next link in the chain is the low-pressure lift pump. This little electric pump has one job: feed the big, expensive high-pressure pump. If it's weak or failing, the high-pressure side will starve for fuel no matter how healthy your SCV is.

You can do a quick check by cracking a line after the filter and before the high-pressure pump. Cycle the key. You should see a healthy, steady stream of fuel, not just a sad dribble.

For a more precise test, tee in a low-pressure gauge. You’re looking for a consistent 5-10 PSI. Anything less, and your lift pump is the prime suspect.

The Lying Sensor: FRP And Wiring

Sometimes, the fuel pressure is perfectly fine, but the sensor telling the ECM what's happening is lying. The Fuel Rail Pressure (FRP) sensor can fail, sending a bogus low-voltage signal back to the computer. The ECM believes the pressure is low, throws the P0087 code, and derates the engine, even when the mechanical system is working perfectly.

Don't forget to check its wiring harness, too. Just like the SCV, these wires can chafe, corrode, or break, causing erratic signals. A quick visual inspection and a wiggle test of the connector can often reveal the problem without the cost of a new sensor.

The rise in P0087 codes isn't just in your head; it’s a global trend. Statistically, P0087 with SCV issues in JCB machinery has ballooned repair demands by 37% since 2018, thanks to supply chain issues and a surge in machine rentals. A faulty SCV can lead to 15-25% efficiency losses, costing you hundreds of extra gallons of fuel. This problem is so common that JCB even issued a service bulletin to address it. Catch up on the latest industry insights and see why this matters.

When It's Actually Something Serious

Okay, so you've ruled out filters, the lift pump, and the sensor. Now you might be looking at a more serious mechanical issue. These are the problems nobody wants to find, but you have to be prepared for them.

- Leaking Injectors: An injector stuck open or with a bad internal seal will bleed off rail pressure faster than the pump can build it. You can often spot this with a cylinder cutout test or by checking for excessive fuel in the return lines.

- Worn High-Pressure Pump: This is the worst-case scenario. If the pump itself is internally worn, it simply can't generate the commanded pressure. It's an expensive fix and usually the last thing you'd suspect unless the machine has extremely high hours or a history of severe fuel contamination.

To help keep things straight, here's a quick checklist to run through before you zero in on the SCV.

P0087 Diagnostic Checklist SCV vs Other Causes

| Component to Check | Test Procedure | What A 'Good' Result Looks Like | What A 'Bad' Result Looks Like |

|---|---|---|---|

| Fuel Filters | Visual inspection of both filters. Drain the primary water separator bowl. | Filters are clean, no water or debris in the bowl. | Filters are clogged, water/gunk in the separator bowl. |

| Low-Pressure Lift Pump | Tee in a pressure gauge between the filter and the high-pressure pump. | Steady 5-10 PSI with the key on. | Pressure below 5 PSI, erratic, or zero. |

| FRP Sensor & Wiring | Visually inspect the sensor connector and harness. Perform a wiggle test. | Connector is clean, secure. Wires are intact with no chafing. | Corroded pins, loose connector, damaged wires. |

| Injectors | Perform a cylinder cutout test or check fuel return volume. | Minimal and consistent return flow from all injectors. | One or more injectors show significantly higher return flow. |

| High-Pressure Pump | Last resort test, usually after all else fails. Monitor actual vs desired. | Actual pressure closely tracks desired pressure under load. | Actual pressure consistently lags far behind desired, especially under load. |

By methodically checking these other potential causes, you ensure that when you finally point the finger at the SCV valve, you're doing it with absolute confidence. This is how you fix it right the first time.

Why You Should Fire Your Dealer's Parts Counter

Let's get real for a minute. Your JCB is down with a P0087 code, the job clock is burning cash, and your first thought might be to ring up the dealer.

Don't. That call is the first move in a long, expensive game you're guaranteed to lose. Dealers aren't in the business of getting your machine running fast. They're in the business of locking you into their service schedule and their parts monopoly.

Their supply chain is often a joke. The SCV you need is probably collecting dust in a central warehouse a thousand miles away, waiting for a transfer truck that only runs twice a week—if it's even in the country. While you wait, the parts guy quotes you a price that’ll make your eyes water for a part that likely rolled off the same assembly line as a quality aftermarket one.

This isn't about being cheap. It’s about being smart and taking back control of your fleet's uptime. Every minute that machine sits idle, profit is just evaporating. You're not just paying for their overpriced part; you're paying for their bloated overhead and the "privilege" of being squeezed into their schedule.

Build Your Own Parts Department

The pros know uptime isn't an accident—it's a strategy. That strategy means stocking the high-failure parts you know are going to break. For any modern JCB, that list has to include SCV valves, fuel filters, and a few common sensors.

Think about the math. The cost of having a $150 SCV sitting on your shelf is nothing compared to the $2,000+ you can lose in a single day of downtime.

When a machine throws that P0087 code, you shouldn't be on the phone with a service writer. You should be walking over to your parts shelf, grabbing a new SCV from Flat Earth Equipment, and getting that machine back to earning its keep in under an hour. This is the mindset that separates the profitable outfits from the ones constantly playing catch-up.

The hard truth is the dealer model is designed to keep you dependent. They want you locked into their systems, their parts network, and their god-awful Regen cycles. Breaking that dependency is the single most powerful move you can make for your operational efficiency and your bottom line.

The Flat Earth Equipment Advantage

So, why work with a supplier like Flat Earth Equipment? It comes down to the gritty realities of keeping yellow iron in the dirt and making money.

- Speed: Their entire operation is built for fast fulfillment from their US hubs. Even if you don't have the part on your shelf, you can often get it overnight. The dealer might take a week for the same part.

- Expertise: When you call them, you’re not talking to a script-reader in a call center. You’re talking to someone who actually understands the iron and can give you practical support.

- Quality: They source parts specifically for uptime and proper fitment. This isn't about selling the cheapest junk they can find; it's about providing a reliable component that fits right the first time and keeps your machine out of the shop.

Ultimately, this is about fixing your own gear without asking for permission. It's about having the right parts, the know-how to diagnose the problem, and the confidence to get it done. The team at Flat Earth Equipment shares that philosophy, which is why they’ve become a go-to for so many independent techs and fleet managers. They get it. They know you need sensors, solenoids, and filters to bypass the dealer wait times.

Field Q&A: Straight Talk on P0087 and SCV Valves

You've wrestled with a P0087, run through the diagnostics, and got the machine making money again. But the job isn't over until the questions stop. I get hit with the same ones all the time, so here are some straight, no-BS answers from the trenches.

Can I Just Clean The Old SCV Valve?

Look, I've seen guys try it. To be blunt, it's a rookie move.

Sure, you might get lucky. Maybe you'll flush out a piece of grit and buy yourself a few more hours of runtime. But cleaning does absolutely nothing for a worn-out solenoid coil or a plunger that's scored from thousands of hours of work. It’s a band-aid, not a fix.

The real issue is your time. You're already doing the labor to pull the valve out. Why risk a callback and another full day of downtime just to save a few bucks on a critical fuel system component? Do the job right the first time with a quality replacement part from Flat Earth Equipment.

A temporary fix is just a permanent headache waiting to happen. For the cost of the part, replacing the SCV is the only professional move. You're paid to fix machines for good, not to kick the can down the road.

Will A Cheap Aftermarket SCV From Amazon Work?

You're rolling the dice, plain and simple. Common rail fuel systems operate on insane pressures and microscopic tolerances that leave zero room for error. A cheap, knock-off SCV made with sloppy quality control can fail right out of the box, cause wild pressure spikes, or even grenade your entire high-pressure pump.

Just think about the math. Is saving $50 on a mystery part worth the risk of a $5,000 pump failure and a furious customer? Not a chance. You need a precision part from a supplier who actually understands heavy equipment and stands behind their products.

Does Bad Fuel Cause SCV Failure?

Absolutely. One hundred percent. Bad, contaminated fuel is the number one killer of every single component in a common rail system.

Water, dirt, rust, algae—it’s all poison to an SCV valve, your injectors, and the pump. If you keep seeing P0087 codes pop up across your fleet, it's time to stop blaming the parts and start looking at your fuel supply. Drain your water separators daily. This isn't optional; it's the most basic maintenance there is. A brand-new part can't fix a bad fuel problem.

Do I Need The Dealer Laptop To Program The New SCV?

Here’s some good news. On most JCB applications, the SCV is a simple plug-and-play part.

Unlike new injectors or certain pumps that have to be coded to the ECM, the SCV doesn't require a special "re-learn" or calibration procedure with the dealer's Service Master software. Just install the new valve, clear the codes with your standard scan tool, and cycle the key. The ECM is smart enough to adapt to the new component on its own. It's one of the few repairs left on modern iron that hasn't been locked behind a software paywall.

When you're ready to skip the dealer prices and get parts that actually work, Flat Earth Equipment has the SCV valves and filters you need, in stock and ready to ship. Let's get your iron back to work.