When your JCB Loadall refuses to start, the first thing everyone blames is the immobilizer or that finicky keypad. But let me tell you from years in the field, jumping straight to that conclusion is a rookie mistake that can cost you hours of downtime. The dealer loves that call.

A dead machine means a dead job site, and more often than not, the real problem is something much simpler than a fried electronic module. Before you start dreaming up conspiracy theories about the dealer's software, a few basic, gritty checks right there in the dirt can get you up and running again.

Your Loadall Is Dead In The Dirt. Now What?

The silence is deafening, isn't it? The crew is staring, the clock is ticking, and your machine has suddenly become a very expensive, multi-ton paperweight. Every minute it sits idle, it's burning a hole in your pocket.

Of course, the dealer's first suggestion will be to haul it in, hook it up to their precious "Service Master" laptop, and hand you a bill that'll make your eyes water. Forget that. We fix things where they break—in the dirt.

Before you even think about bypass tricks or secret codes, you have to rule out the simple stuff. JCB electronics, especially on anything with AdBlue/DEF, are notoriously sensitive to voltage drops. What looks like a complex computer meltdown is often just a weak battery or a loose wire tricking the whole system into shutting down. Don't let a five-dollar fuse cost you a thousand-dollar service call.

Start With The Simple Stuff

Your first move should always be checking the power source. A battery showing 12 volts on a meter might not have enough cranking amps to turn over the engine and power all the sensitive electronics at the same time. You need to put it under a proper load test.

While you’re there, check the terminals. Make sure they're clean and tight. Corrosion is the silent killer of electrical systems.

Initial Checks Before Blaming The Immobilizer

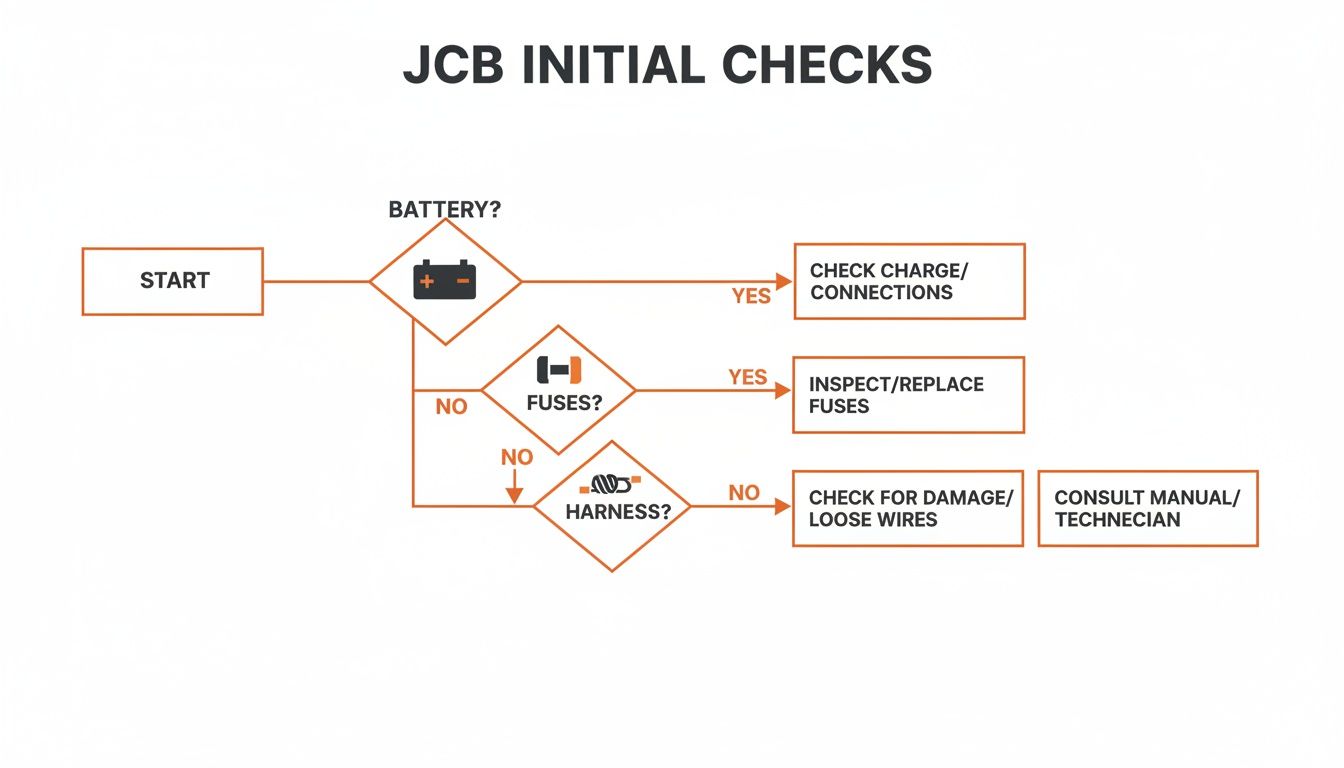

Run through these common culprits first. A few minutes here can save you hours of downtime and a costly service call for what might be a simple fix.

| Check | What To Look For | Why It Matters |

|---|---|---|

| Battery Health | Use a load tester, not just a voltmeter. Check for clean, tight terminals. | A weak battery can't supply the steady voltage JCB electronics need, causing false immobilizer faults. |

| Key Fuses | Pull fuses for the ignition and ECU. Test for continuity with a multimeter. | A tiny, invisible crack in a fuse is enough to stop the entire machine dead in its tracks. |

| Wiring Harness | Visually inspect the keypad and immobilizer wiring for pinches, rodent damage, or corrosion. | A chafed wire or a dirty connector is the most common cause of "no-start" issues on any job site. |

These basic steps will solve the problem more often than you'd think, saving you a massive headache.

This flowchart breaks down the process. You have to confirm the basics—battery, fuses, and wiring—are solid before you ever start pointing fingers at the immobilizer.

Next up, pull the fuses for the ignition and the ECU. Don't just glance at them—use a multimeter to check for continuity. A hairline crack you can't see will stop you cold. If your battery is good but just won't hold a charge, you can find reliable industrial battery chargers that will get you back in business without waiting on a service truck.

The golden rule in the field is this: 90% of all electrical problems are mechanical problems in disguise. A loose ground, a chafed wire, or a corroded pin is almost always the culprit before a major component truly fails.

Finally, do a quick walk-around. Trace the keypad wiring harness as far as you can see. Look for obvious signs of damage—wires pinched by a raised boom, chewed on by critters, or connectors packed with mud. A quick shot of contact cleaner can work miracles.

These simple, no-cost checks solve the "JCB Loadall won't start" headache more than half the time. It keeps the dealer out of your yard and your machine right where it belongs: earning its keep.

Decoding The Flashing Lights On Your Silent Engine

So, you’ve done the rounds. The battery's good, the fuses check out, and the wiring looks solid. But your engine is dead quiet, and that blinking light on the keypad feels like it's mocking you. Don't sweat it just yet. That flashing light is the machine's way of telling you what’s wrong; you just have to learn its language.

Think of the immobilizer system as a three-part security team guarding your engine: the key with its transponder chip, the keypad, and the brain of the operation, the ECU (Engine Control Unit). When you turn the key, the transponder sends out a secret handshake. If the keypad and ECU recognize it, the ECU tells the fuel solenoid to open for business, and the engine fires up.

But if any part of that handshake fails—a busted key, a fried keypad, or a glitchy ECU—the gate stays locked. The fuel solenoid never gets the signal, and your engine will crank until the battery dies but never actually start. That’s the classic sign of a true immobilizer fault.

Reading The Machine's Signals

Your job now is to play detective and figure out where that communication broke down. The machine gives you clues through the dashboard lights and that LED on the keypad. A simple keypad lockout from too many wrong PINs looks very different from a deep system fault where the components aren't even talking to each other.

This isn't some new-fangled problem, either. JCB Loadall telehandlers have used these advanced systems for years, especially on models like the 526-56 and 527-58 Agri Loadalls with Tier 4 Final engines. Digging into JCB service logs shows that while their engines are absolute workhorses, immobilizer glitches are behind roughly 12% of all reported starting failures. You can get a better feel for the tech in these machines when you read the full JCB 526-56 Agri Loadall brochure.

Learning to read these signals is the difference between guessing and diagnosing.

Differentiating Lockout From Failure

Here’s the first big question: are you dealing with a simple operator error or a genuine hardware problem? They look different if you know what to watch for.

Keypad Lockout Symptoms: This is your most common headache. It usually happens after someone punches in the wrong PIN too many times. You'll likely see the keypad light flashing steadily or just staying on, and the dash might show a lockout icon (often a key with a line through it). The key takeaway is that the system is actually working perfectly—it’s just doing its job of keeping unauthorized users out.

Immobilizer Failure Symptoms: This is a whole different beast. You might see a rapid, frantic flashing from the keypad LED the instant you turn the key, before anyone even tries to enter a PIN. You’ll often get a specific engine management or security warning light on the dash you don’t normally see. This points to a deeper communication breakdown between the key, the keypad, or the ECU.

A slow, steady flash is often the machine waiting for a correct PIN. A fast, erratic flash is usually the machine screaming that it can't recognize the key or communicate with its own brain.

Knowing this difference is everything. One situation calls for patience and the right code; the other means it's time to grab a multimeter and start digging into the wiring. Don't waste hours trying to bypass a system that's just locked out, and don't spend half the day searching for a lost PIN code when the key reader itself is toast. Getting this first step right is the fastest way to get your machine back to making you money.

Handling The Keypad Lockout: The Most Common Job Stopper

We've all been there. You get a new operator fumbling with the code, a seasoned pro has a moment of forgetfulness, or maybe just greasy fingers make a mess of the keypad. Five wrong tries, and boom—you're locked out. The machine puts itself in a mandatory 15-minute time-out, and your entire job site grinds to a halt.

This keypad lockout is, without a doubt, the single most frequent reason for a JCB no-start call. It isn't a mechanical fault; it's the security system doing exactly what it's supposed to do. But that doesn't make it any less infuriating when you're burning daylight and losing money. Forget calling the dealer for this one—it’s a total waste of a service fee for something that just needs a little patience.

This scenario is frustratingly common. According to JCB's global service data, keypad and immobilizer issues are a pain point for about 18% of Loadall telehandlers, especially in farm-heavy areas. The keypad immobiliser, which became standard on most models after 2005, arms itself just two minutes after the engine is shut down. Those five failed entries lead directly to a 15-minute lockdown, contributing to a whopping 22% of all downtime incidents reported in fleet management systems. You can dig into the specifics in this JCB immobiliser overview.

What A Keypad Lockout Looks Like

When the machine locks you out, the keypad gives a pretty clear signal. You’ll usually see the LED light flash in a steady, rhythmic pattern, or sometimes it might just stay on solid. The key word here is "steady." It’s not the frantic, irregular flashing you get with a legitimate communication error. The machine is basically telling you, "I'm working fine, but you're in time-out."

During this 15-minute period, nothing you do is going to work. You can't enter another code, you can't restart it, and you certainly can't bypass it.

Field Technician's Tip: Whatever you do, don't turn the key off and on again thinking it will reset the timer. It won't. The countdown is managed by the ECU, and cycling the power will almost always restart the 15-minute clock from the very beginning. Just leave the key in the 'on' position and wait it out.

Once the 15 minutes are up, the keypad light will change its pattern—usually returning to a slower, more relaxed blink—letting you know it's ready for another try. This is your chance to carefully enter the correct code.

Preventing The Lockout In The First Place

Honestly, the best way to deal with a lockout is to make sure it never happens. This isn't about fancy electronics; it's about good crew management and having a clear process. Your JCB Loadall can store up to 14 different user codes on top of the master code (which only a dealer's laptop can change). There's absolutely no reason every operator should be sharing the same PIN.

Put these simple steps into practice to keep your crew moving:

- Assign Unique Codes: Give every single operator their own 4-digit PIN. This creates accountability and makes it dead simple to add or remove users without having to change the code for the entire team.

- Establish A Handover Protocol: When one operator finishes their shift, they should shut down the machine properly. The incoming operator should know their own code and not have to guess or ask around for it.

- Keep The Keypad Clean: This sounds obvious, but greasy, muddy, or wet fingers are a leading cause of wrong entries. A quick wipe with a clean rag can prevent a world of headaches.

- Write It Down Securely: Keep a secure record of all assigned PINs in the site office or with the foreman. This isn't for operators to access freely, but for management to have a backup when someone inevitably forgets.

A little bit of discipline here goes a very long way. Setting up a simple system for managing your user codes is a free and incredibly effective way to prevent the most common "JCB Loadall won't start" issue. It keeps your team productive and saves you from making that embarrassing call for a problem you could have solved with a stopwatch.

When The Immobilizer Is Truly Fried

Alright, you've waited out the lockout, you’ve checked the battery and fuses, and the machine is still dead. Now we’re getting into the real guts of the problem. This is where you put down the operator’s manual and pick up a multimeter.

A simple keypad lockout is one thing; a genuinely fried immobilizer component is another. This is where water, vibration, and JCB’s finicky electronics team up to ruin your day.

The issue is no longer about a forgotten code. We're talking about a hardware failure—a dead fuel solenoid, a busted key reader, or corroded wires in the keypad harness. The communication chain between the key, the keypad, and the ECU has been broken. Your job now is to find that broken link without just throwing expensive parts at it until something sticks. This is the difference between being a parts-swapper and a technician.

This is where the dealer loves to trap you. They’ll tell you it's a "no-communication" fault that only their proprietary Service Master laptop can diagnose. That's their way of getting a truck out to your site and locking you into their parts and labor rates. We're not playing that game. With a bit of know-how and a multimeter, you can pinpoint the failure yourself.

Hunting Down The Point Of Failure

Your first target is the fuel shutoff solenoid. This little part is the immobilizer’s muscle. The ECU can scream "start" all day, but if this solenoid doesn't get power and physically open, no fuel will reach the engine. It’s the final gatekeeper, and it’s a common point of failure.

Get access to the solenoid on the injection pump. It will have a wire running to it. Have a helper turn the key to the 'on' position and enter the correct code. You should hear a distinct "click" as the solenoid activates. No click means no power, or a dead solenoid.

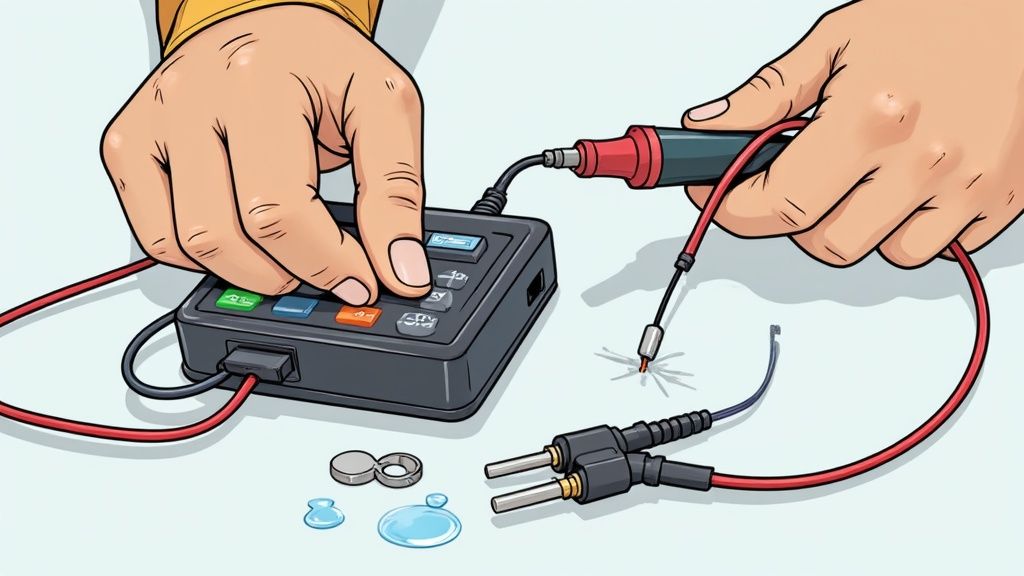

Use your multimeter to confirm. Put the black probe on a good ground and the red probe on the solenoid's power terminal. When the key is on and the code is entered, you should see 12 volts. If you have 12 volts but no click, the solenoid itself is fried. If you have no voltage, the problem is further upstream.

Checking The Keypad Harness And Reader Ring

If the solenoid isn’t getting the signal, the next step is to trace the wiring back to the keypad and the key reader ring. The reader ring is the plastic loop around the ignition barrel; it’s the antenna that reads the transponder chip in your key. These can get brittle and crack, or the wiring can get frayed.

Give the reader ring a close visual inspection. Any visible cracks or damage are a red flag. Next, unplug the main harness from the back of the keypad. It’s usually a multi-pin connector. Here’s what you’re checking for with your multimeter set to continuity:

- Power and Ground: Check for a constant 12V power supply and a solid ground connection right at the keypad harness. No power here means you have a broken wire or a blown fuse you missed earlier.

- Continuity to ECU: This is trickier without a wiring diagram, but you can check for obvious breaks. Look for signs of corrosion—green or white powder—on the pins. Clean them thoroughly with contact cleaner.

A "no-communication" fault doesn't always mean the ECU is bad. It usually means the ECU isn't receiving the signal it expects from the keypad or key reader. Nine times out of ten, it’s a problem with the wiring in between, not the expensive computer itself.

This gritty, hands-on diagnostic process is what separates the pros from the guys waiting on a service call. You’re not guessing; you’re systematically eliminating possibilities. You’ve tested the final output (the solenoid) and worked your way back through the wiring. By doing this, you can confidently identify the exact failed part, whether it's a simple wire, the reader ring, or the solenoid. Now you know precisely what you need to order from a supplier like Flat Earth Equipment, getting the right part on its way without ever having to talk to a dealer's service desk.

Getting The Parts You Need And Bypassing The Dealer

You've done the work. You’ve traced the wires, tested the solenoid, and found the culprit. The good news is you know exactly what’s wrong. The bad news? You call the dealer, and they hit you with the classic line: "That part is two weeks out, and we'll need to send a tech with the Service Master laptop to program it."

That’s two weeks of your machine sitting, your crew standing around, and your profits evaporating. That’s two weeks of being held hostage by a supply chain and a proprietary piece of software designed to keep you dependent. We don't have time for that. This isn't about waiting for permission to work; it's about taking back control of your own iron.

When a critical component like a fuel cutoff solenoid or a sensor goes down, you don't need the dealer's blessing. You need a reliable source for quality aftermarket parts that gets them to your site fast. This is where a supplier like Flat Earth Equipment becomes your best friend. They stock the parts that fail the most—the solenoids, sensors, and filters—and they understand that uptime is everything. You get the right part without the runaround.

Sourcing The Right Components Now

Forget waiting on parts shipped from overseas. You need a partner who has the iron on the ground, ready to ship today. When your JCB Loadall won't start because of an immobilizer problem, you're usually looking at a few key offenders that are easily replaced.

Here’s your go-to list for common-sense parts sourcing:

- Fuel Cutoff Solenoid: This is the most common failure point. Instead of waiting for an OEM part that’s identical to the one that just failed, you can get a high-quality aftermarket solenoid that does the exact same job. It’s a simple 12V actuator, not rocket science.

- Key Reader Ring: If the antenna around your ignition is cracked or damaged, a replacement is often a straightforward swap. You don't need a dealer laptop to plug in a new one.

- Sensors and Switches: Many of the sensors tied into the ECU and security system are standard industrial parts. Cross-referencing the part number can often lead you to an aftermarket equivalent that costs half as much and ships overnight.

The dealer’s business model depends on controlling the parts and the software. Our business depends on keeping machines running, period. That means finding a way around their bottlenecks.

Once you have the right part in hand, the installation is usually simple. A fuel solenoid is often just two bolts and a single electrical connector. A key reader ring snaps into place. This is work you can do yourself in under an hour, not something that requires a four-hour service call.

The In-The-Field Immobilizer Bypass

Let’s be clear: we're talking about a temporary, emergency bypass to get a machine moved or to finish a critical task. The goal is to get the fuel flowing without the ECU’s permission. The most direct method is to bypass the fuel cutoff solenoid.

The immobilizer’s entire job is to prevent that solenoid from getting 12V of power. So, we give it power ourselves. You can run a fused jumper wire directly from a 12V power source (like the battery positive terminal or a hot post on the starter) straight to the power terminal on the fuel solenoid.

When you supply this direct power, the solenoid will click open, and as long as the rest of the engine is healthy, it will start and run. This completely sidesteps the keypad, the key reader, and the ECU’s security logic. It’s a brute-force solution, but it’s brutally effective when you’re in a jam.

This method gets your machine out of the mud and back to the shop where you can perform a proper repair with the parts you ordered. If you run into a unique part or need advice on a workaround, don't hesitate to get in touch with the techs at Flat Earth Equipment. They've seen these problems before and can help you find a practical solution. It's about having a team that’s on your side, not one that sees your downtime as their payday.

A Word Of Warning On Legal And Safety Issues

Look, the mission is always to get the machine running. I get it. But before you start jumping solenoids or pulling apart wiring harnesses, you need to stop and think about the consequences. Bypassing a security system, even on your own equipment, isn't a simple fix. It's a move that can open up a real can of worms with your insurance, your warranty, and most importantly, the safety of everyone on site.

This isn't just some lecture from a guy in a clean shirt. This is real talk from the field. The moment you permanently disable that immobilizer, you’re handing your insurance company a golden ticket to deny a theft claim. They offer better rates because that machine has a factory-rated security system. Rip it out, and you’ve just broken your side of the agreement.

More Than Just An Anti-Theft Device

That immobilizer isn't just a fancy lock. On modern JCBs, it's woven directly into the machine's other critical safety interlocks. It’s a key part of the central nervous system, constantly communicating with everything from the hydraulic controls to the boom extension limits.

Think of it this way: the immobilizer is often the first link in a safety chain that confirms an authorized operator is in the seat with the controls in neutral before it allows hydraulic power. When you hotwire the fuel solenoid, you might be bypassing those crucial checks. This could easily create a situation where the machine lurches or the boom moves unexpectedly on startup—a massive hazard on any job site.

A "quick fix" that bypasses factory safety protocols is a liability waiting to happen. If someone gets hurt by a machine with a disabled interlock, the legal fallout will be a hell of a lot more expensive than any dealer service call.

Doing The Job Right

This isn't about scaring you away from a field repair. It's about being smart and seeing the whole picture. A temporary bypass to get a machine moved to a safe location for proper repair is one thing. A permanent, shoddy workaround is just asking for trouble.

Your primary goal should always be to repair the system correctly, not just eliminate it. This protects your investment, your warranty, and the people working around that machine.

- Insurance Implications: A permanent bypass can easily void your theft coverage and potentially your entire policy.

- Safety Interlocks: Disabling the immobilizer might also disable critical checks on hydraulics, the transmission, and operator presence sensors.

- Liability: If an accident occurs with a modified machine, you could be held personally and financially responsible for the outcome.

Protecting your crew and your equipment is always priority number one. For more information on maintaining a safe work environment and understanding equipment protocols, you can find valuable resources on our page about job site safety standards. Always choose the proper fix to protect your assets and your team.

Frequently Asked Questions

Got questions? You're not the first. When a JCB immobilizer starts acting up, it throws a wrench in the whole operation. Here are some straight answers to the questions we get all the time from guys on the ground.

Can I Permanently Disable The JCB Immobilizer Keypad?

Technically, yes, a full JCB keypad bypass can be done, but it’s a terrible idea. Doing a permanent removal means reprogramming the ECU, and it’s a surefire way to void your insurance policy on the spot.

That Thatcham-rated security system is a big reason you get a break on your theft coverage in the first place. It's always a smarter move to fix the broken component than to gut a core security feature of your machine.

What Is A Master Code And How Do I Use It?

The master code is real, but it's not for you or me. It's a special tool baked into the JCB Service Master software that authorized dealers use to reset a user PIN when it’s completely lost.

There's no secret "backdoor" code an operator can punch into the keypad to get around a lockout. Don't waste your day hunting for one online—it doesn't exist.

The only 'master' on your job site is you. The dealer's software is designed to take that control away. Focus on repairing the hardware you can access, not chasing codes you can't.

Will A New Battery Fix My Unresponsive Keypad?

It absolutely can, and it's one of the first things you should check. The immobilizer's electronics are extremely sensitive to voltage fluctuations.

A weak or dying battery can make the keypad and ECU act erratically or fail to communicate altogether, perfectly mimicking a major immobilizer fault. Always load-test your battery and check your connections before you start tearing anything else apart.

Can I Bypass The Fuel Solenoid To Start The Engine?

Yes, but only for a temporary fix to get you out of a jam. You can run a fused 12V wire directly to the fuel shutoff solenoid to get the engine fired up.

This should only be a short-term solution to move the machine to a safer spot. It bypasses all security and safety interlocks, so use it to limp back to the shop, not as a permanent workaround.

When your JCB Loadall won't start, don't let a faulty immobilizer or a dealer's long lead time shut down your job. For the solenoids, sensors, and other critical parts you need to get back to work now, Flat Earth Equipment has your back. Get the right parts shipped fast, without the runaround.

Get The Parts You Need to Get Running at flatearthequipment.com