That high-pitched scream or gravelly groan from your JCB Loadall isn't just background noise—it's the sound of your hydraulic pump tearing itself apart from the inside. This is JCB Loadall hydraulic pump cavitation, and it's robbing your machine of power and costing you money with every hour of downtime. Forget the dealership's vague promises and two-week wait for a technician who's just going to plug in his laptop; this is a problem you can understand and attack yourself, right in the dirt.

That Whine Is Your JCB Loadall Crying For Help

Let's cut right to it. You’re on a job site, trying to make a living, and your telehandler sounds like it's grinding up a bucket of bolts. The boom feels sluggish, it won't lift what it did yesterday, and you can feel the power loss right through the seat.

That noise is your machine screaming that it's being starved of hydraulic fluid. It’s not some phantom sensor glitch or finicky electronic nonsense that requires the dealer's laptop to fix. This is a mechanical problem, pure and simple.

This is cavitation, a mechanical killer that happens when the pump tries to move more oil than the suction line can deliver. This creates tiny vacuum bubbles—or vapor cavities—in the fluid. When these bubbles travel from the low-pressure suction side to the high-pressure outlet side of the pump, they implode with incredible force.

Think of it like thousands of microscopic hammer blows hitting the pump's internal components. Each collapse blasts away a tiny piece of metal, leading to rapid wear and, eventually, catastrophic failure.

Real-World Symptoms You Can't Ignore

The dealer might try to tell you it’s a complex control valve issue or blame the computer, hoping you’ll schedule an expensive haul back to their shop where they can plug in their precious "Service Master" laptop. But the signs of cavitation are unmistakable if you know what you're looking for out in the field.

You'll notice things like:

- A high-pitched whine or a low, gravelly rumble: This is the signature sound of those bubbles collapsing under pressure. It gets noticeably louder as you put the machine under load.

- Serious power loss: The machine just feels weak. The boom is slow to respond, it struggles to lift a full bucket, and the cycle times get longer and longer.

- Excessive heat from the hydraulic system: The pump and hydraulic tank feel hotter than usual to the touch. Cavitation generates a ton of heat, cooking your fluid and destroying its lubricating properties.

- Foamy or milky hydraulic fluid: This is a dead giveaway that air is getting into the system, which is a close cousin to cavitation and often happens at the same time.

Recognizing these symptoms early is the key to avoiding a complete pump failure. This table breaks down what you're seeing and hearing versus what's actually happening inside your machine.

Cavitation Warning Signs You Can't Afford To Ignore

| Symptom | What You Hear Or Feel | What's Happening Inside | Consequence If Ignored |

|---|---|---|---|

| Loud Whining/Rumbling | A high-pitched squeal or a gravelly noise that changes with engine RPM or load. | Vapor bubbles are forming and violently collapsing inside the pump. | Pitting, erosion, and eventual destruction of internal pump components. |

| Sluggish Performance | The boom is slow to lift, tilt, or extend. The machine feels weak and unresponsive. | The pump isn't moving a full volume of oil, starving the cylinders and motors. | Reduced productivity, increased cycle times, and potential for complete system failure. |

| High Hydraulic Temperature | The pump housing, lines, and tank are unusually hot to the touch. | The implosion of bubbles generates intense localized heat, superheating the fluid. | Oil breakdown, seal failure, and damage to other hydraulic components. |

| Foamy/Milky Fluid | The oil in the sight glass or on the dipstick looks cloudy or full of bubbles. | Air is being drawn into the suction side of the system, often with the fluid. | Poor lubrication, erratic operation, and accelerated wear on the entire system. |

Paying attention to these signs lets you get ahead of the problem before it turns into a five-figure repair bill and weeks of downtime.

This isn't just a maintenance headache; it’s a direct threat to your uptime. Ignoring that sound is like ignoring a check engine light while driving through the desert. Sooner or later, you're going to be stranded with a very expensive piece of yellow iron. The good news is, finding the cause is usually straightforward—no "Service Master" laptop required.

The Prime Suspects Behind Pump Cavitation

That grinding, whining noise coming from your JCB Loadall isn't just an annoyance—it's the sound of your hydraulic pump destroying itself. Cavitation is the symptom, but the root cause is almost always something starving the pump for oil. Before you call the dealer and start the clock on their expensive labor rates, let's look at the usual suspects you can find yourself.

The problem almost always starts on the suction side of the system. Think of it as the pump's lifeline. Any restriction here is like trying to breathe through a pinched straw. The pump is going to pull fluid no matter what, and when it can't get enough, it creates a vacuum, boils the hydraulic oil, and those collapsing vapor bubbles start chipping away at the pump's internals.

The Most Common Culprit: A Clogged Suction Strainer

If you're making a list, put this one at the top. The suction strainer inside the hydraulic tank is your number one suspect. This simple filter is often forgotten during maintenance, but when it clogs up with sludge and debris, it becomes the primary cause of JCB Loadall hydraulic pump cavitation.

A partially blocked strainer forces the pump to work overtime just to pull in oil. Even a small restriction can create enough vacuum to start the cavitation process. If you ignore it long enough, the strainer can collapse under the strain, sending a cocktail of metal and filter media directly into your very expensive pump. Game over.

Compromised Suction Hoses: The Hidden Killers

If the strainer is clean, your next stop is the main suction hose running from the tank to the pump. These hoses don't last forever, and their failures are rarely visible from the outside.

Keep an eye out for these common issues:

- Internal Delamination: The inside liner of an old hose can peel away, creating a flap that chokes off flow as the pump pulls a vacuum. The hose looks perfectly fine from the outside, but it’s strangling your pump from within.

- Kinks and Sharp Bends: A hose that’s been routed incorrectly or crushed can create a permanent bottleneck, severely restricting the fluid's path.

- Wrong Replacement Hose: It happens. Someone grabs whatever hose is on the shelf. A suction hose that’s even a little too small in diameter will cause fluid velocity to skyrocket, all but guaranteeing cavitation.

A suction hose isn't just a hose. Its size and condition are critical. Using the wrong one is like putting a garden hose on a fire hydrant—the results are never good, and the failure is on you, not the machine.

Low or incorrect hydraulic fluid is another simple-but-deadly cause. Running the tank low is an obvious invitation for the pump to suck air. Less obvious is using oil with the wrong viscosity. On a cold morning, fluid that's too thick is like trying to suck molasses through a coffee stirrer. The pump cavitates until the oil warms up and thins out, causing cumulative damage with every cold start.

Air Leaks: The Invisible Poison

Finally, you need to hunt for air leaks on the suction side. Unlike a pressure-side leak that drips oil, a pinhole in a suction fitting won't leave a puddle. Instead, it will constantly suck in small amounts of air, poisoning the hydraulic fluid.

This aerated, foamy oil is compressible and a terrible lubricant, leading to noise, poor performance, and eventual pump failure. It’s a more common problem than you might think. Across the industry, cavitation is the second leading cause of hydraulic pump failure, right behind contamination. These simple suction-side issues can slash a pump's life from over 10 years down to just 2—an 80% reduction in service life.

There are documented cases where a strainer rated for 132 GPM was installed on a system where the pumps demanded 200 GPM, creating a permanent flow deficit that ensured cavitation under any real load. You can learn more about how small design flaws can cause major failures from the experts at Muncie Power. By learning to spot these prime suspects yourself, you keep your machine running and your money in your pocket.

Field Diagnostics Without The Dealer's Laptop

Alright, enough theory. The dealer wants you to believe you need their fancy laptop and a four-hour diagnostic fee just to tell you what you already know: the machine is down. But when you’re dealing with JCB Loadall hydraulic pump cavitation, the real evidence is right there in the iron, not locked away in some electronic control module that a regen cycle can shut down.

You don’t need a computer to tell you a pump is starving for oil. You just need your eyes, your ears, and a few basic tools. This is about finding the proof yourself, so you can fix it yourself and get back to work.

Start With Your Senses

Before you even grab a wrench, do a walk-around. Get your ears close to the hydraulic pump while a buddy cycles the functions. Can you hear that gravelly, marbles-in-a-can sound coming directly from the pump housing? That's your first major clue.

Next, lay your hands on the suction line—the big hose running from the tank to the pump. Does it feel unusually hot? Does it feel stiff and brittle, or soft and spongy? Now, trace it from end to end. Look for kinks, flat spots where it might have been crushed, or tight bends that are choking off flow. Any of these can be the source of your entire headache.

Finally, check the hydraulic tank. Pop the cap and look at the fluid on the dipstick or in the sight glass. If it looks milky or foamy like a latte, you've got an air leak on the suction side, which is just as destructive as a fluid restriction.

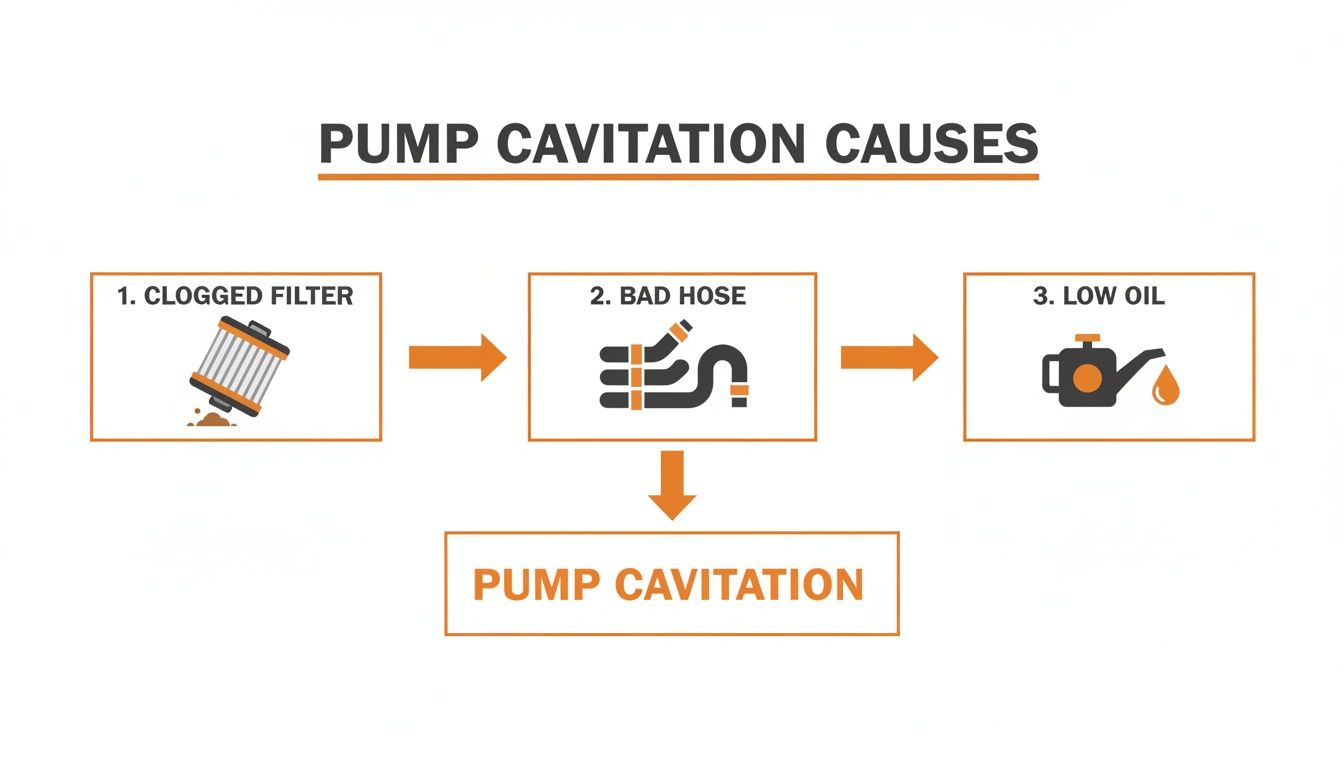

This infographic nails the usual suspects.

As you can see, the root cause is almost always a simple, physical restriction—a clogged filter, a bad hose, or low oil—not some complex electronic failure.

The Definitive Test: Suction Line Vacuum

Your senses will point you in the right direction, but a vacuum gauge gives you the hard evidence. This is the single most important test you can run to prove cavitation, and it costs less than a decent lunch.

You'll need a compound gauge that can read both pressure and vacuum in inches of mercury (inHg). Find a spot on the suction line between the hydraulic tank and the pump to tee in your gauge.

Here’s how to do it right:

- Safety First: Make sure the machine is on level ground, the parking brake is set, and the boom is lowered and secured.

- Install the Gauge: Find a port or carefully install a tee fitting into the suction line. Ensure all connections are airtight—you don't want to create a new problem while diagnosing the old one.

- Run the Test: Start the machine and let it idle. Note the vacuum reading. It should be low, typically 1-2 inHg.

- Load the System: Have someone operate the boom functions, preferably by deadheading a cylinder (like extending the boom all the way out and holding the lever). Watch that gauge like a hawk.

The numbers don't lie. A healthy system might pull 4-5 inHg under a heavy load. If you see that needle jump past 8-10 inHg, you’ve found your problem. That’s a pump screaming for oil, and you’ve just proven it without touching a single wire.

This vacuum is what causes the hydraulic fluid’s pressure to drop below its vapor point, creating those destructive bubbles. From a physics standpoint, cavitation in a JCB Loadall’s hydraulic pump begins when the inlet pressure drops, allowing vapor bubbles to form and then violently implode in high-pressure zones.

At the discharge side of a cavitating pump, local temperatures at the point of bubble collapse can exceed 5,000°F (≈2,760°C), creating micro-jets that pit metal surfaces and eat pump components alive. In one real-world hydraulic installation, using a 1-inch suction hose at 30 GPM resulted in fluid velocity around 12.5 ft/s, more than double the recommended 5 ft/s maximum for pump suction lines; the fix required increasing hose size to 1¾ inch to bring velocity back under control and eliminate cavitation. You can learn more about the destructive force of cavitation at Universal Servo.

Inspecting The Suction Strainer

If your vacuum test points to a restriction, your next job is to pull the suction strainer from the tank. Don't just glance at it. Hold it up to a light and look through the mesh. It might look clean, but it could be varnished with a thin, almost invisible layer that’s choking off flow.

If it’s anything but spotless, replace it. A new strainer from Flat Earth Equipment costs a hell of a lot less than a new pump.

The Fix That Gets You Back To Work Fast

You’ve done the hard work, you've found the evidence, and you’ve proven the pump is being starved of oil. Now is not the time to sit on your hands waiting for a dealer to find your part number, only to tell you it’s on backorder.

Fixing the most common causes of JCB Loadall hydraulic pump cavitation is pretty straightforward, but it demands the right parts and a no-nonsense approach. Every minute you wait for a part is burning daylight and money.

Replacing The Suction Strainer The Right Way

If your diagnostics pointed to a clogged or collapsed suction strainer, the fix is a simple replacement—but don't just grab whatever fits off the shelf. Using the wrong strainer is just as bad as leaving the clogged one in there. You have to match the OEM specs precisely, or you’ll be chasing this exact same problem again in a hundred hours.

Here’s what actually matters when you're picking a new one:

- Micron Rating: This number tells you how small the particles are that the strainer will catch. Go too fine, and it will clog up way too fast. Too coarse, and you're letting junk straight into your very expensive pump. Always stick with the factory rating.

- Flow Capacity (GPM): The strainer has to be able to handle the full flow rate of your hydraulic pump when it's working its hardest. An undersized strainer creates a permanent restriction, which is a guaranteed recipe for cavitation.

- Bypass Valve Setting: A lot of strainers have an internal bypass. If the spring is too weak, it'll open early and let dirty oil into the pump. If it's too strong, it won't open when it should, causing the strainer to collapse under heavy suction.

Don’t try to save a few bucks here. A quality, correctly-spec'd strainer is the cheapest insurance you can buy for a multi-thousand-dollar pump.

A No-Nonsense Guide To Suction Hose Replacement

That big suction hose is the pump's main artery. If it’s compromised in any way, the whole system suffers. When you replace it, you can't afford to get it wrong. The size, construction, and routing are absolutely non-negotiable.

First, measure the inside diameter (ID) of the old hose and get one that is identical. Even a quarter-inch reduction in size dramatically ramps up the fluid velocity and creates the vacuum that causes cavitation. It's just simple physics.

Next, look closely at the hose's construction. Suction hoses are built differently, with internal wire reinforcement to keep them from collapsing under vacuum. Using a standard pressure hose on the suction side is a rookie mistake that will guarantee a callback. That hose will suck itself flat the second the pump is put under any real load.

The machine was built with a hose of a specific size and bend radius for a reason. Don't try to outsmart the engineers by forcing a tighter bend or a shorter route. A kink in that hose is a guaranteed restriction, and it will kill your new pump just as fast as the old one.

Proper routing is just as critical. Stay away from sharp bends and make sure the hose isn't rubbing against the frame or anything else that could wear it out. Every bend adds restriction, so follow the original path as closely as possible to maintain the designed flow.

When you're ready to get the right parts without the dealer markup and the endless waiting, you need a supplier that understands you're losing money every hour that machine is down. The team at Flat Earth Equipment knows the difference between a suction line and a pressure line, and they have the parts on the shelf. If you have questions or need to confirm a part number, you can easily get in touch with their experienced support team. They ship fast so you can get back to turning wrenches and making money.

Preventing Cavitation Before It Kills Your Pump

Let’s be honest, the best repair is the one you never have to make. That’s not some fluffy slogan from a sales brochure; it's the absolute truth when you’re trying to keep a fleet of yellow iron running. You can chase down cavitation problems all day long, but if you're not getting ahead of them, you’re just biding your time until the next breakdown.

This isn’t about adding another layer of paperwork to your day. This is about building a maintenance routine that actually works in the dirt and dust of a real job site, not just in the sterile environment of a service manual. It’s about being smart, not just busy.

A Maintenance Schedule That Works in the Field

The manufacturer’s service intervals are a good starting point, but let’s face it—they’re written for ideal conditions. Your JCB Loadall doesn’t live in an ideal world. It lives in the mud, the dust, and the pouring rain, often running ten hours a day. Your maintenance schedule has to reflect that hard reality.

Start with your hydraulic fluid. Don't just top it off—pull a sample every 500 hours and send it for analysis. When you get that report, don't just glance at the particle count. Look for tell-tale signs of water, glycol (a dead giveaway of a cooler leak), and shearing, which tells you the fluid's viscosity is breaking down. These are your early warning flares, long before the pump starts to scream.

Next up are your filters and strainers. The book might say 1,000 hours, but in a dusty, high-demand environment, that’s just asking for trouble.

Cut that interval in half. A suction strainer is a wear item, plain and simple. Trying to stretch its life to save fifty bucks is how you end up buying a five-thousand-dollar pump. It's the worst kind of math.

The Daily Walk-Around: Your Best Defense

The most powerful diagnostic tool you own is your own two eyes. A daily walk-around, when done right, can catch a budding problem before it takes your machine down. But you have to know what you’re looking for. Forget the tire-kicking and get focused on the hydraulic system.

Specifically, put your hands on the suction hose every single morning. Is it soft? Spongy? Do you see any chafing where it’s rubbing against the frame? Check the fittings at both ends. Any hint of weeping or dampness is a glaring red flag for a potential air leak. These little details are what separate a proactive tech from one who’s always putting out fires. Making this a habit is a cornerstone of job site safety and equipment reliability. You can learn more about building these routines in our JCB operator safety guide.

This proactive mindset is critical. The economic hit from hydraulic cavitation is massive for fleets running telehandlers like the JCB Loadall. Industry experts have noted a rise in cavitation incidents, driven by aggressive duty cycles and the tighter packaging of modern machines. As explained in this deep dive on how to avoid pump cavitation from the experts at Xylem, cavitation appears when the available suction head (NPSHa) drops below what the pump requires (NPSHr). Once that margin is gone due to a clogged strainer or a bad hose, you're on a fast track from noise to power loss, heat buildup, and total pump failure.

This checklist isn't meant for a clipboard in the office; it's a mental list you should run through out in the field.

Field-Ready Hydraulic Preventive Maintenance Checklist

This isn't a textbook checklist. It's a real-world guide for keeping your JCB Loadall's hydraulic system healthy under the tough conditions you actually work in.

| Check Point | Frequency (Under Heavy Use) | What to Look For | Why It Matters |

|---|---|---|---|

| Hydraulic Fluid Sample | Every 500 Hours | Water, high particle counts, fluid breakdown (shearing). | Catches contamination and wear metals before they cause a failure. |

| Suction Strainer & Filters | Every 500 Hours (or less) | Any visible debris, discoloration, or deformation. Don't clean—replace. | A clogged strainer is the #1 cause of cavitation and catastrophic pump failure. |

| Suction Hose Condition | Daily Walk-around | Soft spots, kinks, chafing, wet fittings. | A collapsed or leaking hose will starve the pump just like a clogged strainer. |

| Hydraulic Tank Breather | Every 250 Hours | Clogged with dirt or debris. | A plugged breather creates a vacuum in the tank, making the pump work harder to pull fluid. |

Sticking to this routine isn't about adding more work. It’s about doing the smart work that prevents the expensive, time-sucking breakdowns that absolutely kill your productivity.

Frequently Asked Questions From The Field

Out on a job site, you don't have time for a call center or a service manual that reads like a legal document. You've got work to do, and that grinding hydraulic pump is the only thing standing in your way. Here are the straight-up, no-nonsense answers to the questions we get every single day from operators wrestling with JCB Loadall hydraulic pump cavitation.

Can I Just Keep Running It If The Noise Isn't Too Bad?

Absolutely not. That whining or grinding sound isn't just an annoyance—it's the sound of your pump eating itself from the inside out. Every single minute you run a cavitating pump, those tiny imploding vapor bubbles are physically blasting metal off the pump's internal components.

What starts as a barely audible whine will eventually escalate into a gravelly roar. By that time, you've likely circulated a fine metal paste through your entire hydraulic system. That contaminates everything: valves, cylinders, and motors. Pushing through it is the difference between a hundred-dollar fix today and a ten-thousand-dollar system rebuild down the road.

Think of it like this: Running a cavitating pump is the same as running an engine with no oil. The outcome is identical—catastrophic, expensive failure. It’s not a question of if it will fail, but when.

Will Using Thicker Hydraulic Oil Stop The Noise?

This is a common piece of job-site advice, and it's completely wrong. In fact, using a hydraulic fluid with a higher viscosity (thicker oil) will almost always make your cavitation problem worse, especially on a cold start.

A thicker fluid is much harder for the pump to draw from the tank, which dramatically increases the vacuum on the suction line. This increased suction is exactly what causes the fluid to vaporize and form those destructive bubbles in the first place. You might mask the noise from worn parts for a little while, but you’re actually accelerating the cavitation and starving the pump even more severely. Always, always stick with the JCB-recommended fluid viscosity for your operating temperatures.

Is Cavitation The Same As Aeration?

They sound similar and both make a hell of a racket, but they’re two entirely different problems. Here’s the simple breakdown:

- Cavitation is when the pump boils the hydraulic fluid by pulling it under such a strong vacuum that it turns to vapor. It's a fluid restriction issue.

- Aeration is when the pump is sucking in outside air through a bad seal, a loose fitting, or a crack in a suction line. It's an air leak issue.

The sound is a bit different, too. Cavitation is often a high-pitched whine or a low rumble, like there's gravel in the pump. Aeration sounds more like rattling or banging, and you'll almost always see foamy, milky-looking fluid in the hydraulic tank. Both will destroy a pump, but you need to know which one you're hunting down to fix it.

Why Didn't The Onboard Computer Throw A Code?

Here's the biggest misconception that gets operators in trouble: thinking the machine's computer knows everything. The simple truth is that most JCB Loadalls do not have a sensor on the suction side of the hydraulic pump capable of detecting a vacuum or fluid restriction.

The machine's electronic control module (ECM) is completely blind to the mechanical problem that’s slowly killing your pump. It’s too busy trying to force a DPF regen or complaining about an AdBlue sensor to worry about actual mechanical failures.

You might get a low-pressure warning, but that only happens after the pump has failed and system pressure has already dropped off a cliff. By then, it's far too late. This is exactly why you can't rely on the "dealer laptop." You have to trust your own senses and a simple vacuum gauge to find the root cause. We believe in empowering technicians with the right parts and knowledge; you can learn more about our technician-focused approach and the reason we started this business.

When you're tired of waiting on the dealer and need the right hydraulic filters, hoses, and strainers to fix your JCB Loadall now, Flat Earth Equipment has your back. We stock the parts you need and ship them the same day, so you can get your machine off the sidelines and back to earning its keep. Get the parts you need at https://flatearthequipment.com.