When your JCB starts crawling or gets stuck in a never-ending regen cycle, you're almost certainly staring down an AdBlue pump failure. This isn't just a minor hiccup; it's a problem that brings expensive, critical equipment to a dead stop. You're looking at a JCB AdBlue pump replacement cost that can run anywhere from $2,500 to over $5,500, once you factor in parts, labor, and the brutal cost of downtime.

This guide is for the technician in the field, not the service manager sitting behind a desk. We're cutting through the dealer's BS to get your yellow iron back up and running. Fast.

What Is a JCB AdBlue Pump and Why Does It Fail?

Let's be honest: the Selective Catalytic Reduction (SCR) system on your JCB is a necessary evil, a complex piece of engineering forced on us by emissions standards like Tier 4 Final. Think of it as a little chemical factory bolted onto your exhaust, designed to turn toxic nitrogen oxides (NOx) into harmless nitrogen and water.

At the very heart of this finicky system is the AdBlue pump, also known as the Diesel Exhaust Fluid (DEF) pump. Its sole mission is to pressurize and inject a precise dose of urea solution—AdBlue—into the hot exhaust stream. When it works, you don't even know it's there. When it fails, your entire operation grinds to a halt.

The Real Problem on the Job Site

The frustration isn't just a broken part; it's the domino effect of downtime it triggers. The machine’s brain, the Engine Control Unit (ECU), expects a perfect, constant signal from the SCR system. When that AdBlue pump stumbles, the ECU panics and starts a countdown designed to force your hand:

- Engine Derate: The ECU slashes engine power, sometimes by over 40%, turning your powerful loader into an oversized paperweight.

- Forced Regen Cycles: The machine might get stuck in an endless regeneration loop, desperately trying to burn off soot it can’t treat without a proper AdBlue spray.

- "No Start" Countdown: Ignore the dashboard warnings long enough, and the machine will flat-out refuse to restart after you shut it down.

This is exactly where the dealership model fails the guy in the field. They want you to haul the machine to their shop, wait for them to plug in their proprietary "Service Master" laptop, and then wait again for parts to arrive on their schedule. We know that's not how you keep a job site profitable. If you want to know more about our mission to keep your equipment running, check out the story behind Flat Earth Equipment.

We're not just selling parts; we're providing a lifeline. When a machine is down, every single hour costs real money. Our goal is to get you the right component, fast, so you can fix the problem and get back to work without the dealership runaround and their precious laptop.

In the world of JCB telehandlers and backhoes, AdBlue pump failures are a massive headache. Field data from thousands of service reports show they account for 35-45% of all AdBlue system faults. This guide is your playbook for diagnosing the failure yourself, understanding the real costs, and getting the sensors, solenoids, and filters you need to bypass the dealer wait times.

AdBlue Pump Failure Quick Diagnostic Summary

To get a quick handle on the situation, this table breaks down the most common symptoms, their likely causes, and a ballpark cost for the fix. It's a fast way to gauge what you're up against.

| Symptom | Most Likely Cause | Estimated Cost (Parts & Labor) |

|---|---|---|

| Engine Derate Warning | Pump motor failure or pressure loss | $3,000 - $5,500 |

| AdBlue/DEF Warning Light On | Clogged filter or internal pump leak | $2,500 - $4,800 |

| Machine Stuck in Regen Loop | Incorrect dosing or sensor feedback | $3,200 - $5,000 |

| Fault Codes (SPN/FMI) | Electrical failure or sensor malfunction | $2,800 - $4,500 |

This summary gives you a starting point. Now, let's dive into the specifics of how to confirm the diagnosis on your own.

Decoding the Telltale AdBlue Pump Failure Symptoms

Before you even think about plugging in that laptop, your JCB is already screaming what’s wrong. You just have to know how to listen and what to look for. The machine doesn't whisper; its symptoms are loud, obvious, and costly if you ignore them. This isn't about deciphering some cryptic code—it's about recognizing the real-world signs that point directly to a failing AdBlue pump.

When that pump starts to go, it triggers a chain reaction that's impossible to miss. The machine's computer, the ECU, is programmed to protect the emissions system at all costs, even if it means shutting down your entire operation. It's a system designed by engineers in a lab, not by guys who have to get a job done in the mud.

The Dreaded Engine Derate and Dashboard Warnings

The first and most infuriating symptom is the engine derate, or "limp mode." This is the ECU’s nuclear option. When the AdBlue pump fails to deliver the right pressure, the NOx sensors down the line send a panic signal back to the brain. The ECU's response is to slash engine power—often by 40% or more—until the problem is fixed.

Suddenly, your telehandler can barely lift its own boom, and your backhoe struggles to climb a gentle slope. This isn't just an inconvenience; it's a safety hazard and a productivity killer. In fact, sudden engine derate is a massive problem across the industry. Reports from crane rental professionals revealed that AdBlue system failures were behind up to 30-33% of on-road breakdowns in their heavy equipment fleets. You can read the full update on AdBlue issues to see just how widespread this problem is.

Alongside the power loss, your dashboard will light up like a Christmas tree. Expect to see:

- A solid or flashing AdBlue/DEF warning light.

- A check engine light that refuses to go away.

- A text warning on the display, often showing a countdown to a "no restart" condition.

These aren't suggestions. They are ultimatums from a system that holds your uptime hostage.

Translating the Fault Codes Yourself

While the dealer wants you to believe you need their "Service Master" laptop, many common fault codes can be read with generic heavy-duty scanners. The king of all AdBlue pump failure codes is P20E8 - Reductant Pressure Too Low. If you see this code, your pump is almost certainly the culprit.

This code tells you the pump is not building enough pressure to properly atomize the AdBlue fluid in the exhaust stream. It's not a sensor issue or a fluid quality problem; it's a direct indictment of the pump itself.

When P20E8 shows up, stop wasting time on other diagnostics. The pump can't do its one job: create pressure. It’s the smoking gun that tells you exactly where to focus your attention and your budget.

Listening for the Sounds of Failure

Your ears are one of your best diagnostic tools. A healthy AdBlue pump makes a faint, consistent humming or whirring sound for a few seconds when you first turn the key to the "on" position. This is the priming cycle, where it builds pressure before the engine even starts.

Get familiar with that sound, because a change in it tells a story:

- Complete Silence: If you hear nothing when you turn the key, the pump's internal motor is likely dead. This could be from an electrical failure or a complete mechanical seizure.

- Loud Whining or Grinding: This is the sound of a pump struggling to build pressure. The motor is working overtime, often because of internal wear, a blockage, or crystallized AdBlue grinding away at its components.

If you hear that high-pitched whine, the pump is on its last legs. It's not a matter of if it will fail, but when—and it will likely be at the worst possible moment.

Spotting the Telltale Visual Cues

Finally, get out of the cab and do a walk-around. The signs of a failing system are often visible if you know where to look. Check around the AdBlue injector where it enters the exhaust pipe. A poorly pressurized system results in improper fluid atomization, causing the urea to "flash boil" and crystallize on contact.

Look for a build-up of white, crusty residue that looks like frost or salt. This is crystallized urea, a clear sign that the AdBlue isn't being injected as a fine mist but is instead dribbling out due to low pressure. This is wasted fluid and a clear indicator your pump isn't up to the task.

Why JCB AdBlue Pumps Fail in the Real World

That AdBlue pump on your JCB didn't just decide to quit for no reason. These things fail because they’re forced to operate in conditions that are a far cry from the clean engineering lab where they were designed. Understanding why they fail is the only way to stop the cycle of breakdowns and get ahead of the next one.

Out here in the dirt and mud, every component is under assault. The AdBlue pump is a precision instrument tasked with a dirty job, and it’s often the weakest link in a chain of interconnected, finicky electronics. The dealer will sell you a new pump, but they won't tell you how to stop the next one from dying an early death. That's our job.

The Slow Grind of Internal Wear and Tear

Think of that pump as the heart of your emissions system, constantly cycling on and off to maintain pressure. Every time you turn the key, it primes. Every time the system calls for a dose of fluid, it works. Over thousands of hours, this constant cycling leads to inevitable mechanical wear on the internal motor and diaphragm.

It’s a simple case of fatigue. The bearings wear out, the seals degrade, and the motor just gets tired. This isn't a sudden catastrophic event; it's a slow death by a thousand cycles, accelerated by the constant vibration and harshness of a construction site. Eventually, the pump can no longer generate the required 5-bar (75 PSI) of pressure, the sensors scream, and your machine goes into limp mode.

The pump isn't designed to last forever, but its life is cut drastically short by the brutal reality of field operations. It's a component built for a perfect world but forced to live in a harsh one.

Contamination: The Silent Killer

The single biggest enemy of your AdBlue pump is contamination. This system demands surgically clean, ISO 22241-compliant Diesel Exhaust Fluid. Even the smallest amount of dirt, dust, or tap water can wreck the pump from the inside out.

So, where does it come from?

- Dirty Jugs: Refilling from an open, dusty container or using a dirty funnel is like injecting poison directly into the system.

- Water Dilution: Topping off the tank with water, even distilled water, throws off the precise 32.5% urea concentration. This forces the pump to work harder and can cause crystallization.

- Fuel Contamination: Accidentally putting even a small amount of diesel in the AdBlue tank is a death sentence for the pump and the entire SCR system.

This contamination doesn't just clog the filter; it scores the pump's internal surfaces and destroys its delicate diaphragm. The result is a pump that can't build pressure, leading directly to that dreaded P20E8 fault code.

The Crystal Menace and Cold Weather Chaos

AdBlue has a nasty habit: when it dries, it forms hard, abrasive urea crystals. If the injector isn't atomizing the fluid correctly due to low pressure, these crystals build up in the lines and even inside the pump itself. These tiny, sharp particles act like sandpaper, grinding away at the pump's internals with every cycle.

Cold weather just makes everything worse. AdBlue freezes at -11°C (12°F). While JCBs have heaters in the tank and lines, a machine left overnight in freezing temperatures can still have frozen fluid in the pump. When you start it up, the pump tries to force a solid block of ice through its delicate system.

This starves the motor and can lead to immediate, catastrophic failure. You might hear a loud whine as it strains, and then... silence.

Common Causes of Pump Failure and Prevention Tips

To truly manage your fleet, you need to recognize these failure modes. It's not just about replacing a broken part; it’s about implementing smarter maintenance to prevent the failure in the first place. This table breaks down the most common ways these pumps die and what you can do about it out on the job site.

| Failure Mode | Primary Cause | Field Prevention Tip |

|---|---|---|

| Motor Burnout | Constant cycling and electrical fatigue | Ensure proper battery and alternator health to avoid voltage spikes. |

| Internal Contamination | Dirty DEF, water, or fuel | Use only sealed, new jugs of DEF and dedicated, clean funnels for refilling. |

| Urea Crystallization | Low pressure, improper shutdown | Allow the machine to complete its shutdown cycle, which purges the lines. |

| Cold Weather Seizure | Frozen AdBlue in the pump/lines | Allow the machine’s tank heater adequate time to thaw the fluid before heavy operation. |

Think of these tips as cheap insurance. A few extra minutes of careful handling can save you thousands in parts and downtime later on.

Diagnosing a Bad Pump Without the Dealer Laptop

Forget waiting around for a dealer tech to show up with their proprietary "Service Master" laptop. You don't need their permission—or their pricey software—to figure out what's gone wrong with your machine. This is your playbook for taking back control and diagnosing a failed AdBlue pump using just the tools you already have in your service truck.

The goal here is simple: get a conclusive diagnosis in the field, right now. No second-guessing, no waiting on a callback. Just a clear, confident answer so you can get the right part ordered and that yellow iron back to making you money.

The Essential Visual Inspection

First thing's first: use your eyes. A solid five-minute walk-around can tell you more than an hour hooked up to a diagnostic computer. Pop the engine cover and get a good look at the AdBlue pump module and everything connected to it.

You're hunting for the obvious signs of failure that sensors and software just can't see. These visual clues are often the most reliable smoking guns pointing directly to a bad pump.

What to look for:

- AdBlue Leaks: Check every fitting and line connected to the pump. You're looking for any wet spots or, more commonly, the tell-tale white, crusty residue of dried urea. A leak means a loss of pressure, plain and simple.

- Crystallization: Pay close attention to the pump's outlet port and the line heading to the injector. A heavy build-up of white crystals is a dead giveaway that the fluid isn't being properly pressurized and is drying out where it shouldn't be.

- Damaged Wiring: Trace the wire harness running from the pump. Look for any signs of chafing, pinching, or corrosion on the wires and connectors. Rodents absolutely love to chew on these things, and a single broken wire can take down the entire system.

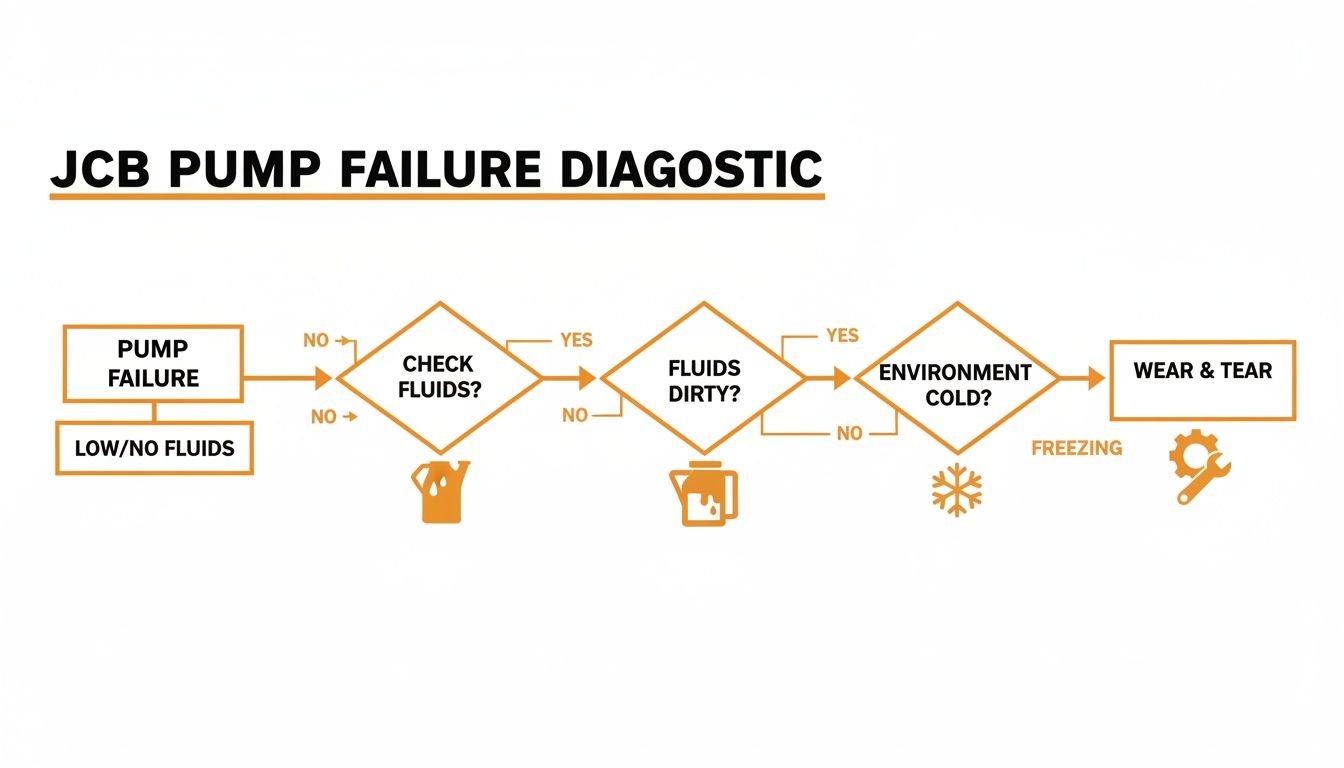

This visual roadmap is the fastest way to spot the root cause of many pump failures, from fluid contamination and freezing damage to simple, everyday wear and tear.

This decision tree shows how common issues like fluid contamination, freezing, and component wear lead directly to the pump failure symptoms you're seeing. The key takeaway? Most failures leave behind a physical trail you can find without ever plugging in a diagnostic tool.

Basic Electrical Checks with a Multimeter

If the visual inspection comes up clean, it's time to grab your multimeter. We need to confirm the pump is getting the juice it needs to run. Unplug the main electrical connector right at the pump and get ready to test the pins. Always remember to work safely—messing with electrical systems has its risks. For a good refresher, check out these guidelines for working safely around heavy equipment.

- Check for Power: With the key turned to the "on" position, probe the power supply pin in the harness connector. You should see a steady 12V or 24V, depending on your machine's electrical system. If you get no voltage, you've got a problem upstream—could be a blown fuse, a bad relay, or a break in the wire.

- Verify a Good Ground: Next, check for continuity between the ground pin and a clean, unpainted spot on the machine's frame. A weak or nonexistent ground will stop the pump from working correctly, even if it's getting full power.

If you've confirmed you have both solid power and a good ground right at the connector, but the pump is dead silent when you turn the key, you've just proven the pump's internal motor has failed. It's getting the command to work but is physically incapable of doing its job.

The Definitive Pressure Test

This is it—the final, undeniable test that separates a weak pump from a healthy one. You'll need a basic pressure gauge with the right fittings to tap into the outlet line coming from the pump. Disconnect the line, install your gauge, and turn the key to the "on" position.

A healthy pump will prime immediately, building pressure to at least 4-5 bar (around 60-75 PSI) within just a few seconds.

- If pressure builds and holds steady: Your pump is likely fine. The problem is probably downstream, maybe a clogged injector or a faulty sensor.

- If pressure is low, erratic, or zero: You've found your culprit. The pump is internally worn out or damaged and simply cannot build the pressure required.

This simple test gives you a definitive, data-backed conclusion. No dealer laptop, no guesswork—just a clear result that tells you it's time to order a replacement pump and get your machine off the sidelines.

Calculating the Real JCB AdBlue Pump Replacement Cost

Let's talk numbers—the real numbers, not the inflated quote the dealer’s service manager slides across the counter. Figuring out the true JCB AdBlue pump replacement cost goes way beyond the price of the part itself. It’s a painful equation of parts, labor, and the brutal cost of a machine sitting idle while you're on the clock. The dealer is banking on you not doing this math, but we will.

When that pump dies, you're looking at a total bill that can easily range from $2,500 to over $5,500. That huge gap isn't random. It’s a combination of the choices you make and the hidden costs that pile up faster than you can blink. Let's break this expense down so you know exactly what you’re up against and how to keep more of your hard-earned cash where it belongs.

Breaking Down the Part Cost: OEM vs. Aftermarket

The single biggest line item is, of course, the pump module. Right out of the gate, you have a choice to make: stick with the dealer's OEM part or go with a high-quality aftermarket alternative.

- OEM Pump: This is the one that comes in a JCB-branded box. You'll pay a serious premium for the name, with prices typically falling between $1,500 and $2,200. You’re paying for the brand, not necessarily for better quality, and you're stuck waiting on their supply chain.

- Aftermarket Pump: A quality aftermarket pump from a trusted supplier like Flat Earth Equipment is engineered to meet or exceed OEM specs. These parts deliver major savings, usually costing between $900 and $1,400 without sacrificing an ounce of performance or reliability.

The choice is pretty clear. Going with a trusted aftermarket supplier can save you nearly 40-50% on the part alone—money that goes straight back to your bottom line.

Factoring in Labor and Field Rates

Next up is labor. If you haul that machine to the dealership, you’re paying their inflated shop rate, which can be $180 per hour or more. A pump replacement is typically a 3 to 5-hour job, depending on how easy it is to get to on your specific machine. That’s a labor bill of $540 to $900 before they even start tacking on their mysterious "shop supply" fees.

Fixing it yourself or calling a trusted independent mechanic out to the field is always the smarter play. Even at a realistic field rate, you're in control of the timeline and the cost.

The real game the dealer plays is making you think their shop is the only option. The truth is, this is a straightforward replacement you can handle in the field with basic tools, saving you a thousand bucks in labor and transport fees.

The Hidden Costs That Bleed You Dry

This is the part of the bill the dealer never talks about, but it's where the real financial pain comes from. These are the costs that stack up every single hour that machine isn't moving dirt.

- Downtime: This is the absolute killer. A single down machine can cost a project $1,000 to $3,000 per day in lost productivity, missed deadlines, and crew wages. Waiting a week for a dealer appointment can turn a $3,000 repair into a $15,000 catastrophe.

- Transport: Hauling a disabled telehandler or backhoe to the dealership isn't cheap. You're looking at $300 to $600 or more each way for a lowboy, depending on the distance. That's money spent just moving your problem around.

- Related Parts: A failed pump often takes other components with it. You might need to replace a clogged AdBlue filter ($50 - $90), flush contaminated lines, or even swap out a fouled injector nozzle ($200 - $400).

When you add it all up—the inflated OEM part price, the high dealer labor rates, and the crushing cost of downtime—it's easy to see how a simple pump failure spirals past the $5,500 mark. By sourcing a reliable aftermarket part and doing the work yourself, you can cut that cost in half and get back to work in hours, not weeks.

Get the Right Parts and Get Back to Work

You've already done the hard part. You wrestled with the diagnostics out in the field, sidestepped the dealership's runaround, and nailed down the problem: a failed AdBlue pump. Now comes the critical part—getting a solution that respects your time and money. Letting your machine sit idle while you wait on the dealer’s supply chain isn’t a strategy. It's giving up.

This is where you regain control of the job. The only move that makes sense is sourcing parts from a supplier who actually understands the urgency of fieldwork. Forget the parts counter kid who thinks a solenoid is a type of battery. You need a partner who gets that when a JCB goes down, every tick of the clock costs you money.

Your Supply Line Built for the Field

At Flat Earth Equipment, we don't just ship boxes. We are your supply line, built from years of hands-on experience. We stock the exact-fit pumps, sensors, and filters you need because we've been there—miles from the shop, knowing "close enough" is the same as "wrong." Our parts are sourced for rock-solid reliability and dead-on fitment, so they work the first time, every time.

This isn't just about selling a part; it's about delivering a real solution. You need fast shipping from hubs that are actually close to you, minimizing downtime. You also need access to support from people who've actually turned a wrench on this stuff. That's the difference between being just another customer and being a partner.

When you're staring down a JCB AdBlue pump replacement cost that makes your eyes water, picking the right supplier is everything. We get it. That’s why we’re laser-focused on:

- Precision-Fit Components: No wrestling with parts, no guesswork. Just components engineered to meet or beat OEM specs right out of the box.

- Rapid Shipping: With parts staged in key hubs across the country, we get you what you need overnight, not next week.

- Expert Support: Got a question mid-install? You can reach a team that actually knows the machine you're working on.

For technicians who trust their own skills more than dealership bureaucracy, the choice is clear. Stop waiting and start fixing. If you have any questions or need to get a part heading your way today, get in touch with our team and let’s get that machine back on the job.

Frequently Asked Questions

When you're out in the field staring at a derated machine, you need straight answers, not a sales pitch. Here are the most common questions I get from other techs trying to wrestle these finicky JCB AdBlue systems into submission. No fluff, just the facts.

Can I Bypass or Delete the AdBlue System on My JCB?

Look, I get the temptation. It’s a constant headache, and the idea of just ripping it out is appealing. But the short answer is no, you shouldn't. While it's technically possible, deleting the AdBlue/SCR system is illegal in most places because it violates emissions laws, and the fines are no joke.

More importantly for your machine, it messes with the ECU. The machine’s brain is programmed to see signals from that SCR system. When they vanish, it can cause all sorts of unpredictable engine problems that are even harder to diagnose than the original fault. The smart, legal, and ultimately cheaper solution is to fix the system right with reliable parts.

How Do I Know If It's the Pump or the Injector?

This is the million-dollar question out on a job site. It’s easy to throw parts at a problem, but that gets expensive fast. The clues are in the codes and the pressure.

A failed pump almost always throws a P20E8 fault code for low DEF pressure. You’ll also notice the pump is either dead silent or making a hell of a racket. A clogged injector, on the other hand, usually won’t cause a low-pressure code. Instead, you'll see a heavy build-up of white crystals around the exhaust outlet or get codes related to dosing performance.

The definitive field test is to check the pressure. Hook up a gauge to the pump's outlet line. If that pump can't build and hold at least 4-5 bar (around 60-75 PSI), your prime suspect is the pump. End of story.

Does Using Cheap DEF Fluid Really Cause Pump Failure?

Absolutely. This is one of the fastest ways to kill a brand-new pump. I’ve seen it happen time and time again. Low-quality Diesel Exhaust Fluid is poison for these systems.

Cheap DEF is often loaded with impurities that clog the pump’s tiny internal filter and grind away at its components. It can also have the wrong urea concentration, which forces the pump to work overtime to meet the ECU's demands. Always, and I mean always, use DEF that meets the ISO 22241 standard and comes from a sealed, clean container. It’s the cheapest insurance you can buy.

How Long Should a JCB AdBlue Pump Last?

In a perfect world, an OEM pump might last between 3,000 and 5,000 operating hours. But we don’t work in a perfect world. We work in mud, dust, and freezing cold.

Out in the real world, with harsh temperature swings, constant vibration, and the ever-present risk of contamination, that lifespan can be cut in half. Proactive maintenance—like using quality fluid and checking for leaks—is the only way to squeeze every last hour out of it and avoid that surprise phone call about a machine that won’t move.

When downtime isn't an option and the dealer is weeks out, you need a better source for your parts. Flat Earth Equipment stocks the precision-fit pumps, sensors, and filters you need, shipped fast to get your yellow iron back to work. Get the right part the first time at https://flatearthequipment.com.