When your JCB 4CX starts feeling lazy in 3rd or 4th gear and that unmistakable burnt oil smell creeps into the cab, your transmission is cooking itself. Don't immediately assume it's some finicky electronic fault that needs the "Dealer Laptop". Nine times out of ten, JCB 4CX transmission overheating is a straightforward flow problem you can spot right from your seat, long before you need to call a suit from the dealership. The culprit is almost always a plugged-up oil cooler or a clogged filter choking the life out of your iron.

Diagnosing Transmission Overheating From the Operator's Seat

Forget about hooking up a diagnostic laptop for a minute. Your own senses—what you see, feel, and smell—are the best tools you have when that transmission temp light starts blinking. In my experience out in the dirt, the machine will tell you exactly what’s wrong long before any sensor decides to throw a code, force a "Regen," and lock you out. You just have to listen.

The powershift transmission in these machines is a workhorse, and that work generates a massive amount of heat. That heat is supposed to be carried away and dissipated by the oil cooler circuit. But when that circuit gets packed with clutch material, job site grime, and other junk, the oil temperature skyrockets. Hot oil thins out, losing its ability to protect the clutch packs, and that's when things go south fast.

The First Signs of Trouble

You’ll feel it first. It starts as a noticeable loss of grunt, especially when you're pushing into a pile or roading the machine with a heavy load. It feels like you're fighting the machine, or it might just stall out completely when you try to shift into higher gears. This isn't just a weak engine; it's the transmission starving for hydraulic pressure because the oil is too thin and hot to do its job.

Then comes the smell. That burnt, acrid odor of cooked transmission fluid is a dead giveaway. By the time you smell it, the damage is already starting. This is your immediate signal to check the oil cooler and filter. When the PS764 transmission oil gets over 100°C, the high-ratio clutch packs start to slip and fail, causing those stalls you're feeling. A healthy machine should hit around 1950 RPM in 4th gear during a stall test; a sick one will struggle to get past 1700 RPM.

The real problem isn't the machine; it's the downtime. Waiting for a dealer tech with his "Service Master" laptop to tell you what you already know—that your filter is clogged—is a waste of time and money. The goal is to identify the problem and get the parts you need without that delay. Flat Earth Equipment has the sensors and filters to get you running, bypassing the dealer wait times.

Field Diagnosis Symptoms vs Likely Causes

Here’s a quick-reference table to connect what you're experiencing in the cab to the likely culprits in the transmission cooling circuit. It’s a good starting point before you even grab a wrench.

| Symptom | What It Feels Like | Primary Culprit | Secondary Culprit |

|---|---|---|---|

| Power Loss | Machine feels weak, especially pushing into a pile. | Clogged Transmission Filter | Low Transmission Fluid |

| Stalling in High Gear | Engine dies when shifting to 3rd or 4th under load. | Clogged Oil Cooler | Failing Torque Converter |

| Burnt Oil Smell | A sharp, acrid smell from the transmission. | Clogged Oil Cooler | Internal Clutch Failure |

| Warning Light | Transmission temp light is flashing or solid. | Clogged Filter & Cooler | Low Fluid Level |

This table isn't exhaustive, but it covers the most common scenarios. As you can see, almost everything points back to a restriction in the cooling circuit.

Key Symptoms to Watch For

Keep your senses tuned for these red flags during operation:

- Sluggish Shifting: The machine hesitates or jerks between gears, and it gets worse as the machine heats up.

- Engine Stalls Under Load: When you push into a stockpile or try to climb a grade, the engine bogs down and dies instead of digging in.

- Flashing Warning Lights: The transmission temperature light on the dash is your final, screaming warning. Ignoring it is asking for a five-figure repair bill.

These clues all point directly to a restriction in the cooling circuit. This is your cue to park the machine, let it cool, and get your hands dirty with an oil cooler and filter check. Catching it now can turn a catastrophic failure into a simple fix.

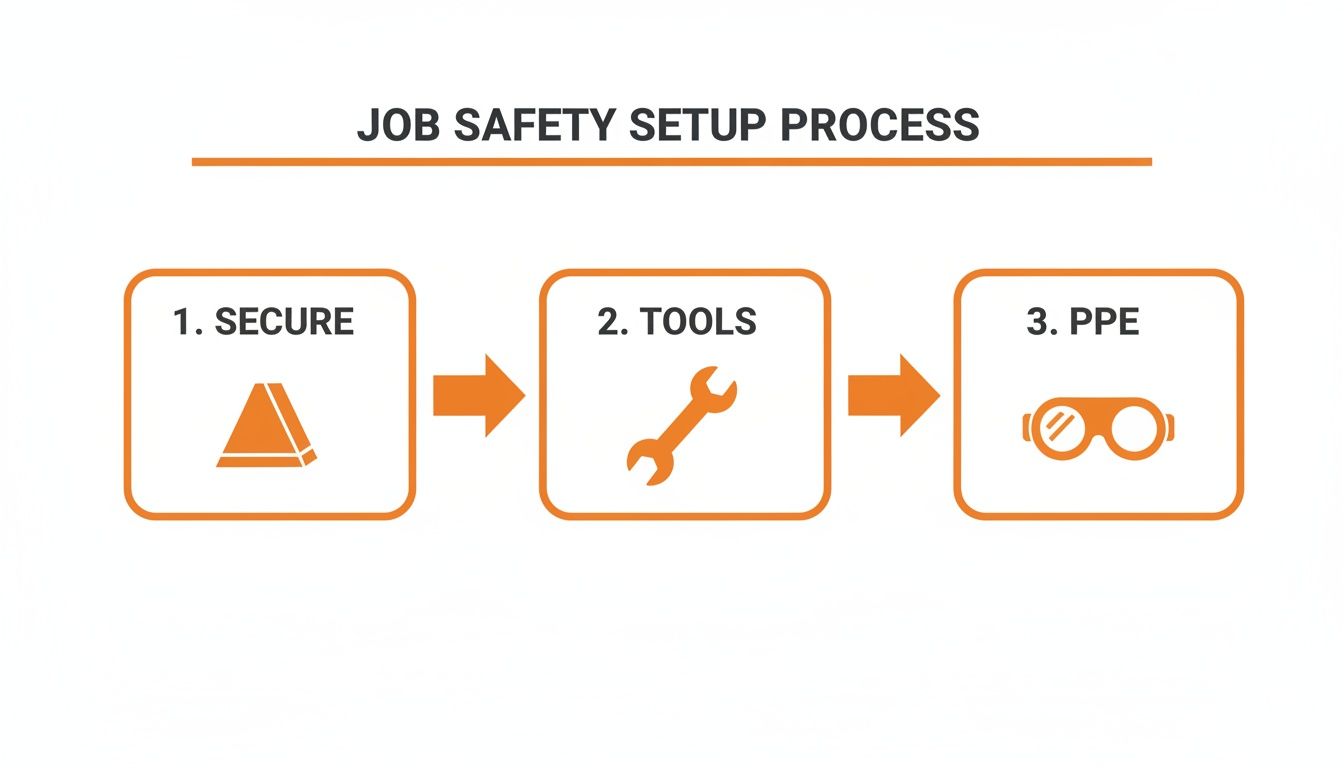

Gearing Up for the Job and Staying Safe

Alright, let's get set up. We aren’t tearing down the entire transmission on the job site, but you still need the right gear to properly inspect the oil cooler and filter. This is about fixing it in the field, not hauling it to the shop.

This isn't a job for a crescent wrench and a prayer. Having the right tools laid out before you start is the difference between a quick, professional fix and a day-long headache chasing your tail.

You’re going to need a solid set of metric wrenches and sockets, because JCB doesn’t mess with imperial sizes. Make sure you have a few different filter wrenches on hand. The cheap band-style ones can be useless in tight spots, so a cap-style wrench or even a big pair of channel locks is a must-have.

Don't forget a drain pan that’s big enough to handle a few gallons of hot, sloshing transmission fluid. The last thing you want is to create a superfund site on the ground.

Essential Tools for the Field

Here's the bare minimum kit I carry for this kind of work:

- Metric Wrench & Socket Set: A good 3/8" or 1/2" drive set will cover almost every fitting you'll run into.

- Large Drain Pan: Seriously, get something bigger than you think you need. Hot oil expands and splashes.

- Filter Wrenches: Keep a few styles in your toolbox. That filter won't always be cooperative.

- Torque Wrench: When you put the drain plug and new filter back on, you do it to spec. No guesswork.

- Infrared Thermometer: This used to be a "nice-to-have" but has become absolutely essential for me. Pointing it at the cooler's inlet and outlet hoses gives you instant, real-world data on whether the cooler is actually doing its job.

Safety First, Always

Now for the most important part: safety. This isn't office work. That transmission fluid can easily be over 100°C (212°F), and it will give you third-degree burns in an instant. It’s no joke. A face full of that stuff can end your career.

Securing the machine isn't just a suggestion; it's a requirement for staying in one piece. Loader bucket down, backhoe boom down and on the ground, park brake set, and wheels chocked. Never work under an attachment supported only by hydraulics.

Before a single drop of oil is spilled, you need the right Personal Protective Equipment (PPE). At a minimum, that means heavy-duty gloves and proper safety glasses—or even better, a full face shield. Don't learn this lesson the hard way.

For a deeper dive, review our guide on essential job site safety protocols and get your mind right before you even think about turning a wrench. Taking a professional approach is what separates a successful field repair from a trip to the emergency room.

A Hands-On Guide to Your Oil Cooler and Filter

Alright, let's get our hands dirty. I'm going to walk you through the entire transmission cooling circuit inspection, just like I would on a service call. Forget the Dealer Laptop or waiting around for a service truck—this is about you, your tools, and a methodical approach to finding the root of the problem.

This process isn't about throwing parts at the machine and hoping for the best. It's about finding evidence. We're hunting for the root cause of that JCB 4CX transmission overheating, and nine times out of ten, the trail starts right here with the oil cooler and filter.

Locating the Cooling Circuit Components

First things first, you need to know what you're looking at. On the 4CX, JCB tucks the transmission oil cooler into the main radiator stack at the very front of the machine. It's usually the smallest cooler in the group. If you're unsure, just trace the two hydraulic lines running from the transmission housing forward—they'll lead you straight to it.

The transmission filter is almost always a spin-on canister mounted on the side of the transmission case itself. It's typically painted black and might be partially hidden by a frame rail or some hydraulic lines, so have a flashlight handy. Once you've positively identified both, the real inspection can begin.

But before you even think about putting a wrench on anything, we need to talk safety. This isn't just a suggestion; it's a non-negotiable part of the job.

This simple flow—secure the machine, gather your tools, and put on your PPE—is the routine that keeps you safe when you're working around hot, high-pressure systems. Don't skip it.

Inspecting the Oil Cooler and Lines

Start with a simple visual check of the cooler. The fins should be straight and clean. It’s incredibly common to see them packed solid with a nasty combination of mud, grass clippings, and oily grime. That layer of filth acts just like a blanket, trapping heat and preventing air from passing through to do its job.

While you're there, check the cooler fins for physical damage. Bent fins are just as bad as dirt when it comes to blocking airflow. Next, carefully inspect the hose fittings at the top and bottom of the cooler. You're looking for any wet spots, drips, or grime buildup that indicates a slow leak. A low fluid level is a surefire way to cause a heat problem.

Performing a Transmission Filter Autopsy

Now for what I consider the most important part of this whole inspection: dealing with the filter. Get a drain pan underneath and slowly unscrew it. Be ready for hot oil to spill out.

Once the filter is off, don't just chuck it in the bin. We're going to perform an autopsy. The cleanest way is with a dedicated filter cutter, but a grinder or a hacksaw will work in a pinch. Just be extremely careful not to introduce any metal shavings from the cutting tool into the filter media.

Slice the can open and carefully pull out the pleated paper element. Unroll it and spread it out flat in your drain pan. Think of yourself as a detective, and this is your crime scene.

What you find inside this filter tells you the true story of your transmission's health. You're hunting for clues—shiny metal flakes, black friction material from the clutch packs, or chunks of rubber from a failing seal. This is crucial information the "Service Master" laptop will never give you.

A tiny amount of fine, dark silt is normal wear and tear. However, if you see any of the following, you've got much bigger problems on your hands:

- Brass or Bronze Flakes: This is material from bushings and thrust washers. It means there's serious internal wear happening.

- Steel Shavings: This is bad news. It could be from gears or bearings starting to come apart.

- Black, Gritty Material: That's friction material from your clutch packs, a sure sign they are burning up and failing.

This evidence is everything. The amount and type of debris you find will tell you if a simple filter and fluid change is enough, or if it’s time to start planning for a transmission rebuild. In the world of heavy equipment, the oil cooler circuit's health is directly tied to the transmission's lifespan. We know that at 100°C, the proper oil flow rate should be between 6.2 to 9.5 L/min. Anything less, often caused by a plugged filter or cooler, means your transmission is slowly cooking itself to death. You can learn more about the official JCB transmission check list and its specifications.

After your inspection, clean the cooler fins with low-pressure compressed air, always blowing from the engine side out towards the front. Then, grab your new filter. Wipe the sealing surface on the transmission housing clean, apply a thin film of fresh oil to the new filter's rubber gasket, and pre-fill the filter with fresh fluid. Spin it on hand-tight, then give it another quarter to half turn with your wrench. Done. You’ve just performed a vital diagnostic and service step that a dealer would charge you hundreds for.

Choosing the Right Transmission Fluid for Your JCB

A brand new filter and a spotless cooler are useless if you pump the wrong blood into the system. The dealer will try to sell you their gold-plated, JCB-branded oil, insisting it's the only thing that will work. That's a story for guys who don't pay their own bills.

Here's the truth: you need to meet the spec, not the brand name. Pouring cheap, universal tractor fluid into a 4CX powershift is the fastest way I know to smoke a set of clutch packs. I'll give you the real-world specs so you can find a high-quality aftermarket fluid that does the job without emptying your wallet.

Getting an Accurate Fluid Level Check

Checking the transmission fluid on a 4CX isn't like checking the engine oil. You can't just do it cold and expect an accurate reading. This machine needs to be at full operating temperature, running at a specific RPM, to get the level right.

Here’s the field-tested procedure that works every time:

- Warm It Up: Get the machine fully warmed up by working it hard for at least 15-20 minutes.

- Level Ground: Park on a perfectly flat surface. This is non-negotiable for an accurate dipstick reading.

- Engine Running: With the park brake locked on and the transmission in neutral, keep the engine running at a steady 1200 RPM.

- Check the Stick: Pull the transmission dipstick, wipe it completely clean, re-insert it fully, and then pull it again for your reading. The level should be right at the full mark.

Remember, overfilling is just as bad as underfilling. Too much fluid can foam up, causing erratic pressure and, you guessed it, more heat.

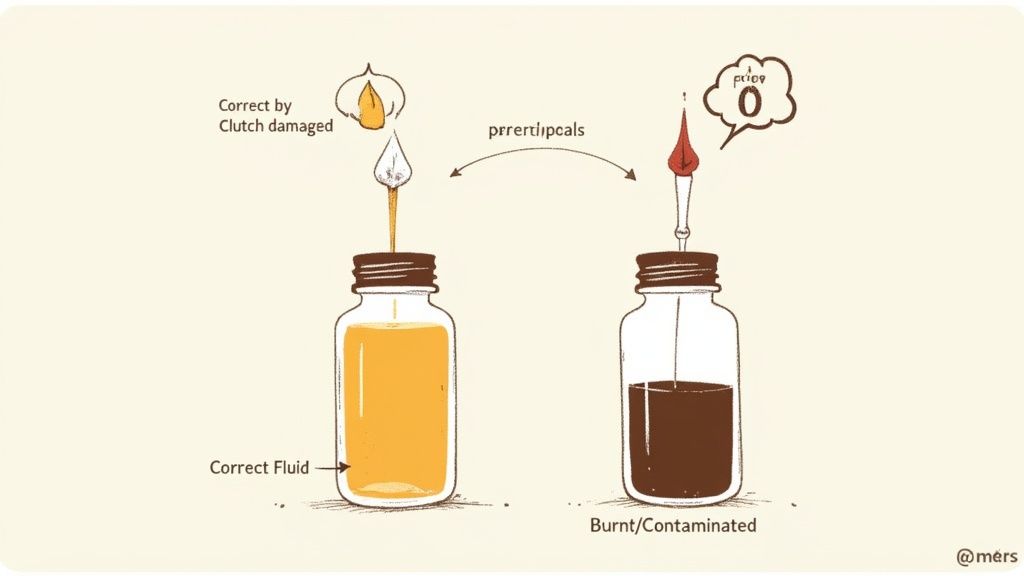

Reading the Story Your Oil Is Telling You

Before you even think about draining it, take a good, hard look at the old fluid on the dipstick. That oil holds secrets the dealer's laptop can't decode. The color and smell are vital clues about the health of your transmission.

This quick cheat sheet breaks down what you need to know about your 4CX's transmission fluid. It covers the specs, the right way to check it, and what the condition of the old oil really means.

JCB 4CX Transmission Fluid Cheat Sheet

| Check/Spec | JCB Requirement | Field Technician's Note |

|---|---|---|

| Fluid Specification | JCB Special Transmission Fluid EP10W or equivalent that meets JCB STD 4000/2200. | Don't fall for the "dealer-only" pitch. Any quality brand that meets the spec is fine. Just stay away from generic "universal" fluids—they'll cook your clutches. |

| Fluid Level Check | Engine at 1200 RPM, transmission in neutral, oil at full operating temperature. | The machine must be hot and running on level ground. Checking it cold will give you a false low reading, leading you to overfill it and cause foaming and overheating. |

| Normal Oil Condition | Clean, transparent, amber-colored fluid with a slight oily smell. | This is what you want to see. It means everything is likely running cool and there's no major internal wear or contamination happening. |

| Burnt Oil Condition | Dark brown or black fluid with a sharp, acrid, burnt smell. | Bad news. This confirms your overheating problem and is a dead giveaway that your clutch packs are getting cooked. A fluid and filter change is mandatory, but you might have deeper damage. |

| Contaminated Oil | Milky, cloudy, or foamy appearance. | You've got water or coolant in the transmission. This is an emergency. Water destroys the oil's lubricating properties and will rust internal components fast. Find and fix the leak immediately. |

The Dealer Laptop can tell you a sensor value is out of range, but it can't tell you the fluid itself has failed.

Think of the transmission fluid as a diagnostic report. Dark, burnt oil with a sharp smell screams cooked clutch packs. Milky, cloudy fluid means you've got water contamination, which will rust internal components and destroy lubrication.

These physical clues are what separate parts-changers from real technicians. Using the correct fluid at the precise level is the best insurance you can buy against a five-figure transmission rebuild.

And when you do need that filter or a new cooler, skip the dealer markup and the wait. Get the parts you need from a reliable source like Flat Earth Equipment and get back on the job.

Knowing When to Throw in the Towel and Where to Get Parts

Look, most days, we can tackle just about anything right there in the field with a solid set of tools and some hard-earned experience. But a huge part of being a good mechanic is knowing when you're beat. Knowing your limits is just as important as knowing your torque specs.

If you’ve gone through the whole process—the cooler is spotless, you've got a brand-new filter in, and the fluid is clean and correct—but that transmission is still cooking itself or spitting out metal, it’s time to stop. Pushing that machine any further is how a manageable repair turns into a catastrophic, budget-destroying failure. Don't be the guy who costs the company a new transmission because of stubbornness.

Red Flags That Scream Internal Damage

There are a few symptoms that are absolute deal-breakers. These aren't just suggestions; they are giant, flashing neon signs telling you the problem is deep inside the transmission housing, well beyond a simple cooling circuit fix.

If you spot any of these, it’s time to pick up the phone and call a transmission specialist:

- Consistent Metal Debris: You just changed the filter, ran the machine for maybe an hour, and the new filter is already glittering with fresh metal flakes. That means something inside is actively grinding itself into oblivion.

- Complete Failure to Engage Gears: The machine just sits there. No forward, no reverse, nothing. This is a classic sign of a failed torque converter or a grenaded clutch pack.

- Loud Grinding or Whining Noises: Any new, nasty mechanical sounds coming from the transmission under load are a dead giveaway of severe internal damage.

Here's a hard truth: ignoring the evidence is a costly mistake. Our data shows that skipping routine oil cooler and filter checks contributes to a staggering 40% of premature transmission failures in machines like the JCB 4CX. A seized gearbox can easily run $18,000 to repair, while a proactive filter swap costs about $200. It's simple math.

Bypass the Dealer and Get Back to Work

Now, for the parts you can replace—filters, sensors, solenoids, or even a complete oil cooler assembly—don't let yourself get stuck in the dealer's slow lane. You don’t have time to wait three days for a quote, only to find out the part you need is on backorder for a month.

This is all about cutting downtime and keeping that iron making money. Companies like Flat Earth Equipment stock the JCB-spec parts you need, ready to ship. You can get a quality filter or a new solenoid sent directly to your job site, often before the dealer has even found the part number in their system.

When your machine is down, every single hour counts. Get in touch with a parts specialist who gets it. You can contact them directly and get what you need without the usual runaround.

Common Questions from the Field

Out on the job site, I get the same questions over and over from operators and mechanics wrestling with a hot JCB transmission. There's a lot of bad advice floating around, so let's cut through the noise. Here are the straight answers, no fluff.

This isn't about some phantom electronic glitch the Dealer Laptop needs to find. It's about practical, real-world problems that show up in the dirt. These are the things you need to know to solve the JCB 4CX transmission overheating issue without getting stuck waiting on a service call.

How Often Should I Change My Transmission Filter?

JCB's book says change the transmission filter every 500 hours, and for once, I agree with them. However, that’s for ideal conditions, which almost never exist in the real world. If you're working in the brutal summer heat or a dusty quarry, you need to be more aggressive.

I tell every crew I work with to cut that interval in half—change it every 250 hours in severe conditions. A $50 filter is dirt-cheap insurance against a five-figure transmission rebuild. And if you just bought a used 4CX, change all the filters on day one. You have no idea what kind of neglect it's been through, and starting with a clean slate is the only smart move.

Can I Temporarily Bypass the Oil Cooler?

Absolutely not. Don't even think about it. I've seen guys try to limp a machine back to the shop by looping the cooler lines, and it always ends with a catastrophic failure. The powershift transmission generates a massive amount of heat, especially under load.

Bypassing the cooler is like trying to run your truck's engine without a radiator. You will cook the oil in minutes, warp the clutch plates, and turn a simple cooling problem into a complete transmission teardown. There are no shortcuts here.

The cooler is not an optional component. The system is designed as a whole, and removing any part of the cooling circuit guarantees you will destroy expensive internal parts. Fix the problem; don't create a bigger one.

My Cooler Is Clean But It's Still Overheating. What's Next?

This is a great question. If you've confirmed the cooler fins are clean, the filter is new, and the fluid is fresh and at the correct level, your next suspect is an internal flow restriction. The problem is now deeper than simple maintenance.

Grab your infrared thermometer and check the temperature of the inlet and outlet hoses on the cooler.

- If there’s a massive temperature drop (e.g., 200°F going in, 120°F coming out), you likely have an internal blockage inside the cooler itself.

- If both hoses are scorching hot with very little temperature difference, the cooler isn't dissipating heat, or the transmission is generating far more heat than it should due to internal failure.

At this point, you could be looking at a failing transmission oil pump, a collapsed internal hose, or a stuck bypass valve.

Will Using a Non-JCB Filter Void My Warranty?

If your machine is still under the factory warranty, you might have to play the dealer's game to avoid a fight. But let’s be real—most of this Yellow Iron is long out of warranty. For the rest of us, the answer is no, as long as you use the right part. We've built a whole business on this principle, and you can learn more about our philosophy on getting the right parts for yellow iron.

The key is to use a high-quality aftermarket filter that meets or exceeds the OEM specifications. Pay attention to the micron rating and the bypass pressure setting. As long as those match the JCB spec, your transmission will never know the difference, but your bottom line will.

Don't get stuck waiting for the dealer's parts counter. When you need the right filters, sensors, or cooler to get your JCB back to work, Flat Earth Equipment has you covered with quality parts that ship fast. Get what you need at https://flatearthequipment.com.