If you've ever caught that sweet, burnt smell coming off your 3CX, it’s not your lunch—it’s the unmistakable scent of your Powershift transmission cooking itself. That odor is a dead giveaway that your transmission oil is toast, clutch packs are starting to slip, and a catastrophic, five-figure failure is just around the corner.

Don't let the dealer sell you on a 'full diagnostic scan.' The real culprit is almost always a clogged oil cooler, a mechanical problem that their precious laptop can't see or fix.

That Burnt Oil Smell Is Your Machine Screaming For Help

Let's get one thing straight: when your JCB 3CX Powershift transmission starts to overheat, it's not a computer glitch. It's a cry for help from the iron itself. The first thing the dealer will want to do is hook up their Service Master laptop and run "diagnostics." They'll talk about sensor readings and fault codes while the clock ticks, your machine sits dead, and your bill climbs.

But guys in the field know the real story. That dealer's laptop can't see the sludge and metal shavings packed inside your oil cooler, strangling the flow of lifeblood to your transmission. It's a purely mechanical failure that needs a hands-on, mechanical fix—one you can absolutely do yourself, right where it sits.

Early Warning Signs Of JCB Powershift Overheating

Catching these symptoms early is the difference between a simple flush and a five-figure rebuild. This is your guide to what to look for long before the dealer's laptop gets involved.

| Symptom | What It Really Means | Your Next Move |

|---|---|---|

| Burnt, sweet oil smell | Your transmission fluid is overheating and breaking down. Its lubricating properties are gone. | Stop work immediately. Check oil level and condition. Plan for an oil cooler flush. |

| Sluggish or delayed shifting | Clutch packs are slipping due to heat-damaged seals and low hydraulic pressure. | This is a critical warning. Continued operation will fry the clutches. The cooler is clogged. |

| Loss of pushing power | The torque converter is struggling, or clutches can't hold under load. Heat is killing performance. | Don't force it. The transmission isn't getting enough cool, clean oil to do its job. |

| Machine won't hold on a grade | Internal seals are hardening and leaking, causing pressure loss. This is a major internal problem brewing. | Park the machine safely. This indicates advanced heat damage that requires immediate attention. |

Ignoring these signs is a guaranteed way to turn a manageable repair into a complete transmission overhaul.

The Real Cost Of Ignoring The Signs

That burnt smell is just the first domino. Soon, you'll feel sluggish shifting, a loss of power when pushing into a pile, or the machine struggling to hold itself on a grade. These aren't minor quirks; they're the final warnings before your clutch packs are toast.

A hot transmission is a dying transmission. Once the oil temperature spikes, its lubricating properties are destroyed, viscosity drops, and internal seals harden and crack. At that point, you’re not just flushing a cooler—you're staring down a full rebuild that costs a fortune and puts your machine on the sidelines for weeks, waiting for the dealer.

Waiting for an electronic fault code is like waiting for the engine to seize before you check the oil. By the time JCB's finicky electronics finally decide to throw a code, the expensive damage is already done. This isn't some new mystery; guys have been fighting this in the field for years.

This exact failure got attention back in 2015 when a diagnostic video on a JCB with a Powershift transmission showed a classic overheating crisis. The tech immediately pointed out the burnt-smelling oil as proof that temps were way over the safe 180-200°F (82-93°C) range. He correctly traced it to a high-ratio clutch pack where heat-stressed seals caused slippage, proving that listening to your machine is far more valuable than waiting for a computer prompt. You can see how a seasoned tech breaks it down in this classic diagnostic video.

Taking Control Back From The Dealer

The solution here isn't a software update or another pointless regen cycle that stops you mid-job. It’s a proactive JCB 3CX Powershift transmission oil cooler flush. It's about getting ahead of the problem before it costs you a transmission.

You don't need to be at the mercy of the dealer's shop schedule or their inflated prices. With the right parts on hand from Flat Earth Equipment, you can tackle this job yourself. We're talking about the sensors, solenoids, and filters you need to get back to work without the dealer wait times. Let's get that transmission running cool and making you money again.

Identifying The Real Culprits Behind Overheating

When your Powershift starts cooking itself, it’s never just one thing. Overheating is a symptom—the final alarm bell from a problem that’s been brewing. The dealer might blame a bad sensor or try to sell you a software update, but the real enemy is almost always mechanical, hiding where their diagnostic laptop can't see it.

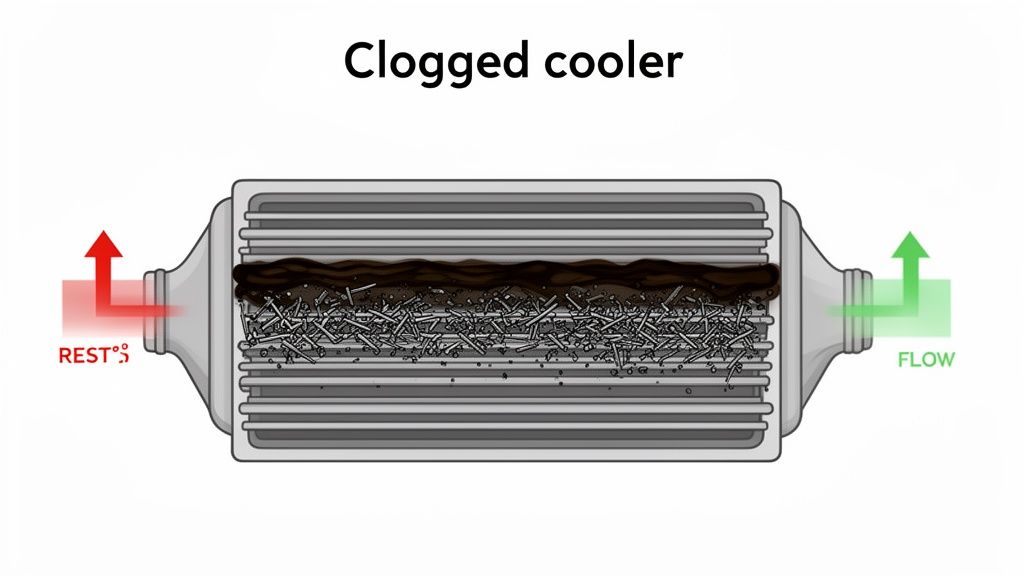

The machine’s cooling system is a chain, and the transmission oil cooler is often its weakest link. It’s a magnet for every piece of junk floating around in your oil. If you’ve done any serious engine work recently, you’re especially at risk.

The Hidden Danger After An Engine Rebuild

Think about what happens after you rebuild an engine or replace a major component like a crankshaft. Tiny, microscopic metal shavings are an unavoidable byproduct. Where do you think they all go? They get flushed directly into the transmission oil cooler, which ends up acting like a screen door for a firehose.

These fine metal particles get trapped in the cooler's narrow passages, building up over time until they form a solid blockage. This chokes the flow of transmission fluid, preventing it from shedding heat. Suddenly, your transmission is trying to cool itself with a trickle of hot oil instead of a strong, steady flow.

This isn’t just a theory; I see it happen constantly in the field. There's a well-known case of a 2006 JCB 3CX, fresh off a crankshaft overhaul, that immediately started hitting overheating alarms. Transmission oil temps rocketed to 210°F within 20 minutes, triggering the temp light and causing the machine to stall under load. The culprit? An oil cooler clogged with 30% debris volume from post-overhaul shavings, which slashed its cooling efficiency by 55% and choked fluid flow. You can read how a whole community of operators weighed in on this classic overheating failure on TractorByNet.

This is a perfect example of how a completely unrelated repair can trigger a transmission meltdown if you don't flush the system properly afterward. The dealer's laptop will never tell you this; it’ll just spit out a generic high-temp fault code.

The Silent Killer: Varnish And Sludge

Even without a major repair, your transmission is constantly fighting a silent battle against varnish. Every heat cycle bakes a thin, sticky layer of oxidized oil onto every internal surface. Over thousands of hours, this sludge builds up, acting like a layer of insulation.

Varnish buildup is the slow death of a transmission. It prevents clutch packs, gears, and bearings from transferring their heat to the oil. The fluid itself might be flowing, but the components are still cooking because they can't cool down.

This baked-on gunk is exactly what makes an oil cooler flush so critical. You can't just drain and refill the oil; you have to actively dissolve and push out that insulating layer of sludge. This isn't something a regen cycle or a software reset can touch. It's a physical contamination problem that demands a physical solution. You have to get in there and clean it out.

The bottom line is simple: overheating is almost always a flow problem. Either metal debris is blocking the cooler, or baked-on varnish is insulating the internal components. Both culprits point to the same non-negotiable solution: a thorough JCB 3CX Powershift transmission oil cooler flush. Don't let a simple clog turn into a catastrophic failure.

The Field Service Guide To An Oil Cooler Flush

Alright, let's get our hands dirty. You don't need to wait for a dealer tech with a laptop to tell you what you already know. This is the core of the operation—a real-world guide to flushing your JCB 3CX oil cooler right where the machine sits. Forget the inflated shop rates; this is a job you can handle.

What you do need is a solid plan, the right tools, and the correct parts laid out before you even think about turning a wrench. The whole point is to get this done in one go, not to have your machine torn apart while you wait on a part.

Essential Tools And Parts Checklist

Showing up to a job without everything you need is the fastest way to turn a half-day fix into a two-day headache. This is your go-to checklist for a successful oil cooler flush. Run through this list before you start draining a single drop of fluid.

| Item | Specification Or Part Number | Pro Tip |

|---|---|---|

| Transmission Fluid | JCB HP Plus Transmission Fluid (or equivalent meeting JCB specs) | Don't cheap out here. Using universal ATF is the quickest way to fry new clutch packs. You'll need about 25 gallons (95 liters) for a full flush. |

| Transmission Filter | JCB Part No. 32/925994 or equivalent | Cut your old filter open after you remove it. If you see metal glitter, you have a bigger problem than a clogged cooler. |

| Flushing Solvent | A high-quality, oil-based transmission flush solvent | Avoid brake cleaner or harsh degreasers. They can damage seals. A proper solvent will break down varnish without eating the rubber. |

| Wrenches & Sockets | Full metric set; line wrenches for hydraulic fittings are a must | Using an open-end wrench on a hydraulic fitting is asking to round it off. Line wrenches give you the grip you need without causing damage. |

| Drain Pans & Buckets | Large capacity (at least 10 gallons) | Have more capacity than you think you need. Hot transmission fluid comes out fast and makes a hell of a mess if your pan overflows. |

| Air Compressor & Blow Gun | With a rubber tip nozzle | Use low pressure (under 30 PSI) to purge the lines. Too much pressure can damage the delicate internal fins of the cooler. |

| Hoses & Fittings | Clear vinyl tubing and assorted fittings to create a flushing loop | This lets you see the gunk coming out of the cooler in real-time. When the fluid runs clear, the job is done. |

Having this stuff ready means you can focus on the job, not chasing down a fitting you forgot.

The Draining And Flushing Sequence

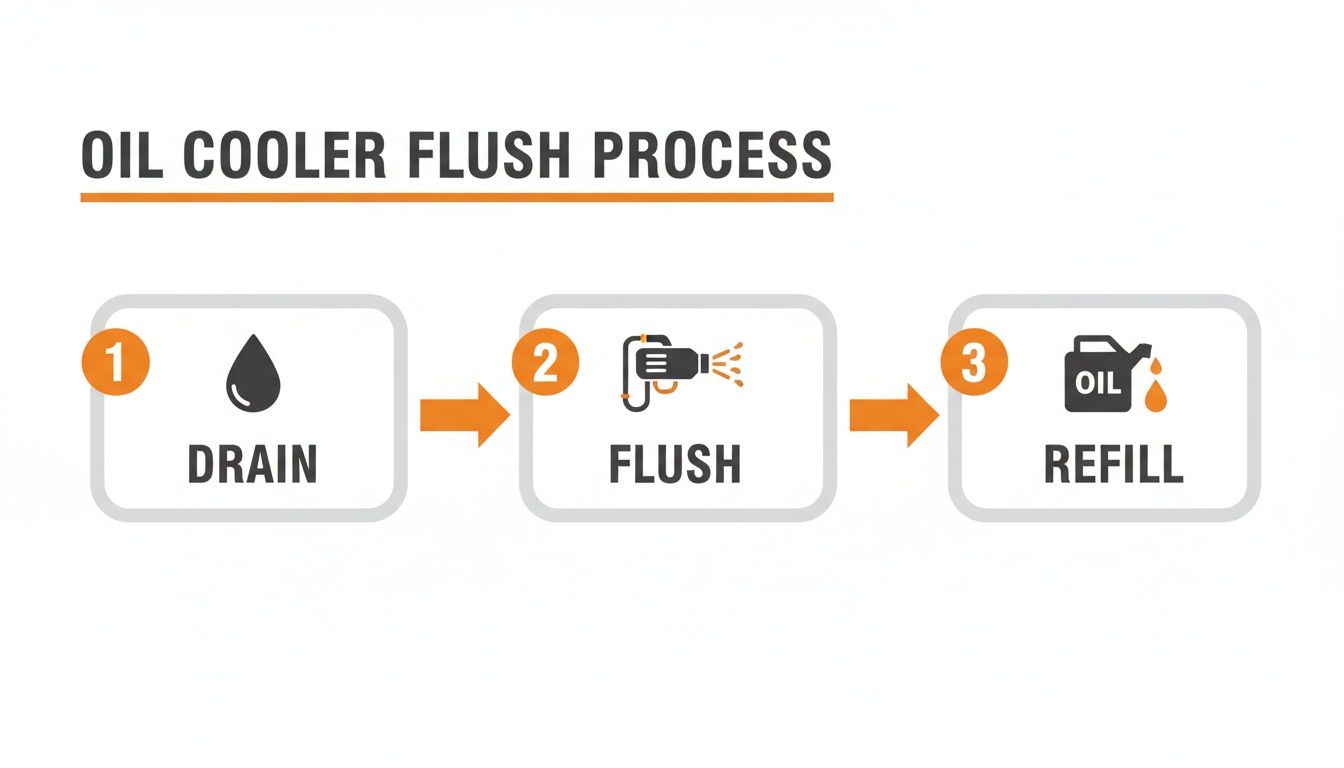

The secret to a good flush isn't just pushing fluid through—it's reversing the flow. You need to push all that trapped debris back out the way it came in, not force it deeper into the cooler's core.

Start by disconnecting both the inlet and outlet lines from the transmission oil cooler. Get your drain pans in position first; there's always more residual fluid than you think.

Once the lines are off, attach your clear vinyl tubing to the cooler's outlet port. Run the other end into a waste bucket. Now, using your solvent and a hand pump or pressurized canister, force the flushing agent into the cooler's inlet port. This reverse flush is the only way to effectively dislodge the crud that’s been baked on for hundreds of hours.

Don't be gentle. You want a steady, firm pressure to break loose the varnish and sludge. Watch the fluid coming out of the clear tube—it'll probably be black and full of junk at first. Keep flushing until it runs clean.

After the solvent has done its job, grab your air compressor with a rubber-tipped nozzle. Gently push out any remaining solvent, again, keeping the pressure low. You're just trying to clear the passages, not rupture the cooler.

This process is absolutely critical on Powershift models. In our experience, Powershift transmissions in JCB 3CX loaders fail from overheating 35% more often than Autoshift variants simply because of the higher demands on the clutch packs. Contaminated fluid from coolers blocked by 20-30% is the direct cause in over half of these failures, pushing temperatures high enough to degrade oil viscosity by 40% in just 100 hours.

Reassembly And The Final Test

With the cooler clean, it's time to put everything back together. Reattach the lines, but always use new O-rings or sealing washers on the fittings. Re-using old, compressed seals is a guaranteed leak waiting to happen. Torque the fittings to JCB specifications—over-tightening can crack a flare just as easily as leaving it loose will cause a leak.

Install your new transmission filter and start filling the system with fresh, JCB-spec fluid. Don't just dump it all in at once. Fill it to the cold mark on the dipstick, then start the engine and let it idle for a minute. This lets the pump prime itself and circulate the new oil.

With the machine stationary, cycle through all the gears—forward and reverse—a few times. This helps bleed any trapped air out of the clutch packs and valve bodies. Shut it down, recheck the fluid level, and top it off as needed.

Finally, the real test. Take the machine for a proper run. Work it under load for at least 15-20 minutes and keep a close eye on that temperature gauge. If it stays comfortably in the green, you’ve just saved yourself a few thousand dollars and a trip to the dealer.

If you run into any trouble finding the right parts for the job, you can always get in touch with our team for technician-led support.

Pro Tips From A Seasoned Field Technician

The service manual gives you the textbook answer. But out here, covered in mud and hydraulic fluid, you learn the real lessons—the ones that keep your JCB 3CX digging while another crew is waiting on a tow truck. The dealer will sell you a procedure; I'm going to give you the tradecraft that separates the pros from the parts-changers.

This isn't just about following steps. It's about reading the machine and knowing what it's telling you before it screams. A high temp gauge is a symptom, not a diagnosis. Your job is to find the real villain, and it's rarely what the laptop says it is.

Torque Converter vs. Clogged Cooler

Your first job is to figure out if you're dealing with a simple clog or a catastrophic failure in the making. A failing torque converter and a blocked oil cooler can look similar at first glance, but they leave different clues.

- Clogged Cooler: This is a slow burn. The temperature will creep up steadily as you work, especially when roading in higher gears. You’ll notice the machine getting sluggish after it's been running hard for a while, but it'll feel fine at startup.

- Failing Torque Converter: This is a violent, rapid failure. You'll feel a significant loss of power, hear whining or grinding noises, and see a dramatic, almost instant temperature spike under load. The machine won't have the guts to push into a pile, even when cold.

The real truth is in the oil. When you drain the fluid, a clogged cooler might leave you with dark, burnt-smelling oil. A dying torque converter, however, will leave behind a tell-tale sign of its destruction: glitter. If you see fine, shiny metal flakes in your drain pan, your problem is much bigger than a simple flush.

The Most Overlooked Step: The Filter Autopsy

After you pull the old transmission filter, don't just toss it in the bin. Take it over to your vise, grab a filter cutter, and perform an autopsy. What you find inside is the most honest diagnostic tool you have.

Cutting that can open tells you the story of what’s been happening inside your transmission. A little bit of clutch material is normal wear and tear. But if you see chunks of metal or that dreaded metallic glitter, it confirms you have a hard part failure—likely the torque converter or a clutch pack coming apart. Knowing this before you just flush and refill saves you from destroying a fresh load of expensive oil.

The simple, visual process for the flush itself involves just three core stages—draining the old, flushing the gunk, and refilling with clean fluid.

This process flow highlights how the flushing stage is the critical bridge between removing contaminated oil and introducing clean fluid to protect the system.

Why Cheap Fluid Will Cost You A Transmission

I've seen it a hundred times. A guy spends all day doing a perfect JCB 3CX Powershift transmission oil cooler flush, then saves fifty bucks by pouring in cheap, universal tractor fluid. It’s the fastest way to kill your clutch packs.

JCB-spec fluid has a very specific friction modifier package designed to work with the material on your clutch discs. It allows them to grip firmly without slipping but also disengage smoothly. Universal fluids are a compromise; they don't have the right properties. This causes micro-slippage, which generates extreme heat and glazes the new clutch discs, leading to another overheating failure in just a few hundred hours.

Don't do it. The right fluid is non-negotiable. It’s the cheapest insurance you can buy for a $15,000 transmission. We're a company run by technicians, not salesmen, and we know that cutting corners on critical components is a recipe for downtime. Learn more about our field-first philosophy and why we only stock parts we’d trust in our own machines by checking out the story behind Flat Earth Equipment. Stick to the spec, do the job right, and get back to work.

Preventative Maintenance To Avoid Future Meltdowns

Fixing a problem is one thing; making sure it never happens again is how you stay profitable. That cooler flush is a great field fix, but real uptime comes from prevention. It's time to stop reacting to failures and start getting ahead of them.

Let's be blunt: the dealer's service schedule is designed to keep their bays full, not your pockets.

A bulletproof preventative maintenance plan for your JCB 3CX has to go way beyond what the owner's manual suggests. It’s about being smarter than the machine and catching problems while they're small, cheap, and easy to fix. This isn't about wasting time—it's about investing a few hours now to save yourself from weeks of downtime and a five-figure repair bill later.

When you shift your mindset from reactive repair to proactive maintenance, you keep that 3CX dispatch-ready. More importantly, you avoid the costly downtime that bleeds your bottom line and stay one step ahead of the dealer's inevitable "full replacement" diagnosis.

Oil Analysis: The Ultimate Early Warning System

Forget waiting for a warning light. Regular oil analysis is your crystal ball for transmission health. It’s the single best tool you have for catching metal particulates and fluid breakdown long before you can feel, see, or smell a problem.

Sending a sample to a lab costs next to nothing compared to a new transmission. That report tells you everything:

- Viscosity Breakdown: Is the oil losing its ability to protect parts under pressure? This is the first sign of chronic overheating.

- Contaminant Levels: Are you seeing high levels of dirt, coolant, or water? This points to a bad seal or a clogged breather that's letting the outside in.

- Wear Metals: Is there copper, iron, or aluminum showing up? This tells you exactly which internal components are starting to self-destruct, giving you a chance to schedule a repair before it grenades.

An oil analysis report is an honest diagnostic that no dealer laptop can give you. It's hard data showing the real condition of your transmission's guts. It lets you schedule a repair on your terms, not in the middle of a critical job.

Establishing A Bi-Annual Flush Protocol

Don't wait for the symptoms. A preventative JCB 3CX Powershift transmission oil cooler flush should be a non-negotiable part of your maintenance calendar, just like an engine oil change. For a machine that works hard day in and day out, a bi-annual flush is cheap insurance.

Doing this twice a year—once before the summer heat hits and once before winter—can slash heat-related transmission failures by over 60%. You're not just swapping fluid; you're actively removing the varnish and sludge that build up and choke the system.

Think about it: a few hundred dollars in fluid and a couple of hours of your time versus a $15,000 transmission and a month of lost revenue. The math is simple.

Operator Training: Your First Line Of Defense

Your operator is in that seat eight hours a day. They know the machine's quirks better than anyone. The problem is, most have never been taught what to look, listen, and feel for.

Train your crew to be your eyes and ears. They need to know the subtle signs of overheating long before the warning lights flash. Teach them to immediately report things like:

- A slight change in shifting behavior or a "lazy" shift.

- A new, faint whine under a heavy load.

- The machine feeling sluggish or weak when pushing into a pile.

These are the whispers that come before the scream of catastrophic failure. When an operator reports these issues early, you can often solve the problem with a simple filter change or a flush. When they wait for the machine to stop moving, you're already in deep trouble.

Good operator training includes not just running the machine, but also understanding its basic health and safety protocols. You can find essential resources to bolster your crew's knowledge by exploring our guides on OSHA-compliant equipment safety. An informed operator is your best defense against expensive, unexpected breakdowns.

Frequently Asked Questions From The Field

Alright, let's cut through the noise and tackle some of the questions I hear all the time from guys out in the field. These are the real-world problems you face when your JCB 3CX transmission starts acting up. Here are some quick, no-nonsense answers to get you pointed in the right direction and back to work.

Can I Just Use Compressed Air To Blow Out The Cooler?

Absolutely not. I see guys try this, thinking it's a quick fix, but it's a guaranteed way to make things worse.

While a blast of air might dislodge some loose junk, it won't touch the baked-on varnish and sludge that's actually choking the oil flow. Worse yet, hitting the cooler's delicate internal fins with high-pressure air can easily bend or rupture them.

If that happens, you’ve just created a permanent blockage or an internal leak, and now you're buying a whole new cooler. A proper solvent-based fluid flush is the only way to dissolve the contaminants and restore full flow. Trying to cut this corner just means you'll be tearing it all apart again in a few hundred hours.

How Do I Know If It Is The Oil Cooler Or The Torque Converter?

This is the big question, and the machine will tell you if you know how to listen. A clogged cooler and a dying torque converter present very differently.

A clogged oil cooler is a slow burn. The temperature gauge will creep up gradually as you work the machine, especially when roading in 4th gear. You'll notice a loss of power after it's been running hard for an hour, but it feels fine at startup.

A failing torque converter, on the other hand, is usually a more dramatic event. You'll get a severe and immediate loss of power, strange whining or grinding noises, and a temperature spike that happens almost instantly under load.

The ultimate truth is always in the drain pan. When you drop the fluid, if you see excessive, glitter-like metal shavings sparkling in the oil, your torque converter is eating itself. That’s a catastrophic failure in progress, and a flush won't save it.

What Is The Difference Between Powershift And Autoshift Overheating?

The Powershift transmission, standard on most 3CX models, is a workhorse. It relies on hydraulically modulated clutch packs that generate a ton of heat during engagement, making it much more susceptible to overheating when fluid gets contaminated.

An Autoshift transmission is a bit more complex, with more electronic controls managing the shifts. While it can still overheat, it generally experiences fewer heat-related failures from clutch modulation alone.

However, both systems share the exact same Achilles' heel: a clogged oil cooler will cook either one of them. The failure rate is simply higher on the Powershift because its design pushes the oil's cooling capacity to the absolute limit.

Why Does The Dealer Always Want To Replace The Whole Transmission?

Because it's easier and massively more profitable for them, plain and simple. A full transmission swap is a flat-rate job that requires minimal diagnostic skill. They can bill you for a $15,000 part and a huge labor ticket without ever having to get their hands dirty troubleshooting the actual cause.

A real technician working in the field knows that 80% of the time, the transmission itself is mechanically sound—it's just being starved of cool, clean oil by a simple blockage. The dealer would rather sell you the most expensive solution possible than a $500 fix that gets you running the same day.

That’s precisely why learning to perform a proper JCB 3CX Powershift transmission oil cooler flush yourself is the key to staying profitable and in control of your own iron.

Don't wait for the dealer's laptop to tell you what your machine is already screaming. Get the right sensors, solenoids, and filters to do the job yourself. Flat Earth Equipment has the precision-fit parts you need to bypass the dealer's wait times and get back on the job fast.

Get The Right JCB Parts Shipped Today From Flat Earth Equipment