When you're comparing Jaltest and CAT ET for skid steer diagnostics, it boils down to one thing: who's in control?

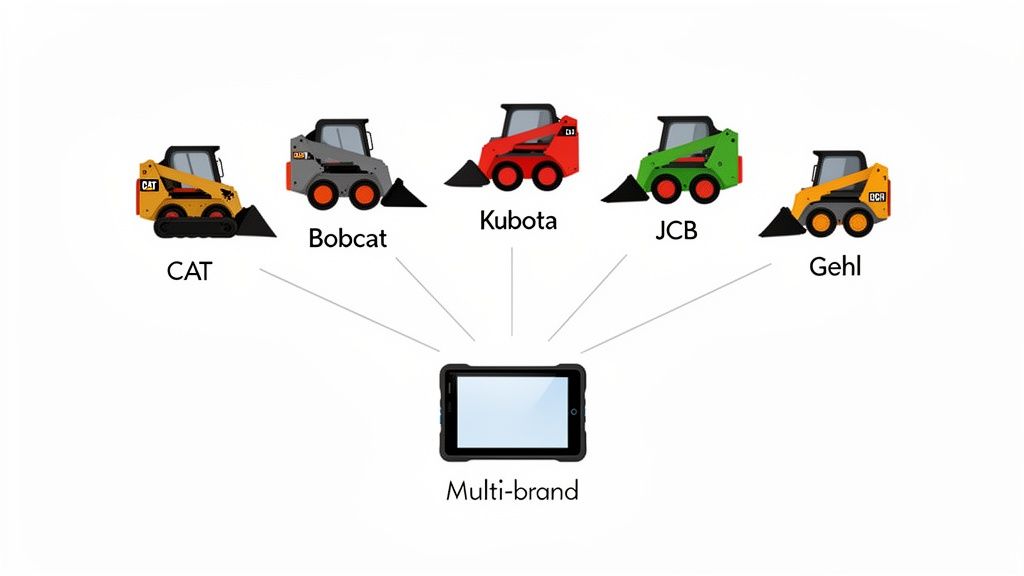

CAT ET is a scalpel. It gives you deep, factory-level diagnostics for one brand, but it also chains you to the dealer's ecosystem. On the other hand, Jaltest is the master key. It cracks open powerful capabilities across a whole fleet of iron—CAT, Bobcat, JCB, you name it—and snaps the chain of dealer dependency for good.

The Real Cost of Being Chained to a Dealer Laptop

Every one of us knows this scene by heart. A skid steer goes down mid-job, the dash is lit up like a Christmas tree, and the machine is derating. You call the dealer, and the story is always the same: they’ll try to get a tech out in a day or two. That’s a full day of lost revenue, a crew standing idle, and a service bill that's guaranteed to make you wince.

This is the hard reality of being held hostage by the "Dealer Laptop." For Caterpillar, that tool is CAT ET. For us JCB guys, it's Service Master. It’s a powerful piece of software, no doubt. But it's also a leash, designed to drag you right back to their service bay for every little hiccup. We're talking about simple fixes that spiral into major downtime.

This isn't just an inconvenience; it's profit bleeding out while you're stuck waiting. Every hour a machine sits is an hour it's not earning money. The dealer model is built on your downtime.

Why Dealer Exclusivity Is the Real Enemy

Look at any real job site—it's a mixed bag of yellow iron. You’ve got a CAT skid steer working next to a JCB telehandler and a Bobcat excavator. Relying on a single-brand tool like CAT ET means you're helpless the second any other color machine throws a code. It's a system built to benefit the OEM, not the guys in the field trying to get a job done.

These are the pain points that grind us all down:

- Forced Regens: The machine shutting down in the middle of a critical pour because the DPF cycle suddenly decides it's time. This is the villain that stops the job cold.

- Finicky DEF Systems: Constant alerts from a cheap sensor you could swap in ten minutes, but the system needs the dealer's software to clear the code. JCB's AdBlue systems are notorious for this nonsense.

- OEM Lockouts: Simple calibrations for a new joystick or solenoid that are intentionally locked behind proprietary software, forcing you to make that expensive service call.

| Attribute | The Dealer Model (CAT ET) | The Independent Model (Jaltest) |

|---|---|---|

| Brand Access | Single brand only (Caterpillar) | Multi-brand (CAT, Bobcat, Kubota, JCB, etc.) |

| Control | OEM holds the keys; you wait for them | You control the diagnostics and repair timeline |

| Workflow | Wait for a dealer tech to arrive on-site | Diagnose and fix it yourself, immediately |

| True Cost | High service fees + costly equipment downtime | Upfront tool investment + massive savings on downtime |

This is the exact reason we started Flat Earth Equipment. We got fed up with the delays, the runaround, and the gatekeeping. We offer the sensors, solenoids, and filters you need to bypass the dealer wait times. In today's world, having a powerful, multi-brand diagnostic tool isn't a luxury; it's a fundamental requirement to keep your equipment running and your business alive.

It's about taking back control.

Comparing the Core Philosophies of Jaltest and CAT ET

Let’s get straight to the point. When you’re choosing between Jaltest and CAT Electronic Technician (ET), you're not just picking software—you're deciding if you're a prisoner or the warden. Are you going to be tied to the dealer network, or are you taking control of your own shop and fleet?

CAT ET is the official factory tool. Caterpillar built it for one reason: to give their dealer techs deep, granular access to CAT machines. It’s a surgeon’s scalpel—perfect for performing complex operations on a CAT engine, but completely useless the moment a Bobcat or JCB skid steer rolls into your bay.

The whole philosophy behind CAT ET is about maintaining a closed ecosystem. It's designed to ensure that for anything beyond basic service, you have to call the dealer, wait for their tech, and pay their rates. This specialization is both its biggest strength and its most significant limitation.

The Independent Shop’s Master Key

Jaltest, on the other hand, is built on the opposite principle. It's not a scalpel; it’s the master key for the independent tech's toolbox. It was designed for shops and mixed-fleet owners who can't afford to be locked into a single brand. Its core mission is to give you dealer-level diagnostic power across the board—CAT, Bobcat, Kubota, JCB, and whatever else is parked in the mud.

This difference in philosophy changes everything. While CAT ET is focused on locking you into their brand, Jaltest is all about opening doors. It assumes you have the skills to fix your own iron and gives you the firepower to prove it.

This isn't just a matter of convenience; it’s a strategic business decision. Are you investing in a tool that serves one brand, or a tool that serves your entire operation? Your answer dictates who really controls your fleet’s uptime.

This philosophical divide directly impacts your day. With CAT ET, a multi-brand fleet means juggling multiple laptops, paying for several expensive licenses, and wrestling with a tangle of different cables. It's an operational headache. With Jaltest, you grab one diagnostic kit and get to work on any machine that needs attention.

Before we dive deeper, let's look at how their core philosophies translate into practical differences. This table sums up the high-level comparison of their fundamental approaches.

Core Philosophy at a Glance

| Attribute | Jaltest Off-Highway (OHW) | CAT Electronic Technician (ET) |

|---|---|---|

| Primary Goal | Empower independent repair on all brands | Maintain dealer control over CAT equipment |

| Ideal User | Mixed-fleet owner, independent technician | CAT-exclusive fleet, dealer service tech |

| Workflow Impact | One tool for all jobs, faster diagnostics | Separate tools for different brands, slower workflow |

| Business Model | Sell you a key to unlock everything | Sell you a key that only fits one lock |

Ultimately, CAT ET is designed to protect the dealer network's business. Jaltest is built to empower shops to bypass that network entirely. One philosophy keeps you dependent; the other hands you the independence to fix your own equipment and get back to work.

Evaluating Brand Coverage for Modern Fleets

Let's be blunt: a diagnostic tool is just an expensive paperweight if it can't talk to the machine in front of you. That’s the hard truth. CAT ET speaks one language, and one language only: Caterpillar. For CAT iron, it’s flawless, diving deep into every system.

But take a walk through your yard. It’s not just a sea of yellow and black. The reality is, your fleet is a mix of different colors, each with its own electronic quirks. Relying solely on CAT ET is like bringing a single socket to a job that needs a full wrench set—you’re dead in the water the minute a non-CAT machine throws a code.

The numbers don't lie. Recent data on new financed equipment shows that 28.4% of skid steers sold were Bobcat units, followed by Kubota at 19.2%, with Caterpillar trailing at 15.5%. If you're only equipped to handle CAT, you're unprepared for nearly 85% of the new machines hitting the dirt. You can discover more insights about these sales trends and see how the market is shifting.

Beyond a Single-Brand Mindset

This is where a multi-brand tool like Jaltest has a massive practical advantage. It’s built for the real world, not the perfect, single-brand utopia that dealers sell. One minute you’re diagnosing a stubborn regen on a CAT 299D3, and the next you’re calibrating a new joystick on a Kubota SVL97-2.

With separate dealer laptops, that scenario means shutting down, swapping out hardware, firing up different software, and praying the right subscription is paid up. It’s a workflow killer. Jaltest erases that entire song and dance. One interface, one laptop, one subscription, and you’re connected.

It’s all about efficiency. Time spent fumbling with different laptops is time the machine isn’t working. Jaltest consolidates your diagnostic arsenal into a single, powerful weapon, turning a chaotic mess of OEM tools into one streamlined solution.

True Coverage Means More Than Just Reading Codes

Let's be clear about what real coverage means. It’s not just pulling a generic fault code. It’s about getting the same vital information and commands across all your equipment.

With Jaltest, you can handle the specific, high-value jobs that keep machines running, no matter the brand:

- CAT Machines: Get deep access to engine parameters, aftertreatment systems, and hydraulic pressures.

- Bobcat Skid Steers: Perform critical functions like DPF regeneration and sensor calibrations without needing the dealer.

- Kubota Loaders: Troubleshoot complex electronic issues and adjust hydraulic settings in the field.

- JCB Equipment: Finally get a handle on those notoriously finicky AdBlue/DEF systems and clear recurring electronic faults for good.

This multi-brand capability transforms your operation. Instead of juggling multiple expensive licenses, you have a single-source solution. The comparison of Jaltest vs CAT ET for skid steers isn't just about software features; it's about whether your tool serves the brand, or if it serves your entire fleet. CAT ET serves Caterpillar. Jaltest serves you.

Analyzing Real-World Diagnostic Capabilities

Pulling fault codes is the easy part. A ten-dollar code reader can do that. The real work—the stuff that gets a machine off the lowboy and back on the job—is in the fix. This is where the rubber meets the road when you compare what Jaltest and CAT ET can actually do in the field, covered in dirt and hydraulic fluid.

Let’s be straight about CAT ET. For a Caterpillar machine, its power is undeniable. You can get into the guts of the ECM and perform deep, dealer-level functions. We’re talking about uploading injector trim files, fine-tuning hydraulic response, and changing critical machine parameters. It’s the factory tool, and it acts like it.

But that power hits a brick wall the second you hook it up to anything that isn’t yellow and black.

Jaltest, on the other hand, was built for the guy who has to fix whatever rolls into the yard. It delivers an impressive amount of that same dealer-level functionality, but across the brands you actually work on every day. It’s the difference between having a single, specialized key and having a master key that opens almost every door.

Beyond the Codes: Bidirectional Controls

This is the real test of a diagnostic tool's worth. Can it command the machine to do something? This is what separates a simple code reader from a true diagnostic solution.

CAT ET lets you command every solenoid and actuator on a CAT machine. That’s its home turf. But what happens when a Bobcat with a Perkins engine won’t complete a regen? The dealer’s answer is to haul it in.

Jaltest lets you plug in, take control of the aftertreatment system, and command a parked DPF regeneration right there on the job site. That’s not a small difference; that’s the difference between an hour of diagnostics and two days of downtime.

They call these "bidirectional controls" for a reason. Your tool talks to the machine, and the machine talks back. A tool that only listens is just half a conversation. You need the power to give commands, not just read what the machine is complaining about.

Essential Calibrations Across Your Fleet

The real money in diagnostics isn't just fixing what's broken; it's correctly setting up what's new. Every time you replace a major component—a joystick, a sensor, a pump—the machine’s computer needs to be told how to talk to it. This is where the Dealer Laptop has held us hostage for years.

- Joystick Calibration: You swap a worn-out joystick on a Kubota SVL. Without a calibration, the controls are sloppy and unresponsive. The dealer wants a service call. With Jaltest, you access the hydraulics module and run the joystick calibration procedure in five minutes.

- VGT Actuator Calibration: The variable geometry turbo on a JCB goes out. You replace it, but the engine still throws codes. The new actuator needs to learn its position. Jaltest has the function to run the VGT calibration and get it dialed in.

- Hydrostatic Pump Adjustments: A hydrostatic drive system needs fine-tuning after a repair. Jaltest allows you to view live data and make the necessary electronic adjustments to ensure smooth operation without paying for a dealer tech to click a few buttons.

The debate of Jaltest vs CAT ET for skid steers comes down to this: CAT ET gives you total control over one brand. Jaltest gives you the essential, money-making controls you need across your entire fleet. For the independent shop or mixed fleet, that’s not a choice; it’s a necessity for survival.

Breaking Down the True Cost of Ownership

Let's cut the bull and talk dollars and cents. When you're looking at a diagnostic tool, the initial sticker price is just the tip of the iceberg. The real cost—the one that hits your bottom line year after year—is the one that matters.

With a factory tool like CAT ET, that initial setup with the Comm Adapter, a ruggedized laptop, and the first year's license is a serious punch to the wallet. But the pain doesn't stop. That annual license isn't for new features or expanded coverage; it's a recurring fee you pay just to keep using the software on machines you already own. It's a guaranteed revenue stream for the dealer, paid for by your shop.

Jaltest plays a completely different game. Yes, it's a significant upfront investment. But that annual subscription fee buys you a hell of a lot more than just access. It gets you consistent updates, new features, and expanded coverage for every single brand in your package. You avoid "license creep"—that slow financial bleed of buying a new OEM license every time you add a different color of iron to your fleet.

The Five-Year Battle for Your Bottom Line

Let's run a common scenario. Imagine your shop works on a typical mix: a couple of CATs, a few Bobcats, and that one JCB that just won't quit. Here’s how the five-year cost battle plays out.

- Year 1: You buy the CAT ET license and hardware. Then you do it again for the Bobcat license. Then you add the JCB Service Master license. Before you've even cleared a fault code, you're tens of thousands of dollars in the hole.

- Years 2-5: Now the annual tribute begins. You're paying each of those dealers just to keep your software turned on. Decide to add a Kubota? That’s another license, another laptop you have to keep charged. You’re going to need a good setup—check out our guide on reliable heavy-duty battery chargers.

With a single Jaltest kit, your five-year cost is predictable. One upfront hardware cost, one annual subscription that covers your entire fleet. The return on investment isn't some fuzzy concept; you can calculate it in the service calls you didn't have to make and the OEM licenses you never had to buy.

This isn't just about saving a few bucks on software. It’s about stopping the endless financial drain to multiple dealers. Every dollar you don't send to them is a dollar you can invest back into your own operation.

The global skid steer loader market is only getting bigger, and as more complex machines hit the dirt, the cost of being chained to a stable of different dealers will only get worse.

The real cost of ownership isn't what you pay for a tool today. It's what you lose over the long haul by being dependent on someone else's ecosystem. The multi-brand approach of Jaltest flips that script, putting you back in control of your expenses and your uptime.

The Verdict: Which Tool Gives You Control?

Alright, let's cut to the chase. After digging into features, brands, and costs, the real question is simple: which tool puts you back in the driver's seat? It's not about which one is "better" in a vacuum, but which one fits the reality of your shop floor.

If your world is exclusively yellow and black—and you have a solid, responsive dealer you can count on—then CAT ET is your weapon. It’s the factory key, built to give you the deepest possible access to your Caterpillar machines. No multi-brand tool will ever go quite as deep on a single OEM.

But for everyone else—the independent tech, the mixed-fleet manager, and the owner who’s tired of waiting for a service call—Jaltest is the only logical choice. This is the tool of independence. It breaks the chains that tie you to a single dealer network and gives you the power to service nearly any color of skid steer that rolls into your shop.

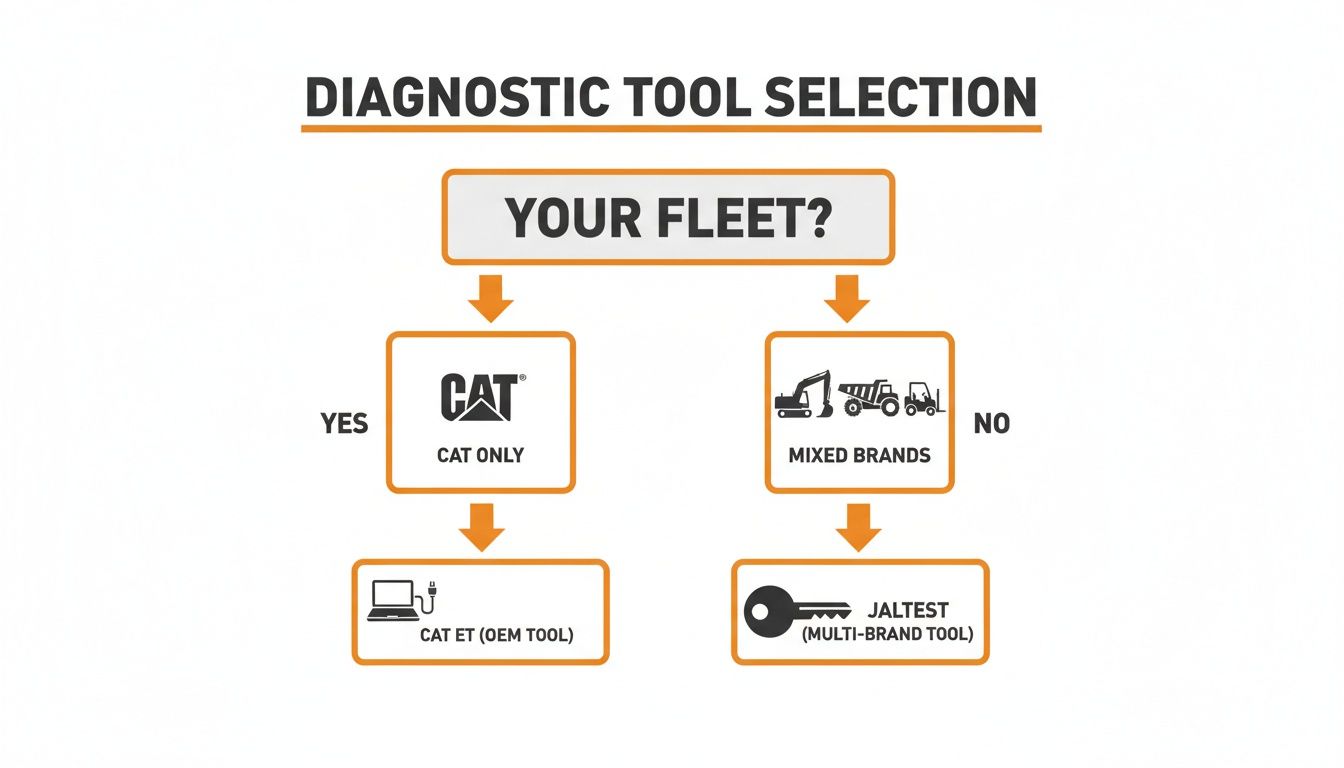

This decision tree shows a simple path to choosing the right tool for your fleet.

As the flowchart shows, the choice really hinges on the diversity of your equipment. CAT ET is the specialist's tool, while Jaltest is the master key for the real-world fleet.

Taking Back Your Uptime

This isn't just about software; it’s about control. It’s about being able to force a regen on a Bobcat at dusk so it’s ready for the crew at dawn. It’s about calibrating a joystick on a Kubota in ten minutes instead of waiting two days for the dealer tech to show up. It's about finally fixing that finicky DEF sensor on a JCB telehandler yourself.

The ultimate verdict in the Jaltest vs. CAT ET debate comes down to this: CAT ET makes you an expert on their equipment. Jaltest makes you an expert on your equipment, no matter the brand.

At the end of the day, this choice is about taking back control of your repairs, your time, and your bottom line. It’s about fixing your own iron and getting your machines back to making money, fast.

Frequently Asked Questions

When you're knee-deep in grease and a machine is down, you need straight answers, not a sales pitch. Here are the common questions I get from guys in the field when they’re weighing Jaltest vs. CAT ET for skid steers.

Does Jaltest Completely Replace CAT ET for Caterpillar Skid Steers?

For over 95% of the diagnostics and repairs you handle day-in and day-out, the answer is a hard yes. Jaltest reads and clears proprietary fault codes, views live data from every module, forces a DPF regen, and performs critical calibrations like injector trims and hydraulic adjustments.

The only time you might need to dust off the dealer laptop is for deep ECM programming—like flashing a brand new, blank controller or illegally altering factory horsepower ratings. For every practical repair that keeps you making money, Jaltest gets it done.

What Is the Learning Curve Like When Switching to Jaltest?

Honestly, it’s shorter than you think. CAT ET looks like it was designed in the 90s. Jaltest has a modern, graphical interface with built-in wiring diagrams and step-by-step troubleshooting that actually helps you fix the problem faster.

The biggest switch is learning to think by system (engine, hydraulics) rather than just by a model number. Most techs who are comfortable with any diagnostic software get the hang of it in a couple of hours. The time you save by not swapping laptops for different brands makes it a no-brainer.

Look, the real learning curve is trying to figure out the dealer's excuses for why their tech is two days late. Learning new, useful software is easy by comparison.

How Do Software Updates and Support Compare?

This is a night and day difference. With CAT ET, your annual license buys you the privilege of using their software and calling the dealer for "support." Good luck with that when you're in a jam.

With Jaltest, your subscription delivers three major software updates every year, adding new models, systems, and functions across all covered brands. More importantly, when you need help, you talk to a real diagnostic specialist who understands both the tool and the equipment.

If you still have questions, you can get in touch with technician-led support that understands your problems instead of just reading from a script. You get help from a pro, not a parts guy, and that’s a huge advantage when you’re against the clock.

When you’re ready to ditch the dealer dependency and take control of your repairs, Flat Earth Equipment has the tools and parts to back you up. Get the hardware you need to keep your whole fleet running.

Get Your Diagnostic Solution Today at https://flatearthequipment.com