Picture this: your skid steer is dead in the dirt, flashing codes, and every second of downtime is costing you money. The old way means calling the dealer, waiting for a flatbed, and then getting stuck with their timeline and their bill. They plug in their proprietary "Service Master" laptop, hold your machine hostage, and then hit you with an invoice that stings.

That whole song and dance is a brutal waste of time and cash. It ends now. The Jaltest cable kit for skid steers 9-pin is your ticket to taking back control, figuring out the real problem right on-site, and getting your yellow iron back to making you money.

Ditch the Dealer Laptop and Take Control in the Field

There’s a clear line drawn in the mud between fixing it yourself and waiting on someone else. On one side, you have the dealer's locked-down system—a tool designed to keep you calling them for every little blinky light. On the other, you have a rugged, multi-brand diagnostic tool that puts the power right back where it belongs: in your hands. This isn't just about convenience; it's about reclaiming your uptime and protecting your wallet.

When a modern machine like a JCB throws a fit, especially with its finicky AdBlue/DEF system, the dealer’s first move is a forced "Regen" that doesn't even touch the root cause. You lose a day, maybe more, for what could have been a five-minute sensor swap you handled yourself.

Here's a quick breakdown of why taking diagnostics into your own hands beats waiting on the dealer's service truck every single time.

| Factor | Dealer 'Service Master' | Your Jaltest 9-Pin Kit |

|---|---|---|

| Location | Their shop, miles away. | Your job site, right now. |

| Downtime | Days, sometimes weeks. | Minutes to hours. |

| Control | They tell you what's wrong. | You see the live data yourself. |

| Cost | Towing + diagnostics + labor. | One-time tool investment. |

| Scope | Only works on their brand. | Multi-brand, one tool for all. |

| Parts | Wait for their stock. | Source your own, or get it from us. |

The math is simple. The dealer model is built around their service bay, not your schedule. The Jaltest system is built for the field.

The Field-Ready Diagnostic Advantage

The whole point of field service is to stay in the field. Every trip back to the shop is a loss. With the right diagnostic kit, you can troubleshoot complex electronic issues right from the cab of your truck.

- Pinpoint the Problem Instantly: Stop the guesswork. Pull active fault codes and watch live data streams to see exactly which sensor or solenoid has failed.

- Fix It On-Site: Once you know the problem, you can fix it. No more hauling a perfectly good machine miles away just for a simple part replacement.

- Bypass the Parts Counter Delays: The dealer might have the fancy tool, but they don't always have the part. At Flat Earth Equipment, we stock the high-failure components—NOx sensors, filters, solenoids—that leave other machines down for the count.

The 9-pin Deutsch connector has become the go-to standard for heavy-duty diagnostics, and that includes skid steer loader systems. For technicians like us who work on a mixed fleet of yellow iron, the Jaltest cable kit is a game-changer. It solves the massive headache of needing a different proprietary tool for every color of machine on the job site. You can learn more about how this connector became the standard for heavy equipment diagnostics right here.

Why the 9-Pin Connector Is Your Master Key

Ever waste half a morning wrestling with a machine because you grabbed the wrong plug? We’ve all been there. Out in the field, time is money, and fumbling with a box full of mismatched connectors is a quick way to burn through both.

This is exactly why the 9-pin Deutsch connector is the hero of this story. It's the one key that unlocks almost every piece of modern yellow iron you’ll find on a job site, from a Bobcat skid steer to a Cat dozer.

It’s not just about having a plug that fits. It’s about getting a direct, clean line into the machine's brain. Think of it like a master key for a building; instead of lugging around a giant ring of keys for every single door (Bobcat, Case, JCB), you have one that grants you access to everything. This single, rugged connection is the industry standard for a reason—it handles all the critical communication lines in one clean shot.

It’s the universal language that lets a multi-brand tool like the Jaltest speak fluently with any machine. Packed inside that one plug are the dedicated pins for everything that matters:

- CAN High/Low: This is the two-way data superhighway where the engine, transmission, and hydraulic modules are all talking to each other.

- J1939 Data Links: The specific protocol used by nearly all heavy equipment, carrying thousands of crucial data points every second.

- Power and Ground: A stable, reliable connection to power your diagnostic tool without messing with the machine's battery or needing a separate power source.

The Universal Language of Yellow Iron

So, why did everyone finally agree on this one plug? Simple: it makes life easier for everyone involved. Major manufacturers like Bobcat, Case, Gehl, Caterpillar, and John Deere have all moved toward standardized connectors to simplify parts and service for their customers (and themselves).

The big players—with Caterpillar Inc. and Komatsu Ltd. each holding over 8% of the skid steer market share—drove this push for a common interface. You can dig deeper into how these standards benefit technicians and fleet managers.

This standardization is your secret weapon. It means your Jaltest cable kit for skid steers 9-pin isn’t just a tool for one brand; it’s a tool for your entire fleet. You can roll up on a mixed job site with a JCB, a Cat, and a Bobcat lined up and use the exact same setup to diagnose all three.

No more brand-specific headaches. No more calling in three different dealers for three different machines. You just plug in, pull the codes, and find the problem—no matter what color paint is on the side.

This is what breaking free from the dealer’s grip really looks like. You're no longer stuck depending on their proprietary "Service Master" laptop that only works on their equipment. The 9-pin standard, paired with a powerful tool like Jaltest, puts you back in the driver's seat. You get dealer-level access without the dealer-level restrictions.

Connecting and Pulling Codes: A Real-World Workflow

Alright, enough theory. Let’s get our hands dirty. Knowing what the Jaltest cable kit for skid steers 9-pin does is one thing, but putting it to work is what gets that machine back on the job. Forget the dealer's overcomplicated manuals; this is how a real tech gets from a dead machine to a solid diagnosis in just a few minutes.

First things first: find the diagnostic port. On most modern skid steers—whether it's a Bobcat, Case, JCB, or anything else—you’re hunting for that round, 9-pin Deutsch connector. It’s almost always tucked away somewhere in the cab, usually near the fuse panel, under the operator's seat, or behind a side panel. A quick look is all it takes.

Once you’ve spotted it, the connection process is dead simple. Crucially, make sure the machine's key is OFF before you plug anything in. Connect your 9-pin cable to the machine's port, then link the other end to your Jaltest V9 interface. Finally, hook up the Jaltest V9 to your laptop with the USB cable. A solid, clean connection is everything here. A loose plug can feed you garbage data or, worse, no data at all.

Running a Full System Scan

With everything physically connected, it's time to let the software take over. Turn the machine's key to the ON position, but don't start the engine just yet. Fire up the Jaltest software on your laptop and let it automatically detect the machine. This initial handshake is where the magic happens—the software figures out the make, model, and every electronic module on board.

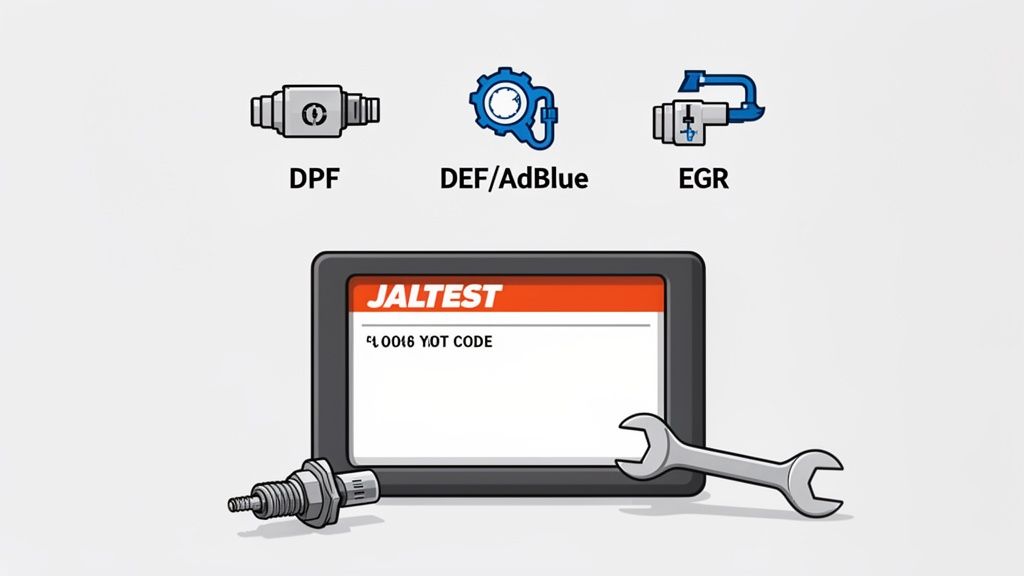

From there, kick off a full system scan. This isn't just about pulling engine codes. It’s a complete diagnostic sweep of the engine, the aftertreatment system (your DPF and DEF components), the hydraulics, and any chassis controllers. The software lays out a list of fault codes, neatly separating them into two categories you actually care about:

- Active Faults: These are the problems happening right now. This is your priority list—the stuff that's probably causing the shutdown or derate.

- Inactive/Stored Faults: Think of these as the machine's diary. Maybe a sensor had a momentary hiccup a week ago. They provide good context, but they aren’t the immediate cause of your headache.

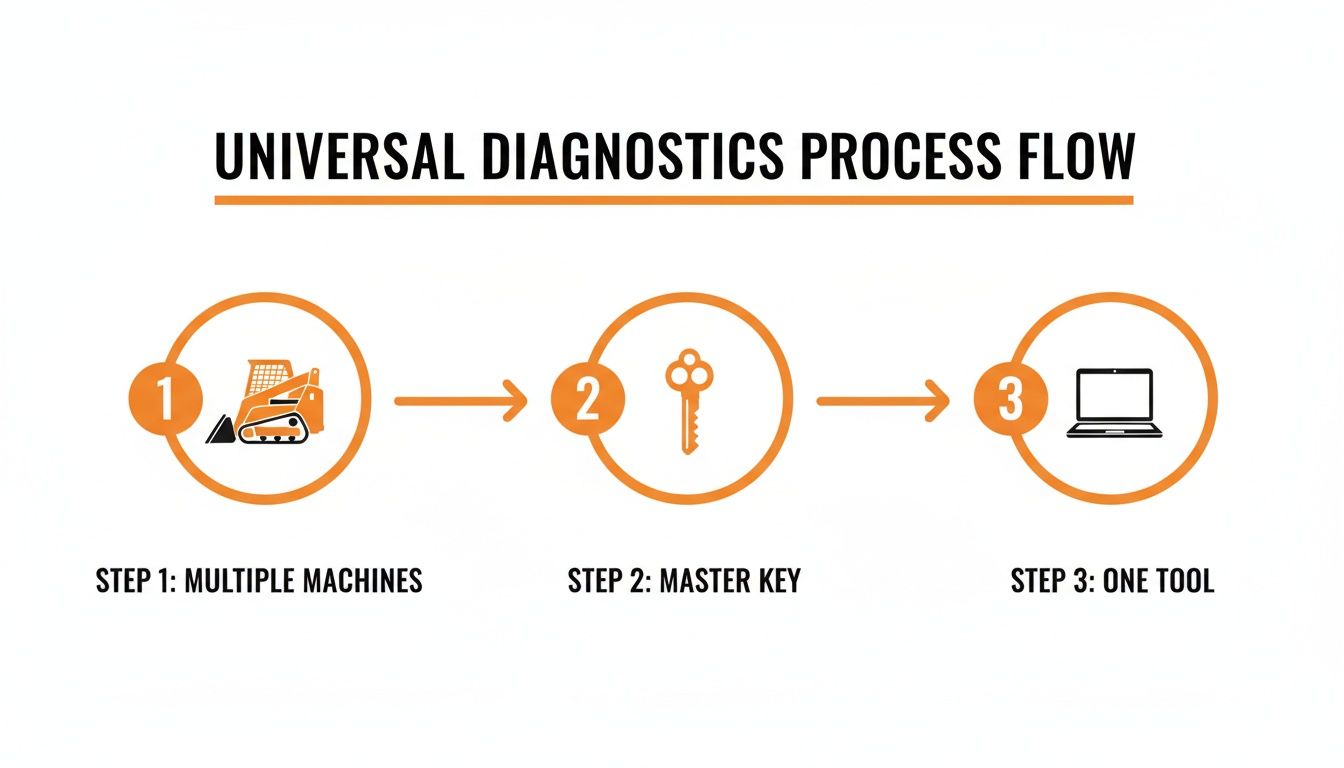

This diagram really simplifies it, showing how one tool becomes the master key for all your different machines.

It shows you just how much more efficient it is to have a single diagnostic solution for a mixed fleet. You cut down on tool clutter and complexity in a big way. This process is also worlds safer than just guessing and throwing parts at a problem. For more on that, you can check out our guide to job site and workshop safety practices at Flat Earth Equipment.

Interpreting the Live Data Stream

Pulling a code is just the first step. The real diagnostic power comes from watching the live data. Let's say you get an active code for a DPF differential pressure sensor. Instead of just grabbing a new one off the shelf, you can navigate to the live data screen and watch its voltage readings in real time.

Is it stuck at 0 volts? Is it jumping all over the place? This is how you confirm a failed component with 100% certainty before ever picking up a wrench. You can monitor everything from soot levels and DEF quality to individual sensor voltages, which turns pure guesswork into a precise, surgical repair.

Diagnosing Common Skid Steer Faults That Stop You Cold

A fault code popping up on the dash is just noise until you know what to do with it. That blinking light doesn't tell you how to get back on the job. Think of this as your field guide for tackling the most common—and profit-killing—electronic gremlins that sideline modern skid steers. We're talking about everything from the dreaded "Engine Derate" warning to that infuriating "Regen Required" shutdown that always hits at the worst possible time.

Pulling a code is just step one. The real skill is connecting that code to a specific failed part, getting the right replacement from a place like Flat Earth Equipment that actually stocks what you need, and then confirming the fix. Let's get into the guts of it.

Chasing Aftertreatment Ghosts

Your aftertreatment system—the DPF, SCR, and DEF components—is the source of at least 70% of the electronic headaches you'll run into. The dealer's default move is almost always the same: hook up their laptop and force a regen. That’s like putting a band-aid on a broken bone. It doesn't fix the root problem.

With your Jaltest cable kit for skid steers 9-pin, you can see what the machine's ECU is actually seeing. This is how you stop guessing and start fixing.

Common Scenarios and Your Plan of Attack:

Fault Code: DPF #1 Differential Pressure Sensor Erratic

- The Symptom: The machine is constantly screaming for a regen, even if you just ran one. It might even derate power because it's convinced the filter is plugged solid.

- Your Jaltest Play: Fire up the live data. Find the "DPF Differential Pressure" reading and watch it. With the engine off, it should be sitting at or very close to zero. If you see it reading high or jumping all over the place, that sensor is toast.

- The Fix: Don't waste your time trying to clean it. Just replace the DPF differential pressure sensor. We keep these on the shelf at Flat Earth Equipment because they're a common failure point.

Fault Code: NOx Sensor Circuit Malfunction

- The Symptom: You're getting DEF warning lights, derate messages, and regens that fail to complete. JCBs are notorious for this one.

- Your Jaltest Play: In the live data, monitor the "NOx Sensor 1" and "NOx Sensor 2" readings. If one of them is stuck at a default number or isn't changing with engine load, you've found your culprit.

- The Fix: Swap out the bad NOx sensor. It's a quick job that saves you from a trip to the dealer and a massive bill.

Taking Control of the Regen Cycle

The biggest lie we've been sold is that only the dealer can command a regen. It’s how they keep you chained to their service bay. A forced regen is a powerful tool, but it's worthless if you can't kick one off yourself after making a repair.

You don't need their permission. Once you've replaced a faulty sensor or cleared out a legitimate DPF blockage, the Jaltest software gives you the power to initiate a "Stationary Regeneration" right there on the job site. You put the machine back in control, not the other way around.

This one capability is the difference between an hour of downtime and losing a day or two hauling the machine to the shop. You diagnose the real problem, replace the bad part with a reliable component from Flat Earth Equipment, and use your own tool to run the cycle that clears the codes for good. You're no longer just a parts changer; you're the complete solution.

Why Your Parts Supplier Is as Critical as Your Tools

Figuring out the problem with your Jaltest cable kit for skid steers 9-pin is only half the battle. A perfect diagnosis doesn't mean a thing if the replacement part you need is a week away, collecting dust in some dealer’s warehouse. Every hour that machine sits idle, you're losing money.

This is where Flat Earth Equipment changes the game. We're built for technicians who measure downtime in hours, not days. We get it—waiting isn't an option.

Built for Technicians, Not Ticket Numbers

When you call us, you're not getting a salesperson reading from a script. You're talking to a fellow technician who knows what you're up against. We've been there, wrestling with a finicky JCB that won't regen or a Bobcat throwing ghost codes. We can help you double-check your diagnosis and make sure you're ordering the right part the first time.

We don't just sell parts; we sell uptime. It’s the mission our entire operation is built around. You can learn more about our technician-led approach and see why we're different from the big-box suppliers. We stock the high-failure sensors, solenoids, and filters that dealers always seem to have on backorder.

The machine doesn't care about supply chain issues or business hours. It only knows it’s broken. We operate with that same urgency, stocking the critical aftertreatment and hydraulic parts that put you back in control.

And the need for that urgency is only getting bigger. The global skid steer loader market hit a value of USD 9.7 billion in 2023 and is projected to keep climbing. For fleet managers and technicians, this boom means more machines in the field and a greater demand for precision parts to keep them running.

Shipping That Keeps You Working

A part sitting on our shelf doesn't do you any good. It needs to get to your shop or directly to the job site—fast. That’s why we offer same-day shipping nationwide.

We know that a $150 sensor can hold up a $100,000 machine. When you partner with us, you're not just buying a component; you're buying a logistics solution that gets your equipment moving again. You diagnose it, we ship it, you install it. It's a workflow designed to crush downtime and keep your profits where they belong.

Straight Answers From Technicians in the Field

No fluff, no sales pitch. When you're in the dirt with a machine down, you need straight answers, not excuses. This is the stuff we hear every day from technicians on the job site—the real questions that matter when you're trying to get a piece of yellow iron back to work and the clock is ticking.

We've pulled together the most common questions we get about the Jaltest cable kit for skid steers 9-pin right here.

Will This 9-Pin Cable Work on My Specific Bobcat or Kubota?

More than likely, yes. This is the exact cable you're looking for. The 9-pin Deutsch connector has become the industry-wide standard for the diagnostic port on almost every modern skid steer from Bobcat, Case, Kubota, JCB, and others that use the J1939 communication protocol. Think of it as the master key for your yellow iron.

To be 100% sure, just hop in the cab and take a look. You’re searching for a round, black or grey port, usually tucked away near the fuse panel, under the operator's seat, or behind a side panel. If you spot that 9-pin connector, this cable is your direct line into the engine, aftertreatment, and hydraulic control modules.

How Is This Different From the Dealer's Diagnostic Laptop?

The single biggest difference? Freedom. The dealer’s proprietary laptop, their "Service Master" or whatever they call it, is built to lock you into their ecosystem. That means their parts, their procedures, and their inflated prices. It’s a closed loop that always leads back to their service bay.

The Jaltest system, on the other hand, is a multi-brand powerhouse. It gives you true dealer-level capabilities—reading proprietary fault codes, watching live sensor data, running component tests, and kicking off forced DPF regens—across a huge range of manufacturers. It lets you service your entire fleet with one tool, cutting the dealer out and putting control firmly back in your hands.

Can I Really Perform a Forced DPF Regen With This?

Absolutely. This is easily one of the most valuable, money-saving functions you’ll have. When a machine derates and shuts down because of a clogged DPF, you no longer have to pay for a flatbed to haul it to the dealer. That whole song and dance is over.

With the Jaltest tool and this 9-pin cable, you can diagnose the real cause of the blockage, replace a bad sensor or part from Flat Earth Equipment, and then command a stationary regen yourself, right on-site. The software walks you through the safety checks and kicks off the process, saving you thousands in downtime and transport costs.

This isn't just about clearing a code; it's about taking command of the machine's most frustrating system. You become the solution instead of waiting for one.

What If I Can't Figure Out a Code or Find the Right Part?

That's exactly why you call us at Flat Earth Equipment. Our support team isn't staffed by salespeople reading from a script; it’s run by experienced technicians who’ve been in your boots. We speak your language.

Give us a ring, and we can help you walk through the diagnostic data to pinpoint the exact failed part. Once we nail it down, we'll confirm we have the right high-quality component in stock and get it shipped out the same day. We bridge that gap between the diagnosis and the repair, making sure you have the tools, the knowledge, and the parts to get the job done right the first time.

If you ever get stuck or just have a question, our team is ready to help when you get in touch with our technician-led support.