Alright, enough searching for a sketchy Hyster H50FT service manual pdf—it's time to get your hands dirty and start turning wrenches. Forget those generic downloads. What you need is a real field guide to diagnose actual problems and knock out essential maintenance without getting the dealer involved. We're cutting through all the fluff to give you the critical info that keeps your machine productive and out of the shop.

Why You Need More Than Just a PDF

Let's be real: that H50FT isn't making you a dime while it's collecting dust, waiting for a dealer tech to show up with his laptop. Out in the field, we don't have the luxury of dealing with error codes that lock us out or regen cycles that bring the whole job to a grinding halt. Downtime is the real enemy here, and a generic PDF isn't going to show you how to get around it. You need practical, hands-on knowledge that connects the manual's clean diagrams to the greasy reality under the hood.

This guide is for the technician in the dirt, not the service manager behind a desk. We’ll break down the must-know sections of the factory manual so you have the confidence to tackle the job yourself. Stop waiting weeks for a simple sensor or solenoid. The goal here is to diagnose the issue, get the right part from a supplier like Flat Earth Equipment, and get that machine moving again—today.

Understanding the Specs That Matter

Before you even crack open a manual, you need to know the beast you're working on. The Hyster H50FT has been a material handling workhorse for years, and its core specs are the foundation for every single repair.

The Hyster H50FT forklift comes with a solid 5,000 lb (2268 kg) rated lifting capacity at a standard 24-inch load center. It's powered by a dependable Kubota 2.4L diesel that delivers all the muscle you need. But it's the hydraulic system—operating at 2250 PSI with a 13.9-gallon capacity—that demands precise maintenance to prevent a catastrophic failure. For a deeper dive, you can always cross-reference Hyster H50FT specifications on a platform like RitchieSpecs.

You don't need a dealer's permission to fix your own iron. What you need are the correct specs, the right schematic, and a supplier who understands you can't wait two weeks for a part that's holding up the entire operation. That's where we come in.

Properly maintaining this machine means sticking to the book but also knowing the common failure points from experience. We focus on practical application because knowing how to work both safely and efficiently is what really matters. Our team put together some key information, and you can learn more about forklift safety in our detailed guide. This isn't just about fixing what's broken; it's about taking control of your equipment.

Hyster H50FT Quick Reference Specifications

Every tech needs key performance and dimension specs handy for quick diagnostics and ordering the right parts. Here's a table with the essentials you'll find yourself looking up constantly.

| Specification | Metric |

|---|---|

| Lifting Capacity | 5,000 lbs (2268 kg) |

| Load Center | 24 in (609.6 mm) |

| Engine Model | Kubota 2.4L Diesel |

| Hydraulic Pressure | 2250 PSI |

| Hydraulic Capacity | 13.9 gal (52.6 L) |

| Max Fork Height | 127.5 in (3238.5 mm) |

| Turning Radius | 83.1 in (2110.7 mm) |

| Operating Weight | 8,690 lbs (3941.8 kg) |

Keep these numbers in your back pocket. Whether you're troubleshooting a weak lift or making sure a replacement part is correct, these specs are your starting point for getting the job done right the first time.

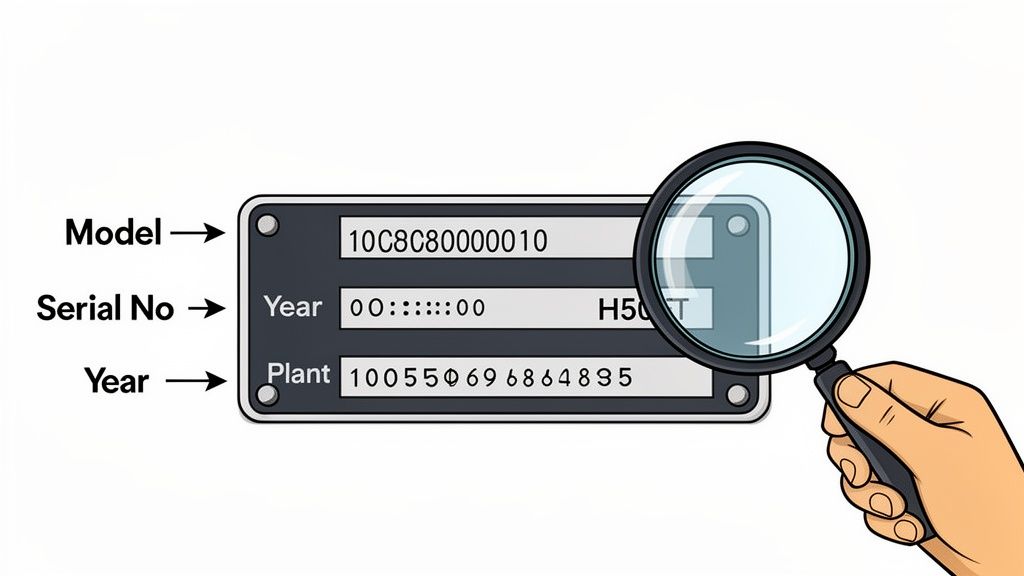

Decoding Your Hyster H50FT Model and Serial Number

Before you even think about cracking open a toolbox, you need to know exactly what machine you’re up against. Getting the wrong part because you misread the data plate is a rookie mistake that costs you time and money. Your Hyster H50FT’s model and serial number are the absolute keys to ordering the right parts from Flat Earth Equipment and ensuring the Hyster H50FT service manual pdf you're using actually matches your iron.

Ordering parts blind is a good way to get your machine stuck in the yard for another week. The dealer won’t help you if you give them bad info, and you’ll be the one eating the cost of the wrong sensor. Take the extra 30 seconds to get it right.

Finding and Reading the Data Plate

First, locate the data plate. On most H50FT models, you'll find it riveted to the cowl right in the operator's compartment, or sometimes on the frame near the right-hand front wheel. It’s a metal tag that contains all the critical information about your specific lift.

Once you find it, you need to understand what you're looking at. The model and serial number are not just random digits; they tell a story.

- Model Number (e.g., H50FT): This is the easy part. It identifies the series and basic capacity.

- Serial Number: This is the critical code. It breaks down the machine's entire history and build configuration.

The Hyster serial number format is typically a sequence of letters and numbers. For the H50FT, it usually starts with a letter-number-letter combination like L177. Each character has a meaning, breaking down the design series, manufacturing plant, and production year.

Don't guess. The difference between two serial numbers can be a completely different wiring harness or hydraulic pump. Verifying this number is the first step to bypassing the dealer and fixing it yourself.

This isn’t like working on some new piece of yellow iron where a laptop tells you what’s wrong. Here, the data plate is your starting point for every repair. Getting this right means the parts you get from us at Flat Earth Equipment will fit, and the schematics in your service manual will match the wires you're tracing.

Core Maintenance Schedules and Fluid Specifications

A service manual isn't just a book; it's your battle plan for keeping that Hyster H50FT out of the shop and making money. If you ignore preventative maintenance, you're not saving time—you're just scheduling a catastrophic failure for a later date. This is where you get ahead of the problems, armed with the right schedules and fluid specs pulled directly from the Hyster H50FT service manual pdf.

Sticking to these intervals is non-negotiable. These machines aren't like newer equipment where a sensor will scream at you before things go south. On this iron, you have to rely on the hour meter and your own discipline to keep it running. Neglect these simple checks, and you’ll be the one dealing with a blown transmission or a seized engine down the road.

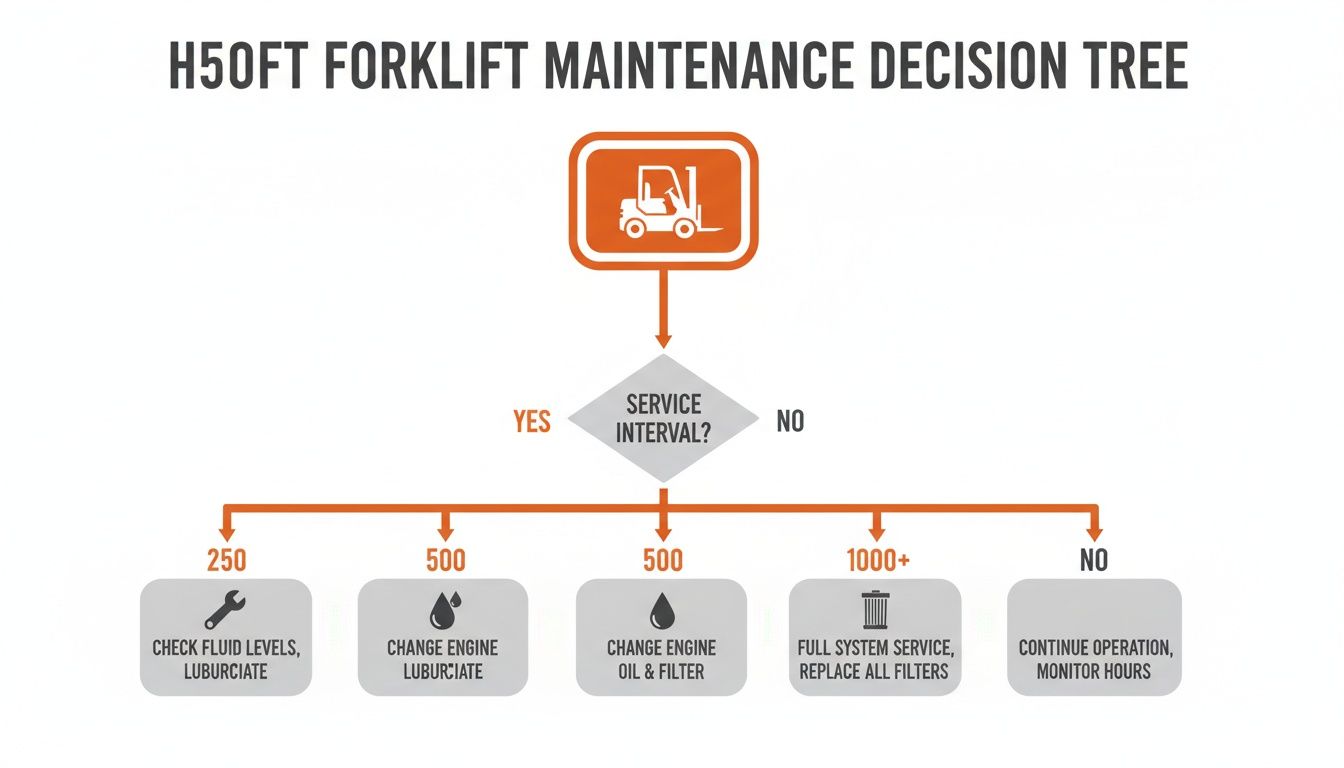

Essential Service Intervals

Don't overthink it—the manual lays out a clear roadmap. The most critical checkpoints are the 250, 500, and 1000-hour intervals. Each one builds on the last, ensuring all critical systems are inspected and greased before normal wear turns into serious damage.

- Every 250 Hours (or Monthly): Think of this as your basic walk-around on steroids. Check engine oil levels, inspect belts and hoses for cracks or fraying, and lubricate every grease point on the mast and chassis. This is also when you'll want to test the brakes and check hydraulic pressure to maintain the required 106-110 ft/min lift speeds.

- Every 500 Hours (or 6 Months): Now you’re changing fluids. It's time for an engine oil and filter change. You'll also replace the fuel filter, check the differential and transmission fluid levels, and closely inspect the mast chains for any sign of stretching or damage.

- Every 1000 Hours (or Annually): This is a more involved service. You'll be changing the hydraulic fluid and filter, replacing the air filter, and performing a full tune-up that includes spark plugs and valve adjustments.

Sticking to the schedule is the cheapest insurance you can buy. A few hours of preventative maintenance costs a hell of a lot less than a week of downtime waiting on major components from a dealer who doesn't care about your schedule.

No-Nonsense Fluid Specifications

Using the wrong fluid is just as bad as not changing it at all. Don't just grab whatever 15W-40 is on the shelf and call it good. The Hyster H50FT, a workhorse since its introduction in the H40-70FT series, has very specific requirements. For instance, improper valve adjustments alone can slash efficiency by 22%, and using the wrong fluids is just as critical. For a complete technical breakdown, you can explore the official Hyster tech guide.

Here’s exactly what your H50FT needs to stay healthy:

| Component | Fluid Type | Capacity (Approx.) |

|---|---|---|

| Engine (Kubota) | API CJ-4/CK-4 15W-40 Diesel Engine Oil | 7.4 Quarts |

| Hydraulic System | ISO VG 46 Hydraulic Oil | 7.9 Gallons |

| Transmission | Dexron III/Mercon ATF | 10 Quarts |

| Cooling System | 50/50 Ethylene Glycol Based Antifreeze/Coolant | 2.4 Gallons |

These specs are your baseline for reliability. Keep them handy, stick to the schedule, and you’ll spend more time working and less time waiting. And for related electrical needs, our Hyster remanufactured 24V battery charger will make sure your machine always has the power it needs to get the job done.

Troubleshooting Common H50FT Failures

When a machine goes down, the clock starts ticking—and it’s your money burning with every minute of downtime. You don’t have time to wait for a dealer tech to show up, plug in a laptop, and tell you something you probably could have figured out yourself. This is your field guide for diagnosing the most common Hyster H50FT problems, using the same logic from the service manual without the dealer's gatekeeping.

We’re tackling the issues that sideline these machines most often. From a dead-in-the-water no-start to a transmission that won’t engage, the approach is always the same: start simple and follow the logic. Don't just throw parts at it; that’s what amateurs do. A real tech diagnoses the problem with purpose.

Hydraulic System Headaches

A weak lift or a complete lack of hydraulic function is one of the most frequent calls we get. But before you start pricing out a new pump, walk through the basics. It sounds obvious, but is the hydraulic fluid level correct? And is it clean? A low or contaminated system is a surprisingly common culprit.

Next, get your eyes on the suction-side filter. A clogged filter will starve the pump for oil, causing it to whine and perform poorly long before it fails. If the fluid and filter are good, it's time to check system pressure. The Hyster H50FT service manual pdf gives you the specs, but you’ll need to hook up a gauge at the main hydraulic pump or the control valve to get a real reading.

- Low Pressure: This could point to a failing pump, a relief valve that's stuck open, or a significant internal leak somewhere in the system.

- No Pressure: This usually means something more catastrophic, like a complete pump failure, a sheared pump drive shaft, or a massive air leak on the suction side.

The dealer might want you to think it's a black box only they can fix. The truth is, most hydraulic failures are purely mechanical. A pressure gauge and a good understanding of the schematic are far more powerful than any diagnostic laptop for these problems.

No-Start and Electrical Gremlins

A machine that won’t even crank is frustrating, but it’s almost always something simple. Start with the most obvious stuff: are the battery terminals clean and tight? Is the battery actually charged? Check the basics before you even think about tracing wires. The manual's wiring diagram is your best friend here.

If the battery checks out, move on to the starter solenoid. You should hear a solid "click" when you turn the key. No click? Check for power at the solenoid's small signal wire. If you've got power there but the starter isn't engaging, you've likely got a bad solenoid or the starter motor itself has given up.

This maintenance decision tree shows the basic preventative tasks based on operating hours.

Sticking to these service intervals is the absolute best way to prevent the common failures we end up troubleshooting in the field.

Transmission Engagement Failures

If the engine runs great but the forklift won’t move an inch, your problem is likely in the transmission. The very first place to look is the transmission fluid level and its condition. If the fluid smells burnt or looks dark and gritty, that's a bad sign and points toward internal clutch pack wear.

Next, check the simple mechanical stuff. Is the parking brake actually released? Is the inching pedal functioning correctly and not stuck partway down? Sometimes a simple mechanical hang-up can prevent the transmission from engaging.

If those checks pass, you'll need to start testing the transmission control solenoids for power and resistance. A failed solenoid won't allow the clutch packs to get pressure, leaving you dead in the water. The good news is that these solenoids and sensors are parts you can get from Flat Earth Equipment without waiting weeks for the dealer to get them in.

How to Read Hyster H50FT Schematics

Schematics are the language of the machine. If you can't read them, you're just guessing and swapping parts. A true technician knows how to follow a hydraulic circuit or trace an electrical path to find the root cause of a failure. The dealer wants you to believe it’s some dark art, but with the Hyster H50FT service manual pdf, it's a roadmap anyone can learn to follow.

This isn't about memorizing every symbol. It's about understanding the logic. Fluid and electricity both follow the path of least resistance, and the schematic shows you every possible route, junction, and dead end. This knowledge is what separates a professional from a parts-changer and keeps you from getting stuck waiting on a "specialist."

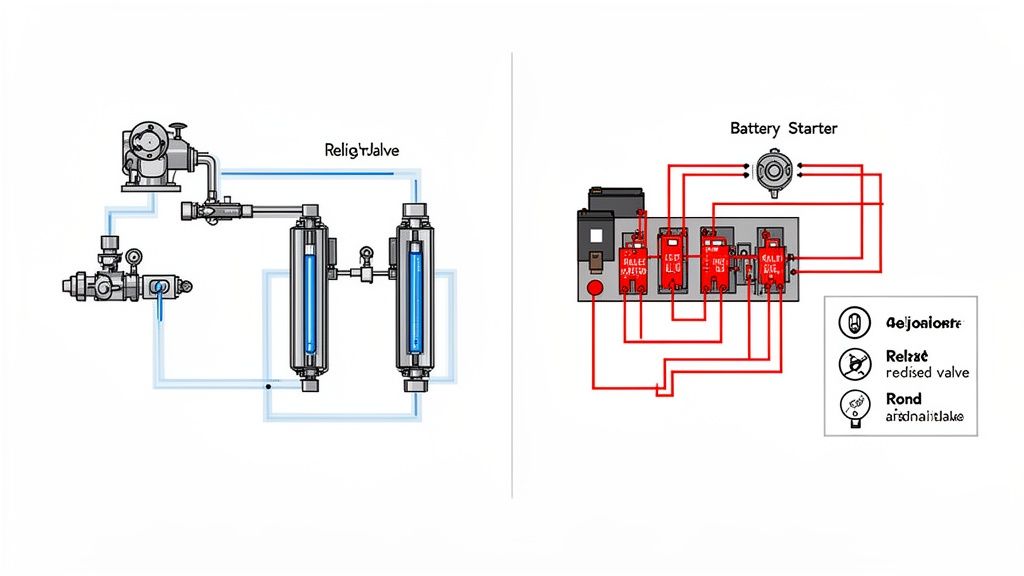

Decoding the Hydraulic Schematic

The hydraulic diagram looks complex, but it’s just a map of the machine’s circulatory system. Every line represents a hose or tube, and every symbol is a component doing a specific job. To start, find the hydraulic pump—it’s the heart of the system—and trace the lines coming from it.

You'll see lines leading to the main control valve, which directs fluid to different functions like lift and tilt. Look for key symbols along the way:

- Relief Valves: These are the system's safety net, designed to open and dump excess pressure back to the tank. A weak or failed relief valve is a common cause of poor hydraulic performance.

- Cylinders: Represented by a simple rectangle with a T-shaped line inside, showing the piston and rod that do the actual work.

- Directional Control Valves: These complex symbols show how spools shift to route fluid to extend or retract cylinders.

Tracing a circuit is simple. Pick a function, like "lift," and follow the high-pressure line from the pump, through the control valve section for that function, and out to the lift cylinders. Then, follow the return line back to the tank. Any blockage or leak along that specific path is your problem.

Tracing the Electrical Wiring Diagram

Electrical schematics follow the same principle. The battery is your starting point. From there, you trace power through fuses, switches, relays, and finally to the component that needs it, like the starter solenoid or a headlight. The ground path back to the battery is just as important.

The starter and ignition circuit is a perfect example. When you turn the key, you're closing a switch that sends a small amount of current to the starter solenoid. This solenoid is just a heavy-duty relay that then closes a high-amperage circuit directly from the battery to the starter motor. If the starter doesn’t crank, you use the schematic to test for voltage at each point in that chain—key switch, neutral safety switch, solenoid—until you find where the power stops. It’s that simple. Mastering this skill means you find the real problem instead of just throwing a new starter at it.

To help you get started, here's a quick-reference table for some of the most common symbols you'll encounter in both types of diagrams.

| Common Hydraulic and Electrical Schematic Symbols | ||

|---|---|---|

| Symbol | Component Name | Function |

| ⏣ | Hydraulic Pump | Generates fluid flow. |

| ⧰ | Relief Valve | Limits maximum pressure. |

| ▭ T | Hydraulic Cylinder | Converts fluid pressure to linear motion. |

| ⎓ | Resistor | Reduces current flow. |

| ⟞ | Switch (Normally Open) | Closes a circuit when activated. |

| ⏚ | Ground | Provides a return path for current. |

Learning these symbols is the first step. The real skill comes from applying that knowledge to trace a complete circuit from its power source to the component doing the work and back again. This methodical approach will save you countless hours and thousands of dollars in parts you didn't need.

Key H50FT Torque Specs and Procedures

Doing the job right means torquing to spec. Guesswork gets you stripped threads, dangerous leaks, and frustrating comebacks that kill your reputation. A torque wrench isn't just a suggestion; it's the only tool that guarantees a bolt's clamping force is exactly where it needs to be. The Hyster H50FT service manual pdf is loaded with these critical numbers, and ignoring them is a sure-fire way to create bigger problems down the line.

We're not talking about minor details here. An improperly torqued wheel could come off under a heavy load, and a loose engine mount can cause catastrophic vibration damage. This is about safety, reliability, and doing the job like a pro.

Critical Torque Specifications

You don’t have to memorize the entire book, but some numbers should become second nature for any tech working on these machines. These are the high-stakes fasteners you absolutely must get right every single time. Keep this list handy for the most common heavy-duty jobs on an H50FT.

- Wheel Lug Nuts: 240-260 ft-lbs. Under-torque them and the wheel can wobble; over-torque and you risk stretching or breaking the studs.

- Engine Mount Bolts: 110-120 ft-lbs. These bolts prevent the excessive vibration that cracks brackets and rattles other components loose.

- Mast Mounting Bolts: 180-200 ft-lbs. Absolutely critical for ensuring the entire mast assembly is secure and safe under load.

- Hydraulic Line Fittings (JIC 37°): Varies by line size, but a common 3/4-inch fitting needs about 60-65 ft-lbs. Overtightening is a classic mistake that deforms the flare and causes persistent leaks.

The tough service demands of the H50FT are a direct result of its 8,500 lb operating weight, making every spec a critical part of a precise repair. Following these details is crucial. Field technicians report that hydraulic leaks show up in 12% of units after five years, often from failed seals on improperly tightened fittings. Using the right torque and correct 2250 PSI seals from suppliers like Flat Earth Equipment prevents those costly return visits. You can dive deeper into these in-depth Hyster H50FT specifications to understand the full scope of this machine.

Essential Service Procedures

Beyond just hitting the right torque values, following the correct procedure is what separates a professional repair from a botched job. Here are two procedures where the steps you take matter just as much as the final twist of the wrench.

Bleeding the Brake System

- Top off the master cylinder with fresh DOT 3 brake fluid.

- Start at the wheel cylinder farthest from the master cylinder to work the air out of the longest line first.

- Attach a clear hose to the bleeder screw and submerge the other end in a container of fresh brake fluid.

- Have a helper pump the brake pedal several times, then hold it down firmly.

- Crack open the bleeder screw until the fluid flows, then tighten it before your helper releases the pedal.

- Repeat this process until you see no more air bubbles in the hose. Then move to the next wheel.

Adjusting Mast Chains

- Raise the forks about one foot off the ground to put some tension on the chains.

- Feel the tension of both lift chains; they should feel equal. A loose chain will cause jerky lifting.

- If they're uneven, find the adjusting nuts on the chain anchors.

- Loosen the lock nut, then turn the adjusting nut until both chains have the same amount of give.

- You're looking for roughly 1/2 inch of slack when you press on them.

- Once they're even, tighten the lock nuts securely to hold the adjustment.

Finding and Verifying Your H50FT Manual PDF

Let's get one thing straight: a bad manual is worse than no manual at all. The internet is a junkyard of sketchy PDFs, many of them loaded with viruses or, just as bad, filled with the wrong information for a completely different machine.

Grabbing the first free Hyster H50FT service manual pdf you find is a rookie move. It's a quick way to strip the wrong bolt or use the wrong fluid, turning a simple fix into a total nightmare. You need the right intelligence for the job, not just some random file from the web.

Verifying You Have the Right Manual

Before you even think about downloading, you have to know what you're looking for. A legit service manual isn't just a collection of pages; it's a specific technical document tied directly to your forklift’s build.

Here’s your pre-flight checklist to avoid getting burned:

- Check the Serial Number Range: The first page of any real service manual will list the exact model and serial number ranges it covers. If your machine's number isn't in that range, the manual is useless to you.

- Identify the Engine: The H50FT came with different power plants over its production run. You've got to ensure the manual specifies the correct engine—whether it's a Kubota, GM, or Mazda. The specs for a GM engine will wreck a Kubota.

- Look for Publication Dates: A good manual will have a publication number or date. This helps you match it to the era your machine was built, ensuring the wiring diagrams and specs are actually accurate for your lift.

A manual for the wrong serial number is just bad intel. It’s like using a map of the wrong battlefield—it’ll get your machine killed. Verify the numbers first, every time.

Know the Difference in Manual Types

Finally, understand that there are three distinct types of manuals. Getting the wrong one means you won’t have the technical data you need for a real repair.

- Operator's Manual: This covers daily checks and basic operation. It's not a repair guide.

- Parts Manual: This one has exploded diagrams and part numbers. It's great for ordering parts but won't help you diagnose a problem.

- Service Manual: This is the one you need. It has the troubleshooting steps, schematics, and torque specs required for actual wrenching.

If you’re ever stuck trying to identify a part or need expert guidance, don’t guess. Having the right support is just as critical as having the right manual. For those tough jobs, you can get technician-led support by contacting Flat Earth Equipment.

Your Top Hyster H50FT Service Manual Questions, Answered

Out in the shop or stuck in the field, you'll run into questions that a perfect PDF on your laptop just can't answer. You need advice from guys who’ve actually turned the wrenches and busted their knuckles on these machines. This isn't about theory; it's about what really works when you're under pressure to get a forklift back to making money.

We get calls all the time from techs and fleet managers working on the H50FT. Here are the straight-up answers to the questions we hear the most. Don't let the dealer convince you this stuff is rocket science. Most failures on these lifts are predictable, and the fix is usually mechanical, not some digital mystery. It all comes down to knowing where to look first.

What Is the Most Critical Section for Preventing Major Failures?

For any tech worth their salt, the Preventative Maintenance section of the Hyster H50FT service manual pdf is the holy grail. This is where you win the war before the battle even begins. Blowing off these maintenance schedules is the fastest way I know to guarantee a catastrophic failure of the engine, transmission, or hydraulic system. Think of them as commandments, not suggestions.

If you read nothing else, zero in on the hydraulic fluid and filter change intervals. A clogged filter will starve the pump, making it whine and scream before it grenades itself. That's a multi-thousand-dollar repair that sidelines your machine for days—all because somebody decided to skip a simple fluid service.

Can I Use a Manual if My H50FT Has a Different Engine?

Absolutely not. Don’t even think about it. Hyster used several different power plants in the H50FT chassis over its production run, including engines from GM, Mazda, and Kubota. Trying to fix a Kubota-powered lift using a manual for a GM engine is a recipe for disaster.

You'll be chasing your tail with the wrong torque specs, the wrong firing order, and completely useless diagnostic steps for the fuel and electrical systems. Always, always verify your forklift's data plate against the manual's introduction, which spells out the serial number ranges and engine types it covers. If they don't line up, you've got the wrong intel and you’re risking serious damage.

A manual is only as good as its accuracy for your specific machine. Using the wrong one is like trying to fix a JCB backhoe with a telehandler schematic—you're going to break something expensive.

Does the Service Manual Include Part Numbers?

Typically, no. The service manual is your "how-to" guide—it lays out the diagnostics, the step-by-step procedures, and all the specs. The actual part numbers are listed in a separate Parts Manual.

But the service manual is still your starting point. You use it to follow the troubleshooting flowcharts and diagnose that bad hydraulic pump or a faulty sensor. Once you’ve pinpointed the component, you’ve got what you need. Just bring that component description and your machine's serial number to a supplier like us. We can almost always cross-reference that info to get you the exact OEM-quality part without you ever needing to hunt down a specific part number.

Stop waiting on the dealer and take control of your own repairs. For the sensors, solenoids, filters, and other critical parts you need to get your Hyster H50FT back to work today, Flat Earth Equipment has you covered. Get the right parts, right now.