A dead forklift truck charger isn't just a dead battery—it's a dead operation. While the dealer is telling you it'll be a week before some kid with a laptop can even look at it, your entire workflow grinds to a halt. This isn't some minor headache; it's the same nonsense we deal with when a JCB's regen cycle decides to quit mid-lift. It's the first domino to fall in a chain reaction that costs you cold, hard cash.

Why Your Charger Is a Ticking Time Bomb

Let's get one thing straight. That charger box sitting in the corner isn't just a power supply. It's the heart of your entire electric fleet.

When it goes down, everything stops. Suddenly you have operators leaning on their machines, shipments that can't move, and a production line that's quickly turning into a parking lot. It’s the same story we see with "Yellow Iron"—a single finicky AdBlue sensor on a telehandler brings a fifty-ton machine to its knees, and you’re stuck waiting on the dealer and their proprietary "Service Master" laptop.

A busted forklift charger creates the exact same bottleneck. The problems pile up fast:

- Wasted Payroll: Operators are on the clock whether the lifts are moving or not. Their idle time is a direct drain on your bottom line.

- Missed Deadlines: You can't load or unload trucks with dead equipment. Those missed shipments lead to unhappy customers and potential penalties.

- Operational Chaos: A single stalled forklift can jam up the whole flow of your warehouse, creating logjams and safety hazards as people scramble to work around the problem.

Taking Back Control from the Dealer Laptop

The dealer wants you to believe you need their "certified technician" and special software for every little hiccup. They profit from your downtime. But when a DEF sensor quits on a backhoe, the real solution isn't to haul it to the shop. The solution is having the parts on hand and the know-how to fix it right there in the mud.

You don't make money waiting for a regen cycle to finish. You make money by keeping your iron moving. That means bypassing the dealer's gatekeeping and getting the parts you need—the sensors, solenoids, and filters—to solve the problem now.

This is why treating your charging equipment as a critical asset is non-negotiable. You need to understand how it works, what can go wrong, and where to get the right components without getting stuck in a service queue.

At Flat Earth Equipment, we stock the chargers, connectors, and parts that keep you running. This guide is your field manual—the practical, no-fluff breakdown of what you actually need to know to keep your electric fleet powered up and earning.

Decoding Charger Tech Without the Sales Pitch

Not all chargers are created equal, and grabbing the wrong one is an expensive mistake you'll likely pay for twice. Let's cut through the typical sales pitch and break down the tech you'll actually see in the field. This isn't about fancy brochures; it's about what works and what will leave your fleet stranded.

First up is the most fundamental choice: on-board vs. stationary chargers. An on-board unit is exactly what it sounds like—it’s bolted directly onto the forklift. You just find a standard outlet and plug the machine in, which is incredibly convenient for operations without a dedicated charging bay. The downside? It adds weight and another potential point of failure—more finicky electronics—to the machine itself.

Stationary chargers, on the other hand, are the big, heavy-duty boxes you see lined up in a battery room. They live in a fixed spot, are far more powerful and robust, and are much better suited for multi-shift operations where you're constantly swapping batteries.

The Speed Game: Standard, Opportunity, and Fast Charging

Once you know where the charger will live, you have to decide how fast you need to pump juice into the battery. Think of it like filling an air tank for your tools. You can use a small compressor that runs all night, a shop compressor that tops you off during lunch, or a high-pressure system that fills a tank in minutes.

Each method has its place, and choosing wrong will either kill your productivity or your batteries.

Standard Charging: This is the slow-and-steady approach. You plug in at the end of a shift and let it charge for 8-12 hours, followed by an 8-hour cool-down period. It’s the gentlest method for your lead-acid batteries but means you absolutely need one battery per forklift, per shift.

Opportunity Charging: This is all about topping off during breaks. The operator plugs in for 15-30 minutes during lunch or other downtime. It keeps the battery level up and can often eliminate the need for battery swaps entirely. Just know that it works best with batteries and chargers designed for it, like AGM or lithium-ion.

Fast Charging: This is the high-pressure blast. A true fast charger can take a battery from nearly dead to fully charged in just a couple of hours. This requires specialized, expensive batteries and some seriously beefy electrical infrastructure to handle the massive power draw. It’s a total game-changer for 24/7 operations but will absolutely cook a standard lead-acid battery.

To make it simple, here’s a quick breakdown of how these technologies stack up.

Charger Technology Comparison At a Glance

| Charging Technology | Charging Speed | Impact on Battery Life | Best For |

|---|---|---|---|

| Standard Charging | Slow (8-12 hours) | Low (Gentlest method) | Single-shift operations with downtime for full charging cycles. |

| Opportunity Charging | Medium (During breaks) | Moderate | Multi-shift operations aiming to avoid battery swaps. |

| Fast Charging | Very Fast (1-3 hours) | High (Requires special batteries) | High-demand, 24/7 facilities that need maximum uptime. |

This table gives you the 30,000-foot view, but the real devil is in the details of battery chemistry.

Lead-Acid vs. Lithium-Ion: You Can't Just Plug and Pray

This is the single most critical point, and it’s where most of the expensive damage happens. You cannot use a charger designed for a traditional lead-acid battery on a lithium-ion (Li-ion) battery, or vice versa. It’s like putting diesel in a gasoline engine—it will end badly.

Lead-acid chargers follow a specific multi-stage profile that expects the battery's voltage to behave in a predictable way as it charges. Li-ion batteries need a completely different charging algorithm, which is managed by an internal Battery Management System (BMS). Using the wrong profile will destroy the battery, void your warranty, and create a very real fire hazard.

A lot of money is flowing into this market, with the global forklift battery charger market projected to hit USD 2,088.68 million by 2030. That growth means more options, but also more chances to buy the wrong thing. Don't become a statistic because you skipped checking the data plate.

Always match the charger to the battery chemistry. No exceptions. A good supplier can confirm you’re getting the right match, like ensuring a versatile unit such as the Green4 48V 40A charger is properly configured for your specific battery type. When in doubt, check the battery’s data plate and the charger’s spec sheet. It’s the simplest way to avoid a four-figure mistake.

Matching the Right Charger to Your Machine

Compatibility isn't just a suggestion—it's a hard rule. Grabbing the wrong forklift charger is a fast way to fry expensive electronics, cook a battery, or worse, start a fire. This is where you separate the pros from the guys who are about to make a very expensive phone call to the dealer.

Getting this right means you can bypass the dealer markups. You can get the right parts from a supplier like Flat Earth Equipment and handle it yourself. But first, you have to know what you’re looking at. The single most important piece of metal on that battery is its data plate. Read it. Every single time. No exceptions.

Non-Negotiable Specs: Voltage and Amperage

Let's get one thing straight: voltage and amperage are not interchangeable. Mismatching them is like trying to run a 12V starter on a 24V system—you’re going to let the magic smoke out, and it’s an expensive mistake.

Voltage (V): Think of this as the pressure. Your forklift's electrical system is built for a specific voltage—usually 24V, 36V, 48V, or 80V. Hooking a 48V charger to a 36V battery will cause catastrophic failure. The charger simply won’t recognize it, or it will force-feed it a voltage level that will destroy the battery cells.

Amperage (A): This is the flow rate. The charger’s amp output needs to match what the battery can safely accept, which is based on its Amp-Hour (Ah) rating. Too low, and the battery may never reach a full state of charge. Too high, and you'll overheat the battery, causing permanent damage and venting dangerous gases.

The golden rule is simple: the charger's output voltage must match the battery's nominal voltage.

Plugs and Connectors: The Field Guide

You wouldn't try to fit a JCB hydraulic fitting onto a CAT machine, and forklift connectors are no different. They might look similar from ten feet away, but they are not the same. Using the wrong plug is a rookie mistake that can lead to a bad connection, arcing, and melted components.

Here are the most common ones you'll run into:

SB Connectors: These are probably the most common. You’ll see them on everything from Toyota to Hyster machines. They are color-coded by voltage to prevent mishaps (yellow for 12V, red for 24V, gray for 36V, blue for 48V).

Euro Connectors (DIN): These are the big, beefy rectangular plugs, often found on European-made machines like Linde or Jungheinrich. They are robust and designed for high-current applications.

Specific Brands: Some brands, like Crown, sometimes use proprietary connectors. It’s their way of trying to lock you into their ecosystem, just like when JCB puts a proprietary diagnostic port on an excavator to force you to call for their laptop.

Always visually confirm the connector type before ordering. A quick photo with your phone can save you the headache and cost of a return shipment because you ordered an SB175 when you needed an SB350. It’s a simple check that prevents a major delay.

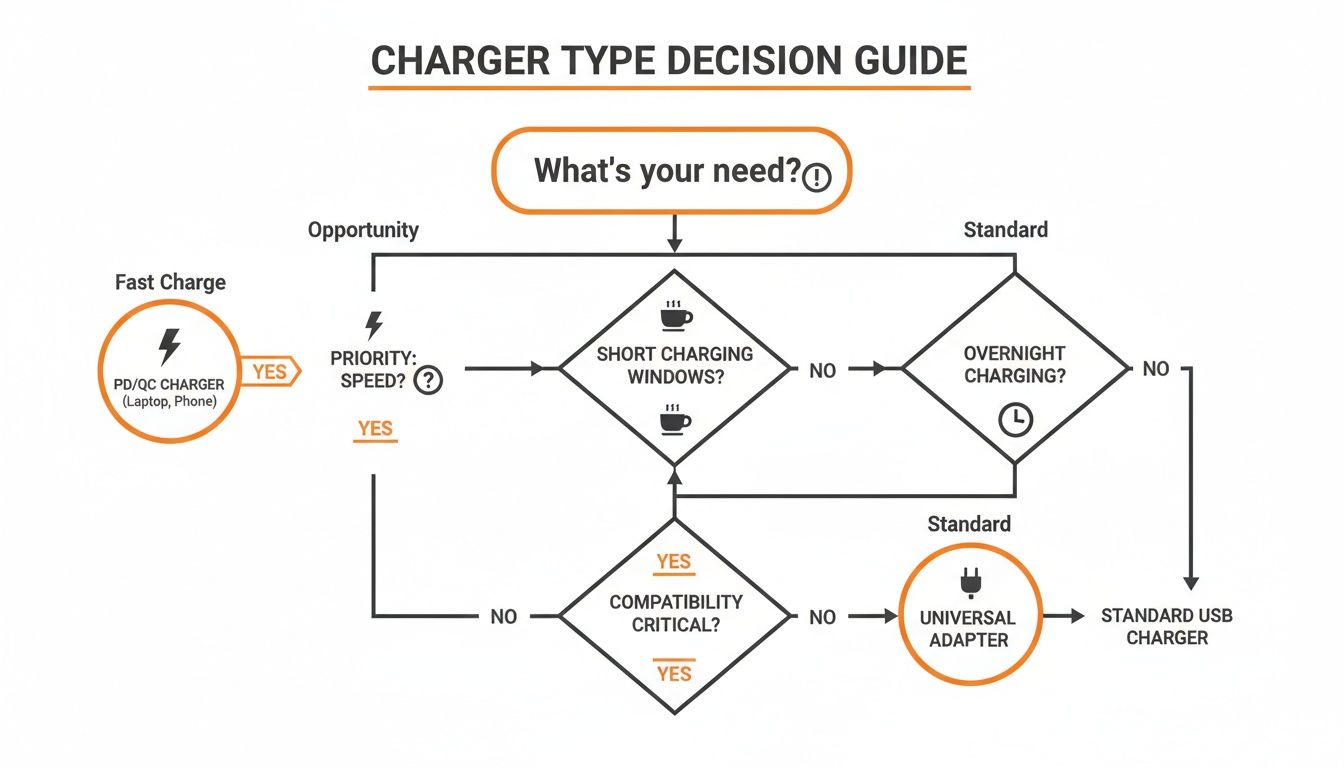

This flowchart lays out the common charging strategies to help you narrow down the type of charger you'll need.

The chart makes it clear: your operational needs—whether you need all-day power, quick top-ups between shifts, or simple overnight charging—directly determine the right charger technology for your fleet. Getting this match right is the first step toward reliable performance.

Setting Up Your Charging Station Safely

A charging station is way more than just a heavy-duty extension cord plugged into the wall. Think of it as a dedicated industrial zone that demands your full respect. Getting the setup wrong is a surefire way to get a visit from OSHA or, worse, the fire department.

Here’s your no-nonsense guide to creating a safe, compliant setup that keeps your people out of harm's way and your machines running smoothly.

This isn’t about just ticking boxes on a safety form. It’s about preventing real-world accidents—chemical burns, fires, and explosions—that are infinitely more expensive than any forklift truck charger. The rules laid out in OSHA 29 CFR 1910.178 aren't just suggestions; they're the absolute bare minimum for keeping your operation safe.

The entire material handling industry is going electric, with these machines now dominating new equipment sales. The global forklift market, valued at USD 81.4 billion in 2025, is on track to hit USD 281.6 billion by 2035. Electrics are the main driver, holding a massive 58.0% market share. This boom means more charging stations are popping up everywhere, often installed by people who haven't been trained on the very real risks involved.

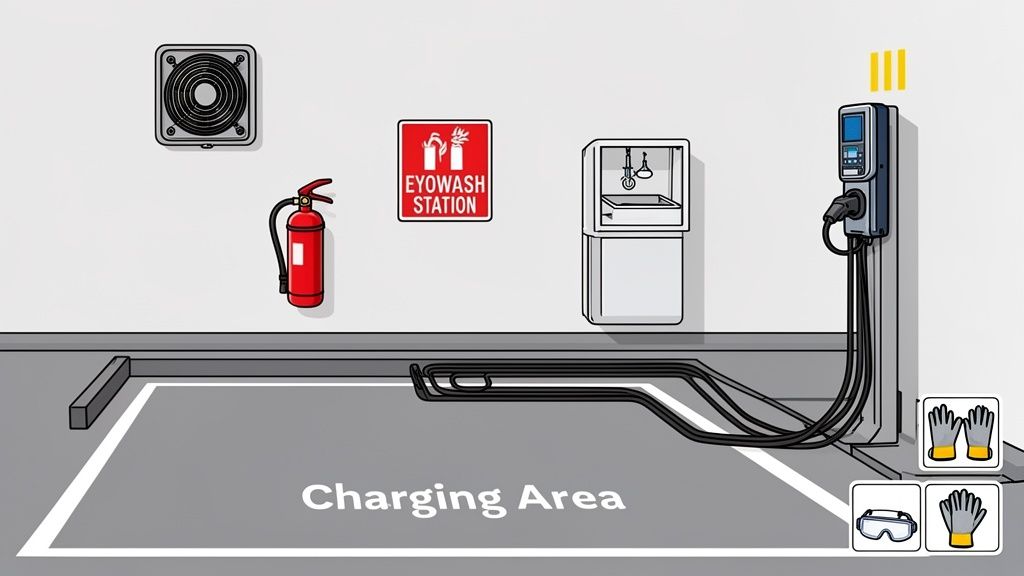

Creating a Designated Charging Area

First things first: your charging area needs to be a clearly marked, designated area. This isn't just a random corner of the warehouse. It’s a purpose-built zone with strict safety protocols, starting with keeping it clear of all combustible materials.

Proper ventilation is another big one. When a lead-acid battery charges, it lets off hydrogen gas. You can't see it or smell it, but it's incredibly explosive. You absolutely need adequate airflow to keep this gas from concentrating to dangerous levels.

Next, you have to equip the area with the right safety gear. This part is completely non-negotiable.

- Fire Extinguisher: A dry chemical ABC or CO2 extinguisher needs to be mounted nearby and easily accessible.

- Eyewash Station: If you’re dealing with lead-acid batteries and handling electrolyte, an eyewash station is mandatory. Acid splashing in an eye can cause permanent blindness in seconds.

- Neutralizing Agent: Keep baking soda or another approved acid neutralizer on hand to deal with any spills the moment they happen.

Don’t treat safety equipment like an afterthought. An eyewash station that costs a few hundred dollars is cheap insurance against a devastating, life-altering injury and the massive lawsuit that comes with it.

Cable Management and Personal Protection

Damaged charger cables are a leading cause of electrical shorts and fires. All it takes is one forklift running over a cable to crush the internal wiring, creating a hot spot that can easily ignite.

Get those cables up off the floor. Use wall-mounted brackets or automatic retractors to keep them organized and out of the way. This also eliminates a serious trip hazard for your crew. And when you connect the charger, make sure the plug is seated all the way in. A loose connection can arc, which will melt the plug and create a huge fire risk.

Finally, anyone handling batteries or connecting a forklift truck charger must be wearing the right Personal Protective Equipment (PPE). This is no place to cut corners. For a deeper dive, check out our guide on essential forklift safety protocols, which covers best practices for operators and maintenance staff.

Essential PPE for battery handling includes:

- Safety Goggles or a Face Shield: This protects your eyes from acid splashes.

- Acid-Resistant Gloves: Your standard work gloves won't do the trick. You need rubber or neoprene.

- Apron: A full, acid-resistant apron protects your torso from any spills.

Treating your charging station with this level of seriousness is what separates a professional, safe operation from a future accident report.

Field Maintenance and Troubleshooting Common Faults

A forklift charger that's ignored is a charger that's going to fail—it's that simple. Out in the field, we don't have time for a dealer tech to show up with his laptop just to tell us a connection is corroded. Keeping this equipment alive comes down to simple, gritty maintenance and knowing how to diagnose a problem yourself.

Just like a JCB telehandler, these chargers talk to you if you know how to listen. Error codes and weird behavior aren't a reason to panic; they're your starting point. You don’t make money waiting for a service call. You make money by identifying the root cause, getting the right parts from a supplier like Flat Earth Equipment, and getting your machine back in the fight.

Your Pre-Charge Checklist

Before you even think about troubleshooting, you need to do the basics. Honestly, most of the "catastrophic failures" I see are just the result of months of neglect. Make these checks a non-negotiable part of your routine.

- Inspect the Cables: Look for any cuts, cracks, or bare copper showing. A damaged cable isn't just a failure point; it's a fire hazard. Pay extra attention to where the cable enters the charger and the connector—these are high-stress areas.

- Check the Connector: The plug itself is a common weak link. Look for signs of arcing (black scorch marks), melted plastic, or bent pins. A sloppy connection creates resistance and heat, which will eventually cook the plug from the inside out.

- Clean the Terminals: Corrosion is the enemy. On lead-acid batteries, that white and blue crust is a dead giveaway of acid creep. Scrub it off with a wire brush and a solution of baking soda and water. A clean connection is a good connection.

- Clear the Vents: Every charger has cooling fans and vents. They suck in dust, dirt, and whatever else is floating around your shop. When they get clogged, the charger overheats and shuts down. Blow them out with compressed air regularly.

This isn't rocket science; it's basic upkeep. A five-minute inspection can save you from a five-day wait for a new charger. It's the same principle as checking the hydraulic fluid on an excavator before you start a trench—you do it every single time.

Diagnosing Common Charger Faults Without the Dealer Laptop

When the charger acts up, don't just stare at it. Follow a logical process to narrow down the problem. This is how you figure out if it’s the power source, the charger, or the battery itself.

The Charger Won't Turn On at All

This is the most common call. The operator plugs it in, and... nothing. No lights, no hum, no action.

- Check the Source: Is the breaker tripped? Is the outlet dead? Grab a multimeter or just plug a drill into the same outlet to confirm you have power coming from the wall. You'd be amazed how often the problem is the building's electrical, not the charger.

- Inspect the AC Input Cable: Walk the entire length of the power cord, checking the plug and the cable itself for damage. It’s not uncommon for a forklift to run over it, severing the connection internally.

- Check Internal Fuses: Many chargers have internal fuses that can blow from a power surge. Always disconnect the power before you open the case, but a simple fuse check can often be the fix.

The Charger Gives an Error Code

Don't just guess what the blinking lights mean. Every single charger has a legend printed on it or in its manual that tells you what the error codes signify. Common culprits include:

- Battery Voltage Too High/Low: The charger won't even start if it detects a battery that's either completely dead or has been severely over-discharged.

- Over-Temperature Fault: This usually points right back to those clogged cooling fans we talked about. The machine is protecting itself.

- Communication Error: On smarter chargers, this can mean a bad connection or a fault in the battery's own internal monitoring system.

The Battery Isn't Getting a Full Charge

If the charger seems to be working but the battery dies halfway through a shift, something's wrong.

First, verify the charger is set to the correct profile for your battery type (lead-acid vs. lithium). Next, test the charger on a battery you know is good. If that second battery charges up just fine, your problem isn't the forklift charger—it's the original battery that's likely sulfated or at the end of its life.

This systematic approach lets you pinpoint the real issue fast. It's about taking control back from the dealer's service department and solving problems yourself, on your schedule.

How to Source Your Next Charger Like a Pro

Buying a new forklift charger isn't like ordering office supplies. Get it wrong, and you're stuck with an expensive paperweight. Get fleeced by a supplier who promises the world but delivers a lemon? Even worse. This isn't just about the sticker price; it's about making a smart investment that doesn't come back to bite you.

Forget the initial cost for a second. The real number you need to care about is the Total Cost of Ownership (TCO). That cheap, old-school ferroresonant charger might save you a grand upfront, but its dismal energy inefficiency—sometimes as low as 75%—will absolutely bleed you dry on the power bill month after month.

Compare that to a modern high-frequency unit. Sure, it costs more, but with efficiency ratings topping 95%, it starts paying for itself in energy savings from day one. It's the same logic as buying a quality tool once instead of a cheap one three times.

Renting vs. Buying Your Charger

Sometimes, buying just doesn't make sense. If you're gearing up for a seasonal rush or taking on a short-term project, renting a charger gives you the power you need without the long-term capital hit.

Here’s a quick gut check for the rent-vs-buy decision:

- Rent When: You have a temporary spike in fleet size, you want to test a specific charging technology (like fast charging) before committing, or you need an immediate stand-in while waiting for a permanent unit to arrive.

- Buy When: The charger is for a permanent addition to your fleet, you have a long-term operational need, and you want full control over the asset and its maintenance schedule.

For many operations, a hybrid approach is the right call—own your core chargers and rent for the peaks.

Questions to Hammer Your Supplier With

Before you sign any purchase order, you need to grill the supplier. Don't let them off the hook with vague promises. Here’s your checklist—if they can't give you straight answers, walk away.

- What's the real lead time? Don't accept "a few weeks." Ask them if the unit is physically in their warehouse right now, ready to ship.

- What does the warranty actually cover? Get the details. Does it cover parts and labor? Who pays for shipping on a warranty claim? What actions will void it?

- Who provides tech support when it breaks? Find out if you'll be talking to a real technician who knows the equipment inside and out, or just a call center agent reading from a script.

- Are replacement parts readily available? Can you get common failure items like fans, fuses, and connectors quickly, or are they a special order from overseas with a long wait?

This process weeds out the order-takers from the real partners. The growth in logistics is fueling a massive demand for charging equipment, with the North American forklift battery charger market projected to hit US$ 1,292.26 million by 2033. This boom means more suppliers are flooding the market, but not all of them understand that your downtime is their problem. You can find more details about this market growth in a recent industry report.

Partner with suppliers like Flat Earth Equipment who get it. We know that a down machine is costing you money every single minute. When you need a reliable forklift truck charger, you need a team that stocks what they sell and can get it to you fast.

Straight Answers to Common Charger Questions

When you're out in the field, you don't have time to flip through a dense manual. You need straight talk to get your equipment moving again. Here are the quick, no-nonsense answers to the charger questions we hear all the time.

Can I Use Any Charger If the Voltage Matches?

Absolutely not. That’s a fast track to starting a fire.

Matching the voltage is just step one—the easy part. The real danger is in the charging profile, which is the specific algorithm the charger uses. It has to match the battery’s chemistry. Trying to juice up a lithium-ion battery with a standard lead-acid charger is a recipe for disaster. The charger will completely misread the battery's state, leading to overcharging, permanent cell damage, and a very real risk of thermal runaway.

You also have to make sure the charger’s amperage output is correctly sized for the battery's Amp-Hour (Ah) rating. Always triple-check the data plates on both the battery and the charger. No excuses.

What Is the Difference Between Opportunity and Fast Charging?

Think of it like this: Opportunity charging is like sipping water all day to stay hydrated. You plug the forklift in during short breaks—lunch, shift changes, any downtime you have—to keep the battery constantly topped off. The goal is to maintain a high state of charge, avoiding deep discharges and eliminating the need for mid-shift battery swaps.

Fast charging, on the other hand, is like chugging a gallon of water when you're completely parched. It’s an aggressive, high-amperage blast designed to take a battery from a low state of charge to nearly full in just an hour or two. This gets the machine back in the game quickly, but it requires special, heavy-duty batteries and chargers built to handle all that heat and stress.

Don't confuse the two. Trying to fast charge a standard battery is like hooking a fire hose to a garden sprinkler—you're going to destroy it.

How Do I Know If the Charger or the Battery Is Bad?

Before you assume the worst, check the simple stuff. Is the charger even getting power from the wall? Is the breaker tripped? Are the connectors clean and seated properly? Look at the indicator lights and compare them to the legend printed right on the charger's case.

If the basics check out, the easiest way to pinpoint the problem is to swap components with a known-good setup.

- Take the suspect forklift truck charger and connect it to a battery you know works. If that good battery won't charge, you’ve found your culprit: the charger is bad.

- Next, connect a known-good charger to the suspect battery. If it still fails to take a proper charge, your battery is likely the problem.

A quick check with a multimeter at the charger’s output terminals can also tell you if it's putting out the correct voltage. This basic troubleshooting process will get you to the root of the problem fast, without having to wait around for a dealer technician with a laptop.

When your troubleshooting points to a dead charger, you can't afford to wait. Flat Earth Equipment stocks the reliable, field-tested chargers and parts you need to get back up and running fast. Get the right equipment shipped today from https://flatearthequipment.com.