Forklift training isn't just a good idea—it's the law. OSHA is crystal clear on this, and their core rule, found in 29 CFR 1910.178, lays out a non-negotiable, three-part process for certification. This includes formal instruction (the book smarts), practical training (hands-on driving), and a final performance evaluation. This isn't just for the full-timers; it applies to everyone who touches the controls, from permanent staff to temporary help.

Understanding OSHA's Core Forklift Training Mandate

So, what does OSHA really require? It's more than just watching a few videos or passing a quick driving test. Think of it as a complete safety blueprint designed to build real competence and stop accidents before they can happen. It’s less of a bureaucratic checkbox and more of an investment in a safer workplace.

The federal standard 29 CFR 1910.178 is the final word on the matter. There are no loopholes for part-time, seasonal, or temp workers. If someone operates a powered industrial truck—even for a few minutes a day—they have to be properly trained and certified under this rule. No exceptions.

OSHA's Three Pillars of Forklift Certification

At its heart, OSHA's rule is built on three pillars. Each one supports the next, creating a well-rounded operator who understands both the "why" behind the rules and the "how" of safe, practical operation.

These are the three non-negotiable components of any legitimate, OSHA-compliant training program.

| Training Component | Description | Objective |

|---|---|---|

| Formal Instruction | Classroom-style learning covering OSHA regulations, truck specifics, and workplace hazards. | To build a strong theoretical foundation of safety principles and operational knowledge. |

| Practical Training | Supervised, hands-on exercises where the operator uses the forklift in a real-world setting. | To translate theoretical knowledge into practical skills and build operational confidence. |

| Performance Evaluation | A final test where an evaluator assesses the operator's ability to safely perform required tasks. | To verify and document that the operator is competent and ready for independent operation. |

This three-part structure is exactly why you can't get a real forklift certification entirely online. The classroom part? Perfect for an online course. But the hands-on practice and the final evaluation must happen in person, at the actual worksite, on the equipment the operator will be using. You can explore comprehensive forklift safety information to dig deeper into these critical distinctions.

The seriousness of this approach is reflected in the numbers. The global market for forklift operator training hit $1.2 billion in 2024 and is expected to climb to $2.4 billion soon, all driven by these strict safety rules. It’s a massive investment, but one that underscores a worldwide commitment to keeping operators safe.

What Every Forklift Certification Course Must Cover

Let’s be clear: not all forklift training programs are created equal. For a certification to be worth anything in the eyes of OSHA, the course has to follow a very specific curriculum. Think of it as a non-negotiable checklist. If a training program skips any of these core areas, it simply doesn't meet federal standards, putting both the operator and the employer in a tough spot.

OSHA breaks these requirements down into two main buckets. The first is all about the machine itself—what they call "truck-related topics." The second covers the actual environment where the forklift will be used, which they refer to as "workplace-related topics."

Any legitimate training course will hammer both of these areas hard. This ensures operators don't just know how to pull the levers, but also how to handle the real-world challenges of their specific job site.

Truck Related Training Topics

Before anyone can zip around a busy warehouse, they have to get intimately familiar with the machine under them. This part of the training is all about the nuts and bolts of the forklift—its mechanics, its limits, and the physics that keep it upright. This is the foundational knowledge that prevents tip-overs, dropped loads, and costly equipment damage.

OSHA mandates that every single training program must cover these truck-specific subjects:

- Operating Instructions and Warnings: This means knowing how to read every label, decal, and manual instruction for the specific forklift model being used.

- Differences from an Automobile: Trainees need to understand why a forklift isn't just a funny-looking car. This covers critical concepts like rear-wheel steering, unique weight distribution, and maneuverability.

- Controls and Instrumentation: A hands-on tour of the cockpit—what every lever, pedal, and gauge does, from lifting the mast to checking the battery level.

- Engine or Motor Operation: A basic understanding of what powers the machine, whether it’s an internal combustion engine or an electric motor.

- Steering and Maneuvering: This is the practical side—learning to navigate forward, backward, and through tight spots while accounting for the machine's unique handling.

- Visibility: Operators must learn how to work around the massive blind spots created by the mast and the load itself to keep their path clear and pedestrians safe.

- Fork and Attachment Adaptation: An explanation of how adding attachments like clamps or rotators changes the forklift’s stability, capacity, and overall performance.

- Vehicle Capacity and Stability: This is one of the most critical safety topics. It teaches operators how to read a data plate and understand the "stability triangle" to prevent catastrophic tip-overs.

- Vehicle Inspection and Maintenance: Training operators to perform a thorough pre-shift inspection every time and to immediately report any problems to a supervisor.

- Refueling and Recharging: Covering the strict safety protocols for refueling gas or propane trucks and for charging or swapping batteries on electric models.

The stability triangle is an imaginary area under the forklift between the front wheels and the center of the rear axle. To keep from tipping over, the combined center of gravity of the forklift and its load must stay inside this triangle at all times.

Workplace Related Training Topics

Mastering the machine is only half the battle. A truly skilled operator also has to be an expert in their specific work environment. These workplace-related topics train operators to spot and react to hazards unique to their job site, whether it's a slick spot on the floor or a coworker stepping out from behind a rack.

This site-specific training is a major reason why a forklift certification isn't a "one-and-done" ticket that works everywhere. What's perfectly safe in a wide-open lumberyard could be a recipe for disaster in a narrow-aisle warehouse. For a closer look at local nuances, you can explore what it takes to get your forklift certification in Texas and other states.

OSHA requires every training program to include these workplace-specific factors:

- Surface Conditions: How to operate safely on everything from smooth concrete to bumpy lots, including ramps and potentially slick floors.

- Load Manipulation: The correct way to stack, unstack, and move loads to ensure they are stable and secure from point A to point B.

- Pedestrian Traffic: The rules of the road for working in areas with people on foot, like using the horn at intersections and keeping a safe distance.

- Navigating Hazardous Locations: Special precautions for operating in places with poor ventilation, flammable materials, or other environmental risks.

- Ramps and Slopes: The right way to drive on an incline—loaded forks always face uphill, unloaded forks always face downhill. No exceptions.

- Confined Spaces: How to operate safely in tight quarters like the inside of a semi-trailer or between cramped racking where there’s no room for error.

- Environmental Conditions: Making smart adjustments for things like poor lighting, loud noises, or extreme temperatures that can impact safety.

- Leaving a Forklift Unattended: The specific rules for parking a forklift, which always includes lowering the forks completely, setting the brake, and turning off the power.

The Critical Role of Hands-On Training and Evaluation

Passing an online quiz is one thing, but safely navigating a 9,000-pound machine through a busy warehouse is a completely different ballgame. This is exactly why OSHA insists on hands-on, practical training as a non-negotiable part of any legitimate forklift certification. Classroom or online courses are great for building that essential foundation of knowledge, but they can't teach the muscle memory, spatial awareness, and real-time decision-making that only come from actually operating the equipment.

Think of it like learning to be a pilot. You wouldn't want to fly with someone who has only read books about aviation but never actually touched the controls of a plane. The same exact logic applies here. The real learning—the journey from just knowing the rules to truly being competent—happens on the warehouse floor, not on a computer screen.

From Knowledge to Competence

The whole point of hands-on training is to prove competence, not just knowledge. It's the bridge that connects what an operator knows with what they can safely do. This part of the training is always supervised by a qualified evaluator who guides the trainee through a series of exercises, building both skill and confidence in a controlled setting.

This practical instruction has to cover the real-world tasks an operator will face every day. Before anyone can even think about being evaluated for certification, they need to master several core skills.

- Performing a Pre-Use Inspection: This isn't a checklist you just glance at. The operator has to physically walk around the vehicle, checking fluid levels, tire pressure, the horn, lights, and fork condition to prove they can spot a safety issue before a shift even starts.

- Maneuvering in Tight Spaces: This is a test of finesse. It shows the operator understands the forklift's unique rear-wheel steering and pivot point, requiring them to navigate narrow aisles and sharp corners without hitting anything.

- Stacking and Tiering Loads: Operators must show they can lift, place, and retrieve loads at different heights, making sure every pallet is stable, centered, and positioned correctly on the racking.

- Operating on Ramps and Inclines: A critical skill. This involves knowing how to keep the load pointed uphill at all times to maintain stability and control—something you can't learn from a video.

The Final Check Ride: Proving Your Skills

After getting enough practice, the final step is the performance evaluation. Think of this as the forklift equivalent of a pilot's check-ride—a formal, observed test to prove the operator can handle the machine safely and efficiently under the typical conditions of their workplace. An evaluator will watch them perform the exact tasks they'll be expected to do on the job.

This evaluation isn't another training session; it's the final exam. The operator has to perform the required tasks without any coaching or assistance, proving they are ready for the responsibility.

The stakes for this practical evaluation are incredibly high. According to OSHA, forklift accidents are responsible for about 85 fatalities in the United States every single year. That statistic alone highlights why effective, hands-on training is an absolute must. It's pushed the whole industry toward competency-based training models that confirm an operator can actually perform safely, not just that they logged a few hours in a classroom. For a deeper dive into this shift, you can find more about the innovations transforming workplace safety on ForkliftAcademy.com.

What Makes a Trainer Qualified to Evaluate?

OSHA is very clear that the person conducting the hands-on training and evaluation must be qualified. But what does that really mean? A qualified trainer is someone who has the necessary knowledge, training, and experience to properly train and evaluate powered industrial truck operators.

This person doesn't need a special certificate from OSHA itself, but the employer has to be able to prove they have the expertise to make a sound judgment. This is often an experienced supervisor, a seasoned veteran operator, or a third-party safety professional who has a deep understanding of both the equipment and the specific hazards of that workplace. Their sign-off is the final, critical step in creating a truly competent and certified operator.

Navigating Refresher Training And Recertification

Getting a forklift certification isn't a one-and-done deal. It’s more like a pilot's license—it requires regular check-ins to make sure your skills are still sharp and you’re up-to-date on safety. OSHA is very clear on this: every operator's performance has to be formally re-evaluated at least once every three years.

This three-year rule is your baseline. Think of it as a mandatory safety checkup to catch any bad habits that might have crept in over time. It's a scheduled way to make sure even your most seasoned operators are still following the book before a minor issue becomes a major accident.

But you can't always wait three years. Certain events on the job will instantly trigger the need for retraining, no matter how recently an operator was certified.

Triggers For Immediate Retraining

These triggers are non-negotiable because they signal a sudden change in risk. An operator might be a pro on one type of forklift in a quiet warehouse, but put them on a different machine or in a busier environment, and the situation changes entirely.

OSHA breaks these triggers down into four main categories:

- Operator-Related Incidents: This is the big one. If an operator is involved in an accident or even a near-miss, retraining is mandatory to figure out what went wrong and prevent it from happening again.

- Unsafe Operation: A supervisor spots an operator driving too fast, handling a load improperly, or just breaking the rules. That observation alone is enough to require immediate retraining.

- Equipment Changes: When an operator switches to a new type of forklift—say, from a standard sit-down counterbalance to a narrow-aisle reach truck—they need retraining on that specific machine's controls and handling.

- Workplace Changes: The environment itself can change. If you reconfigure racking, see a big jump in foot traffic, or change the surfaces operators drive on, they need training to adapt to the new hazards.

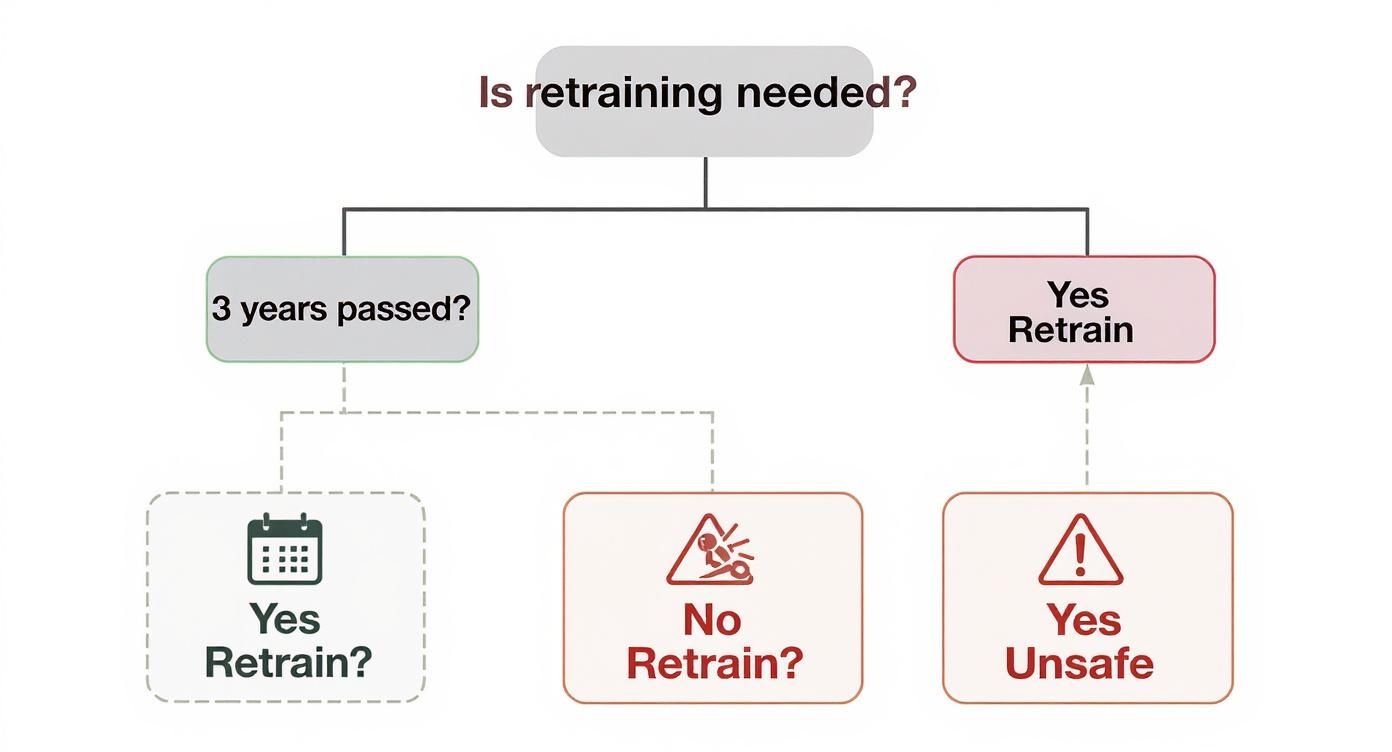

This flowchart makes it easy to see when retraining is needed.

As you can see, the three-year clock is always ticking, but any safety event or significant change in the job resets the need for training right now.

Routine Vs. Event-Triggered Training

It helps to think about the two types of retraining differently. The three-year evaluation is a proactive check-up, while event-triggered training is a reactive fix to a specific problem.

Refresher training isn’t a punishment. It’s a vital safety intervention that reinforces best practices and corrects unsafe behaviors before they result in a serious accident.

Understanding this distinction is key to keeping your whole team safe and compliant. The table below breaks it down.

Forklift Refresher Training Triggers

| Requirement | Frequency / Trigger | Purpose |

|---|---|---|

| Routine Evaluation | At least once every three years | Proactively verifies that an operator's skills are still sharp and compliant with current safety standards. |

| Event-Triggered Retraining | Immediately following a specific event | Reactively addresses a specific safety issue, like an accident, unsafe action, or a change in equipment or environment. |

Ultimately, these forklift training requirements create a system of continuous oversight. By combining scheduled evaluations with quick responses to safety triggers, you ensure your operators stay competent, compliant, and ready to work safely every single day.

Mastering Documentation and Employer Responsibilities

A forklift certification isn't just a laminated card for an operator's wallet. It's the final, official proof that a rigorous, documented training process took place. When an OSHA inspector shows up, they’ll want to see that paper trail—and it better be complete.

This isn't just about checking a box. Proper records create a clear line of accountability for every operator on your floor. Without that documentation, a certification is essentially worthless in the eyes of the law, leaving your business exposed.

The Anatomy of a Compliant Certificate

Think of the training certificate as the operator's official safety file. It’s got to have all the right pieces of information to hold up under scrutiny. Missing even one detail creates a compliance gap that can lead to some hefty fines.

Every operator's certification record must include these four key elements:

- Operator's Name: The full name of the person who was trained.

- Date of Training: The exact date the classroom and practical instruction happened.

- Date of Evaluation: The date the operator passed their hands-on driving test.

- Identity of the Trainer/Evaluator: The name of the qualified person who conducted the training and signed off on the evaluation.

This commitment to strict documentation is a big reason why North America is a global leader in forklift safety, holding about 35% market share in the operator training industry. The high bar set in the U.S. for certification and record-keeping continues to shape safety standards worldwide.

The Employer's Ultimate Responsibility

Here’s a common—and dangerous—misconception: many employers think that if a new hire shows up with a forklift card, their job is done. That couldn't be further from the truth. The final responsibility for certifying an operator for your specific workplace always falls on the employer.

An external training certificate is proof of past instruction, not a universal license to operate any forklift, anywhere. The employer is the final gatekeeper who must verify that an operator is competent to use their equipment in their unique environment.

Simply accepting a card from a previous job isn't enough. You have to watch them operate your equipment and confirm their training applies to your site. Are your aisles narrower? Is the forklift a different make or model? If anything is different, you are required to provide additional, site-specific training before authorizing them to work.

It all comes down to this: the employer has the final say and carries the ultimate responsibility for safety. Our guide on implementing a robust safety program can help you build that culture of accountability from the ground up.

Your Action Plan for OSHA-Compliant Certification

Knowing the OSHA rules is one thing, but turning that knowledge into a real-deal certification takes a solid plan. This final roadmap breaks the whole process down into simple, manageable steps. Whether you're an employer setting up a safety program from scratch or an operator trying to get certified, this is your guide from start to finish.

Think of this less like a one-off task and more like a journey. Each step builds on the last, making sure that by the end, the operator isn't just certified on paper—they're genuinely competent and safe. This structured approach is the key to nailing all the forklift training requirements and building a safety culture that actually works.

Step 1: Find a Qualified Training Provider

First things first, you need to pick a program for the formal instruction—the "classroom" part of the training. The goal is to find a provider that covers all the truck- and workplace-specific topics OSHA demands, and does it in a way that's clear and engaging, not just a box-ticking exercise.

Modern training gives you flexibility without cutting corners. For example, online courses like the ones from Flat Earth Equipment let trainees learn at their own speed. These programs often use interactive modules, quizzes, and even offer bilingual options in English and Spanish, making them a great tool for building a strong foundation before anyone gets near a real forklift.

Step 2: Complete the Formal Instruction

Once you’ve got a provider, the trainee has to go through the entire formal curriculum. This is where they learn the "why" behind the rules—from understanding the stability triangle to the nitty-gritty of refueling or recharging their specific machine. This phase has to be done before any hands-on practice starts.

After finishing this part, the operator should get some proof. Today's systems often issue an instant, QR-verifiable certificate for the classroom portion. This creates a clean, accessible record showing the first critical piece of the OSHA puzzle is in place, setting the stage for the practical stuff.

Remember, completing an online course alone does not make an operator certified. It is only the first of three mandatory steps. The real test of skill happens on the warehouse floor.

Step 3: Undergo Supervised Hands-On Practice

Alright, time to get behind the wheel. The operator now has to practice on the exact type of forklift they'll be using on the job, all while being watched by a qualified evaluator. This could be an experienced supervisor who knows the equipment inside and out or a dedicated third-party trainer.

This is where the theory hits the concrete. The operator gets to practice the real-world skills they’ll use every day:

- Running through pre-shift inspections to spot potential problems before they happen.

- Navigating tight aisles and getting a feel for the actual workplace layout.

- Safely lifting, moving, and stacking loads at different heights.

Step 4: Pass the Performance Evaluation

After getting enough practice time in, it’s time for the final performance evaluation. Think of it as the official driving test. The qualified evaluator watches the operator perform their duties without any help, making sure they can handle the forklift safely and competently in their specific work environment.

Passing this evaluation is the last hurdle. The evaluator’s sign-off is the official confirmation that the operator has successfully turned classroom knowledge into real-world skill. This step is the most critical part of ensuring an operator is truly ready to work alone safely.

Step 5: Document Everything and Issue Certification

With the evaluation passed, the last piece is the paperwork. The employer must create a certification record that includes the operator's name, the training date, the evaluation date, and the name of the person who conducted the training and evaluation. This document is the official proof that you're compliant.

This complete, documented process is what officially turns training into a legally recognized certification. It proves every requirement has been met, creating a safe operator and a compliant workplace ready to meet OSHA standards head-on.

Frequently Asked Questions

When it comes to OSHA compliance, the details matter. Let's clear up some of the most common questions we hear about forklift training so you can feel confident you're doing things the right way.

Can I Get My Forklift Certification Completely Online?

No, and this is a big one. A 100% online certification simply doesn't meet OSHA's requirements. While online courses are a fantastic way to handle the classroom part—what OSHA calls "formal instruction"—that's only piece number one.

The rule, 29 CFR 1910.178, is crystal clear: every operator needs a hands-on, practical evaluation. This isn't just a quick drive around the parking lot. It has to be done in person, on the exact type of forklift they'll be using for their job, right there in your actual work environment.

Does My Forklift Certification Transfer to a New Job?

Not really. Think of your certification as being tied to the employer who issued it, not to you as an individual. Your new boss has the final say and the legal responsibility to certify that you are competent to operate their equipment in their facility.

So while having prior training is a huge plus, your new employer still needs to evaluate your skills. They have to make sure you're up to speed on their specific machines, attachments, and any unique workplace hazards before they can officially certify you.

Your forklift certification is tied to the employer who issued it. Think of it as site-specific clearance rather than a universal driver's license that works anywhere, for any vehicle.

How Long Is a Forklift Certification Valid?

OSHA requires a performance evaluation at least once every three years. But don't mistake that for a guarantee—it's just the maximum time allowed between evaluations.

In reality, a certification needs to be revisited much sooner if certain things happen. An operator must get immediate refresher training and a new evaluation if they:

- Are involved in an accident or even a near-miss.

- Are spotted operating the forklift unsafely.

- Get assigned to a different type of forklift.

- Run into major changes in the workplace that could affect safe operation.

So, staying certified is about both the calendar and consistent, safe performance on the job.

Ready to meet OSHA’s forklift training requirements with a program that's both compliant and convenient? Flat Earth Equipment offers online, bilingual courses that cover the formal instruction you need, complete with instant, QR-verifiable certificates. Get your team started today at https://flatearthequipment.com.