Let's be blunt. Your entire operation runs on uptime, and nothing torpedoes a good shift faster than a dead forklift hunting for a charge. Most guides on forklift charging stations read like a sales brochure, but this is the real deal—straight talk from someone who actually works with heavy iron and its finicky electronics.

The Unvarnished Truth About Your Charging Stations

Forget the dealership fluff for a second. A forklift charging station isn't some glorified extension cord you just plug into the wall. It's the beating heart of your material handling operation. If you get it wrong, you’re not just looking at a minor inconvenience; you're actively burning cash through crippling downtime, fried batteries, and workflow jams that screw up the whole facility. It's like running a JCB telehandler on a low DEF cycle—the machine just quits, and your day is shot.

This isn’t about buying shiny new gear. It's about building a bulletproof system that keeps your crew moving and your product flying out the door. A slapped-together charging setup is a direct path to expensive headaches the sales reps never seem to mention.

What’s Really at Stake

Think of your charging area as the pit stop for your warehouse race team. A poorly planned one guarantees you’ll lose the race. You’ll be dealing with:

- Crippling Downtime: An operator wandering around looking for an open charger or waiting on a battery swap is an operator not moving pallets. That lost time adds up faster than you can count.

- Premature Battery Failure: Using the wrong charger or messing up the charging cycles will absolutely murder a battery that should have lasted for years. A single lead-acid battery runs anywhere from $2,000 to $6,000, so sloppy management is a massive financial leak.

- Serious Safety Hazards: We’re talking about real dangers here—hydrogen gas buildup, acid spills, and electrical fires. OSHA doesn’t mess around with this stuff, and a violation under standard 29 CFR 1910.178 can bring steep fines and even shut you down.

Out in the field, you learn one thing fast: the weakest link breaks the whole chain. For an electric fleet, that weak link is almost always a poorly designed or mismanaged charging station. It's the "Dealer Laptop" of the warehouse—it promises to solve your problems but usually just gets in your way.

This guide is your counterattack. We're going to tear down the what, where, and how of setting up a station that actually works in the real world, not just on a spec sheet.

Decoding Your Charging Options Without the Sales Talk

When it's time to choose a charging system, the dealership will hit you with glossy brochures and promises of magic solutions. But out here, in the real world, the wrong choice doesn't just mean a bad investment—it means your whole operation grinds to a halt. It's like being locked out by the dealer's laptop when you’re trying to fix a simple sensor on a JCB backhoe; you know what needs to be done, but the system is working against you.

Let's cut through the noise. There are really only a few ways to power your electric fleet, and each one comes with its own set of brutal truths. Your job is to pick the one that fits your workflow, not the one that fits a salesman's commission.

Conventional Charging and Battery Swapping

This is the old-school, tried-and-true method. You run a battery until it's nearly dead, pull it out with a hoist or extractor, drop in a fresh one, and put the spent battery on a charger for its full 8 to 12-hour cycle. It’s straightforward and incredibly effective for multi-shift operations that simply cannot afford to stop.

- The Good: This system guarantees maximum uptime for the forklift itself. A battery swap takes minutes, not hours, so your machine is back on the floor immediately.

- The Bad: It demands a dedicated, well-ventilated battery room that eats up valuable floor space. You also need heavy-duty handling equipment and a crew trained to move thousand-pound batteries without crushing a hand or causing a dangerous short. It’s a serious setup for a serious operation.

Opportunity Charging

Opportunity charging is basically the "plug it in whenever you can" method. The operator connects the forklift to a charger during breaks, lunch, or any other short period of downtime. The whole idea is to keep the battery topped off throughout the shift instead of running it all the way down.

This sounds great on paper, but it’s a lot like trying to keep a finicky AdBlue system happy by just adding a little at a time. It might work for a while, but if you're not careful, you're causing long-term damage. Standard lead-acid batteries hate this kind of cycle, and this method can cook them over time if not managed perfectly. For this to really work, you need batteries specifically designed for it, like certain lithium-ion or thin plate pure lead models.

The decision tree below maps it out perfectly: a good charging setup leads directly to uptime, while a bad one creates a constant cycle of downtime and errors.

This visual makes it crystal clear—a well-planned system is the only path to reliable fleet availability.

Fast Charging

Fast charging is the brute-force approach. It dumps high-amperage current into the battery to get it from nearly empty to fully charged in just a couple of hours. This approach completely eliminates the need for battery swapping and a dedicated battery room, letting you charge the battery while it’s still inside the forklift.

The catch? Your facility's electrical system better be ready for a fight. A bank of fast chargers pulling power simultaneously can put an incredible strain on your grid. It’s like firing up multiple welders on the same circuit—you’re just asking to trip a main breaker and plunge the whole warehouse into darkness.

The global forklift battery charger market, a key component of these stations, was valued at USD 1,128.22 million in 2023 and is projected to hit USD 2,088.68 million by 2030. This growth shows just how many operations are electrifying their fleets, making the right charger choice more critical than ever.

Each of these systems has its place. The key is knowing which one aligns with your operational intensity, your facility's limitations, and your budget—for both the initial setup and long-term battery replacement. If you’re not sure which hardware fits your fleet, you can explore a range of forklift battery chargers to compare specs directly. Don't let a sales pitch lock you into a system that creates more problems than it solves.

Charging Station Types At a Glance

To make the choice a little clearer, here's a quick, no-nonsense breakdown of how these methods stack up against each other.

| Charging Method | Best For | Charging Speed | Impact on Battery Life | Space Requirement |

|---|---|---|---|---|

| Conventional/Swapping | 3-shift, 24/7 operations; high-throughput warehouses | Slow (8-12 hours/battery) | Good (allows for full charge/cool-down cycles) | High (dedicated battery room) |

| Opportunity Charging | 1-2 shift operations with scheduled downtime (breaks, lunch) | Medium (frequent, short bursts) | Can be poor on standard batteries; requires specialized batteries | Low to Medium (chargers placed strategically) |

| Fast Charging | 2-3 shift operations aiming to eliminate battery swapping | Fast (1-3 hours/battery) | Can be harsh; reduces lifespan due to heat and high current | Low (no battery room, but needs ample electrical capacity) |

Ultimately, the best system is the one that integrates seamlessly into your existing workflow without creating new bottlenecks.

Site Prep and Electrical Realities the Dealer Won't Mention

Alright, let's talk about where these projects go completely off the rails. You can spend a fortune on the shiniest new fast charger, but if your building isn't ready for it, you’ve just bought yourself a very expensive, very heavy paperweight. The dealer sells you the hardware; they don’t stick around to deal with the expensive change orders and project delays when you realize your electrical panel is from the stone age.

This is the stuff that gets conveniently overlooked in the planning phase. Getting your site prep wrong means you're either creating a massive safety hazard or you're dead in the water before you even start. This isn't like swapping a solenoid on a JCB telehandler in the field—you can't just rig it to work.

Getting Your Power Straight

Before you even think about the layout, you need to handle the juice. A bank of forklift chargers, especially fast chargers, pulls a hell of a lot of power. It's not like plugging in a coffee maker; this is a serious industrial load that can bring an unprepared system to its knees.

First, get an electrician who actually knows industrial equipment to inspect your main service panel. You need to know if you have the capacity.

Here’s what you need to figure out, no excuses:

- Voltage and Amperage: Does your panel supply the correct voltage (208V, 240V, or 480V) and have enough amperage to handle the new load without tripping the main breaker every shift?

- Dedicated Circuits: Every single charger needs its own dedicated circuit. You can't daisy-chain these things. It’s a massive fire risk and will cause constant electrical faults.

- Phase: Are you running single-phase or three-phase power? Heavy-duty chargers almost always require three-phase power, and if your facility doesn't have it, you're looking at a huge, expensive upgrade.

This is the point of no return. Miscalculating your electrical needs is like ignoring a regen warning on a new piece of yellow iron. You can try to push through it, but eventually, the machine is just going to stop, and you'll be stuck waiting for someone with a laptop to fix a problem you could have avoided.

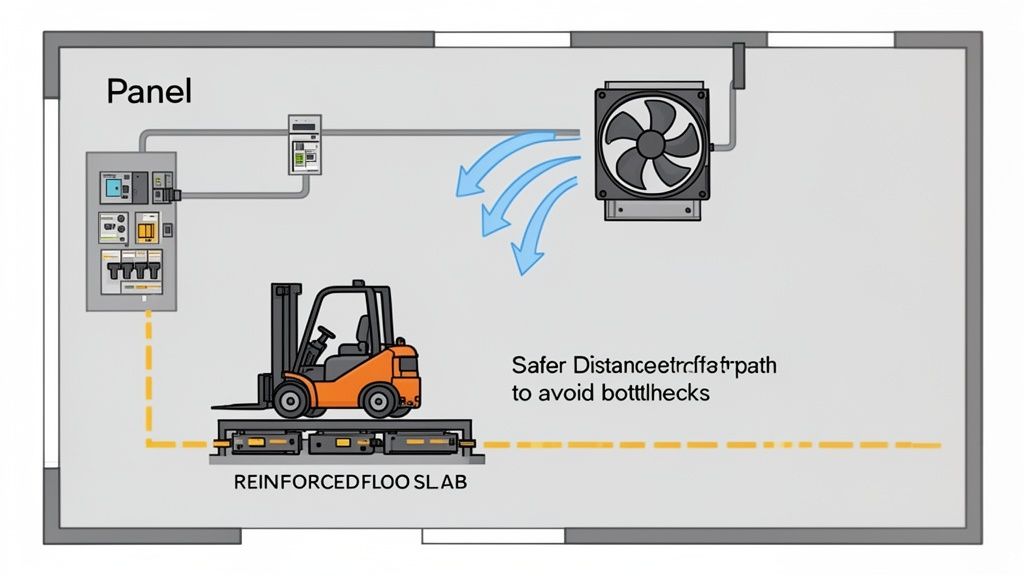

The Physical Battleground

Once the electrical is sorted, you have to think about the physical space. A forklift charging station isn't just a parking spot. It's a designated industrial area with real dangers if you get it wrong. The whole point is to optimize traffic, not create a bottleneck where operators are jockeying for position.

Think about the flow. Where do operators finish their routes? Place the chargers there. Don't make them drive across the entire warehouse just to plug in. Keep the area clear, marked, and protected with bollards or guardrails to prevent a stray fork from taking out a $5,000 charger.

For a tough unit that can handle the environment, a powerful option like the GreenX 48V 300A charger is built for the demanding conditions of a busy warehouse floor.

This isn't just about convenience. The global push for warehouse automation is massive, with the forklift charger market expected to grow at a 7% CAGR through 2033 from a $5 billion base in 2025. With that much investment pouring in, getting the fundamental layout and electrical right is the only way to keep up.

The Hazards They Don't Emphasize

Finally, let's talk about the stuff that can actually get someone hurt. With traditional lead-acid batteries, the big boogeyman is hydrogen gas. When these batteries charge, they off-gas hydrogen, which is highly explosive.

- Ventilation is Non-Negotiable: You must have adequate ventilation. This could be a powerful fan system or just good natural airflow, but you have to prevent that gas from building up near the ceiling. A hydrogen gas detector is a cheap investment that could save your building.

- Flooring Matters: A forklift battery can weigh over a ton. Is your concrete slab rated for that kind of dead weight, plus the forklift? And what happens when you inevitably spill some battery acid? It will eat right through standard concrete. You need an acid-resistant coating or flooring.

Ignoring these details is just asking for a visit from OSHA. Take the time to plan the site, run the right power, and build a layout that keeps your people safe and your machines moving.

Mastering Safety and OSHA Compliance in the Real World

Let’s get one thing straight: OSHA doesn't care about your excuses. When it comes to forklift charging stations, they don’t play games, and neither should you.

A poorly managed charging area isn’t just an eyesore; it’s a full-blown disaster waiting to happen. You've got a perfect storm of explosive gas, corrosive acid, and high-voltage electricity all in one place. This isn't some theoretical problem; it’s a real-world threat that can get someone killed and your operation shut down.

This is about more than just checking a box on a form. It's about building a culture of safety that protects your people from chemical burns, fires, and explosions. The official standard, 29 CFR 1910.178, isn't a suggestion; it's the law, and inspectors know exactly what to look for.

The Non-Negotiable Safety Arsenal

An OSHA inspector walking into your charging bay expects to see a specific set of tools. If they’re missing, you’ve already failed. It’s like trying to fix a complex hydraulic leak without the right wrenches—you’re just going to make a bigger mess.

Your safety gear must include:

- Proper PPE: This means having face shields, splash goggles, acid-resistant aprons, and rubber gloves right there, ready to go. Not locked in a cabinet down the hall—at the point of use.

- Spill Kits: You need a neutralizing agent for battery acid spills. Baking soda or a commercial neutralizer works, but it has to be clearly marked and immediately accessible.

- Fire Extinguishers: The right type is crucial. A Class C extinguisher for electrical fires is mandatory. Having an ABC-rated unit is even better.

- Emergency Wash Stations: A functional eyewash station and emergency shower are not optional. OSHA mandates they be within a 10-second, unobstructed walk from the hazard. Test them weekly.

I’ve seen guys get a splash of electrolyte in their eye. The difference between keeping your sight and going blind is having a working eyewash station right there, right then. There is no middle ground on this.

Understanding the Risks: Lead-Acid vs. Lithium-Ion

Not all batteries try to kill you in the same way. You have to know your enemy. The safety protocols for old-school lead-acid are different from the newer lithium-ion packs, and you need a plan for both.

Lead-Acid Battery Hazards

The big villain here is hydrogen gas. During the final stage of charging, these batteries off-gas highly flammable hydrogen. In an enclosed space with no ventilation, a single spark from a dropped tool can blow the roof off.

- Mitigation: Enforce a strict "No Smoking, No Open Flames, No Sparks" policy with prominent signage. Make sure your ventilation system is working and, for larger rooms, install a hydrogen gas detector.

Lithium-Ion Battery Hazards

Lithium-ion batteries don’t produce hydrogen, but their failure mode is far more violent. If they are damaged, overcharged, or short-circuited, they can go into thermal runaway. This is an unstoppable, chain-reaction fire that releases toxic fumes and burns incredibly hot.

- Mitigation: Protect batteries and chargers from impact with physical barriers like bollards. Use only the correct, manufacturer-approved chargers. Never, ever attempt to charge a visibly damaged battery.

Building a truly safe forklift charging station is about proactive planning, not reactive panic. The rules are clear, and the stakes are high. For a deeper look into operator safety protocols, check out our guide to forklift safety requirements that complements these facility standards.

Being prepared isn't just about avoiding a fine; it’s about making sure every one of your crew members goes home in one piece at the end of their shift.

Field-Tested Maintenance to Maximize Battery Life

Your forklift batteries are a massive line item in your operational budget. Treating them like disposable junk is the quickest way to burn through cash and cripple your uptime. Forget the theoretical fluff from a sales brochure—this is a practical, in-the-trenches maintenance plan to keep your batteries from dying an early death.

It’s all about building a routine that prevents the common, costly failures that lazy shops ignore. This isn’t rocket science, but skipping these steps is just as bad as ignoring the check engine light on a piece of heavy equipment. Sooner or later, it’s going to shut down, and it'll be on your watch.

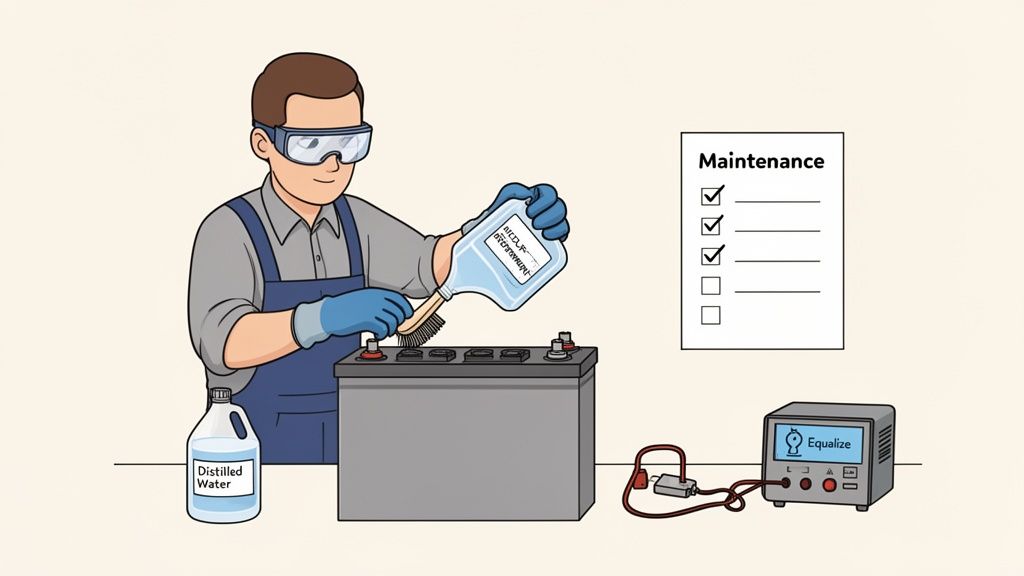

The Gritty Details of Lead-Acid Care

Old-school lead-acid batteries are absolute workhorses, but they’re needy. You can’t just charge them and walk away. If you neglect them, you’ll be buying a new $5,000 battery long before you should be.

Your weekly routine has to include:

- Proper Watering: Batteries lose water when they charge. It's your job to top them off. But here’s the non-negotiable part: you must use distilled or deionized water. Tap water is loaded with minerals that will coat the lead plates and strangle the battery’s capacity over time.

- Correct Timing: Only add water after the battery is fully charged. Watering a discharged battery will cause the electrolyte to overflow during the charge cycle, spilling acid all over your floor. That’s a nasty cleanup and a safety hazard.

This isn’t a suggestion. It's the difference between a battery that lasts five years and one that’s junk in two.

Fighting Corrosion and Sulfation

Corrosion on the terminals is like plaque in an artery—it restricts the flow of power. This makes your charger work harder and your forklift run weaker. It’s a simple fix that most people ignore until it’s too late.

Once a month, get in there with a wire brush and a paste of baking soda and water to scrub the terminals clean. This simple step prevents the voltage drops that can trick a charger into thinking a battery is full when it’s not.

Sulfation is the silent killer of lead-acid batteries. When a battery sits undercharged, lead sulfate crystals build up on the plates. Eventually, they harden, killing the battery’s ability to hold a charge. The only real defense is a regular equalization charge.

An equalization charge is essentially a controlled overcharge that dissolves these sulfate crystals. Most modern industrial chargers have this setting. Running an equalization cycle once a month or so, following the manufacturer's specs, is the single best thing you can do to extend the life of your lead-acid fleet.

Lithium-Ion: The New Rules of the Game

Lithium-ion batteries are a completely different animal. They don’t need watering, and they definitely don't need equalization. In fact, trying to "equalize" a lithium-ion pack is a great way to start a fire. Their maintenance is simpler but just as critical.

For lithium-ion, the game is all about visual inspection and data.

- Check for Damage: Look for any signs of physical damage to the casing—dents, cracks, or swelling. A damaged lithium-ion battery is a serious safety hazard and should be pulled from service immediately.

- Monitor the BMS: The Battery Management System (BMS) is the brain of the operation. Pay attention to any error codes the charger or the forklift throws. These codes are your early warning system. Ignoring them is like waiting for the machine to shut itself down completely.

A little proactive discipline in your maintenance schedule can save thousands in premature battery replacements and avoid the downtime that absolutely kills your bottom line.

A consistent checklist is your best defense against premature failure and unexpected costs. Here’s a straightforward routine to follow for both battery types.

Essential Battery Maintenance Checklist

| Task | Lead-Acid Frequency | Lithium-Ion Frequency | Why It Matters |

|---|---|---|---|

| Visual Inspection | Weekly | Weekly | Catches physical damage, cracks, or leaks before they become major hazards. |

| Watering | Weekly (after charging) | N/A | Prevents plate damage and maintains electrolyte balance for proper charging. |

| Clean Terminals | Monthly | As needed | Stops corrosion from causing poor connections, overheating, and charging errors. |

| Equalization Charge | Monthly | N/A | Reverses sulfation, restoring lost capacity and extending the battery's lifespan. |

| Check BMS Codes | N/A | Weekly | Provides early warnings of cell imbalances or other internal issues. |

| Wipe Down Casing | Monthly | Monthly | Removes dirt and corrosive residue that can interfere with connections. |

| Check Cables | Weekly | Weekly | Ensures no frays or damage that could lead to electrical shorts or fires. |

Following a simple schedule like this turns maintenance from a reaction into a routine, keeping your fleet running smoothly and your budget in check.

Calculating the True Cost and ROI of Your Station

Getting the budget approved for new forklift charging stations is where the real fight usually begins. Let's be honest: the sticker price on the charger is just the down payment. The real cost, the number that actually matters, is the total cost of ownership—and it’s always higher than the initial quote.

To build a rock-solid business case, you have to think like a tech in the field, not a salesman in a showroom. It’s like quoting a simple sensor replacement on a JCB backhoe but conveniently "forgetting" to mention the three hours of labor it takes to tear the machine apart just to reach it. You have to account for everything, or you’ll get burned.

Uncovering the Hidden Costs

The true cost goes far beyond the hardware itself. It's the sum of all the parts, labor, and operational headaches that come with the project. If you ignore these, you're just setting yourself up for budget overruns and a lot of explaining later.

Your budget needs to include:

- Installation and Electrical Upgrades: This is the big one. An electrician doesn't work for free, and if you need to pull new circuits, upgrade a main panel, or run three-phase power, the cost can easily blow past the price of the charger itself.

- Ongoing Maintenance: Think about battery watering systems for your lead-acid fleet, replacement charger cables when they inevitably get run over, and the labor hours for your crew to perform regular cleaning and checks.

- Labor for Charging: How much time does it take for an operator to drive to the station, hook up, and disconnect later? For battery swapping, this cost is even higher. Those minutes add up to real dollars over a year.

- Consumables and Safety Gear: This includes distilled water, acid spill kits, replacement PPE for your team, and annual inspections for your eyewash stations. It all has a price tag.

Ignoring these "soft" costs is like pretending a forced regen cycle on a diesel engine doesn't kill your productivity. The machine stops, the clock keeps ticking, and you're losing money. The same logic applies here—every hidden cost is a drain on your operational efficiency.

Calculating the Payback

Once you have the real, all-in cost, you can start calculating the return on investment (ROI). This isn't just about saving a few bucks; it's about proving that this project isn't a cost center—it’s a profit driver. You’re not just buying a charger; you’re buying uptime.

Focus on these key metrics to show the value:

- Reduced Downtime: Calculate the cost of an idle forklift and operator per hour. If a new fast-charging system saves 30 minutes per shift, that's a hard number you can take straight to the bank. A $25/hour operator saving that time adds up to over $3,000 per year, per forklift.

- Improved Battery Lifespan: A smart charger that prevents overcharging and runs proper equalization cycles can easily extend a battery’s life by a year or more. A single $5,000 battery replacement you can delay is a direct boost to your bottom line.

- Energy Efficiency: Modern high-frequency chargers can be up to 15% more efficient than those old ferroresonant dinosaurs. That translates directly into lower utility bills, every single month.

- Increased Productivity: When operators aren't hunting for an available charger or waiting around for a battery swap, they're moving product. Even a small 5% boost in pallets moved per hour creates a massive ripple effect on your facility's total output.

By laying out the total cost alongside the tangible returns, you completely change the conversation. You’re no longer asking for a handout; you’re presenting a strategic investment that makes the entire operation stronger, faster, and more profitable.

Forklift Charging Station FAQs From the Shop Floor

Out on the shop floor, you hear the same questions over and over. Forget the sales pitch and the technical manual for a minute. Here are straight, no-nonsense answers to the questions that actually matter when you're trying to keep a fleet running and your crew moving product.

Can I Mix Different Battery Types and Chargers?

Absolutely not. Don't even think about it.

Hooking a lead-acid charger to a lithium-ion battery isn't just a bad idea—it's a guaranteed way to start a fire. Mismatching chemistries, voltages, or amp-hour ratings will cook your batteries, void every warranty you have, and create a massive safety hazard.

Think of it like trying to run a JCB telehandler on the wrong hydraulic fluid. It might seem to work for a second, but you're causing catastrophic damage inside. Always match the charger’s nameplate to the battery’s specs. No exceptions.

How Much Space Do I Really Need for a Charging Area?

More than you think. This isn't just about finding a spot to park the forklift.

OSHA requires enough room for operators to safely maneuver the machine without clipping a charger stand or another piece of equipment. You also need proper clearance for ventilation so heat can escape and things don't overheat.

For battery swap stations, you need even more room. You have to account for the lifting equipment, storage racks, and a clear, safe path for a technician to move a 1,000+ pound battery. Map out the entire process from approach to departure and add at least three feet of clearance around everything.

What Are the First Signs of a Failing Battery or Charger?

Your equipment will tell you when something is wrong—you just have to pay attention. For batteries, the signs are usually obvious:

- Run times get shorter and shorter.

- You see corrosion creeping up the terminals.

- The casing itself starts to swell or crack.

If an operator tells you a "fully charged" battery died in two hours, believe them. That’s a huge red flag.

For the charger, look for error codes on the display, listen for weird buzzing or humming sounds, or feel if the unit is getting unusually hot to the touch. A lot of the time, when a battery seems to be failing, the real villain is a charger that isn't completing its cycle correctly.

Is Opportunity Charging Bad for My Batteries?

That depends entirely on the battery's chemistry.

If you try to opportunity charge a standard, old-school lead-acid battery, you will absolutely destroy its lifespan. The constant partial charging creates sulfation that chokes its capacity over time.

However, for batteries built for it—like most lithium-ion packs and some thin plate pure lead (TPPL) models—it's the right way to operate. The key is matching your charging strategy to your battery technology. Using the wrong method is like trying to bypass a DEF sensor without the right tools—you'll just create a bigger, more expensive problem down the road.

When you’re tired of waiting on the dealer for the right parts to keep your equipment running, Flat Earth Equipment has the sensors, solenoids, and electrical components you need shipped the same day. Get back to work faster by visiting our online parts store.