A forklift's center of gravity isn't some abstract physics term—it's the single invisible point that dictates whether the machine stays upright or tips over. Getting this right is the absolute key to preventing accidents, protecting your operators, and keeping materials moving safely on any job site.

Why Forklift Stability Is a High-Stakes Balancing Act

You have to stop thinking of a forklift like a car. It's much more like a tightrope walker, constantly making tiny adjustments to maintain its balance. Every single move—lifting, turning, even accelerating—shifts this invisible point of equilibrium.

This guide will demystify the core principles that keep a forklift stable, starting with the foundational concept of the 'stability triangle.' Nailing this concept isn't just a "nice-to-know"—it's essential for protecting your team and avoiding thousands in equipment damage.

The Real-World Consequences of Instability

The stakes here are incredibly high. According to OSHA and NIOSH, forklift accidents are a major source of workplace injuries, with roughly one in ten forklifts involved in an accident each year. Even worse, over 20% of forklift fatalities are the direct result of overturns. A huge number of these could have been prevented with a better understanding of the machine's center of gravity. You can dig into the numbers in this forklift accident report from Conger.

This goes way beyond a simple compliance checkbox; it's a non-negotiable part of a safe operation. When an operator doesn't respect the machine’s balance, the results can be catastrophic.

Think of a forklift as a seesaw. The front axle is the pivot point (the fulcrum). The massive counterweight is on one side, and the load you're lifting is on the other. To stay stable, the force from the counterweight has to win every time.

This simple analogy gets to the heart of the matter: a forklift is always in a delicate state of balance. The second a load leaves the ground, the entire dynamic of the machine changes. The combined center of gravity—the new balance point for both the truck and its load—instantly shifts forward and up.

Connecting Principles to Daily Operations

When your team truly understands these principles, it translates directly into a safer and more efficient workflow. It gives operators the knowledge to make smart, split-second decisions and helps managers build a fundamentally safer work environment. The benefits are crystal clear:

Fewer Accidents: A solid grasp of stability principles dramatically cuts down the risk of tip-overs.

Longer Equipment Life: Operating within the machine's stability limits reduces wear and tear on the mast, tires, and frame.

Better Productivity: Operators who are confident and well-trained work more smoothly and efficiently, without taking dangerous shortcuts.

Ultimately, mastering the forklift center of gravity is a non-negotiable part of any serious safety program. You can dive deeper with our comprehensive guides on overall forklift safety practices. In the next sections, we'll break down the stability triangle, load center, and the common operator mistakes that push these powerful machines past their breaking point.

Decoding the Forklift Stability Triangle

Picture an invisible triangle on the ground right under your forklift. This isn't just a mental picture; it’s the boundary that defines the machine’s entire stability. This concept, known as the forklift stability triangle, is the single most important principle for preventing tip-over accidents.

The three corners of this triangle are the two front wheels and the center pivot point of the rear axle. An unloaded forklift is built so its own center of gravity sits low and deep inside this triangle, making it naturally stable. Think of a pyramid—it's wide at the base and really hard to knock over.

But the second you pick up a load, the physics completely change. You've just introduced a second center of gravity. The machine no longer has just its own balance point; it now has a combined center of gravity that acts as the new pivot point for the forklift and its load together. This new point is higher up and further forward than the original.

The Balancing Act Within the Triangle

The golden rule of forklift operation is refreshingly simple: as long as the combined center of gravity stays inside the stability triangle, the forklift will remain upright. If any action—turning too fast, lifting a load while moving, or hitting a pothole—shoves that combined center of gravity outside the triangle's edges, a tip-over is almost guaranteed.

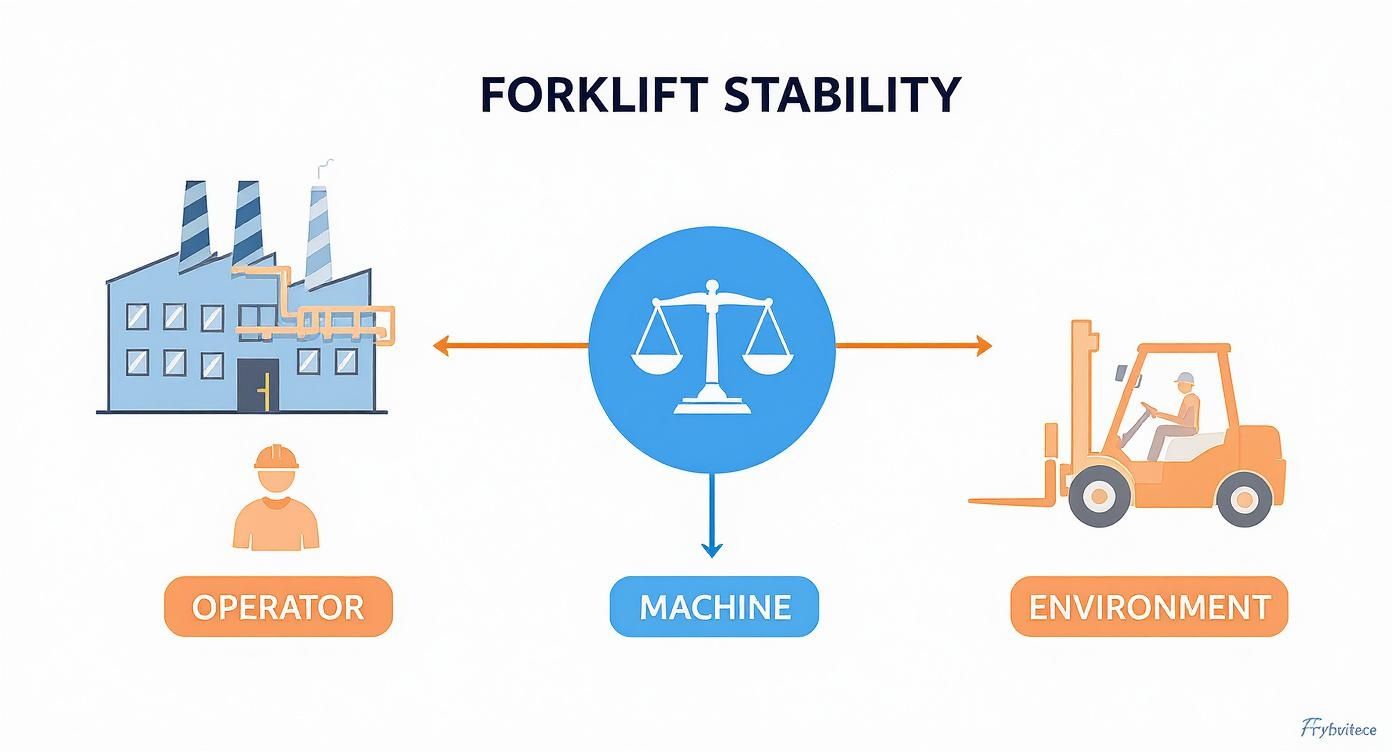

This graphic breaks down the key factors—operator, machine, and environment—that are constantly pulling on the forklift's stability.

As you can see, keeping the machine balanced is a dynamic dance between these three elements, not just a fixed feature of the forklift itself.

You can also think of the forklift as a seesaw. The front axle is the fulcrum, or pivot point. On one side, you have the heavy counterweight at the back of the machine. On the other, you have the load on the forks. For everything to work safely, the counterweight side must always win, keeping the machine firmly planted.

How Operator Actions Shift the Balance

Every single move an operator makes has a direct, immediate impact on where that combined center of gravity sits. Understanding these shifts isn't just a good idea; it's absolutely critical for safe material handling.

Here’s a quick look at how everyday actions affect the machine’s balance:

Lifting a Load: As the forks go up, the combined center of gravity climbs with them, shrinking your margin of safety. A high center of gravity makes the forklift far more likely to tip sideways.

Tilting Forward: Pushing the mast forward moves the combined center of gravity toward the front edge of the stability triangle, dramatically increasing the risk of a forward tip-over.

Turning: When you turn, centrifugal force yanks the combined center of gravity sideways toward the outer edge of the triangle. Take a sharp turn too fast, and you can easily push it right over the line.

Accelerating and Braking: Quick starts and sudden stops throw the center of gravity backward and forward. Any jerky movement can destabilize what was otherwise a perfectly secure load.

The stability triangle isn't a physical part you can touch. It's an imaginary "safe zone" for the forklift's balance that must be respected at all times. Your job as an operator is to keep the combined center of gravity comfortably inside that zone, no matter what you're doing.

The table below gives you a clearer picture of how specific maneuvers directly influence the combined center of gravity and the risks they create.

How Common Actions Shift the Center of Gravity

This table outlines key operational actions and how they shift the combined center of gravity, helping operators visualize the impact of their movements on stability.

| Operator Action | Impact on Combined Center of Gravity (COG) | Resulting Stability Risk |

|---|---|---|

| Turning While Moving | Shifts the COG sideways toward the outer edge of the triangle. | High risk of a lateral (sideways) tip-over, especially if speed is too high. |

| Traveling on a Ramp | Shifts the COG downhill, stressing the triangle's downhill boundary. | Increased risk of tipping forward (going down) or backward (going up). |

| Sudden Braking | Inertia throws the COG forward, toward the front axle fulcrum. | High risk of a longitudinal (forward) tip-over, especially with a heavy load. |

| Lifting an Off-Center Load | Shifts the COG toward the heavier side of the load. | Greatly increases the risk of a lateral tip-over, even at low speeds. |

Getting a feel for these dynamics is the first step toward building the muscle memory needed for safe, instinctual operation. Next, we’ll dig into how the load’s position on the forks—known as the load center—adds another critical layer to this complex stability puzzle.

How Load Center Affects Your True Lifting Capacity

That shiny data plate on your forklift might say it can lift 5,000 pounds, but that number isn't a guarantee—it's more like a conditional promise. The one variable that can sink that number fast is the load center, and understanding it is non-negotiable for knowing what your machine can actually handle.

Think about holding a heavy bowling ball. If you hug it close to your chest, you're stable. Now, extend your arms straight out. The ball suddenly feels ten times heavier, right? Its weight didn't change, but its distance from your body—your center of gravity—did.

That’s a perfect picture of how a forklift works. The load center is simply the horizontal distance from the front face of the forks to the load's own center of gravity. Pushing a load even a few inches further out on the forks is just like extending your arms. It multiplies the tipping force and demolishes how much your forklift can safely lift.

Why Standard Load Centers Matter

Most forklifts in that common 3,000 to 6,000-pound range are rated using a standard 24-inch load center. This assumes you're lifting a perfectly balanced, 48-inch square pallet. The pallet's center of gravity is dead in the middle, exactly 24 inches from the fork face.

But let's be real—how many loads are perfectly symmetrical? Warehouses are full of long, bulky, or just plain weirdly shaped items that push that center of gravity way out. When that happens, the capacity stamped on the data plate becomes dangerously misleading.

This is exactly where operators get into trouble. They see a 4,500-pound load and a forklift rated for 5,000 pounds and think they’re in the clear. But if that load is long, its actual load center might be 30 inches or more, putting the machine deep into the red zone for that specific lift.

Calculating Your Actual Lifting Capacity

Luckily, this isn't guesswork. There’s a simple formula to calculate how much a forklift’s capacity gets "de-rated" when the load center shifts. It’s a core part of any good forklift safety training.

The rule is straightforward: Actual Capacity = (Rated Load Center ÷ Actual Load Center) × Truck Rated Load Capacity. This principle is a cornerstone of safety regulations, giving operators the power to make smart calls before every single lift. You can find more detail on this topic in this helpful guide on calculating forklift capacity.

Let's run the numbers on a real-world scenario.

Scenario: A Forklift Rated for 5,000 lbs at 24 inches

Your operator needs to move a long crate. The crate itself weighs 4,200 pounds, which seems fine next to the 5,000-pound limit. The problem? Because of its length, its center of gravity is 30 inches from the fork face, not the standard 24.

Here’s how the math breaks down:

Divide the Rated Load Center by the Actual Load Center:

24 inches ÷ 30 inches = 0.8Multiply this ratio by the Forklift's Rated Capacity:

0.8 × 5,000 lbs = 4,000 lbs

The forklift’s true, safe lifting capacity for this specific load is only 4,000 pounds. That 4,200-pound crate would overload the machine by 200 pounds, creating a serious tip-over risk.

This quick calculation proves a critical point: where the load sits is just as important as what it weighs.

Practical Steps for Managing Load Center

Ignoring the load center is one of the quickest ways to compromise the forklift center of gravity and cause an accident. To keep your team safe, make sure these practices are part of your daily routine:

Always Assess the Load: Before any lift, operators must eyeball the load to estimate its center of gravity. Standard pallets are easy. For everything else, they need to be cautious.

Keep Loads Close: Train every operator to carry loads as close to the mast as possible. This minimizes the load center distance and maximizes stability.

Consult the Data Plate: The data plate is the source of truth. It states the capacity at a specific load center. If a load pushes past that center, the capacity drops.

When in Doubt, Don't Lift: If an operator can't confirm a load's weight or its center of gravity, the only safe move is to stop. The lift shouldn't happen until that info is verified.

By respecting the powerful influence of the load center, you empower your team to stop overloading incidents before they start, ensuring every lift is well within safe, calculated limits.

Common Mistakes That Push Forklifts Past Their Limits

Knowing the physics behind forklift stability is one thing. Seeing how those rules play out on a busy warehouse floor—that's where safety gets real. Tip-overs almost never happen out of the blue. They're the predictable result of a specific action or condition that shoves the combined forklift center of gravity right outside the stability triangle.

The key to preventing these incidents is learning to spot the real-world hazards that cause them. Most stability-related accidents boil down to three things: operator errors, load issues, and environmental factors. By getting a handle on these common mistakes, operators and supervisors can build a proactive safety culture that stops accidents before they even have a chance to start.

Critical Operator Errors to Avoid

The operator has the most direct influence over the forklift’s balance. But even the most experienced driver can make a split-second decision that compromises the machine's stability. These actions are some of the most common culprits behind tip-overs.

Turning Too Sharply or Too Fast: This is a classic, and for good reason. When a forklift turns, centrifugal force pulls the combined center of gravity outward. A sharp, fast turn can easily yank this point right over the edge of the stability triangle, causing a lateral tip-over. It happens fast.

Traveling with a Raised Load: This is one of the most dangerous moves an operator can make. Lifting a load jacks up the combined center of gravity, making the entire machine top-heavy and incredibly unstable. A load should only be lifted or lowered when the forklift is at a dead stop.

Abrupt Acceleration or Braking: Slamming on the gas or brakes throws the center of gravity forward and backward. Hitting the brakes too hard can cause the load's momentum to pitch the machine forward, a huge longitudinal tipping risk, especially with a heavy load.

A forklift is not a sports car. Every maneuver—from turning to braking—must be smooth, deliberate, and controlled. Jerky movements are a direct threat to the machine’s stability.

Load Management and Stability Issues

How you pick up and position a load is just as critical as how you drive. A poorly managed load creates an unstable situation before the forklift even starts moving. Operators need to treat every single load as a unique stability challenge.

Common load-related mistakes include:

Off-Center Loads: Picking up a pallet that isn't centered on the forks shifts the combined center of gravity way off to one side. This dramatically increases the risk of a sideways tip-over, even during a slow, gentle turn.

Unstable or Poorly Stacked Loads: A load that can shift during transit is a ticking time bomb. If boxes on a pallet aren't properly secured, a simple bump or turn can cause the load’s own center of gravity to move, taking the machine’s combined CG with it.

Overloading the Forklift: This isn't just about the raw weight. As we've covered, exceeding the capacity for a given load center creates a massive forward tipping risk. An operator might lift a load that's technically under the max rated weight, but if its load center is too far out, they've effectively overloaded the machine.

Hazardous Environmental Factors

Finally, the work environment itself is full of challenges to forklift stability. The condition of the floor and the layout of the facility play a huge role in keeping that center of gravity safely inside the stability triangle. A perfect operator with a secure load can still be tipped over by an unseen hazard on the ground.

Key environmental hazards to watch for:

Ramps and Inclines: When you're on an incline, gravity is constantly pulling the center of gravity downhill. Operators must always drive with the load pointing uphill to keep that force in check.

Uneven Surfaces: Potholes, debris, or deep cracks in the floor can cause one wheel to drop or lift suddenly. That abrupt tilt can be all it takes to shift the center of gravity outside the triangle.

Slippery Surfaces: Water, oil slicks, or even loose gravel can cause a loss of traction. That can lead to an uncontrolled slide during a turn that easily ends in a tip-over.

How Technology Is Making Forklifts Smarter and Safer

The core principles of forklift stability—the center of gravity and the stability triangle—haven't changed. They're timeless laws of physics. But the technology we use to manage these forces is evolving fast, driven by a worldwide need for safer, more efficient ways to move materials. Manufacturers aren't just building bigger counterweights anymore; they're engineering intelligent machines that actively help operators stay within safe boundaries.

This intense focus on safety is a huge driver in the global forklift market, now valued at over USD 81 billion. Nimble machines like 3-wheel sit-down counterbalance forklifts are a big part of this trend. Their market segment alone is expected to jump from USD 1.3 billion to USD 2.0 billion by 2035. That kind of growth hinges on advanced engineering that nails the perfect balance between maneuverability and a stable forklift center of gravity. You can dive deeper into these trends in the full report on 3-wheel sit-down counterbalance forklifts.

Advanced Stability Systems

Modern forklifts are increasingly rolling off the line with sophisticated stability systems that act like a digital co-pilot for the operator. These systems use a web of sensors to monitor the machine's every move in real time, giving crucial feedback and sometimes even stepping in to prevent a tip-over.

Here are a few of the key technologies at play:

Dynamic Load Sensing: These systems constantly measure the weight on the forks and the mast's position. They can calculate the combined center of gravity on the fly and throw up visual or audible alerts if a lift is getting dangerously close to the machine's limits.

Speed Control Systems: Some of the smartest forklifts automatically slow themselves down during sharp turns. This directly counters the centrifugal force that tries to shove the center of gravity outward, drastically cutting the risk of a lateral tip-over.

Mast Tilt Compensation: Advanced systems can automatically adjust the mast's forward or backward tilt based on the load height and weight. This helps keep the combined center of gravity tucked safely inside the stability triangle while lifting.

These features shift the burden of stability from a purely manual calculation to a shared responsibility between the operator and the machine itself.

“The goal of this technology isn't to replace a skilled operator, but to empower them. It provides an extra layer of awareness, catching potential stability issues before they become critical incidents and reinforcing safe operating habits.”

Smarter Engineering for a Lower Center of Gravity

It’s not all about electronics. Manufacturers are also fundamentally rethinking the physical layout of their forklifts to bake in more stability from the start. This is especially true for electric models, where the battery's placement is a golden engineering opportunity.

By designing the chassis to cradle the heavy battery pack as low to the ground as possible, engineers effectively lower the forklift’s own unloaded center of gravity. A lower starting balance point means the machine is naturally more resistant to tipping, giving the operator a wider safety margin before a load is even picked up. This design philosophy is all about building safer equipment from the ground up. You can see how essential components work together by checking out our guide on forklift battery chargers.

Ultimately, this forward-thinking approach shows how a deep grasp of classic physics allows companies to build better, safer machines. These advancements don't just move materials more efficiently; they protect a company's most valuable asset—its people.

Practical Checklists to Improve Forklift Safety

Knowing the theory is one thing, but putting it into practice every single day is what truly keeps people safe. All the knowledge about the stability triangle and the forklift center of gravity won't prevent an accident unless it drives consistent, on-the-floor actions.

That’s where these checklists come in. We've built two simple, direct tools to close that gap—one for operators and one for managers. They turn abstract safety concepts into tangible habits, building a culture where safety is second nature, not just a policy on a wall.

Daily Operator Pre-Shift Checklist

Before an operator even thinks about lifting a load, they should be doing a quick walk-around. This isn't just about kicking the tires; it’s a stability-focused review that takes less than five minutes but can stop a serious incident before it starts.

Tire Condition: Are the tires properly inflated? Are they free of major chunks, wear, or damage? Underinflated or damaged tires can mess with the forklift’s base and create instant instability.

Data Plate Legibility: Can you actually read the capacity plate, or is it covered in grease or worn down? If an operator can't see it, they're just guessing at safe lifting limits.

Hydraulic Systems: Any obvious fluid leaks coming from the mast or tilt cylinders? A hydraulic failure isn't a slow problem—it can mean a sudden, total loss of load control.

Forks and Mast: Look at the forks. Are they straight? Does the mast lift and tilt smoothly? Bent forks are a recipe for an unbalanced load.

This daily ritual makes sure every shift starts with a machine that's mechanically solid and ready to operate safely.

A pre-shift check is the operator's first line of defense. It’s the moment they confirm the machine's physical condition aligns with the principles of safe stability, setting the tone for the entire day.

Manager’s Quarterly Safety Audit

While operators handle the day-to-day, managers need to zoom out and look at the bigger picture. A quarterly audit is perfect for spotting system-wide risks and making sure the safety culture is actually working.

Verify Operator Training: Do a spot-check. Are all operator certifications current and properly filed? This confirms that everyone behind the wheel has recently reviewed the core safety rules.

Review Maintenance Logs: Don't just look for completed work orders. Scan the logs for patterns. Are you seeing repeated repairs on stability components like masts, tires, or hydraulics on certain machines? That could point to a bigger issue.

Assess the Work Environment: Get out and walk the floor. Have new hazards popped up? Look for deteriorating concrete, new ramps or inclines, or changes in traffic patterns that could affect a forklift's stability.

Observe Operator Behavior: Spend some real time watching your team work. Are they keeping loads low when traveling? Taking corners at a safe speed? Are they stopping to properly assess a load before lifting?

These checklists aren't about ticking boxes for compliance. They're tools for making the principles of managing the forklift center of gravity a real, daily part of your operation. For a deeper dive into building a safe workplace from the ground up, check out our full guide on workplace safety procedures.

Frequently Asked Questions About Forklift Stability

Even when your team gets the theory behind the stability triangle, real-world questions always pop up on the warehouse floor. Getting these practical points straight is how you turn textbook knowledge about the forklift center of gravity into safe, everyday habits.

How Do Forklift Attachments Affect Stability?

Think of attachments like clamps, rotators, or boom poles as complete game-changers for your forklift's stability. They hang a significant amount of weight off the front, shifting the machine's unloaded center of gravity forward before you even think about picking up a pallet.

But here's the bigger issue: attachments almost always push the load center further out. This drastically cuts down the forklift's true lifting capacity. Slapping an attachment on means you need a new, updated data plate from the manufacturer reflecting this lower capacity. Anything less isn't just a bad idea—it's a serious safety violation.

Attachments aren't simple add-ons; they're major modifications. The moment you install one, the original data plate is void. A new plate is non-negotiable to show the forklift's altered—and almost always reduced—lifting capacity.

Why Is Traveling with a Raised Load So Dangerous?

Moving a forklift with the load high in the air is one of the riskiest things an operator can do. It jacks up the combined center of gravity, turning a stable, well-planted machine into something dangerously top-heavy.

A low center of gravity is what keeps the forklift safely inside its stability triangle. As the load goes up, the balance point goes with it, shrinking your margin for error to practically zero. A slight turn, a small bump on the floor, or a gentle slope can be enough to shove that high center of gravity outside the triangle. The result is a sudden tip-over with little to no warning.

The only safe way to do it is by the book:

Always travel with the forks just a few inches off the ground.

Bring the forklift to a complete stop at your destination.

Only then should you raise the load to stack it.

Can You Feel When a Forklift Is Becoming Unstable?

Absolutely. A skilled, attentive operator can often feel the machine talking to them, giving subtle warnings that it's nearing its tipping point. Learning to recognize these physical cues is a critical skill that can prevent a disaster before it starts.

Keep an eye out for these red flags:

Light Steering: If the steering suddenly feels loose or floaty, it's a huge warning sign. It often means the rear wheels are coming off the ground, causing a loss of both control and balance.

Machine Sway: The forklift might start to rock or sway more than usual, especially when turning or lifting a heavy load.

Rear Wheels Lifting: An operator might physically feel one or both rear wheels lift off the floor during a sharp turn or hard stop. This is the final, most urgent signal that the center of gravity is right on the edge of the stability triangle.

Operators need to be trained to react instantly—not by panicking, but by smoothly lowering the load, easing off the speed, and straightening their path to bring the machine back under control.

At Flat Earth Equipment, we know that safety and uptime are two sides of the same coin. From OSHA-compliant operator training to precision-fit parts that keep your fleet running right, we provide the tools and expertise to build a safer, more productive operation. Explore our solutions at https://flatearthequipment.com.