A forklift aerial platform is a specialized safety cage that essentially turns your standard forklift into a secure personnel lift. Think of it as giving your forklift a temporary, mobile balcony, allowing workers to safely handle maintenance, inventory checks, or installations up high. This simple attachment is a huge boost to both safety and efficiency in countless industrial settings.

Transforming Vertical Work with Forklift Platforms

At its heart, a forklift aerial platform does one job: it lifts people safely. It’s a far more stable and secure option than old-school methods like ladders or stationary scaffolding, especially for jobs that require moving around a lot. Instead of a worker climbing down, dragging a ladder over, and climbing back up, the forklift operator can just lower the platform and drive to the next spot.

This flexibility makes these attachments indispensable in modern warehouses, on construction sites, and in manufacturing plants. They are perfect for everyday tasks like changing lightbulbs in high ceilings, counting inventory on tall racks, or performing maintenance on elevated machinery. The enclosed cage design with built-in guardrails drastically cuts down the risk of falls, one of the leading causes of workplace injuries.

Efficiency Meets Enhanced Safety

The growing use of these platforms is part of a bigger industry shift toward safer, more productive ways to work at height. The global aerial work platform (AWP) market, which includes these attachments, was valued at around USD 19.20 billion and is projected to hit USD 37.74 billion by 2033. This boom is fueled by the demand for better solutions for working at heights between 20 to 50 feet. You can find more insights on the aerial work platform market at Straits Research.

By converting a machine you already own into a personnel lift, you unlock new capabilities without the huge expense of a dedicated scissor lift or boom lift. For many operations, that dual-purpose functionality is a total game-changer.

The greatest advantage of a forklift aerial platform is its ability to turn a material-handling machine into a people-lifting tool, maximizing asset utility and improving on-the-job safety simultaneously.

Forklift Platform vs Traditional Methods

To really get a feel for their value, it helps to see how these platforms stack up against the usual ways of working at height. The main differences come down to mobility, setup time, and overall safety for certain jobs.

Here’s a quick look at how they compare.

| Feature | Forklift Aerial Platform | Scaffolding | Ladders |

|---|---|---|---|

| Mobility | High (easily moved by forklift) | Low (stationary once built) | Medium (portable but limited) |

| Setup Time | Minimal (seconds to attach) | Significant (requires assembly) | Very Fast (instant setup) |

| Worker Capacity | 1-2 workers with tools | Multiple workers | Single worker only |

| Safety for Complex Tasks | High (stable with guardrails) | High (stable work deck) | Low (high risk of falls) |

This comparison makes it clear why forklift platforms have become the go-to choice for so many maintenance and operational tasks. They offer a unique mix of safety, speed, and flexibility that older methods just can't match, paving the way for a more productive and secure work environment.

Exploring Types of Forklift Work Platforms

Not all forklift aerial platforms are created equal. Just like you wouldn't use a hammer to turn a screw, picking the right work platform comes down to the specific job you need to get done. The choice you make has a direct impact on safety, how efficiently your crew works, and whether they can even do the task at all.

To get it right, you first need to understand the main categories. The big differences usually boil down to size, capacity, and special features built for certain kinds of work. Let's break down the most common types you'll run into.

The Standard Safety Cage

Think of the standard safety cage as the versatile workhorse of the bunch. It's the most common type for a good reason—it gives you a secure, enclosed space that fits one or two workers plus their tools. This platform is basically a mobile work deck, perfect for jobs that require a little elbow room.

You'll see these cages used for all sorts of tasks:

- General Maintenance: Changing out high-bay lightbulbs, fixing overhead pipes, or servicing warehouse HVAC units.

- Inventory Management: Doing physical stock counts on tall racking where someone needs to scan a barcode or check a label up close.

- Minor Installations: Hanging signs, running cables, or mounting security cameras high on a wall.

These are built with safety as the priority, featuring high guardrails, a non-slip floor, and a gate that locks securely. They are the go-to for most routine elevated jobs where you need space and capacity for a couple of people.

The Compact Personnel Basket

When the job is a one-person mission in a tight spot, the personnel basket is your best bet. These are much smaller than a standard cage and are designed for just a single operator. Their compact footprint is a game-changer for navigating narrow aisles or working in areas already crowded with machinery.

Imagine a technician trying to get to a single electrical panel squeezed between two massive shelves. A standard cage wouldn't even come close, but a personnel basket can slide right in. That makes them invaluable for:

- Targeted Repairs: Getting to a specific component on a large piece of equipment without having to move everything around it.

- Inspections in Confined Spaces: Checking on machinery tucked away in the tight corners of a facility.

- Light-Duty Tasks: Quick, solo jobs like cleaning a high window or doing a quick paint touch-up.

The trade-off for this agility is limited capacity. These baskets are strictly for one person and a few handheld tools, making them a specialized but absolutely essential tool for a well-equipped fleet.

Picking between a standard cage and a compact basket is like choosing between a pickup truck and a small utility van. One gives you more capacity for general-purpose work, while the other offers focused access to hard-to-reach places.

Specialized and Custom Platforms

Once you get past the two main types, you'll find a whole world of specialized forklift platforms, often designed with a specific industry or task in mind. These attachments come with features that make particular jobs safer and more productive.

A few examples include:

- Platforms with Built-in Tool Trays: Perfect for mechanics or electricians who need their tools and small parts organized and right at hand, which helps prevent dangerous drops from above.

- Material Holding Racks: Some platforms have integrated racks to securely hold things like pipes, conduit, or long fixtures, making it easier for one worker to manage an installation.

- Oversized or Uniquely Shaped Cages: You can get platforms custom-fabricated to fit around specific machinery or building features, giving you safe access for truly unique maintenance challenges.

These specialized options show how a basic forklift aerial platform can be tweaked to solve very specific problems on the ground—or, rather, in the air. By really thinking through the kind of elevated work you do, you can find an attachment that doesn't just lift your team, but actually helps them do their job better and safer once they're up there.

How to Ensure OSHA Compliance and Operator Safety

When you put a person in the air with a forklift, the stakes are as high as they get. Safety isn't just a good idea; it's a legal requirement enforced by the Occupational Safety and Health Administration (OSHA). The key is turning those dense regulations into simple, actionable steps that protect your team during every single elevated job.

Think of OSHA's rules not as red tape, but as a blueprint for a successful lift. Every single regulation, from the height of the guardrail to the type of fall protection required, exists to prevent a specific, known hazard. Cutting corners isn't just a compliance problem—it's an open invitation to disaster. A single mistake can lead to a catastrophic fall, which remains one of the most common causes of serious workplace injuries and deaths.

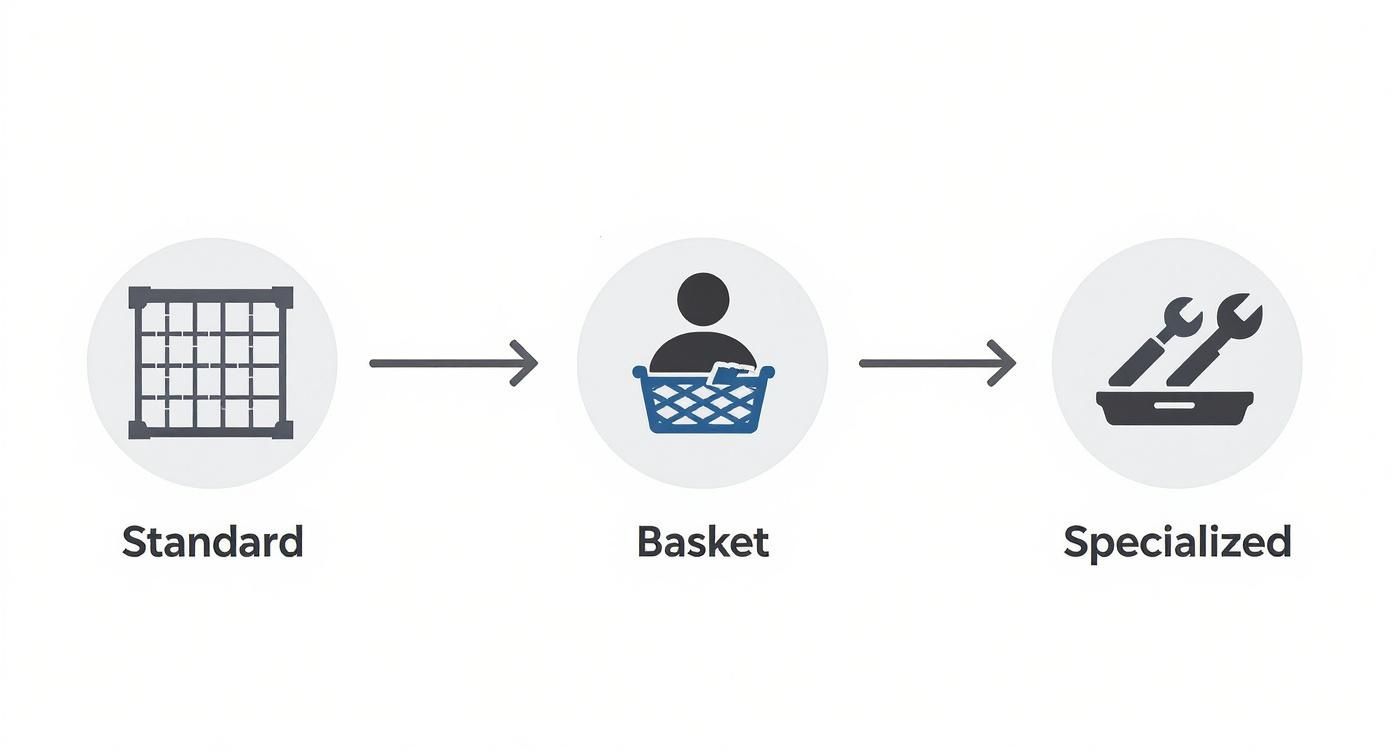

This diagram shows how the equipment choices progress from a standard work platform to more specialized attachments for unique tasks.

As you can see, picking the right platform is the very first step in building a safe and efficient operation for any job that requires working at height.

Translating OSHA Standards Into Practice

The main rulebook for forklifts is OSHA standard 29 CFR 1910.178, but the specific rules for lifting people are woven throughout other sections. Instead of getting bogged down in legal jargon, let's focus on what these rules actually mean on the shop floor. A fully compliant lift is built on three pillars: the right equipment, a trained operator, and a rock-solid procedure.

First, the equipment has to be up to snuff. The forklift aerial platform must be locked securely to the forklift's carriage and forks. This isn't just about sliding it on; it requires a real locking mechanism, like pins that go behind the heel of the forks or a heavy-duty chain, to make it impossible for the platform to slide off.

Next, the operator needs special training. Your standard forklift certification doesn't cut it here. OSHA is crystal clear that anyone operating a forklift to lift personnel must be trained on the specific hazards and procedures involved. They need to be experts in stability, clear communication, and the delicate touch required for a smooth, safe lift.

Finally, the whole process has to be deliberate and controlled. This means running pre-lift safety huddles, inspecting every piece of gear before it's used, and sticking to a strict set of rules while someone is in the air.

The Pre-Lift Safety Briefing Checklist

Picture this: you're the safety manager about to oversee a crew fixing an overhead light. Before that platform moves an inch, you pull the forklift operator and the worker who's going up into a quick huddle. This is your first line of defense.

Your briefing needs to confirm a few critical things:

- Full Equipment Inspection: You've all physically checked both the forklift and the platform. Look closely at the welds, the floor, guardrails, the entry gate, and every attachment point for any sign of damage or wear.

- Fall Protection Readiness: The worker in the basket is wearing a full-body harness and lanyard. The most important part? That lanyard must be clipped to the designated anchor point inside the platform—never to the forklift mast or any other part of the machine itself.

- Clear Communication Plan: The operator and the worker in the basket have agreed on hand signals or are using radios. The operator must stay at the forklift's controls the entire time the platform is elevated. No exceptions.

- Understanding the Work Zone: The area on the ground is roped off and clear of hazards or people passing through. The floor surface has to be level and solid enough to prevent any chance of tipping.

OSHA Mandate: You are strictly forbidden from driving the forklift to a new spot while a worker is up in the platform. The basket must be brought all the way down before the forklift moves horizontally. This rule is non-negotiable and exists to prevent deadly tipping and collision accidents.

Creating a Culture of Aerial Safety

Beyond the checklists and the rules, real safety is born from a workplace culture that puts caution first. Every single person on the team has to feel empowered to stop a lift if they spot something that doesn't look right. This also means making sure operators never try to "nudge" the platform into final position by inching the forklift forward.

This kind of proactive mindset is what keeps your safety record clean and, far more importantly, ensures every one of your workers gets to go home in one piece at the end of the day. For a deeper look at overall machine safety, check out our comprehensive guide on forklift safety protocols and best practices. When you weave these principles into your daily routine, OSHA requirements stop feeling like a burden and become just another part of doing the job right.

Matching Platforms with Your Equipment

Choosing a forklift aerial platform isn't like grabbing a generic accessory off the shelf. Think of it like trying to use the wrong key for a very important, very high-stakes lock—a "close enough" fit is a recipe for disaster. When your team is working dozens of feet in the air, you need a perfect match between the platform and your lift truck to guarantee their safety.

This isn't a process you can eyeball. It demands a careful, meticulous check of the manufacturer's specs for both the forklift and the platform you plan to attach. Every single detail matters, from the rated load capacity of your machine to the exact thickness and width of its forks. Skipping these steps is a dangerous gamble on the structural integrity of the entire setup.

The Critical Trio of Compatibility

To avoid a dangerous mismatch, you absolutely have to verify three non-negotiable compatibility points. These three factors work together to create a secure, integrated system that operates like a single, stable unit.

- Load Capacity: The total weight—the platform itself, plus your workers, plus all their tools and materials—must never exceed the forklift’s rated capacity at the specific height and load center you'll be working at.

- Fork Size and Spread: The platform's fork pockets have to be a perfect match for your forklift's forks. A loose, sloppy fit is a major red flag, as it can cause the entire platform to shift and become dangerously unstable.

- Locking Mechanism: A robust locking system is non-negotiable. The platform must have pins, chains, or another secure mechanism that fastens it tightly to the forklift's carriage, eliminating any chance of it sliding off.

Get any one of these wrong, and you've compromised the stability of the entire lift. For instance, a heavy-duty platform built for the thick, beefy forks of a telehandler will be dangerously loose on the slender forks of a standard warehouse forklift.

The most common cause of platform-related accidents isn't equipment failure. It's a fundamental mismatch between the attachment and the host machine. Verifying compatibility is the single most important step in preventing these incidents.

Telehandlers vs. Standard Forklifts

While they both lift things, telehandlers and vertical mast forklifts are worlds apart in their engineering, and so are their platforms. A telehandler’s telescoping boom introduces entirely different stability challenges compared to a forklift's simple vertical mast. Because of this, platforms designed for telehandlers are often built heavier to handle the dynamic loads and greater reach.

Putting a standard forklift platform on a telehandler is a potentially fatal mistake. The forces created when a boom extends and retracts are far greater than anything a vertical mast attachment was built to handle. You must always use a platform specifically approved by the manufacturer for your exact make and model of machine. Our team at Flat Earth Equipment can help you find the precision-fit parts and attachments for your fleet.

This focus on a perfect match is more important than ever. The market for versatile lifting equipment, including forklifts used for lifting personnel, is projected to hit USD 32.47 billion by 2033. This growth underscores the rising demand for machines that can do it all, making the proper pairing of attachments absolutely critical. You can learn more about the projections for the aerial work platform truck market growth at Global Growth Insights.

At the end of the day, the only way to guarantee a safe and productive operation is to treat the platform and the forklift as an inseparable, factory-matched pair.

Essential Inspection And Maintenance Practices

When it comes to forklift aerial platforms, proactive maintenance isn't just a good idea—it's the absolute cornerstone of safety. Think of it like a pilot's pre-flight check; every operator should treat each lift with that same level of scrutiny. This disciplined approach is what prevents accidents, keeps your equipment running longer, and ensures you stay on the right side of safety regulations.

This responsibility is a shared one. Operators are the first line of defense, handling the quick, daily pre-use checks. Behind them, qualified technicians perform the more intensive, periodic inspections. This two-tiered system is designed to catch potential issues early, long before they can become dangerous failures.

The Operator's Daily Pre-Use Check

Before a single worker steps into that platform, the operator has a non-negotiable job to do: a thorough visual and functional inspection. This needs to become a baked-in routine for every single shift. It's a quick but critical health checkup for the equipment.

This daily once-over only takes a few minutes but focuses on the most common points of failure. The goal is simple: spot any obvious signs of damage or wear that could compromise the platform's integrity once it's in the air.

Here are the key areas to hit every single day:

- Weld Integrity: Scan all the welds, paying close attention to high-stress spots like the fork pockets and guardrail connections. You're looking for any cracks, separation, or serious rust that signals a weakening structure.

- Floor Condition: The platform floor needs to be clean, dry, and totally free of debris. Make sure the non-slip surface is intact—it's essential for providing secure footing.

- Guardrails and Gate: Give the guardrails a solid shake to ensure they're secure and undamaged. The entry gate or chain must close and latch properly, because an accidental opening at height is a worst-case scenario.

- Locking Mechanism: This might be the most critical check of all. You must verify that the locking pins, chains, or whatever mechanism is used to secure the platform to the forks are present, working correctly, and fully engaged.

Deep Dive Periodic Inspections

While daily checks are great for catching immediate problems, the more thorough periodic inspections by a qualified tech are what ensure long-term reliability. These inspections, often done monthly or quarterly depending on how much the platform is used, go way beyond a simple visual pass.

A technician's periodic inspection is a proactive hunt for hidden wear and tear. It involves checking for stress fractures that may not be visible to the naked eye and ensuring all safety components meet manufacturer specifications.

This deeper dive confirms the structural integrity of the platform after thousands of lift cycles. It’s an indispensable part of a complete maintenance strategy that keeps your gear safe and in service for years.

A solid inspection routine should be part of a larger strategy. The checklist below gives a clear breakdown of what operators and technicians should be looking for.

Daily vs Monthly Platform Inspection Checklist

This table outlines the essential checks for both the operator's daily pre-use inspection and the technician's more detailed monthly review.

| Inspection Point | Daily Check (Operator) | Monthly Check (Technician) |

|---|---|---|

| Weld Integrity | Visual scan for obvious cracks or rust | Detailed inspection for stress fractures |

| Floor Condition | Check for debris, damage, non-slip surface | Inspect for structural wear or delamination |

| Guardrails & Gate | Ensure secure and latching properly | Test for rigidity, hinge wear, lock function |

| Locking Mechanism | Confirm pins/chains are present and engaged | Verify mechanism for wear, tolerance, and fit |

| Data Plate | Ensure it's legible and attached | Confirm all information is accurate and clear |

| Fasteners | N/A | Check all nuts and bolts for proper torque |

| Structural Frame | Visual check for obvious bends or damage | Inspect for deformations, bends, or fatigue |

Following a consistent schedule like this is a core component of responsible fleet management.

Speaking of which, going beyond just the platform attachments and implementing robust fleet management best practices can dramatically improve the safety and longevity of your entire equipment lineup.

This level of detailed oversight is more important than ever. The global forklift market was valued at USD 81.8 billion in 2024, with nearly 1.5 million new units being produced each year. As fleets grow, so does the absolute necessity for rigorous maintenance, especially as fatal work-related accidents involving forklifts have been trending upward. By committing to a consistent inspection schedule, you aren't just ticking a box—you're actively protecting your people and your investment.

Rent or Buy? Making the Call on a Forklift Platform

Sooner or later, every manager faces the rent-versus-buy dilemma for equipment. When it comes to a forklift aerial platform, this isn’t just a financial question—it’s an operational one. The right answer comes down to one thing: how often you actually need to send your crew skyward.

Renting is the clear winner for short-term gigs or infrequent tasks. If you're doing a once-a-year inventory count or a one-off installation project, renting is a no-brainer. You get access to the equipment you need without the major capital outlay, plus you don’t have to worry about maintenance or finding a place to store it.

Breaking Down the Costs and Benefits

At its core, this decision is a simple cost-benefit game. Renting gives you incredible flexibility. You can try out different models of forklift aerial platforms to see what works best for your team before ever thinking about a purchase. It also completely offloads the hassle of upkeep—the rental company handles all the inspections and repairs.

On the flip side, buying is the smart long-term play for businesses that have a constant need for elevated work. If your maintenance crew is up on a platform every other day handling repairs, those rental fees will bleed your budget dry. In that scenario, ownership quickly becomes the more economical path.

Think about the break-even point. Do a quick calculation: What would a full year of renting cost you versus the outright purchase price? If those numbers are even close, buying is probably the smarter investment for the long haul.

Key Factors in Your Decision

Cost isn't the only thing to consider. When you own the platform, you own all the responsibility that comes with it. That means handling every inspection, performing all required maintenance, and ensuring it stays OSHA-compliant for its entire service life. That’s not a small commitment.

It's also worth looking into the fundamental advantages of leasing over purchasing, which can sometimes offer a happy medium between the flexibility of renting and the long-term benefits of ownership.

Before you make the final call, run through this quick checklist:

- Usage Frequency: Is this a daily tool or a once-in-a-blue-moon need? This is the biggest driver of your decision.

- Project Duration: Are you tackling a single, long project or a series of ongoing, short-term jobs?

- Capital Budget: Can you handle the upfront investment of a purchase, or does a predictable rental expense make more sense for your cash flow?

- Maintenance Capability: Do you have the in-house expertise and time to manage the rigorous upkeep an owned platform requires?

Ultimately, you're aiming for a strategic choice that clicks with both your daily operations and your budget. If you're stuck trying to weigh the options for your fleet, our team can help you sort through it. Get in touch with our equipment specialists for a consultation on rental or purchase options.

On-the-Job Questions Answered

Even with the best training and procedures, questions always pop up on the floor. Here are some quick, clear answers to the most common things we hear from operators, maintenance techs, and safety managers.

Operator Training and Certification

A lot of folks wonder if a standard forklift license is enough to run a personnel lift. The answer is a hard no.

Think of your general forklift certification as the foundation. But OSHA requires additional, specific training on the forklift aerial platform itself. This isn't just a formality—it has to cover the unique hazards, how to properly attach the basket, stability issues, and what to do in an emergency. More importantly, the company has to document this specific training for every single person authorized to operate that lift.

Common Equipment Failure Points

From a maintenance standpoint, you have to know where to look for trouble. On a forklift work platform, the most common failures happen right where the platform connects to the forks.

Keep a close eye on these areas:

- Worn or cracked fork pockets that allow the basket to wobble.

- Locking pins or chains that are bent, rusted, or don't secure the platform tightly.

- Stress fractures in the welds, especially around the back guard and attachment points.

These weak spots are exactly why a detailed, daily pre-use inspection is mandatory. It’s not just a box to check.

The connection between the platform and the forklift is the single most critical point of failure. If that connection is compromised in any way, the equipment must be tagged out of service immediately until a qualified tech signs off on the repair.

Rules for Moving the Forklift

This is one of the most critical safety rules, and also one of the most asked-about: can you drive the forklift while a worker is up in the basket?

Absolutely not. Under OSHA safety standards, it is strictly forbidden to travel with a worker in an elevated forklift aerial platform. The worker must be back on solid ground with their feet out of the basket before the forklift is moved to a new spot. The platform is built for going straight up and down in one place, not for giving someone a ride across the warehouse.

Determining Maximum Platform Capacity

Finally, let’s talk about weight limits. The maximum capacity—which includes the weight of the person, their tools, and any materials they have with them—has to be clearly marked on a data plate right on the platform. The manufacturer puts it there for a reason.

Never, ever exceed this limit. Just as important, you have to remember that the platform's capacity must be well within the load rating of the forklift itself. You have to account for the weight of the attachment and how the center of gravity shifts as you lift. Overloading is how catastrophic tip-over accidents happen.

Need expert advice on choosing the right attachments or getting your team OSHA-compliant training? The pros at Flat Earth Equipment have you covered. Find the precision-fit parts and rentals you need today.