Let's get one thing straight. You and I, we deal with real iron. When I'm wrestling with a JCB telehandler that's thrown a fault code because its AdBlue system decided to have a bad day, the last thing on my mind is a walk-behind pallet jack. That's a toy compared to the yellow iron I keep running. But here's the kicker: OSHA doesn't care. That little electric mule falls under their rules, and they want paperwork.

So, what is electric pallet jack certification? It’s the process where the boss trains you, watches you run the machine, and signs off that you won't spear a hole in the wall. It’s not just a piece of paper; it's a mandatory OSHA requirement, and it involves book smarts and a real-world driving test.

What This Certification Is Really About

Cut the fluff. Getting certified isn't some bureaucratic game meant to waste your time. It’s about proving an operator won't destroy your equipment or, worse, get someone hurt and shut the whole operation down.

It’s like this: reading the service manual for a backhoe doesn't mean you can actually dig a trench without hitting a gas line. The certification is proof you can handle the machine when it counts. It's your only real defense against accidents, trashed inventory, and the headache that comes after.

The Three Pillars You Can't Dodge

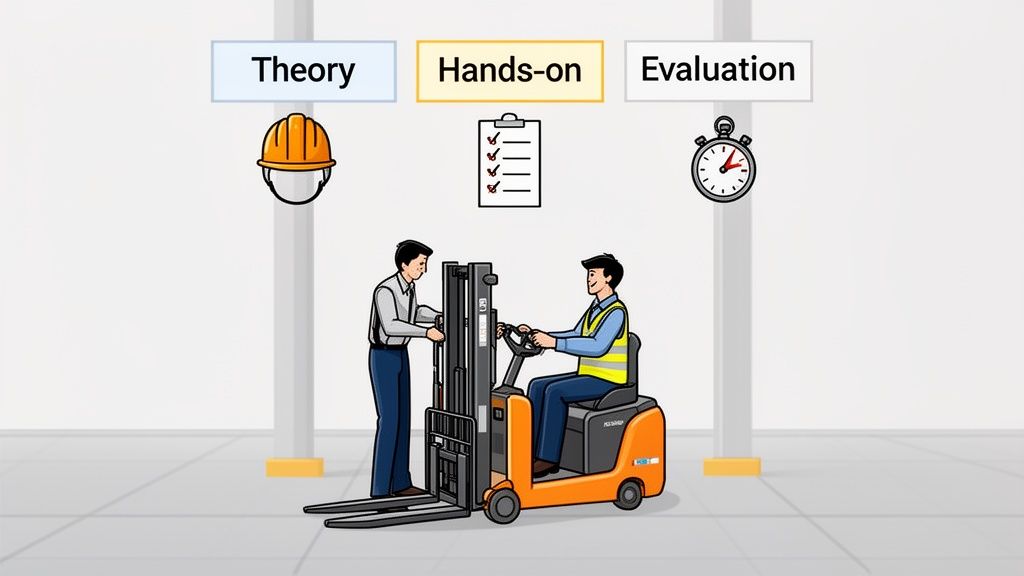

This whole certification thing is built on three parts. Screw one up, and the whole thing is worthless to an OSHA inspector. These aren't suggestions—they're the rules of the road.

A real, OSHA-compliant program has to have all three. No shortcuts.

The Three Pillars of OSHA-Compliant Certification

| Component | What It Covers | Why It Matters |

|---|---|---|

| Classroom Theory | The "why" behind the rules: machine limits, load stability, pre-shift inspections. This can be done online. | Builds a foundation so operators understand the risks before they even touch the controls. It's the brain work. |

| Hands-On Practical Training | Supervised practice. Getting a feel for the jerky controls, learning to turn in tight spots, and handling real loads. | This is where the manual meets the mud. It’s where you build the muscle memory to react, not just think. |

| Final Evaluation | An operator proves they can do the job safely in your warehouse, on the exact machine they'll use every day. | This is the final sign-off. It proves they can apply what they learned where it actually counts—on your floor. |

This three-step process makes sure operators don't just know the rules but can actually use them when a truck is waiting and the pressure is on.

The point is simple: knowing the theory but not having the skill is dangerous. An operator who aces a test but can't back a load onto a dock plate without dropping it is a liability. True certification proves both.

This framework has been the standard for years. In the US, OSHA's rule 29 CFR 1910.178 laid it all out. You can read the fine print on these vital OSHA regulations at Learntastic.com.

Bottom line, proper certification isn't about checking a box. It's about building a crew that can move product without breaking things or people.

Decoding OSHA's Rules So You Don't Get Fined

Let's cut the crap. That big OSHA rule, 29 CFR 1910.178, isn't just for big sit-down forklifts. It covers your little electric pallet jacks, too. This isn't a friendly suggestion—it's federal law, and the fines for blowing it off can cripple a business.

The responsibility for training and certifying every single operator is on the employer. It's your neck on the line. An employee can't just click through some generic online course and print a wallet card. That's not how this works.

Who Needs It and When

The rule is blunt: if you're going to touch the controls, you need to be trained and certified. This goes for everyone—the full-time guy, the temp, even the supervisor who just needs to move one pallet. No exceptions.

And it has to happen before they operate the machine alone. Letting an untrained guy use a pallet jack is like letting an apprentice loose with the dealer laptop—it’s a fast way to cause a lot of damage.

A generic certificate from some random website is useless. OSHA demands the final evaluation is hands-on, at your specific job site, using the exact equipment your team will operate. This is the only way to prove they can do the job without causing chaos.

This hands-on part is everything. An operator trained on a brand-new rider jack in a wide-open space is useless with your beat-up walk-behind in a tight aisle full of parts. Site-specific training isn't just a good idea; it's the law. This focus on practical skill is why the electric pallet jack market keeps growing. For those who care about market stats, you can find details on pallet jack market trends at Fact.MR.

The Real Cost of Ignoring the Rules

Ignoring these rules is a gamble. Sooner or later, someone will have an accident, and an OSHA inspector will show up. If they find uncertified operators, you’re looking at huge fines, potential shutdowns, and legal trouble.

Proper electric pallet jack certification is more than compliance. It’s about running a tight ship. For managers in Texas, knowing state-level rules is also key, which is why resources on Texas forklift safety standards are critical. It's about protecting your crew, your equipment, and your business from preventable screw-ups.

Why Your Forklift License Is Useless Here

Here’s something I hear that drives me nuts: “I’m forklift certified, I can run that pallet jack.” That’s just dead wrong.

Thinking your forklift license covers a powered pallet truck is like me thinking because I can fix a JCB backhoe, I can troubleshoot the finicky electronics on a brand-new excavator without the right software. They’re different animals.

OSHA lumps them under the same rule, 29 CFR 1910.178, but they are not the same machine. You walk behind a pallet jack or stand on a tiny platform. You steer with a tiller, not a wheel. That changes everything—how you turn, how you stop, and where your blind spots are.

The center of gravity is completely different, making them prone to their own special kinds of accidents.

Different Machines, Different Dangers

The skills just don't transfer. Weaving a walk-behind pallet jack down a narrow aisle takes a different touch than running a sit-down forklift in the yard.

Key differences include:

- Steering Mechanism: A tiller arm is direct and jerky. It's not smooth like a forklift's steering wheel.

- Operator Position: You're on your feet, exposed. In a crash, you are the crumple zone.

- Braking and Acceleration: Pallet jacks use thumb controls and "plug braking." It's a whole different feel.

- Stability: Their low profile creates unique tipping hazards, especially on ramps and dock plates.

Because of these differences, OSHA demands equipment-specific training. Your boss is legally required to certify you on each class of machine you operate. An electric pallet jack certification is a separate, mandatory requirement.

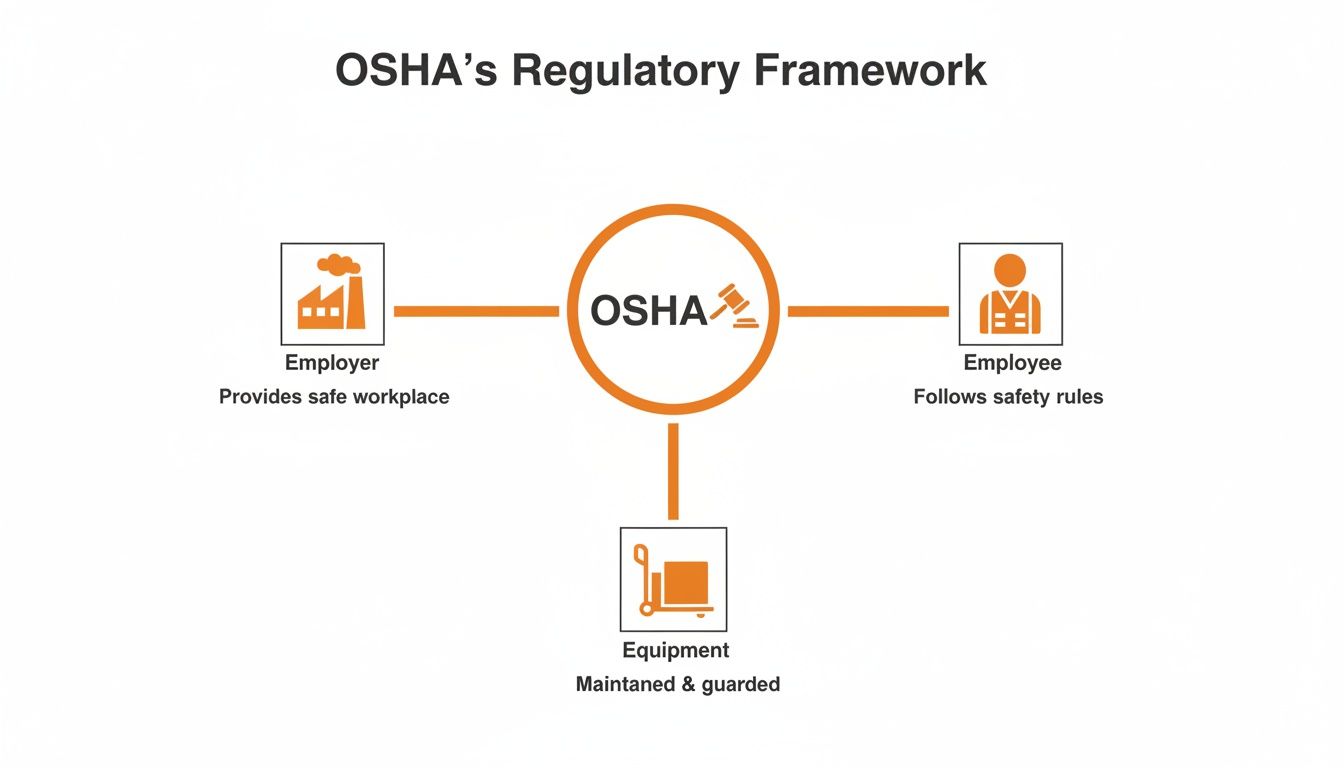

This chart breaks down OSHA's framework. It shows the responsibility is on the employer, the employee, and the equipment itself.

The picture is clear: compliance is a system. Ignoring equipment-specific training breaks that system. For more on these rules, our guide to forklift safety standards has more info.

Simply put, mastering one machine doesn't make you an expert on them all.

The Two-Step Path to Getting Certified

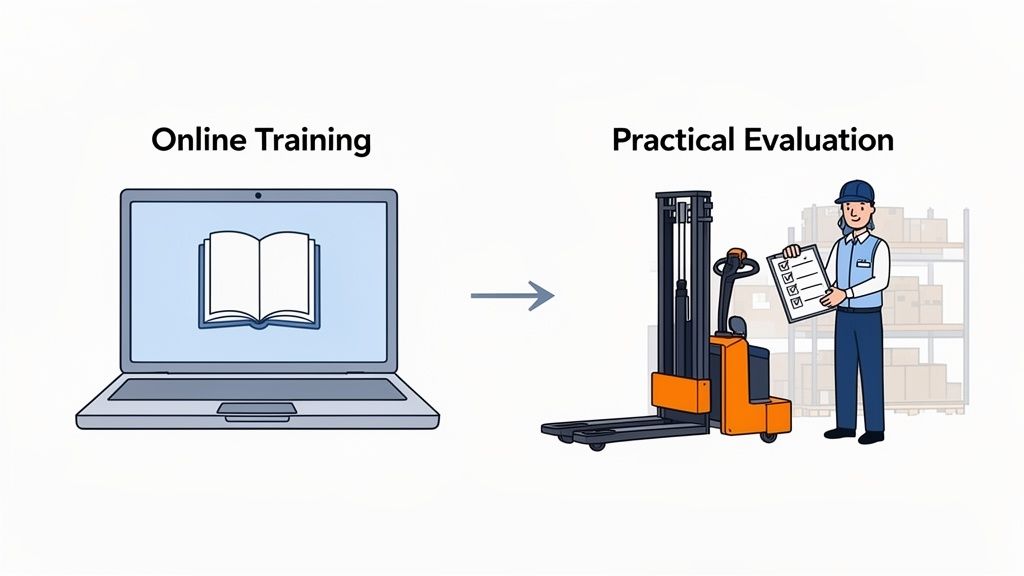

So, how do you get your crew their electric pallet jack certification without the BS? Forget waiting on some third-party trainer. The modern, OSHA-compliant way is a two-step process that puts you in charge.

First is the "classroom" part. This is the theory—safety rules, machine basics, why OSHA cares. Online training is the fastest way to do this. An operator can learn the basics on their own time without you having to shut down the floor for a whole day.

But let's be clear: an online certificate alone is worthless. It's only half the job.

Step 1: Online Theory Training

The point here is knowledge. A good online course drills operators on what they need to know before they touch the equipment. This gets everyone on the same page with the risks and their responsibilities.

Step 2: The On-Site Practical Evaluation

This is where the rubber meets the road. The second step is the hands-on evaluation, and you can't skip it. It must happen at your site, with your equipment, and your typical loads. A joyride in some training facility doesn't count.

Here, an operator proves they can actually do the job safely. A supervisor watches them perform key tasks and confirms they have the skills for your environment. It’s not about driving in a straight line; it’s about proving they won't cause a disaster.

This is the most important part of any real certification. The evaluation must confirm the operator can handle your unique problems—tight aisles, a busy shipping dock, uneven floors. It’s the final proof of skill.

To pass, an operator has to master several core skills. A real evaluation checks the whole process, from startup to shutdown.

A legitimate hands-on evaluation must include:

- Pre-Operation Inspection: The operator has to know how to check the forks, controls, battery, and safety gear before their shift.

- Basic Maneuvering: Controlled starts, stops, and turns, both forward and reverse, without a load.

- Load Handling: They have to show they can safely pick up, move, and place a typical load for your shop.

- Site-Specific Awareness: This means navigating your actual layout—ramps, blind corners, and areas with foot traffic.

This blended model—online theory plus a hands-on skills check—is the fastest, most effective way to get your crew fully certified and OSHA-compliant.

Two-Step Path to OSHA Compliance

Here's a quick breakdown of how this blended training gets you full electric pallet jack certification.

| Step | Method | Key Outcome |

|---|---|---|

| Step 1: Theory | Online Training Course | Operator learns the safety rules and machine specs at their own pace. |

| Step 2: Practical | On-Site Evaluation | A competent supervisor verifies the operator can safely use the equipment in your specific work environment. |

Once an operator passes both, you can officially certify them. This simple, two-part process ensures your team is not just compliant, but actually competent.

What A Real Certification Course Should Teach

Any decent electric pallet jack certification program does more than show you the "go" button. It's about building instincts. A cheap, check-the-box course just creates overconfident operators who become liabilities—wrecking equipment and hurting people.

A real course teaches an operator to think ahead.

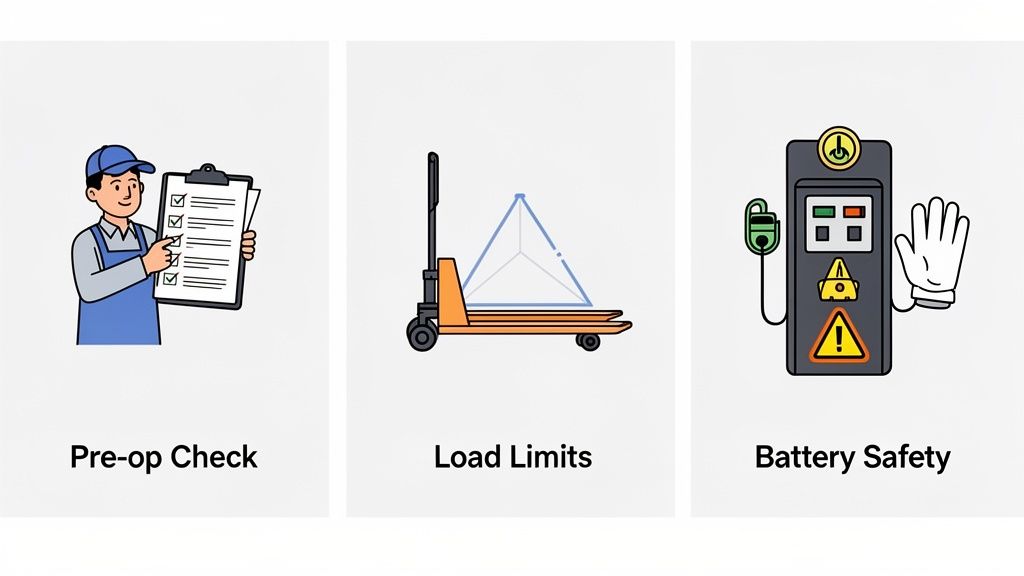

The training has to be based in the real world, starting with the mandatory daily pre-operation inspection. Every operator must know how to check the forks for cracks, inspect the controls, and verify the battery before moving a single pallet. It’s your first defense against a machine failing with a load in the air.

Core Operating Principles

Once the daily check is memorized, the training gets into the physics of the machine. Operators need to have load capacity and the "stability triangle" drilled into them—that’s what keeps the machine from tipping. Pushing those limits is how you flip equipment and destroy thousands in product.

Safe operating procedures are just as critical. This isn't generic advice; it's about handling the machine in your environment:

- Navigating Ramps and Docks: Keeping traction on an incline is a whole different skill than driving on flat concrete.

- Managing Blind Corners: Using the horn and slowing down isn't optional—it's what prevents collisions.

- Working Around People: A warehouse floor is a shared space. That means keeping a safe distance from foot traffic at all times.

Site-Specific Hazard Recognition

A one-size-fits-all program is useless. The training has to be customized to your facility's hazards. That could be wet floors, narrow freezer aisles, or the chaos of a busy loading dock.

It must also cover battery charging and maintenance, which is a huge fire risk if you're careless.

A manager who can spot the difference between a cheap course and real training is protecting their assets. A properly trained operator is safer, more efficient, and less likely to cause thousands in damage from a stupid, preventable mistake.

When you invest in real training, you're investing in fewer disasters and a smoother operation. For more on building a strong safety culture, check out our essential warehouse safety tips.

How Long Does Certification Last and When Do I Need to Renew It?

So, the team is certified. Great. How long is that paper good for? OSHA gives you a maximum of three years before you have to re-evaluate an operator’s skills. But don't just circle a date on the calendar three years out and forget it.

That three-year mark is the absolute longest you can go. It’s like the service interval on a piece of yellow iron—you might hit the hour limit first, or a hydraulic line might blow, forcing you into the shop early. The real world doesn't wait.

When to Recertify Immediately

There are a few times when the rulebook says you pull an operator and get them retrained right away. No excuses.

- They have an accident or a near-miss. Doesn't matter who was at fault. The incident proves there’s a gap in their skill that needs to be fixed now.

- You see them operating unsafely. Whipping around corners, ignoring the horn—bad habits spread fast and need to be stomped out.

- They're assigned a different type of pallet jack. Moving an operator from a walk-behind to a stand-on rider is a big jump. The controls, the feel, the risks—they're all different.

Waiting for the three-year renewal after an incident is just begging for a bigger problem. It's on you, the employer, to step in the second you see a red flag.

Budgeting for Real Certification

Let's talk money. You'll find tons of dirt-cheap, "online-only" courses promising a certificate in an hour. It's a trap. They skip the mandatory hands-on evaluation, which means they aren’t OSHA compliant and won’t protect you when something goes wrong.

A legitimate electric pallet jack certification costs more because it’s a two-part process: online theory plus the practical skills test. Think of this as an insurance policy. The cost of one serious accident—crushed inventory, damaged racks, a worker's comp claim—will make the price of proper training look like pocket change. Paying for real training isn't an expense; it's what keeps your operation from grinding to a halt.

Common Questions About Pallet Jack Certification

You run heavy iron all day—a backhoe, a telehandler. That's a machine. So when someone talks about a walk-behind pallet jack, it feels like a joke. You’ve got bigger problems, like a JCB stuck in a regen cycle because a sensor quit, and the dealer's laptop is the only thing that’ll clear the code.

But here’s the rub: OSHA doesn’t care if you can rebuild a final drive in the mud. That little electric pallet jack falls under their rules, and they want paperwork.

Let’s cut the nonsense and get straight to it.

Does An Online Certificate Make Me Fully Certified?

No. An online course is step one—it’s like reading the service manual. It gives you the theory, but it doesn’t mean you know how to operate the machine.

To be fully certified, you must pass a hands-on skills evaluation at your job site, on the machine you’ll be using. Your boss or a supervisor has to watch you operate it and sign off that you're not a danger to yourself or the equipment. Without that practical sign-off, your online certificate is just a piece of paper.

How Often Do I Need To Renew It?

OSHA says you have to be re-evaluated at least once every three years. But that’s the maximum.

If you have an accident, a near-miss, or a supervisor sees you driving like an idiot, you’re up for immediate retraining. It’s not about the date; it's about proving you can still do the job safely.

Can I Use My Forklift Certification For A Pallet Jack?

No. That's like saying because you’re a certified JCB tech, you can fix the AdBlue system on some other brand. They’re different beasts with their own finicky electronics and operating quirks.

A forklift and a pallet jack are different classes of equipment. Your certification has to be specific to the machine you’re running. End of story.

Don't get sidelined by compliance or wait for a dealer to fix your problems. When a machine goes down because of a faulty sensor or solenoid, you need parts now, not next week. Flat Earth Equipment has the sensors, solenoids, and filters you need to bypass the dealer's wait times and fix it yourself. Get your team OSHA-compliant training and find the exact parts to keep your fleet running. Visit us at https://flatearthequipment.com and get back to work.