Getting your electric forklift charging strategy right is about more than just plugging things in. It’s about matching your battery technology—whether it's old-school Lead-Acid or modern Li-ion—to the real-world pace of your operations. It’s about picking the right charging method, like Opportunity or Fast Charging, and locking down safety standards that are non-negotiable.

Think of it as the unseen engine driving your entire logistics operation. Get it right, and you’ll see more uptime, lower costs, and a safer warehouse floor.

The Hidden Engine of Warehouse Productivity

Let's be honest—forklift charging often gets treated like a simple, repetitive chore. But what if it's actually one of the most powerful levers you can pull to boost your warehouse's performance? A well-planned charging program can go from a routine task to a core strategic advantage that pads your bottom line.

This guide is here to reframe that conversation. We're moving beyond the basics to show you how a smart charging strategy delivers real, measurable results.

Shifting from Chore to Strategy

When you start seeing charging as a strategic asset, you realize its direct impact on everything else. A mismatched charger or a sloppy process creates bottlenecks that send ripples through your entire workflow, leading to missed deadlines and bloated labor costs. An optimized system, on the other hand, keeps your fleet ready to roll, maximizing every minute of every shift.

The industry's explosive growth makes this kind of efficiency essential. The global electric forklift market is on a tear, projected to hit USD 132.7 billion by 2034. This boom is all about the demand for high-performing, sustainable equipment, which puts smart charging right in the spotlight. You can dig deeper into the electric forklift market growth projections on gminsights.com.

A proactive charging strategy does more than just power your equipment; it fuels your entire operation's productivity. By minimizing downtime and maximizing asset utilization, you create a more resilient and profitable logistics chain.

The goal is to build a program that fits your specific operational DNA. That means taking a hard look at a few key factors:

- Battery Technology: Choosing between the workhorse reliability of lead-acid and the nimble efficiency of lithium-ion.

- Charging Methods: Implementing a system—like opportunity or fast charging—that syncs up perfectly with your shift schedules and workflow.

- Safety and Compliance: Establishing rock-solid protocols to protect your team and your equipment, making sure you nail all OSHA requirements.

- Infrastructure: Designing a dedicated charging station that is safe, organized, and ready to scale as you grow.

Choosing Your Power Source: Lead-Acid vs.## Choosing Your Power Source: Lead-Acid vs. Lithium-Ion

Picking the right battery for your electric forklift is the single most important decision you'll make. It sets the stage for your entire charging strategy, shapes your daily workflow, and has a huge impact on your long-term costs. This isn't just about specs on a sheet; it's a fundamental operational choice. The two main players in the game, old-school lead-acid and modern lithium-ion (Li-ion), are worlds apart in how they perform.

Think of a lead-acid battery like a trusty, heavy-duty diesel truck. It’s powerful, cheaper to buy upfront, and it's been the workhorse of the industry for decades. But, it needs long stops to "refuel" (charge), dedicated time to cool down afterward, and requires regular hands-on maintenance like adding water.

A lithium-ion battery, on the other hand, is more like a high-performance EV. The initial investment is higher, no doubt. But it recharges in a fraction of the time, needs practically zero daily maintenance, and runs with far better energy efficiency. Your choice here directly defines your approach to electric forklift charging and, ultimately, your fleet's productivity.

Lead-Acid vs. Lithium-Ion: A Head-to-Head Comparison

To really understand the difference, you need to see how these two technologies stack up side-by-side. One is a legacy system with a low entry cost, while the other is a modern powerhouse built for efficiency and flexibility. Deciding which is right for your warehouse means weighing upfront costs against long-term operational gains.

This table breaks down the key features of each battery type, helping you compare them directly based on what matters most to your operation—from daily charging routines to the total cost over the battery's life.

| Feature | Lead-Acid Battery | Lithium-Ion Battery |

|---|---|---|

| Charging Time | 8-10 hours for a full charge | 1-2 hours for a full charge |

| Cool-Down Period | Requires an 8-hour cool-down after charging | No cool-down period needed |

| Opportunity Charging | Not recommended; damages battery life | Ideal for charging during breaks |

| Daily Maintenance | Requires regular watering and equalization | Maintenance-free; sealed unit |

| Battery Swapping | Often necessary for multi-shift operations | Eliminated; one battery per forklift |

| Lifespan (Cycles) | Approximately 1,500 cycles | 3,000+ cycles |

| Energy Efficiency | Lower efficiency; loses more power as heat | Higher efficiency; up to 30% more efficient |

| Upfront Cost | Lower | Higher |

| Total Cost of Ownership | Higher due to maintenance, replacements, downtime | Lower over the lifespan of the battery |

| Best For | Single-shift, low-intensity operations | Multi-shift, high-demand environments |

Choosing between lead-acid and lithium-ion isn't just a battery purchase; it's an investment in a particular way of working. The data shows that while lead-acid seems cheaper initially, Li-ion often delivers a much stronger ROI through sheer operational efficiency.

Comparing Core Operational Differences

The gap between these two widens when you look at how they impact your day-to-day. Lead-acid batteries are rigid. They demand a strict charge-use-cooldown cycle. You get an 8-hour charge, followed by an 8-hour cooldown. This makes them a decent fit for single-shift operations where forklifts can sit idle overnight.

Lithium-ion completely shatters that rigid cycle. With no cooldown needed and the ability to be opportunity charged—just plug it in during a 15-minute coffee break—it's built for the chaos of multi-shift, high-demand warehouses. This flexibility gets rid of battery swapping, a time-consuming and often dangerous task that’s all too common for lead-acid fleets.

This move toward more agile power sources is a big deal. The forklift battery market is booming, expected to hit USD 2.36 billion in 2025, largely driven by the switch to lithium-ion. Faster charging, longer life, and less maintenance are changing the game. You can dig into more of these trends in the forklift battery market on cognitivemarketresearch.com.

Analyzing Total Cost of Ownership

Lead-acid batteries look attractive because of their low sticker price, but the real story is in the Total Cost of Ownership (TCO). This isn't just what you pay today; it's the cost of energy, maintenance labor, battery replacements, and lost productivity over the battery’s entire life.

TCO reveals that the cheapest option today isn't always the most economical over the equipment's lifespan. Efficiency gains, reduced labor, and longer cycle life often make lithium-ion a more strategic long-term investment.

Let's break down where the real costs hide:

- Energy Costs: Lithium-ion batteries are simply more efficient. More of the electricity you pay for actually goes into moving your forklift, not wasted as heat. This can cut your electricity consumption by up to 30% compared to lead-acid.

- Maintenance Labor: Lead-acid batteries need someone to water them and run equalization charges every week. Those labor hours add up fast. Li-ion batteries? They’re sealed. No maintenance needed.

- Battery Lifespan: A typical lead-acid battery gives you about 1,500 charge cycles before it's done. A Li-ion battery can deliver 3,000 or more cycles, lasting two or even three times as long and pushing back that costly replacement day.

- Productivity and Downtime: Time is money. Every minute spent swapping a heavy lead-acid battery or waiting for it to charge and cool is pure downtime. Li-ion’s quick-hit opportunity charging keeps your forklifts on the floor, doing work.

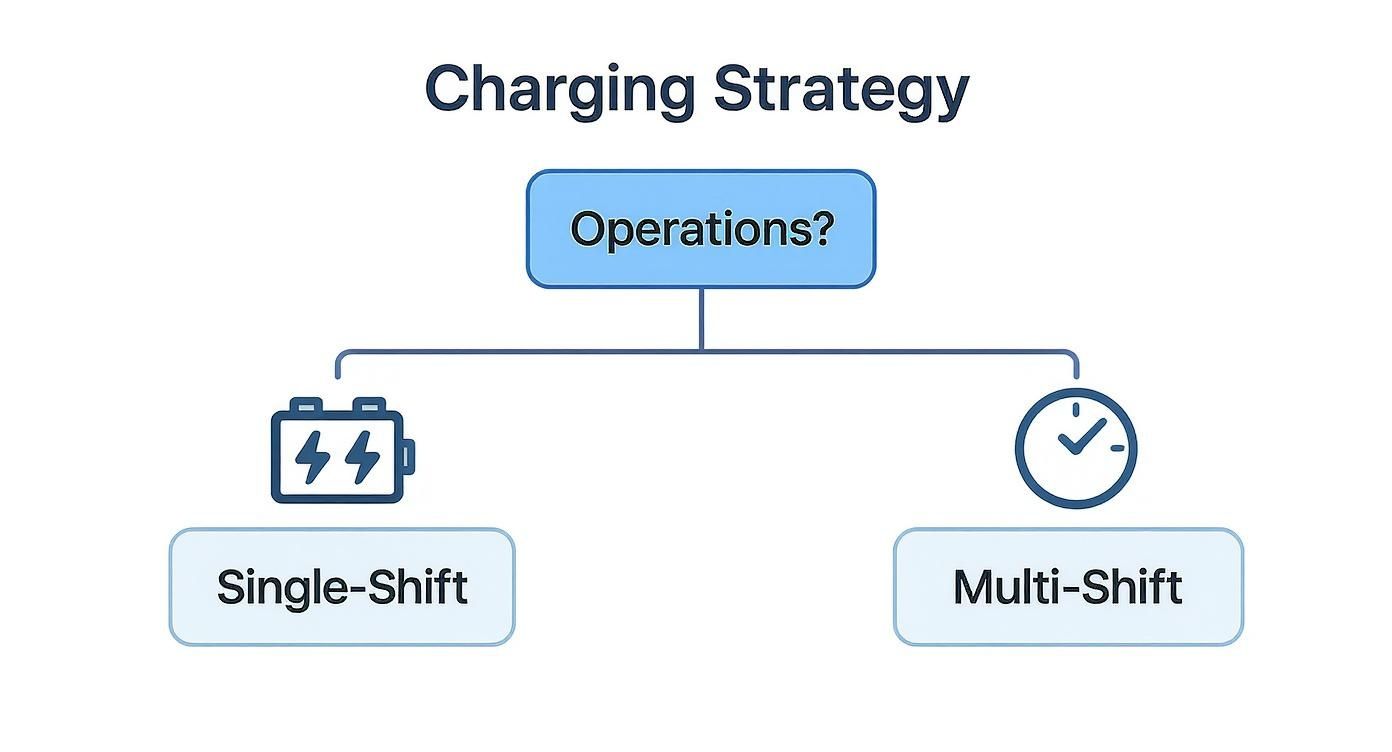

This decision tree helps visualize how your operational needs should guide your choice.

As the chart shows, a single-shift operation can get by just fine with a conventional lead-acid setup. But for multi-shift workflows, the flexibility of lithium-ion provides a serious competitive advantage.

Ultimately, the right choice boils down to the pace of your operation. For a low-intensity, single-shift warehouse, the upfront savings of lead-acid might make sense. But for a bustling 24/7 distribution center, the efficiency, longevity, and uptime from lithium-ion make an undeniable case for long-term value.

Decoding Your Charging Strategy

Picking the right battery is only half the battle. To really get the most out of your fleet, you need a charging plan that fits your workflow, shift schedules, and daily grind. A smart electric forklift charging strategy is what turns a bunch of individual machines into a perfectly synchronized, high-output system.

Think of it like a pit stop strategy in a car race. You wouldn't use the same plan for a quick sprint that you would for a 24-hour endurance event. It’s the same in the warehouse—a single-shift operation has totally different needs than a nonstop, three-shift distribution center.

Conventional Charging: The Classic Approach

Conventional charging is the old-school, tried-and-true method, mostly for lead-acid batteries. It works on a simple, predictable rhythm: run the battery until it's nearly empty, plug it in for a full 8-10 hour charge, then let it cool down for another 8 hours.

This 1-1-1 model (one shift working, one shift charging, one shift cooling) is a solid, cost-effective choice for single-shift operations where forklifts can be parked overnight. But for multi-shift environments that need constant uptime, its rigid schedule just doesn't work.

Opportunity Charging: The Top-Up Tactic

Opportunity charging completely changes the game by ditching the full-depletion cycle. This strategy is all about topping up the battery during short bursts of downtime throughout the day. It's just like plugging in your phone during lunch to make sure it lasts the rest of the afternoon.

This approach is a perfect match for lithium-ion batteries, which actually prefer frequent, partial charges and don't suffer any memory-effect damage. Operators can plug in their lifts during breaks, between tasks, or any time the machine sits idle for a few minutes.

Opportunity charging gets rid of battery swapping, which is a slow, clunky, and often dangerous job. This one change can seriously boost productivity and improve safety by keeping the same battery in the forklift its entire life.

This method keeps the battery's charge in that sweet spot (typically 30-80%), which helps extend its overall lifespan and ensures the forklift is always ready to go. For busy, multi-shift warehouses, it’s a powerful way to keep the fleet moving.

Fast Charging: The High-Speed Solution

When your operation is running 24/7 and you need every ounce of productivity you can get, fast charging is the answer. This is the high-octane approach, using powerful chargers to juice a battery from nearly empty to full in as little as one to two hours.

Fast charging is pretty much exclusively for lithium-ion and some specially designed lead-acid batteries. You'll need some beefy electrical infrastructure to handle the high power draw, but the payoff is huge. It lets a single battery power a forklift through back-to-back shifts with just a few quick charging stops.

- Conventional Charging: Best for single-shift operations with lead-acid batteries and plenty of overnight downtime.

- Opportunity Charging: Ideal for multi-shift facilities using lithium-ion, keeping lifts ready by charging during breaks.

- Fast Charging: The top-tier solution for demanding, 24/7 environments that can't afford to stop.

Matching the right strategy to your battery type and the pace of your operation is everything. You can explore a wide range of advanced forklift battery chargers that support these modern methods to find the perfect setup for your fleet.

At the end of the day, your charging strategy should be a direct reflection of your warehouse's tempo. A well-thought-out plan keeps your equipment powered and ready, turning a potential logistical headache into a real competitive edge.

Building a Safe and Efficient Charging Station

An electric forklift charging station is much more than a parking spot with an outlet. Think of it as a specialized industrial zone. It demands careful planning to keep your operation running smoothly, safely, and in full compliance. Treating this space as an afterthought is a costly mistake that leads to damaged equipment, operational gridlock, and serious safety risks.

A well-designed charging area is the heart of your electric fleet. It’s where your most valuable assets get revitalized, so the layout, equipment, and safety rules have to be on point. Every detail, from calculating the right amount of floor space to installing safety gear, matters.

Designing the Physical Layout

First things first: you need to allocate enough space. This isn't just about making sure the forklifts fit. You have to account for safe maneuvering, easy access to the chargers, and any battery handling equipment like hoists or carts. A cramped station is a recipe for traffic jams and a much higher risk of accidents.

As a general rule, make sure there’s at least a forklift's length of clear space around each charging bay. This gives operators room to approach and leave without having to perform tricky, high-risk maneuvers. Don’t forget about the chargers themselves—they need their own dedicated footprint, clear of any travel paths.

This need for proper infrastructure is a growing trend. As more warehouses switch to electric fleets, the global demand for chargers is skyrocketing. The market was valued at around USD 1.5 billion in 2023 and is expected to more than double to USD 3.2 billion by 2032. You can find more details in this electric forklift battery charger market report.

Establishing the Electrical Infrastructure

The electrical system is the backbone of your charging station, and getting it right is non-negotiable. Industrial chargers draw a serious amount of power, so you can't just plug them into standard wall outlets. That’s a surefire way to overload circuits, which can cause fires and fry your expensive chargers and batteries.

You absolutely need to bring in a licensed electrician to assess your facility’s power capacity. They’ll figure out the right amperage and install dedicated circuits for each charger, ensuring a stable power supply and preventing electrical issues that could shut down your whole operation.

A dedicated, professionally installed electrical system isn't just a best practice—it's a foundational safety requirement. Skimping here exposes your operation to unnecessary risks of fire, equipment failure, and non-compliance with electrical codes.

Keep these key electrical factors in mind:

- Dedicated Circuits: Every single charger needs its own circuit. No exceptions. This prevents overloads and ensures each battery gets consistent power.

- Correct Voltage: Double-check that your power supply perfectly matches the charger's specifications.

- Emergency Shut-Off: Install a master shut-off switch for the entire charging area. It needs to be clearly marked and easy to get to in an emergency.

Meeting Critical OSHA Safety Requirements

Following Occupational Safety and Health Administration (OSHA) standards isn't optional. These rules are there to protect your team from the specific dangers of electric forklift charging, and ignoring them can lead to massive fines and—far worse—preventable injuries.

Ventilation is one of the biggest requirements, especially if you’re charging traditional lead-acid batteries. During a charge cycle, these batteries vent highly flammable hydrogen gas. Without good airflow, that gas can build up and create a serious explosion risk. Your charging area must have fans or a ventilation system to pull those fumes away safely.

But it’s not just about ventilation. OSHA requires a handful of other critical safety features. Building a compliant station means checking every box.

OSHA-Mandated Safety Equipment Checklist

- Fire Protection: A fully charged, ABC-rated fire extinguisher has to be mounted somewhere visible and easy to grab.

- Eyewash Station: You need an emergency eyewash station within a 10-second, unobstructed walk from the batteries in case of an acid splash.

- Spill Containment: Keep a spill kit with neutralizer on hand to safely clean up any battery acid spills.

- Protective Barriers: Install bollards or guardrails to protect your charging stands and equipment from getting hit by a moving forklift.

- Clear Signage: Post signs that clearly state "No Smoking," identify the battery charging area, and remind employees to wear their Personal Protective Equipment (PPE).

Mastering Your Charging Safety Protocols

An efficient electric forklift charging program is great, but a safe one is non-negotiable. Getting lax on safety isn’t just a compliance headache; it’s a direct threat to your people, your equipment, and your entire operation. This is about more than just checking boxes—it's about building a culture of vigilance where every single operator understands the "why" behind every rule.

Think of charging safety like a pilot's pre-flight check. It might feel repetitive, but every step is there to prevent a specific, and potentially catastrophic, failure. In a warehouse, those failures look like electrical fires, battery explosions, or nasty chemical burns from acid spills.

Arming Your Team with Personal Protective Equipment

The first line of defense in any hands-on industrial task is always Personal Protective Equipment (PPE). When your crew is handling forklift batteries, especially the traditional lead-acid kind, this gear isn't optional. It’s the only thing standing between an operator and serious, preventable harm.

Mandatory PPE for battery handling always includes:

- Safety Glasses or Goggles: These are critical for shielding eyes from splashes of corrosive battery acid, which can cause instant and permanent damage.

- Acid-Resistant Gloves: Your standard work gloves won't do the job. You need gloves specifically made from materials like neoprene or PVC that can stop chemical burns cold.

- Face Shield: When watering batteries or doing other up-close work, a full face shield gives you that extra layer of protection for your entire face.

- Apron or Protective Clothing: An acid-resistant apron keeps spills and splashes off your torso, preventing them from soaking through clothing and causing severe skin irritation.

Handing out the gear is step one. Consistent training on when and how to use it is what really builds the muscle memory that keeps everyone safe.

Understanding and Mitigating Unique Hazards

Different batteries come with different risks. While modern lithium-ion batteries are sealed units and generally safer to handle, lead-acid batteries have a couple of specific hazards that demand respect: hydrogen gas and corrosive acid.

The charging process for lead-acid batteries naturally produces hydrogen gas. This gas is completely colorless, odorless, and extremely flammable. If it builds up in a poorly ventilated room, something as small as a spark from a dropped tool or static electricity can trigger a violent explosion. This is exactly why OSHA is so strict about dedicated, well-ventilated charging areas.

A spark is all it takes to turn a routine task into a major incident. Preventing electrical arcing during connection and disconnection is one of the most critical safety procedures in the charging process.

To stop this dangerous arcing from ever happening, operators must follow a strict sequence. No exceptions.

- Turn Off the Charger: Always make sure the charger is switched off before you connect or disconnect the battery.

- Connect the Cable: Plug the charger connector firmly into the battery.

- Turn On the Charger: Only after the connection is secure should you turn the charger on to begin the cycle.

When the charge is done, you just reverse the process: turn the charger off first, then unplug the battery. This simple habit completely eliminates the risk of creating a spark right next to a battery that might be off-gassing.

Establishing Step-by-Step Safety Procedures

The key to making safety second nature is creating a clear, repeatable process for electric forklift charging. Every operator should follow the exact same steps, every single time. A standardized approach is the bedrock of a safe operation.

Here’s a simple, effective protocol to drill into your team:

- Inspect Equipment: First thing's first. Check the charger cables and connectors for any signs of fraying, cracking, or other damage. Damaged gear gets pulled from service immediately.

- Wear Proper PPE: Put on all the required protective gear before you even approach the battery.

- Park and Secure the Forklift: Position the forklift in the designated charging bay and set the parking brake.

- Power Down: Turn off the forklift. Turn off the battery charger.

- Connect Securely: Connect the charger to the battery, making sure you have a snug, complete connection.

- Initiate Charging: Now you can turn the charger on to start the cycle.

- Monitor the Process: Keep the charging area clear. Never mess with the battery or charger while it's active.

By drilling these steps, you build a routine that is both fast and safe. For more resources on building a strong training program, check out our complete guide to forklift safety. Remember, safety is an ongoing commitment, not a one-and-done task.

Calculating the True Cost and ROI of Your Charging System

It’s easy to get hung up on the sticker price of a new charging system, but that initial number is just a fraction of the real story. To build a solid business case for an upgrade, you need to look at the bigger picture: the Total Cost of Ownership (TCO).

This shifts the conversation from "How much does it cost?" to a much more powerful question: "How much will it save us?" By digging into the ongoing expenses, you can clearly show how smarter charging technology pays for itself through serious operational savings and a big boost in productivity.

Beyond the Initial Purchase Price

The price tag on a charger and battery is just the starting line. The real costs show up over the equipment's lifespan, often buried in day-to-day operational budgets. A genuine TCO analysis has to account for these hidden expenses.

Here are the key ongoing costs you need to track:

- Electricity Consumption: Modern systems, especially those using lithium-ion tech, are way more efficient. They can slash energy use by up to 30%, which shows up as a smaller number on your monthly utility bill.

- Maintenance Labor: Lead-acid batteries are needy. They require regular watering and equalization, and those labor hours add up fast. Li-ion batteries, on the other hand, are pretty much maintenance-free.

- Battery Replacements: A standard lead-acid battery is good for about 1,500 charge cycles. A lithium-ion battery can easily deliver 3,000+ cycles. That means you'll be buying far fewer replacement batteries over the life of your fleet.

- Downtime Expenses: Every minute a forklift is sitting idle for charging, cooling, or a battery swap is a minute you're not moving product. Faster, more flexible charging strategies cut that costly downtime dramatically.

Calculating Your Potential ROI

Once you have a handle on the TCO, figuring out the ROI from an upgrade is pretty straightforward. You just compare the total costs of your current setup against the projected costs of the new, more efficient one. The difference is your potential savings.

Investing in modern charging technology isn't just an expense; it's a strategic move to slash operational overhead and crank up output. The ROI comes from lower energy bills, zero maintenance tasks, and keeping your fleet on the floor longer.

Think about it: a warehouse running two shifts could completely get rid of battery swapping by moving to Li-ion and opportunity charging. The labor hours you get back, combined with the extra productivity from keeping forklifts running, can generate enough savings to pay for the entire new system in just a couple of years.

When you're looking at new gear, consider how high-efficiency solutions like the Green4 48V/120A charger can speed up that ROI. On top of that, don't forget to check for rebates. Many utility companies offer incentives for businesses that invest in energy-efficient industrial equipment, which can take a big bite out of the upfront cost and make the business case for upgrading even stronger.

Your Forklift Charging Questions, Answered

Even with a solid plan, questions pop up. Here are some quick, straightforward answers to the things warehouse managers and operators ask us most often about electric forklift charging.

How Long Does It Take to Charge an Electric Forklift?

This one comes down to the technology you're using. A classic lead-acid battery needs a full 8-10 hours to charge, plus another 8 hours to cool down before it's safe to use again. It's an entire shift just for charging and cooling.

A modern lithium-ion battery, on the other hand, is a different beast entirely. It can reach a full charge in just 1-2 hours. Better yet, there's zero cool-down time needed, so it's ready to go immediately. This is a game-changer for multi-shift operations.

Can I Use Any Charger on My Forklift Battery?

Absolutely not. Think of this as the golden rule of battery safety and care. You must use a charger that is perfectly matched to your battery’s chemistry (lead-acid or Li-ion), voltage, and amp-hour (Ah) rating.

Mixing and matching chargers isn't just a bad idea—it's a massive safety hazard. It can cause fires, permanently destroy the battery, and will definitely void your warranty. A simple mismatch can cost you thousands in replacement parts.

The single most important rule in charging is to match the charger to the battery. There is no one-size-fits-all solution, and attempting to create one is both dangerous and expensive.

What Is Opportunity Charging?

Opportunity charging is a whole new way of thinking about power. Instead of running a battery down to empty, operators plug the forklift in for quick power boosts during natural work breaks—like lunch, shift changes, or between tasks.

This approach keeps the battery topped off all day, extending runtime and getting rid of the old, time-wasting process of swapping out heavy batteries. It’s one of the biggest advantages of lithium-ion technology, which actually performs better with these frequent, partial charges.

Do Lithium-Ion Batteries Really Last Longer?

Yes, and it's not even close. A well-cared-for lead-acid battery will give you about 1,500 charge cycles in its lifetime.

Compare that to a lithium-ion battery, which delivers 3,000 or more charge cycles. That means it can have a functional lifespan two to three times longer than its lead-acid counterpart, which dramatically improves its total cost of ownership over the long haul.

Power your fleet with confidence. From advanced chargers to precision-fit replacement parts, Flat Earth Equipment provides the Western tough reliability you need to maximize uptime and efficiency. Request a quote or explore our parts inventory today.