Let's get straight to it. Your Crown electric forklift battery is the heart of your operation, and letting it run thirsty is the fastest way to kill it and bring everything to a grinding halt.

We’re not talking about a minor headache. We're talking about taking a five-year, multi-thousand-dollar asset and killing it in two. The kind of expensive problem that gets the front office's attention fast.

Why Your Forklift Battery Is Always Thirsty

Think of that big lead-acid battery like a piece of yellow iron—it's not some black box you can ignore until it throws a code. Every time it powers your lift and every time you hook it to the charger, a chemical reaction is happening. This process cooks off water from the electrolyte solution (a mix of sulfuric acid and water) as hydrogen and oxygen gas.

This isn't a design flaw; it's just the physics of a lead-acid battery. That water is the highway for electricity to move between the lead plates. When the water level drops, those plates get exposed to air, and that’s when the real damage starts.

The Real-World Consequences of Neglect

Once those plates are exposed, two very bad things happen almost immediately:

- Sulfation: Nasty crystals form on the plates, acting like insulation. This chokes the battery's ability to take a full charge or deliver real power. Your run times drop off a cliff.

- Heat Damage: With less water to absorb the heat, the battery cooks itself during charging. The plates warp, cells short out, and you get a catastrophic failure.

It starts with the lift not finishing a shift. Then it needs charging more often, which just boils off more water and accelerates the damage. This is the death spiral that can slash your lift truck battery's life by 50%.

I’ve seen it a hundred times. A manager tries to save a few bucks by skipping watering checks or using tap water. Six months later, they’re staring at a dead forklift, waiting on the dealer, and spending thousands on a new battery they just killed through sheer neglect.

Understanding the Cycle

The old 8-8-8 rule—8 hours of work, 8 hours of charging, 8 hours of cooling—isn't a friendly suggestion. It’s a core principle. Skipping that cool-down period is like running a machine in a constant regen cycle; it just keeps the battery hot and speeds up water loss.

It’s a simple job, but doing it wrong or ignoring it is the number one cause of premature battery death I see in the field. When the battery dies, the whole operation stops. You can also explore our detailed guide on the best forklift battery chargers to make sure you're not fighting a losing battle with a weak charger.

The Right Tools And Safety Gear For The Job

Walking up to a forklift battery without the right gear is like showing up to a job site in flip-flops—a rookie move that’ll get you seriously hurt. Before you even think about popping a vent cap, we need a quick safety huddle. This isn't corporate box-ticking; it's about respecting the nasty chemistry you're dealing with.

That battery is full of sulfuric acid. Get a splash of that on your skin, and you're getting a chemical burn. Get it in your eye, and you could be looking at permanent damage. There's no room for shortcuts here.

Non-Negotiable Personal Protective Equipment (PPE)

Before you touch the battery, you get kitted out. This is the bare minimum, no exceptions.

- Full Face Shield or Safety Goggles: Don't grab flimsy safety glasses. You need full protection from splashes. A full shield is the best bet when a cell burps back at you.

- Acid-Resistant Gloves: Your standard work gloves won't cut it. You need neoprene or other rated gloves that won't turn to mush if they get hit with electrolyte.

- Protective Apron: An acid-resistant apron is your last line of defense. A small drop of electrolyte will eat a hole in your shirt and skin in minutes.

If you get electrolyte on your skin, flush it with cool water for at least 15 minutes. For a deeper dive into warehouse safety, you can review our guide on comprehensive forklift safety.

Choosing Your Watering Hardware

Once you're geared up, you need the right tools. You can go old-school manual or use a modern single-point system.

A manual watering gun is your basic tool. It’s a simple nozzle that shuts off when the tip hits the electrolyte. They're cheap and they work, but they're slow and prime for human error. It’s too easy to miss a cell when you're in a hurry.

Then you have single-point watering systems. These are a game-changer. They link all the cells with a network of tubes and valves. You make one connection from your water cart, and the system fills every cell to the perfect level, all at once.

For any operation with more than a couple of lifts, a single-point system is a no-brainer. It pays for itself by preventing the over- and under-filling that kills multi-thousand-dollar batteries. It takes the guesswork out of the job.

Essential Diagnostic and Support Tools

Beyond the watering device, a few other pieces of gear are critical.

- Water Deionizer or Distiller: Never use tap water. It’s full of minerals that build up on the lead plates (calcification) and poison the battery from the inside. A deionizer strips these minerals out, giving you pure water that won't kill your investment.

- Hydrometer: This is your battery's dipstick. It measures the specific gravity of the electrolyte, telling you the state of charge in each cell. A healthy, fully charged cell should read around 1.285. If one cell is consistently low, it's a warning sign that the cell is failing—like a bad injector bringing down the whole engine.

A Field Guide To Watering Your Crown Battery

Alright, let’s get our hands dirty. This is where the real work begins. Proper watering isn't complicated, but getting it wrong is the fastest way to turn a multi-thousand-dollar asset into a boat anchor.

Before you pop a single cap, burn this into your brain. This is the one rule you never, ever break.

ALWAYS water a battery AFTER a full charge and AFTER it has cooled down. NEVER water a battery BEFORE charging it.

There’s simple science here. When a battery charges, the electrolyte expands from the heat. If you top it off before charging, that expansion has nowhere to go but out the top. You’ll have a corrosive, acid-laced mess eating your battery tray, the forklift frame, and the concrete floor. It’s a costly, amateur mistake that is 100% avoidable.

Before you start, make sure you're wearing the right gear. This isn't optional.

This is a straightforward reminder: goggles, gloves, and an apron are what stand between you and a serious chemical burn.

Nailing The Correct Water Level

One of the biggest questions I get is, "How much water is enough?" Both over-filling and under-filling will cause serious, irreversible damage.

Look down into a cell. You'll see the lead plates, and above them, a plastic protector or "baffle." The correct water level is about a quarter to a half-inch above this protector. A good rule is to fill until the water is just below the bottom of the vent well opening. You should never see water pooling at the very top.

The only exception: if the water level has dropped so low that the tops of the lead plates are exposed, you have an emergency. In this specific case, you must add just enough distilled water to cover the plates before you charge. Charging with exposed plates will kill them for good. After the charge is complete and the battery cools, perform the normal watering procedure.

Manual Watering One Cell At A Time

If you're using a manual watering gun, you need to focus.

- Check Every Single Cell: Start at one corner and work your way methodically. Don't skip any.

- Get a Good Seal: Insert the nozzle firmly into the cell opening.

- Squeeze Gently: Squeeze the trigger slowly. The gun is designed to shut off automatically when the nozzle tip touches the electrolyte.

- Don't Rush it: Give it a second to stop cleanly. Yanking the nozzle out too fast can cause it to overfill before the auto-shutoff engages.

This method works, but it’s tedious. It's incredibly easy to get distracted and miss a cell, which will kill that cell and eventually the whole battery.

Using A Single-Point Watering System

For any crew running more than a couple of forklifts, a single-point watering system is a lifesaver. It connects all the cells, letting you water the entire battery from one connection. It's faster and it eliminates the human error that costs you thousands.

The process is simple, but you still need to pay attention.

- Confirm Charge Complete: Verify the battery has finished a full charge cycle and has cooled down.

- Connect the System: Attach the water supply hose to the single-point connector. Make sure it clicks securely.

- Open the Valve: Start the flow of water.

- Watch the Indicator: The system is automatic. Each valve on each cell closes as it fills. An indicator on the water supply hose will stop spinning or change color when the battery is full.

- Disconnect Promptly: Once the flow stops, shut off the water and disconnect the hose. Never leave it connected. A pressure change could cause it to leak and over-fill the battery.

Even with an automated system, do a quick visual check for leaks. If it takes way longer than usual to fill, you might have a clog or a leak somewhere in the network that needs to be fixed.

Troubleshooting Common Battery Watering Mistakes

Out on the floor, you don't have time to wait for a service tech with a laptop. This is your field guide for fixing the most common battery watering problems and keeping your Crown forklift moving.

Most problems trace back to a few simple mistakes. It's the same whether you're working on a JCB backhoe with a finicky DEF sensor or a forklift battery—spot the symptom, diagnose the cause, and get it fixed. No "Dealer Laptop" required.

Diagnosing Under-Watering Issues

Ever notice one or two cells that are always thirsty? That’s a red flag. When a specific cell consistently needs more water, it's often a sign that the cell is failing. It's running hotter, boiling off water faster than the others.

Grab your hydrometer and check the specific gravity of that cell after a full charge. If it's reading way lower than the others—say, 1.220 when the rest are at 1.285—that cell is on its last legs. You can try an equalization charge, but chances are it's time to plan for a battery replacement before it dies mid-shift.

The Messy Problem Of Over-Watering

Over-watering is just as destructive and a lot messier. The tell-tale sign is white, crusty acid residue caked on top of the battery. This happens when someone waters the battery before charging, causing the electrolyte to expand and boil over.

This acid spill isn't just ugly; it actively eats the battery tray and the forklift's frame. It’s like a slow, corrosive cancer on your machine. The fix requires discipline: ALWAYS water AFTER the charge is complete and the battery has cooled down.

A little white residue tells me everything I need to know about an operation's maintenance discipline. It’s a clear sign of lazy habits that are actively shortening the life of a very expensive asset.

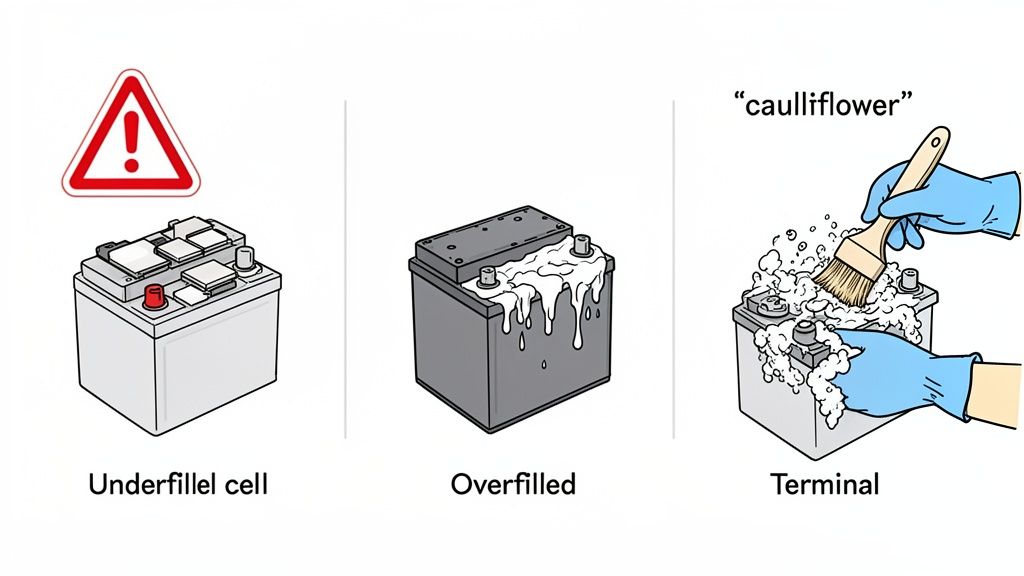

Dealing With Terminal Corrosion

If you see what looks like white or bluish-green cauliflower growing on the battery terminals, that's corrosion. It's an insulator—exactly what you don't want on an electrical connection. It chokes the flow of power and causes performance and charging problems.

To clean it safely:

- Disconnect the battery from the forklift and charger.

- Mix a solution of baking soda and water (a cup of baking soda to a gallon of water).

- Pour it over the terminals. It will fizz as it neutralizes the acid.

- Use a stiff-bristled brush (not wire) to scrub away the corrosion.

- Rinse thoroughly with clean water and let it dry completely.

- Apply a terminal protector spray to prevent it from coming back.

Fixing Single-Point Watering System Failures

Single-point systems are great until they fail. It's usually a simple mechanical issue. If it isn't filling right, check for clogged valves or leaky connections.

Inspect the main hose and connector. Then check each tube leading to a cell. A common culprit is debris stuck in a shut-off valve, causing a cell to under-fill. You can often clear it by disconnecting the tube and blowing low-pressure air through it. This is about spotting the problem on the floor and handling it yourself, keeping the machine running and the dealer's service truck out of your yard.

Smart Record Keeping To Extend Battery Life

If you don't track it, you can't manage it. This is true whether you're logging engine hours on a piece of heavy equipment or tracking the health of your forklift fleet. A simple logbook is your best weapon for making batteries last and keeping your operation moving.

Flying blind with your batteries is just asking for a surprise failure. A good set of records is your early warning system, giving you the hard data you need to spot trouble long before a machine goes down and stops production.

Why Your Records Actually Matter

Let's be blunt—nobody likes paperwork. But this is about protecting a very expensive asset. A detailed log helps you in several practical, money-saving ways.

First, you can spot trends. Is one battery always thirsty? That’s a huge red flag that a cell is failing. Catching this early lets you plan for a replacement instead of reacting to a crisis.

Second, records provide accountability. When every operator knows watering is being logged, the task is far less likely to be skipped. It creates a culture of ownership around critical maintenance.

I’ve seen countless warranty claims denied because the company couldn't produce maintenance records. Without a logbook showing you did your part, the manufacturer will always point the finger at neglect. Your records are your proof.

Building A Practical Maintenance Log

Your log doesn't need to be complicated. A spreadsheet or a clipboard next to the charging station is all you need. Consistency is what's important.

Every time a battery is watered or charged, it gets logged. Your log sheet should be easy to read and quick to fill out. Here's what you must track.

- Battery ID: Give each battery a unique number.

- Date and Time: When was the maintenance performed?

- Action Taken: Standard charge, equalization charge, or watering?

- Specific Gravity Readings: Before and after an equalization charge, record the specific gravity of each cell. This is your best diagnostic data. A healthy, fully charged cell should read around 1.285.

- Water Added (Y/N): A simple "yes" or "no."

- Operator Initials: Who did the work?

This data builds a health profile for each battery. Over a few months, you'll clearly see which batteries are strong and which are becoming liabilities.

Beyond Just Watering The Cells

Smart record keeping is part of a complete maintenance routine. Watering is frequent, but it's not the only task. Your logbook should also include these critical habits.

| Maintenance Task | Frequency | Why It's Critical |

|---|---|---|

| Regular Cleaning | Weekly | Prevents acid residue from corroding the battery tray and forklift frame. A clean battery is safer to handle. |

| Terminal Inspection | Weekly | Clean off any "cauliflower" corrosion before it chokes off power and causes charging issues. |

| Equalization Charge | Weekly/Bi-Weekly | This is a controlled overcharge that de-sulfates the lead plates and balances the voltage across all cells. Skipping this is a primary cause of lost capacity and premature failure. |

By logging these activities, you create a comprehensive history. This log is your evidence that you’re following a professional maintenance program—the kind that saves you thousands in replacement costs and keeps the dealer's service truck out of your yard.

Straight Answers To Common Questions

Out in the field, you need straight answers that get you back to work. Here are the no-nonsense responses to the common questions I hear from operators and mechanics about Crown electric forklift batteries.

Can I Just Use Tap Water For My Forklift Batteries?

Absolutely not. Tap water is full of minerals—calcium, magnesium, iron—that will permanently kill your battery. These minerals coat the lead plates in a process called calcification, which chokes the battery’s ability to take or hold a charge.

Think of it like pouring sand into your engine. It's a cheap shortcut that guarantees an expensive failure. Investing in a water deionizer is pocket change compared to the cost of a new battery.

What Happens If I Forget To Water The Battery?

Forgetting to water a battery is one of the most destructive things you can do. As the water level drops, the tops of the lead plates get exposed to air. Once that happens, they begin to oxidize and harden, a process that permanently ruins them.

The battery will also run much hotter during charging, which accelerates corrosion and can warp the plates. If you catch it early, you might save it with proper watering and an equalization charge. But if it's been neglected, you're just buying time until you have to replace it.

Is An Automatic Watering System Worth The Money?

For any operation running more than a couple of electric lifts, yes. It’s a no-brainer. An automatic, or single-point, watering system turns a tedious 15-minute manual job into a 30-second task.

More importantly, it removes human error. No more missed cells, no more over-filling. The system ensures every cell gets the exact right amount of water, every time. That upfront cost is paid back through longer battery life and avoiding the cost of a new battery killed by a simple mistake.

The real value isn't just time saved; it's consistency. A single-point system does the job perfectly every time, something even the best tech can't guarantee when they're rushing to get five lifts ready for the next shift.

How Do I Know If A Battery Is Toast From Bad Watering?

You can spot a dead one without needing a dealer's laptop. The signs are clear.

- Consistently low specific gravity readings in one or two cells that never recover, even after an equalization charge.

- Visibly warped or damaged plates when you look down into the cell.

- The battery just won't hold a charge long enough to finish a shift.

- The battery case is bulging or cracked from excessive heat—that one’s a goner for sure.

A load test will give you the final verdict, but these signs tell you the end is near. Understanding your charger's capabilities, like those detailed in this 48v 40a industrial charger overview, can also help you diagnose if the problem is the battery or the charging process itself.

Tired of waiting on the dealer for a sensor or solenoid that should be on your shelf? Flat Earth Equipment has the chargers, sensors, and components you need to bypass the dealer wait times and keep your fleet moving. Get the right parts, right now, from people who know yellow iron. Visit us at https://flatearthequipment.com.