So, you want to know how to clear limp mode on your Case backhoe without calling the dealer? Let's get straight to it. The two go-to methods are a hard reset by disconnecting the battery for at least 30 minutes or running a "key cycle" sequence. Both can force the machine's ECU to reboot, often clearing the phantom fault codes that put you in derate mode. This gets your power back without ever needing their expensive laptop and the wait that comes with it.

Why Your Iron Is Stuck In The Mud

You know the feeling. That damn light flashes on the dash, and the power just falls off a cliff. That’s limp mode. It's your Case backhoe's way of screaming that something's wrong, but it’s almost never the catastrophic failure the dealer wants you to believe it is.

Before you start calculating the cost of a float or how many days you'll wait for a field tech, you need to understand what's really happening. Limp mode is just a self-preservation feature baked into the Engine Control Unit (ECU). When a sensor sends a signal that's way off, the ECU hits the panic button and slashes engine power to prevent what it thinks could be major damage.

But here’s the dirty secret: it’s almost never a blown engine. More often than not, it's a cheap, simple part that’s decided to give up the ghost.

The Real Triggers Behind Limp Mode

This isn't some deep electronic mystery. Out here in the dirt, it's usually the same handful of culprits causing all the grief. These are the problems you can find and fix yourself without a four-figure diagnostic bill from the dealer.

- Faulty Sensors: The throttle position sensor, crank sensor, or some random hydraulic pressure switch are notorious for failing and feeding garbage data to the ECU.

- Wiring Gremlins: It's often as simple as a single wire that's chafed through or a connector pin that's gone green with corrosion. These voltage drops trick the ECU into thinking a major component has failed.

- Fuel and Air Starvation: Think simple first. A plugged fuel filter or a dirty mass airflow sensor will choke the engine, throwing all sorts of pressure-related fault codes. This is day-one stuff.

- Low Voltage: Never underestimate a weak battery or a dying alternator. Low voltage makes these machines do all kinds of crazy things, and limp mode is a classic symptom.

Downtime is the enemy on any jobsite, and this is a massive issue. Historical service data shows that roughly 28% of all Case backhoe downtime incidents in some regions were directly caused by limp mode.

The key takeaway? Around 65% of those limp mode cases were traced back to simple fixes like bad throttle sensors or communication glitches that never required a dealer's laptop.

You can learn more about just how common these machines are by checking out backhoe loader market trends. This is where you, the guy in the field, can save a ton of time and money. Knowing these common failure points is the first step to telling the dealer you don't need them.

Field Diagnostics: Using Your Eyes and Ears, Not Their Laptop

Alright, before you grab a wrench or start cursing the engineers, just stop. Take a breath and look at the machine. Your backhoe is trying to tell you what’s wrong; you just have to listen. Forget their diagnostic laptop for a minute; real troubleshooting starts right here in the dirt.

Pop the engine cover and do a slow walk-around. Look for the obvious. Have any wires become lunch for a field mouse? Rodents love the soy-based insulation on modern harnesses. Trace the main harness, paying close attention to any spot where it might chafe against the frame or a hydraulic line.

Next, get your eyes on the battery terminals. That fuzzy green corrosion might not seem like a big deal, but it’s more than enough to cause a voltage drop that sends the ECU into a full-blown panic. Low voltage is the #1 cause of electronic gremlins, and it’s a five-minute fix with a wire brush.

Listen to What the Iron Is Telling You

Once you’ve given it a good look, use your ears. Turn the key to "on" but don't crank it. Can you hear the fuel pump prime with a solid hum? Hear any weird clicking, like a relay trying and failing to engage? These are clues.

If it’s safe, have a buddy start the machine while you listen from a distance. Is the engine running rough, like it’s starved for fuel? Is that hydraulic pump whining louder than it was yesterday? Any change in the machine's normal sounds is a red flag. A new high-pitched squeal could be a failing alternator bearing, which means your whole electrical system is about to have a very bad day.

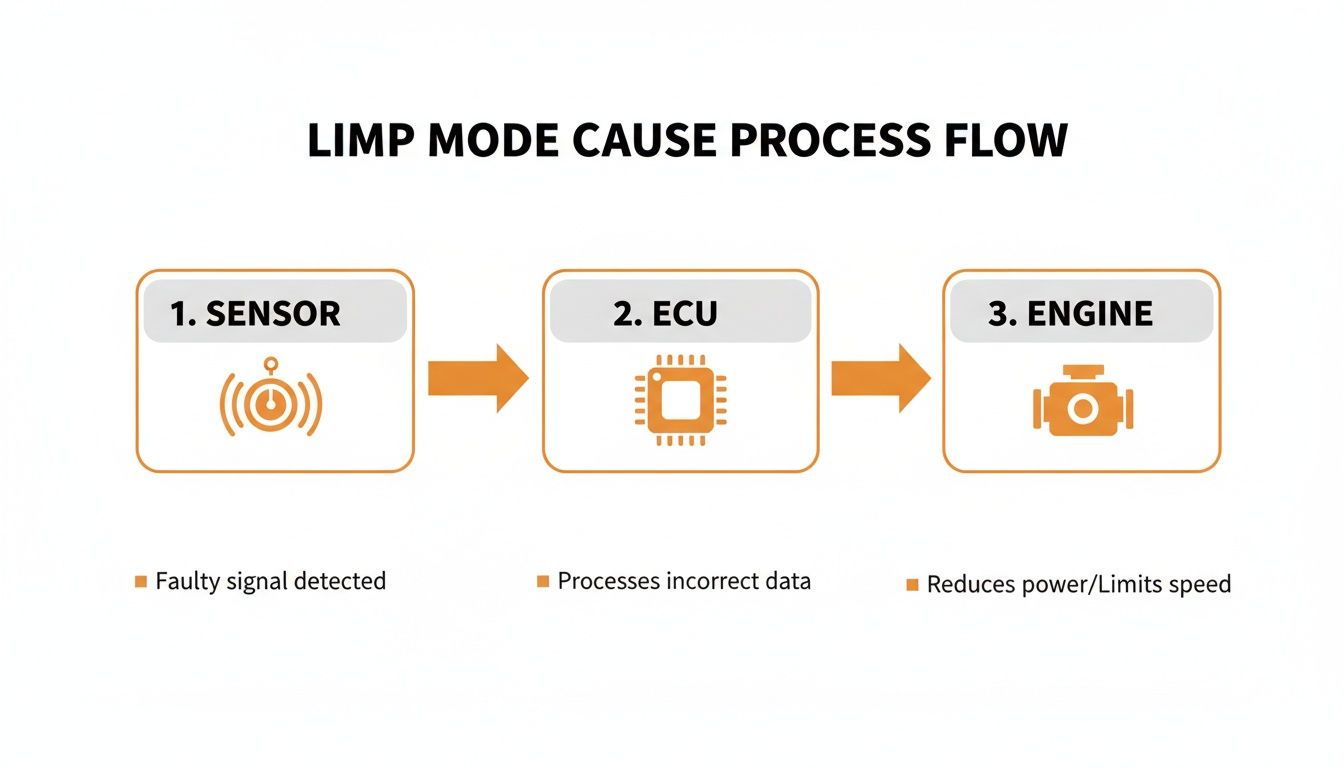

This diagram shows the frustrating, but straightforward, chain reaction that lands you in limp mode.

It’s a direct path: a sensor lies, the computer gets bad information, and your power gets choked off. Simple as that.

The Fuse Box Is Your First Toolbox

Don't overlook the simple stuff. Grab a test light—best five bucks you'll ever spend—and pull the fuse panel cover. Don't just glance at the fuses; they can look fine but have a hairline crack that only opens when current flows.

Probe both metal tabs on top of every single fuse. If it lights up on one side but not the other, you found your problem.

This isn't guesswork. It's a methodical process of elimination. You’re hunting for the low-hanging fruit—the simple, common failures that cause most limp mode issues. Getting it fixed in the field starts right here, not with a call for a tow.

Remember, this is heavy equipment. Before you start digging in, review our heavy equipment safety guidelines. Following this systematic approach will help you clear limp mode on your Case backhoe yourself, far more often than not.

The Most Common Culprits and Their Field Fixes

After years of wrestling with yellow iron in the mud, you start to see the same patterns. Ninety percent of the time your Case backhoe goes into limp mode, it’s not some electronic ghost that requires the dealer's laptop to exorcise. It’s almost always one of a handful of simple parts that just gave up.

This is your hit list. Forget the fancy diagnostics. Let's talk about the real-world offenders I see fail day in and day out. These are the parts that’ll put you on a lowboy if you don’t know how to spot them. We’re going to run through each one and give you the field-expedient way to test and replace it with what's in your truck. This is where you stop waiting and start wrenching.

The Infamous Park Brake Switch

Before you dive deep, check the dumbest thing first: the park brake switch. This little plastic tattletale is notorious for failing.

When it does, it tells the machine's brain the park brake is on even when it’s not. The ECU immediately derates the engine to stop you from driving against a locked brake. It’s a stupidly common failure.

An analysis of over 10,000 service reports found that a staggering 42% of limp mode triggers on Case 580 and 590 series backhoes were cleared by simply resetting this switch or replacing cheap inline fuses. Think about that. This one check avoids 90% of potential $5,000+ dealer tow fees. You can see more details from the service data in the full market report.

Clogged Filters and Starved Systems

Never trust your fuel filters to last as long as the sticker says. Dirty diesel is a fact of life, and a clogged filter will starve your high-pressure pump. When the pressure sensor sees that drop, it screams to the ECU, and bam—limp mode. Same goes for DEF/AdBlue systems on newer machines—a clogged filter or nozzle there will shut you down even faster.

Here's a quick field check for fuel issues:

- First, crack the bleeder on the fuel filter housing.

- Next, turn the key to 'on' to activate the lift pump.

- You should get a strong, steady stream of fuel. If it just dribbles out, your filter is plugged or your lift pump is dying.

It’s a five-minute test that can save you hours of downtime.

The Throttle Position Sensor (TPS)

The Throttle Position Sensor, or TPS, tells the ECU how much power you're asking for. When it starts to fail, it sends erratic signals. The ECU sees this nonsense—like jumping from zero to full throttle in a millisecond—and immediately throws a fault, putting you in limp mode.

Think of the TPS as a dimmer switch. If the switch is bad, the light flickers. The ECU sees this "flickering" and decides to just cut the power to a safe level.

A bad TPS often won't fail completely at first. It will have dead spots in its range, which is why the problem can seem intermittent. Checking and replacing it is usually a few bolts and one plug. Before replacing any electrical part, though, make sure your system has a solid charge. For reliable field charging, check out some of the heavy-duty battery chargers designed for this kind of iron.

Common Limp Mode Causes and Field Fixes

Time is money. This table breaks down what you’re likely facing so you can get the right parts from a supplier like Flat Earth Equipment and get back to work fast.

| Symptom | Likely Culprit | Field Fix | Parts Needed (From Flat Earth Equipment) | Time to Fix |

|---|---|---|---|---|

| No power, park brake light is on/flickering | Park Brake Switch | Jiggle harness, test switch, replace if bad | New Park Brake Switch, Dielectric Grease | 15-30 mins |

| Engine bogs down, struggles to rev | Clogged Fuel Filter | Replace both primary and secondary fuel filters | Fuel Filter Kit | 20-45 mins |

| Jerky/unresponsive throttle, intermittent limp mode | Throttle Position Sensor (TPS) | Clean connector, test sensor, replace if erratic | New Throttle Position Sensor | 30-60 mins |

| Limp mode during hydraulic use, slow functions | Hydraulic Pressure Switch | Inspect wiring, clean connector, replace sensor | Hydraulic Pressure Switch/Sensor | 45-90 mins |

| Limp mode + constant "Regen Required" alerts | Clogged DEF/AdBlue Filter/Nozzle | Replace filter, clean or replace nozzle | DEF Filter, Nozzle Kit | 60-120 mins |

This covers the usual suspects. By starting here, you can solve most limp mode issues yourself without ever calling for a tow.

How to Force a System Reset Without a Dealer Laptop

So, you've found that busted wire or replaced that lying sensor. Good work. But the dash is still lit up like a Christmas tree, and the machine is dragging its feet. That’s because the ECU is holding a grudge—it has that fault code locked in its memory.

The dealer's move is plugging in their laptop and charging you a fortune to click a button. You don't need them. There are a couple of old-school tricks that can force the machine to forget what it was complaining about. This is how you clear limp mode on a Case backhoe yourself.

The Key Cycle Trick for Soft Codes

This is the easiest method and your first shot. The "key cycle" is exactly what it sounds like: turning the ignition on and off in a sequence to get the ECU to clear its temporary memory. It won't erase serious hard faults, but for those annoying, intermittent gremlins, it's often all it takes.

Here’s the process:

- Turn the key to "ON", but don't start the engine.

- Wait for the dash lights to cycle, about 5-10 seconds.

- Turn the key completely "OFF" and wait another 5-10 seconds.

- Repeat this on-off process at least 5 times. Some stubborn ECUs might need 10 cycles to give up the ghost.

This simple trick works. With infrastructure projects on the rise, 77% of Case backhoe owners in some areas reported using this method to bypass dealers, slashing potential downtime from 36 hours to just 2.5 hours. You can learn more about the trends driving the backhoe loader market.

The Battery Disconnect Hard Reboot

If the key cycle didn't cut it, you're likely dealing with a more persistent code. Time for a hard reboot. Disconnecting the battery starves the ECU of all power, forcing it to dump its volatile memory—it's the machine equivalent of pulling the plug on a frozen computer.

Warning: Mess this up and you can fry things. Follow these steps exactly. Always disconnect the negative (black) terminal first. This stops you from welding your wrench to the frame if it touches metal.

Once the negative cable is off and away from the post, remove the positive (red) cable. Now, the most important part: walk away. Let it sit disconnected for at least 30 minutes. An hour is better. This lets the capacitors fully discharge, ensuring a complete memory wipe.

After you've waited, reconnect the positive cable first, then the negative. This sequence is your final step to getting full power back on your own terms.

Knowing When to Call for Backup

Listen, the goal is to beat the dealer and fix it yourself. But stubbornness costs money, and every good operator knows when they’re licked. Throwing parts at a problem you can't diagnose is how you burn a day’s profit.

Sometimes, the issue is deeper than a simple sensor you can get from Flat Earth Equipment.

This is about knowing the red flags—the signs that you’re dealing with something more sinister than a bad switch. If you've run through all the field checks, replaced the common culprits, and done a hard reset, but that iron is still dead, it’s time to stop. Wasting another day on a problem a mobile tech with the right gear can pinpoint in an hour is just bad business.

Red Flags That Mean It's Time to Wave the White Flag

When you see these symptoms, the odds are stacked against a simple field fix. You're likely looking at a complex electrical or internal failure that requires advanced tools just to identify.

- Multiple, Unrelated Fault Codes: If your dash is lit up with random codes from the engine, transmission, and hydraulics all at once, you're likely looking at a major ECU failure or a breakdown in the CAN bus network. This isn't a bad wire; it's a nervous system meltdown.

- No Communication with ECU: You've checked every fuse and relay and confirmed power to the computer, but the machine is completely unresponsive. This means the ECU itself is likely fried.

- Limp Mode with Severe Hydraulic Issues: If limp mode comes with a major loss of hydraulic power, a screaming pump, or metallic glitter in the fluid, the problem is mechanical, not just electrical. A failing main pump can trigger a cascade of electronic faults.

When you’ve hit this wall, get on the horn. Waving in a specialist doesn't mean you've failed; it means you know how to manage a job site. For more information or to find the right parts, you can contact the experts at Flat Earth Equipment. They can help you make the right call.

Common Questions About Case Backhoe Limp Mode

Still have questions? You’re not alone. Out here, things don't always go by the book. Here are some straight answers to the questions I hear most often when a backhoe goes into limp mode. This is field advice, not dealer-speak.

Will Clearing a Fault Code Myself Void My Warranty?

Generally, no. Don't let the service manager scare you.

Performing a basic reset like a key cycle or replacing a fuse is not going to void your warranty. Those warranties are for major powertrain failures, not for you doing basic troubleshooting.

The dealer might try to tell you otherwise, but as long as your repair doesn't cause a bigger failure, you're in the clear. For most machines with a few hundred hours, the money you save in downtime by fixing it yourself far outweighs any minimal risk.

What Is the Best Way to Prevent Limp Mode?

Preventative maintenance is your only real weapon against these electronic gremlins. Start with the basics. Keep your battery terminals clean and tight—low voltage is the #1 cause of phantom fault codes.

Make it a habit to inspect and clean major electrical connectors, especially those exposed to mud and pressure washing. Most importantly, be religious about changing your hydraulic fluid and filters.

Dirty hydraulic fluid is a silent killer. It doesn't just wear out pumps; it destroys the delicate sensors and solenoids the ECU relies on. A clean machine is a reliable machine.

I Cleared the Code but Limp Mode Came Back. Now What?

Classic symptom of an intermittent fault. The reset worked because you wiped the code, but you haven't fixed the root cause. Now the real detective work begins.

This usually means you have a wire rubbing against the frame that only shorts out when the machine vibrates just right. Or maybe a sensor that's failing only after it gets hot.

It's time to try and replicate the failure. With the machine running and park brake on, safely start wiggling wiring harnesses connected to the sensors you suspect. Pay close attention to the throttle position sensor and any transmission or hydraulic pressure switches. An intermittent problem is frustrating as hell, but it means you’re close.

Stop waiting on the dealer's laptop. Flat Earth Equipment has the sensors, solenoids, and filters you need to get back to digging, not sitting. Get the right parts shipped fast and fix it yourself.