Getting your electric forklift charging process right is the backbone of any modern warehouse. It’s not just about plugging in a machine; it’s a critical part of your daily operation that directly hits your uptime, the lifespan of your batteries, and your bottom line. Nailing this down is how you unlock peak performance and keep your work environment safe.

The Essentials of Forklift Battery Charging

Switching from internal combustion to electric forklifts is a huge leap forward. Instead of dealing with propane tanks or diesel fuel, your team now manages a different kind of energy: the industrial battery. Success really boils down to how well you replenish that power. Getting your charging electric forklift strategy right isn't just another maintenance task—it’s a core piece of your operational puzzle.

Think of this guide as your roadmap. We’ll walk through everything from the basic concepts to more advanced fleet management techniques, making sure you can build a charging routine that’s safe, efficient, and doesn’t break the bank.

Here’s a quick look at what we'll cover:

- Charging Strategies: We'll compare the most common methods—conventional, opportunity, and fast charging—to help you figure out which one actually fits your workflow.

- Battery and Charger Types: Time to break down the real differences between lead-acid and lithium-ion technologies, without all the confusing jargon.

- Infrastructure and Safety: You'll get actionable steps for setting up a charging station that meets all the rules and includes the right safety gear.

- Optimization and Maintenance: We'll share practical tips for scheduling charges, troubleshooting common issues, and squeezing every bit of life out of your expensive batteries.

The move to electric power isn't just a small shift; it's a massive trend. The global electric forklift market was recently valued at around $63.65 billion and is expected to keep climbing. That growth is happening because battery and charging tech has gotten so good, making electric fleets a smarter choice than ever. You can explore more about these market trends and their impact on logistics.

A well-run charging program does more than just power your forklifts—it powers your entire operation's productivity. When you treat battery charging with the same seriousness as any other critical workflow, you prevent costly downtime and get the most out of your equipment. This is the kind of proactive thinking that separates the good operations from the great ones.

Decoding Your Charging Strategy

How you charge your electric forklift isn't just a technical detail—it's a strategic decision that sets the entire tempo for your operation and your budget. Get it right, and your fleet becomes a seamless, efficient part of your workflow. Get it wrong, and you'll be dealing with constant bottlenecks and battery headaches.

https://www.youtube.com/embed/y9WqIEAYwZo

At the end of the day, it really boils down to two philosophies. You can treat your batteries like a phone you plug in overnight, or like one you top up whenever you get a free moment. Each approach has its place, and the best one for you depends entirely on how your business runs.

Conventional Charging: The Overnight Approach

Conventional charging is the old-school, tried-and-true method for lead-acid forklift batteries. Think of it as giving your equipment a full night's sleep. You run the forklift for a full shift until the battery is mostly drained—usually down to 20-30% capacity—then plug it in for a long, uninterrupted charge.

This isn't a quick process. It involves a full 8-10 hour charging cycle, which must be followed by an 8-hour cool-down period. That whole 16-18 hour cycle is non-negotiable for lead-acid batteries; it prevents overheating and gives the internal chemistry time to stabilize properly.

Because of that long turnaround, conventional charging demands a "one-battery-per-shift" setup. If you're running three shifts, you need three separate batteries for every single forklift to keep things moving. One battery is in the truck, one is on the charger, and the third is cooling down, waiting for its turn. This means you need a dedicated battery room and the right equipment to swap these heavy units safely.

Opportunity Charging: The Power Nap Strategy

Opportunity charging completely flips the conventional model on its head. Instead of one long charge, this strategy is all about multiple, short charging sessions throughout the day. It’s like giving your forklift a series of quick power naps whenever there's a break in the action.

Operators simply plug the forklift in during scheduled breaks, lunch, or any other bit of downtime. These quick hits, often just 15 to 30 minutes long, are enough to keep the battery topped off and the forklift running across multiple shifts—all without ever needing to swap a battery.

This method is a lifesaver for facilities with 24/7 operations or less predictable workflows. It gets rid of the need for spare batteries and the labor-intensive, risky process of changing them out. It's important to remember, though, that this approach really shines with specific battery types, which brings us to the next step in charging evolution.

Opportunity charging can slash the total number of batteries a facility needs by up to 40%. That's a huge cut in capital investment and a total elimination of the safety risks that come with battery swapping.

Fast Charging: Supercharging Your Uptime

Fast charging is basically opportunity charging on steroids, powered by modern technology. It uses high-amperage chargers to cram a massive amount of power into the battery in a very short time. For high-demand, fast-paced environments, this is the ultimate way to maximize uptime.

While you’d fry a traditional lead-acid battery with this kind of intense charging, lithium-ion batteries thrive on it. A lithium-ion battery can get a huge chunk of its power back in under an hour, allowing a forklift to run almost nonstop with just a few short breaks. The partnership between fast chargers and lithium-ion batteries is a true game-changer for fleet efficiency.

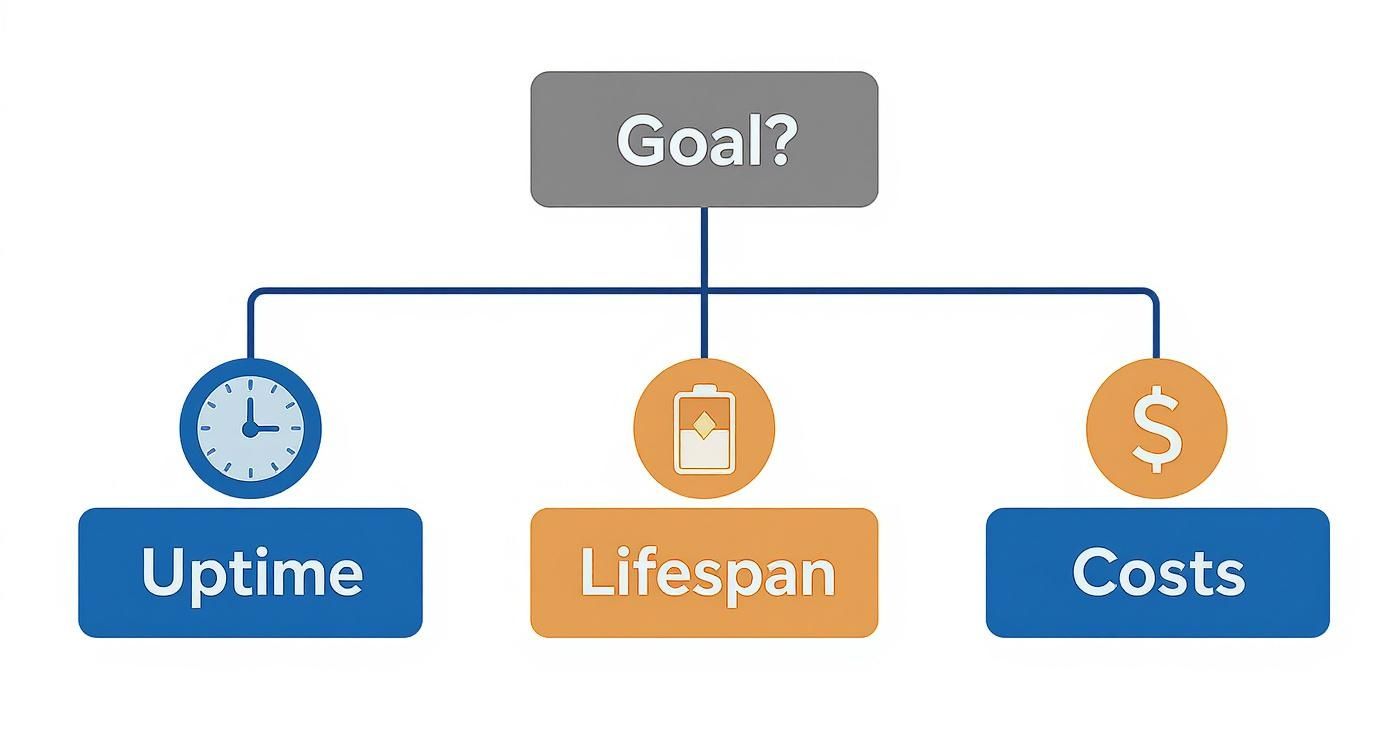

To help you decide, this chart breaks down how your main goal—whether it's uptime, battery lifespan, or cost control—points you toward the right strategy.

The big takeaway here is that there's no single "best" method. The right approach is always the one that fits the unique demands of your facility.

Comparing Forklift Charging Strategies

To make the choice even clearer, let's break down the key differences between these three approaches in a simple table. This will help you see at a glance which strategy aligns best with your operational needs, battery type, and overall goals.

| Charging Strategy | Charging Cycle | Ideal Battery Type | Best For | Key Benefit |

|---|---|---|---|---|

| Conventional | One 8-10 hour charge + 8-hour cool-down | Lead-Acid | Single-shift operations; predictable schedules | Maximizes lead-acid battery lifespan |

| Opportunity | Multiple short charges during breaks | Lead-Acid (Enhanced) or Lithium-Ion | Multi-shift or 24/7 operations | Eliminates battery swapping; increases uptime |

| Fast | Very short, high-power charges | Lithium-Ion | High-demand, continuous operations | Near-constant equipment availability |

Each strategy has its place. The predictable rhythm of conventional charging is perfect for some, while the flexibility of opportunity and fast charging is essential for others.

By understanding these core strategies, you can start matching your forklift charging procedure to what your business actually needs. The ultimate goal is always the same: keep your operations moving smoothly and efficiently.

Choosing the Right Power Source

Figuring out your charging strategy is only half the battle. The other, equally critical piece of the puzzle is the power source itself—the battery. The type of battery you run in your lifts will fundamentally dictate which charging methods are even possible, how much maintenance your team is on the hook for, and what your total cost of ownership looks like down the road.

Think of it like choosing an engine for a work truck. You could stick with a traditional, dependable diesel engine that’s been the industry standard for ages. Or, you could go for a modern electric motor that offers way better efficiency and less upkeep, but comes with a different upfront investment.

In the world of electric forklifts, the two dominant technologies are the old guard, lead-acid, and the modern powerhouse, lithium-ion. Each has its own personality, and getting to know them is key to making the right call for your operation.

The Dependable Workhorse: Lead-Acid Batteries

Lead-acid batteries are the seasoned veterans of the material handling world. They’re built on proven chemistry and have been the go-to for decades, making them a familiar and reliable choice for countless warehouses. Their biggest advantage is a lower upfront purchase price, which can be a major plus for businesses managing tight capital budgets.

But that lower initial cost comes with a catch: maintenance. A lead-acid battery is a bit like a classic car; it needs consistent, hands-on attention to keep it running right.

This routine care involves a few key chores:

- Regular Watering: You have to constantly check the electrolyte levels and top them off with distilled water. If you don't, you risk permanently damaging the cells.

- Equalization Charges: Every so often, the battery needs a special "equalization" charge to rebalance the acid concentration across all the cells. It's a non-negotiable step for its long-term health.

- Temperature Management: These batteries need to run through a full charge cycle and then have a dedicated cool-down period. This makes them a tough fit for 24/7 operations unless you invest in a fleet of spare batteries.

Skipping these tasks will drastically shorten the battery’s life, which typically tops out between 1,000 to 1,500 charge cycles.

The High-Performance Option: Lithium-Ion Batteries

Lithium-ion (Li-ion) batteries are the newer, more advanced kid on the block. If lead-acid is the dependable work truck, lithium-ion is the high-performance electric vehicle. It’s engineered from the ground up for efficiency, speed, and simplicity, and it completely changes the game for charging electric forklift fleets.

Their number one selling point? They are virtually maintenance-free. No watering, no equalizing, and no cool-down periods. This "plug-and-play" convenience allows them to work perfectly with opportunity and fast-charging strategies, keeping your forklifts on the floor and making money across multiple shifts.

Lithium-ion batteries can last up to 3,500 charge cycles—more than double the lifespan of a typical lead-acid battery. That longevity, combined with zero maintenance and better energy efficiency, often leads to a lower total cost of ownership, even with the higher initial price tag.

This move toward more efficient power is a huge reason the market is growing. Electric forklifts recently generated $50.4 billion in revenue, making them the most profitable segment in the industry. As more businesses focus on operational efficiency, their market share is only expected to climb. You can learn more about the forklift market's growth to see the full picture.

Understanding the Total Cost

When you put these two options side-by-side, you have to look beyond the sticker price. Lead-acid batteries might be cheaper to buy, but their true cost includes labor hours for maintenance, the price of spare batteries, and the real estate and equipment needed for a dedicated battery charging room.

Lithium-ion batteries, while more expensive upfront, wipe out nearly all of those extra costs. You get valuable floor space back, cut down on labor, and can run a leaner, more efficient operation. For a deeper dive into matching the right power systems to your fleet, you can explore our guide to industrial battery chargers and see which technology fits your needs.

Ultimately, the right choice boils down to your budget, your shift structure, and your long-term goals for the business.

How to Build Your Charging Infrastructure

Setting up a dedicated, well-thought-out charging area is one of the most critical steps you'll take when managing an electric forklift fleet. This isn't just about finding an empty corner in your warehouse to plug things in; it’s about engineering a safe, efficient, and compliant hub that keeps your whole operation moving. When you get the infrastructure right, you prevent accidents, protect your expensive equipment, and keep your forklifts ready for whatever the day throws at them.

Think of it like a pit stop for a race car. A Formula 1 team wouldn't just park their car anywhere—they have a specific, highly organized bay with every tool and safety measure in place. Your charging infrastructure deserves that same level of strategic thinking to make sure everything runs smoothly and, most importantly, safely.

Planning Your Location

Where you put your charging station has a huge impact on both your workflow and your team's safety. The location needs to be easy for operators to get to but also positioned away from high-traffic zones to cut down on the risk of collisions. A forklift driver rushing to a charger shouldn't have to dodge through a busy aisle.

Ventilation is another non-negotiable, especially if you're running lead-acid batteries. As they charge, these batteries release hydrogen gas, which is highly flammable at concentrations as low as 4%. Your designated spot absolutely must have good airflow—either from natural ventilation or a dedicated exhaust system—to stop this gas from building up.

Defining Electrical Requirements

Once you’ve picked a spot, the next job is getting the power right. Forklift chargers are heavy-duty pieces of equipment; you can’t just plug them into a standard wall outlet. This part of the job will almost always require a licensed electrician to make sure everything is safe and up to code.

Here’s what you and your electrician need to nail down:

- Voltage and Amperage: Every charger has its own power needs. You have to confirm that your building's electrical system can supply the right voltage (like 480V) and that the circuits can handle the amperage draw without constantly tripping.

- Dedicated Circuits: Don't skip this. Each charger needs its own dedicated circuit. This prevents overloading the system and gives you a steady, reliable power supply, which is key for keeping your batteries healthy.

- Future-Proofing: Think about where your fleet is headed. If you plan on adding more lifts or upgrading to powerful fast chargers down the road, it’s much smarter (and cheaper) to install that extra capacity now instead of paying for major electrical work later.

This planning is only getting more important as regulations push for greener logistics. The European market, for example, is seeing massive growth thanks to mandates requiring zero-emission equipment. Electric forklift use there is expected to jump from 40% to 60% by 2030. This trend is a clear signal of the growing need for solid charging infrastructure everywhere. You can discover more insights about the global forklift market to get a better handle on these shifts.

Assembling Essential Safety Equipment

A charging station isn't complete without the proper safety gear. This isn't just a "nice-to-have"—it's an OSHA requirement. The goal is to create an environment where operators can react instantly and effectively to any problem, whether it's a chemical spill or a fire.

According to OSHA standard 1910.178(g), facilities must be equipped for "flushing and neutralizing spilled electrolyte, for fire protection, for protecting charging apparatus from damage by trucks, and for adequate ventilation."

Your safety checklist must include:

- Fire Extinguisher: A Class ABC fire extinguisher needs to be in plain sight and easy to grab.

- Spill Kit: A kit with neutralizing agents is crucial for safely cleaning up battery acid spills if you're using lead-acid batteries.

- Eye Wash Station: A plumbed-in or self-contained eye wash station has to be within a 10-second walk from the charging area. No exceptions.

- Personal Protective Equipment (PPE): This means acid-resistant gloves, safety goggles or a face shield, and an apron for anyone handling lead-acid batteries.

- Clear Signage: Post clear, easy-to-read signs that say "No Smoking" and identify the area as a designated battery charging zone.

Getting your station properly equipped protects your people and your investment. Choosing the right components, like a tough and dependable GreenX 48V charger, is only one part of the puzzle. Pairing it with a safe, compliant infrastructure is what really sets your operation up for long-term success.

Mastering Safe Charging Procedures

When it comes to charging electric forklifts, safety isn’t just another box to check—it’s the absolute foundation of a smooth, productive operation. Getting this right protects your team from serious injury, your expensive equipment from damage, and your facility from accidents that are entirely preventable.

Think of it like a pilot's pre-flight checklist. Every step is simple, deliberate, and critical for a safe outcome. Rushing or skipping steps introduces risks that a consistent, disciplined approach can easily eliminate.

Pre-Charging Safety Checklist

Before anyone even thinks about connecting a charger, a quick but thorough inspection is your first line of defense. This simple visual check can spot potential hazards before they snowball into serious problems. Train your team to run through this mental checklist every single time.

Daily Operator Checklist:

- Inspect the Charger: Look for any signs of damage on the charger's casing, cables, or connector. Frayed wires or cracked connectors are major red flags.

- Examine the Battery: Check for cracks in the battery casing, corrosion building up on the terminals, or any evidence of leaks.

- Clear the Area: Make sure the charging station is free of clutter, debris, or any flammable materials.

- Verify Equipment Match: Double-check that the charger’s voltage and amperage match the battery's specs. Mismatched equipment is a significant fire and safety hazard.

This routine takes less than a minute, but it can be the difference between a normal day and a costly equipment failure or dangerous arc flash.

Battery-Specific Hazards and Precautions

Different battery types come with different risks. Knowing the distinction is key to implementing the right safety measures for your fleet.

Lead-acid batteries are notorious for releasing highly flammable hydrogen gas as they near a full charge. A single spark is all it takes to ignite it, which is why proper ventilation is non-negotiable. On the other hand, lithium-ion batteries are sealed and don't produce gas, but they carry a rare—but very serious—risk of thermal runaway if they are damaged or charged incorrectly.

According to OSHA standard 1910.178(g), facilities must provide "adequate ventilation for dispersal of fumes from gassing batteries." This is why designated charging areas with good airflow and prominent "No Smoking" signs aren't just suggestions—they are federally mandated requirements.

Your procedures must be tailored to the battery chemistry you use:

- For Lead-Acid Batteries: Ban all open flames, sparks, or smoking in and around the charging area. Ensure ventilation systems are working correctly to stop hydrogen from building up.

- For Lithium-Ion Batteries: Train operators to immediately report any physical damage to a battery. A dented or punctured Li-ion battery must be pulled from service and isolated until a professional can inspect it.

Step-by-Step Connection and Disconnection

The physical act of plugging and unplugging the battery is where many accidents happen. A clear, step-by-step process eliminates guesswork and minimizes risk.

Safe Connection Process:

- Position the Forklift: Park the forklift correctly at the charging station and set the parking brake.

- Power Down: Turn the forklift completely off before you do anything else.

- Wear PPE: Put on the required Personal Protective Equipment (PPE), especially when handling lead-acid batteries. This means acid-resistant gloves and safety goggles, at a minimum.

- Connect to Battery: Firmly connect the charger’s output plug to the battery's connector.

- Start the Charger: Only then should you turn the charger on to begin the cycle.

Following these steps in the correct order is vital. For more in-depth training, you can explore our complete guide to forklift safety training to ensure your team is fully prepared. By embedding these habits into your daily workflow, you create a culture where safety becomes second nature.

Optimizing Performance with Smart Charging

There's more to managing your fleet than just plugging in a forklift when the battery gets low. Smart charging takes things to a whole new level. It’s not just about refilling a battery; it’s about using real-time data to make intelligent choices that drive up efficiency, slash your energy costs, and protect your most expensive assets—your batteries. This is how you turn a daily chore into a real competitive advantage.

Think of it this way: old-school charging is like checking the oil in your car with a dipstick. It works, but it’s reactive. Smart charging is the modern equivalent of your car’s onboard computer, telling you exactly when it needs service, tracking fuel efficiency, and warning you about a problem before you're stuck on the side of the road. With this data-driven approach, you can squeeze every ounce of performance out of your electric fleet.

The Brains Behind the Operation: BMS and Telematics

At the core of any smart charging setup, you'll find two key pieces of technology: the Battery Management System (BMS) and telematics. The BMS is the battery’s own internal brain, constantly watching its health, temperature, and how much juice is left. It’s the gatekeeper that stops it from overcharging and makes sure it runs safely and effectively.

Telematics takes all that juicy data from the BMS and sends it to a single dashboard. Suddenly, you have a bird's-eye view of your entire operation. You can see how every single forklift and battery is being used—from charge cycles and energy consumption right down to individual operator habits. You're no longer guessing; you're making decisions based on facts.

This information is pure gold for a few reasons:

- It exposes weak spots: You might find out that forklifts in the shipping department are getting hammered while the ones in receiving are barely breaking a sweat. Now you can rebalance the workload.

- It predicts problems: The system can flag a battery that’s consistently running hot or struggling to hold a charge, giving you a heads-up long before it dies mid-shift.

- It proves your strategy works: You can see exactly how opportunity charging is helping your workflow or get confirmation that your nightly charging schedule is being followed to the letter.

Creating Smarter Charging Schedules

Once you have this data, you can ditch the rigid, one-size-fits-all charging plan. Instead of forcing every forklift onto the same schedule, you can build a dynamic routine that mirrors how your equipment is actually used. For example, your telematics data might reveal that the lifts in shipping are busiest first thing in the morning, making a quick mid-day opportunity charge a no-brainer for that team.

For anyone running lead-acid batteries, this data is absolutely essential for a proper battery rotation system. A smart system keeps tabs on which batteries are charged, which have cooled down, and which are ready to go. This simple tracking ensures every battery gets used equally, putting an end to the common problem of overusing a few "favorite" batteries while others collect dust—a habit that kills the lifespan of your entire battery pool.

A well-managed battery rotation program can extend the life of a lead-acid battery fleet by as much as 25%. It ensures even wear and tear, maximizing your return on investment and preventing premature replacements.

Proactive Maintenance for Maximum Uptime

The last piece of the puzzle is proactive maintenance. Smart charging systems help you move from a "fix-it-when-it-breaks" mentality to a predictive one. But all the tech in the world won't help if you ignore the basics. It has to be paired with consistent, hands-on upkeep of your batteries and chargers.

Building these simple habits into your team's daily routine can head off the vast majority of common charging issues and add years to your equipment's life.

Essential Maintenance Checklist:

- Clean Battery Terminals: Make a habit of cleaning the terminals to get rid of any corrosive buildup. For lead-acid batteries, a simple mix of baking soda and water does the trick, ensuring a solid connection for efficient charging.

- Inspect Cables and Connectors: Before every single charge, give all cables and connectors a quick visual check. Look for any fraying, cracks, or damage that could be a safety hazard or cause a bad connection.

- Check Charger Vents: Make sure the cooling vents on your chargers are free of dust and debris. If they get clogged, the charger can overheat, making it less efficient and eventually causing it to fail.

- Maintain Water Levels (Lead-Acid Only): If you use lead-acid batteries, you need a strict watering schedule. Low electrolyte levels are one of the quickest ways to permanently cook the battery's internal cells.

By combining the intelligence of a BMS and telematics with disciplined maintenance, you create a powerful system for charging electric forklift fleets. It doesn't just keep your operation running—it actively works to lower your total cost of ownership.

Common Questions About Charging Electric Forklifts

Even when you have a solid charging strategy, questions always pop up on the warehouse floor. Getting straight answers is the key to making smart, safe, and efficient decisions when it's time to plug in an electric forklift. Here are the answers to the questions we hear most often.

How Long Does It Take to Charge a Forklift Battery?

There's no single answer here—it all comes down to the battery's technology. A classic lead-acid battery needs a full 8-10 hours to complete its charging cycle. Just as important, it then requires another 8-hour cool-down period before it can safely go back into service.

On the other hand, a modern lithium-ion battery can be fully charged in just 1-2 hours. It also needs zero cool-down time, which is exactly why it's the star of opportunity and fast-charging setups where every minute of uptime is money.

Can I Use Any Charger with My Forklift Battery?

Absolutely not. This is a common and dangerous assumption. You must match the charger to the battery’s specific voltage, amperage, and chemistry (lead-acid or lithium-ion). Using the wrong charger is just asking for trouble.

An improperly matched charger can lead to inefficient charging that kills your battery life, cause permanent and expensive damage to the battery's cells, and create serious safety hazards, including the risk of fire or explosion. Always stick to the manufacturer's specs—no exceptions.

What Is Battery Equalization and Is It Necessary?

Equalization is a specific maintenance job only for lead-acid batteries. Think of it as a controlled overcharge that fights back against sulfation, a process where lead sulfate crystals build up on the battery plates and hurt performance.

The process also re-balances the voltage across all the individual cells inside the battery. While it's a must-do for extending the life and capacity of a lead-acid battery, it's totally unnecessary for lithium-ion batteries. In fact, it would damage them, as they don't suffer from sulfation.

What Are the Signs My Forklift Battery Needs Replacing?

A few clear signs will tell you when a battery is on its last legs. The most obvious is a major drop in run time, forcing operators to head back to the charging station way more often just to make it through a shift.

Other big red flags include:

- Physical Damage: Any visible swelling, cracking, or leaking from the battery case is a serious problem.

- Overheating: If the battery gets unusually hot during normal use or charging, it’s a sign of internal failure.

- Performance Data: A good Battery Management System (BMS) gives you the hard data on declining health, so you can see a failure coming before it brings operations to a halt.

Keeping an eye on these signs lets you plan for a replacement instead of getting caught with unexpected downtime.

For expert help picking the right batteries, chargers, and parts for your fleet, you can count on Flat Earth Equipment. We deliver the precision-fit components and practical support you need to keep your operation running at its best. Visit us online to get a fast quote today.