Let’s get one thing straight: changing the hydraulic oil in your Toyota 7-series forklift is a job you can handle. This isn't some mystical ritual that requires a dealer technician and his laptop. This is about keeping your machine—and your business—running. The process is simple: drain the old, contaminated fluid, slap on a new filter, and fill it with fresh oil. End of story. Don't let a service writer in a clean shirt tell you otherwise.

Why the Dealer Service Bay Is Your Enemy

The dealer loves your forklift. Not because it's a great machine, but because it’s a constant source of income. They’ll try to sell you on a "complex" hydraulic service, hinting that only their "certified" techs, armed with the sacred Dealer Laptop, can do it right. That's a load of bull designed to keep you chained to their schedule and their outrageous labor rates.

I spend my days wrestling with "Yellow Iron," mostly JCBs—backhoes, telehandlers, the whole lot. The biggest fight on any job site isn't a heavy load; it's downtime. It's that sinking feeling when the machine goes into a forced regen cycle, or when a simple sensor dies and the whole operation grinds to a halt. The real villain is the dealer telling you that a part is on backorder for two weeks and their only field tech is booked solid. It's the same game whether it's a JCB excavator stuck in the mud or your Toyota forklift sitting dead on the warehouse floor.

Every hour that machine isn't working, you're losing money. The entire dealer model is built on your dependency. They want you to wait. They want you to believe you're helpless without them.

Takeaway: Doing this job yourself isn't about saving a few bucks on a service bill. It's about seizing control of your uptime and telling the dealership you're not playing their game anymore.

Taking Back Control

This guide isn't based on some clean-room theory. This is about how we get things done in the field to get a machine back to work—fast. Forget the dealer's service manual; this is your new playbook.

The reality is simple: preventing a catastrophic failure is always cheaper than fixing one. Neglected hydraulic fluid is the #1 killer of pumps and valves. It gets contaminated with metal shavings, moisture, and dirt, turning from a lubricant into liquid sandpaper that grinds away at your system's guts.

This contaminated sludge leads to big problems:

- Pump Burnout: Gritty fluid eats pumps for breakfast. A new pump is an expensive, gut-wrenching repair you want no part of.

- Blown Seals: Debris scores cylinder rods and chews up seals, causing leaks that will sideline your machine in a heartbeat.

- Sluggish Hydraulics: Old, broken-down oil gets thin and weak, causing slow, jerky movements that crush your productivity.

The solution is to have the parts you need on your own shelf. At Flat Earth Equipment, we stock the sensors, solenoids, and filters you need to bypass the dealer's wait times and get back to work. This is how you win—by being prepared.

Gearing Up: What You Actually Need

Forget the dealership's shiny, rolling tool chests. Real work happens on a concrete floor with a deadline looming. We’re not playing make-believe; we’re getting this hydraulic oil change done without creating a bigger problem.

You don't need their proprietary Service Master laptop that locks you out. You need real tools. Start with a solid metric wrench and socket set—not that cheap junk that strips bolts. You’ll need it for the drain plug and filter housing.

Next, and listen close: get a drain pan that’s bigger than you think you need. A 10-gallon pan is a good place to start. Hydraulic fluid is an expert at finding its way onto the floor, and a small, overflowing pan is a rookie mistake that creates a slip hazard and a miserable cleanup.

A good strap wrench is your best friend here. The filter was probably put on by a gorilla at the factory, and you’ll need the leverage to break it loose without crushing it.

Sourcing Parts Without the Dealer Markup

Now for the lifeblood of the system—the fluid and filter. Using the wrong fluid is the quickest way to smoke a hydraulic pump, and that’s a repair that will absolutely ruin your month. The Toyota 7-series needs the right ISO grade hydraulic fluid. Don’t let some parts guy sell you "universal" junk. Check your machine's spec plate and get the right stuff.

This is where the dealer’s scam comes in. They’ll insist you need their "genuine" parts, which are just rebranded components with a 100% markup, often stuck on backorder. That’s the game. Waiting for their parts truck is how a one-day fix turns into a week of downtime.

This is the key to taking back control: have the right parts on your shelf before you need them. It’s about beating a rigged system built on delays and inflated prices.

Here are the essentials. No guesswork, no waiting for a callback from a service manager.

Toyota 7-Series Hydraulic Service Kit

This table has the core parts and fluids you need to do this job right, with the Flat Earth Equipment part numbers to bypass the dealer completely.

| Item | Specification or Flat Earth Part No. | Field Notes |

|---|---|---|

| Hydraulic Oil | ISO VG 46 (Typically) | Always confirm your specific model's requirement. Running in extreme cold or heat might require a different spec. |

| Hydraulic Filter | F-65002-U2170-71 | This is your first line of defense. Never reuse an old filter—it's just putting dirt back into your clean system. |

| Suction Strainer | F-67503-13311-71 | Often overlooked but critical. This screen protects the pump from larger debris. Always clean or replace it. |

| Drain Plug Gasket | F-90430-22003-71 | Cheap insurance against leaks. Replace it every time you pull the plug. |

Having these on hand turns a potential week-long shutdown into a two-hour job. While you're at it, keeping your equipment's batteries in top shape is just as crucial. You can learn more about maintaining peak performance by checking out our guide on forklift battery chargers. It's all part of the same mindset: proactive maintenance to eliminate downtime.

Draining the System: The Right Way, Not the Easy Way

Alright, let's get dirty. The dealership wants you to think this is some delicate, clean-room procedure. The only thing special is the bill they'll send you. We’re doing this on your floor, right now, and we're going to do it better.

First, safety and prep. Park the forklift on level ground. You don't want this thing rolling away mid-job. Chock the wheels. Lower the forks completely flat to the ground and shut the machine off. This bleeds the pressure out of the system. For a refresher on general worksite precautions, check out our comprehensive guide to forklift safety best practices.

Getting the Old Gunk Out

Next, warm up the fluid. Don't get it boiling hot, just warm enough so it flows out like water instead of sludge. Fire up the machine and run it for five minutes, tops. This stirs up all the crud sitting at the bottom of the tank so it drains out with the oil.

Once it's warm, kill the engine. Find the hydraulic tank, usually right under the floor plate. Pull that plate up to get access. Slide your oversized drain pan underneath the drain plug. Give yourself plenty of room; oil always splashes more than you think.

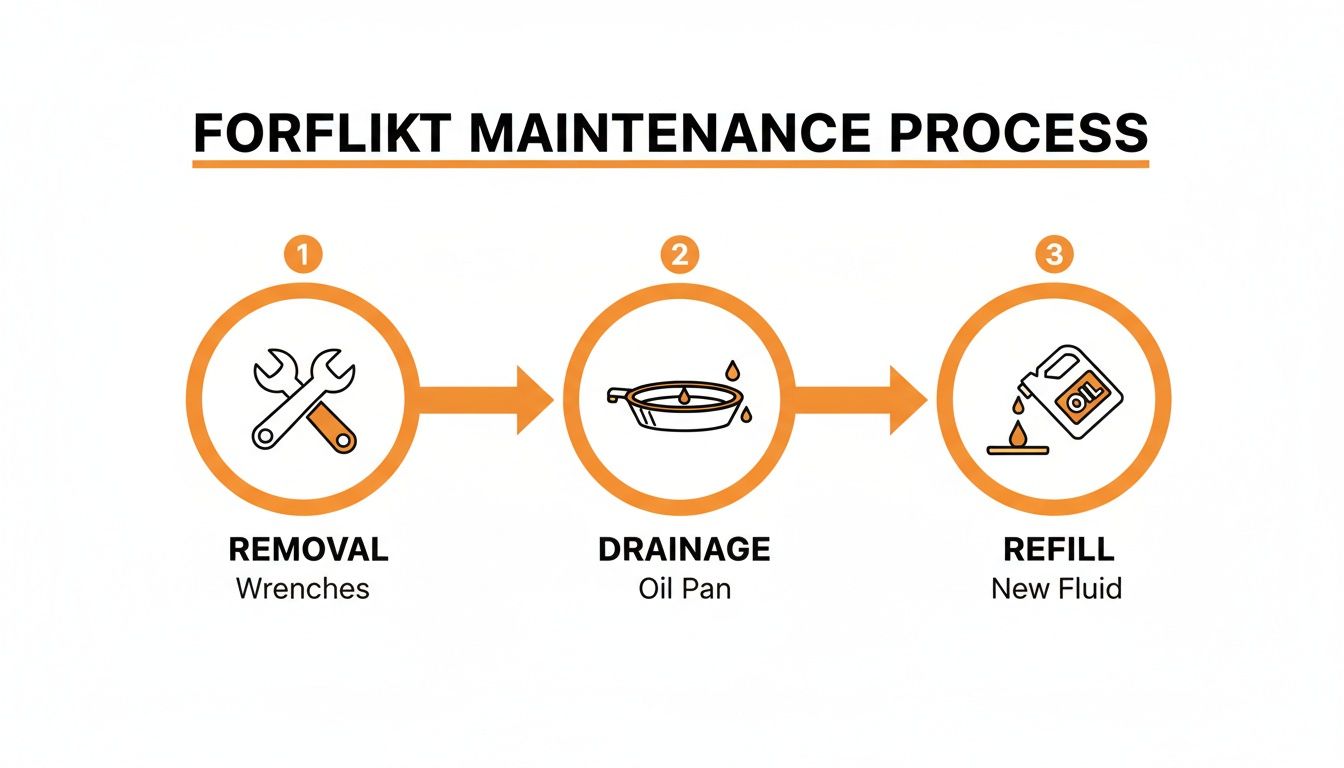

This process flow visualizes the core steps of the fluid change we're about to undertake.

This breaks the job down into three parts: get set up, drain the old poison, and fill with fresh lifeblood. It’s not rocket science.

With your pan in place, use the right wrench to crack the drain plug loose. Spin it out by hand and pull it away fast. Let it drain completely. It'll take a while, so be patient. In high-cycle applications like a logistics hub—think rapid 15-30 second cycles—service intervals shrink by 30-40%, down to around 700 hours, just to curb accelerated wear. For a typical 3-ton 7-series forklift running 2,000 hours a year, that's two full changes plus daily level checks, which catch leaks early and prevent 85% of hydraulic failures.

Cleaning the System’s Arteries

While it's draining, get to work. Find the hydraulic return filter. It looks like an engine oil filter. Grab your strap wrench and spin it off. Have a rag ready; it’s full of oil and it will make a mess.

This next step is what separates a real service from a lazy fluid swap. We're not just changing the oil; we're cleaning the system to protect the pump. Skipping this is asking for a four-figure repair bill down the road.

Once the drain plug is down to a drip, find the suction strainer. This is an in-tank screen that’s the pump’s last line of defense. On most 7-series lifts, you’ll find it behind an access plate on the side of the hydraulic tank.

Unbolt the cover. Pull the strainer out carefully; it will be dripping. Don't just wipe it with a rag. Hit it with brake cleaner and compressed air until it's spotless. You want to see clean mesh when you hold it to the light. If you find metal flakes in it, you've got a much bigger problem—something is already coming apart inside your system.

Cleaning this strainer is non-negotiable. Putting a dirty one back in starves the pump for fluid, guaranteeing it will burn itself up.

Refilling and Bleeding the System

With the old fluid out and the strainer clean, you’re past the messiest part. Now it’s time to button it up and get it running right. This is where precision matters. Rush this, and you'll be chasing gremlins you created yourself.

The Initial Fill and Reassembly

Grab the drain plug. Wipe the threads clean. Put the new gasket from Flat Earth Equipment on it. Thread the plug back in by hand to avoid cross-threading, then give it a final snug with your wrench. You’re not trying to twist it off; just tight enough to seal.

Now, get a clean funnel. Don’t use the one you use for engine oil; cross-contamination will kill your hydraulic system. Start pouring in the new fluid, keeping an eye on the sight glass or dipstick. Your manual lists the capacity, but don't just dump it all in.

A good field trick is to fill it to about 80% of capacity. This leaves room for the fluid to expand as it heats up and prevents foaming. Overfilling is a rookie mistake that aerates the oil and makes the system run hot.

Bleeding Air From the Lines

This is the most critical step. Air is the silent killer of hydraulic pumps. It causes spongy, jerky operation and leads to cavitation—tiny explosions inside the pump that chew up the metal from the inside out.

Never run a hydraulic system under load with air in the lines. It’s the fastest way I know to turn a good pump into scrap metal. That groaning noise you hear is the pump screaming for help as it tries to move air instead of oil.

To bleed it, clear the area. Fire up the forklift and let it idle. Don't touch the throttle. At a low idle, slowly and smoothly cycle every single hydraulic function through its full range of motion.

- Lift: Raise the forks all the way up, then all the way down. Do this three or four times.

- Tilt: Tilt the mast all the way forward, then all the way back. Repeat slowly.

- Attachments: If you have a side-shifter or rotator, cycle it from lock to lock multiple times.

You'll hear the pump groaning and whining as it pushes trapped air back to the tank. This is normal. The sound should get quieter as the air is purged.

Final Top-Off and Inspection

After cycling everything, shut the machine down. Let it sit for five to ten minutes. This allows the fluid to settle and any remaining air bubbles to rise to the surface.

Now, check the fluid level again. It will have dropped as the oil filled the lines and cylinders. Top it off to the 'full' mark. Again, do not overfill.

This process ensures your system is free of the air that causes jerky movements and long-term damage.

Common Bleeding Symptoms And Fixes

Even after a careful bleed, air can be stubborn. Here’s what to look for and how to fix it in the field.

| Symptom | Likely Cause | Field Solution |

|---|---|---|

| Jerky or Spongy Lift | Trapped air is still in the system, usually in the main lift cylinders. | The system needs more cycling. Re-start the machine at low idle and repeat the lift/lower and tilt cycles slowly another 5-6 times to work the last pockets of air out. |

| Foaming Oil in Tank | Caused by either overfilling the reservoir or a suction-side air leak. | If overfilled, drain a small amount of fluid. If the level is correct, check all suction hose clamps and fittings between the tank and pump for tightness. |

| Loud Whining Pump | Severe air ingestion or fluid starvation. | Shut down the machine immediately. Re-check the fluid level. If it’s very low, top it up and re-bleed. If the level is correct, you may have a major air leak on the suction side. |

A smooth, quiet hydraulic system is what you’re after. A little patience during the bleeding process goes a long way.

Setting a Realistic Service Interval

Let's be clear: the dealer's laminated maintenance chart is a revenue-generation tool. It’s a one-size-fits-all schedule that doesn't care if your forklift is working in an air-conditioned warehouse or a dusty lumber yard in 100-degree heat. In the real world, your environment dictates your maintenance schedule, not some piece of paper.

I see it constantly with heavy iron, especially those finicky JCBs and their cursed electronics. A machine working in the salty coastal air needs attention way more often than one digging in a clean field. The same logic applies directly to changing hydraulic oil Toyota 7-series forklift. Extreme heat is the #1 enemy of hydraulic fluid; it breaks down the oil, thins it out, and strips it of its ability to protect that expensive pump.

The hour meter isn't your only guide. Your best tools are your eyes and nose on your daily walk-around. They'll tell you more than a dealer's laptop ever could.

Reading the Signs

Your machine will tell you when it needs a service long before a catastrophic failure stops you dead. You just have to listen.

Here are the dead giveaways that your hydraulic fluid is shot:

- Milky or Cloudy Appearance: This means water contamination. Water causes rust, destroys lubrication, and can freeze in cold weather, cracking expensive components.

- Burnt Smell: If the fluid smells burnt, it’s been overheated. The oil has thermally broken down and is creating sludge that will clog filters and starve your pump.

- Darkened Color: New hydraulic oil is light amber. If yours is dark brown or black, it's full of contaminants. It’s not protecting anything anymore; it's actively damaging your system.

The bottom line: learn to read your machine. Set a maintenance schedule that protects your uptime and your wallet, not one that pads the dealer's bank account.

Of course, the manufacturer's guidelines provide a baseline. According to Toyota's official periodic maintenance guidelines, hydraulic oil must be replaced every 6 weeks or every 250 hours of operation, whichever comes first. This interval is designed to combat the intense thermal stress these systems endure, and statistically, operators who stick to this 250-hour mark see hydraulic failure rates drop by up to 85%.

You can learn more about these guidelines and see how they form a solid foundation by reviewing the details about forklift periodic replacement parts.

Building a Smarter Maintenance Plan

Use the OEM recommendation as a starting point, then adjust for your reality.

If you're running in a dirty, dusty, or high-heat environment, shorten that interval. Maybe change it every 150-200 hours. If your machine is in a clean, climate-controlled facility with light loads, you might be able to extend it.

The key is proactive observation. A quick look at the sight glass during your daily check can save you from a multi-thousand-dollar pump replacement. This is about working smarter, keeping your machine making money, not waiting for a technician who's three calls behind.

Field Notes and Common Questions

You've done the work, but you've got questions. Good. Complacency gets you in trouble. Here are the straight answers to what I hear from guys in the field after they're done changing hydraulic oil on a Toyota 7-series forklift. No fluff.

What Happens If I Use the Wrong Type of Hydraulic Oil?

Using the wrong oil will destroy your hydraulic pump. It's not something you can "get away with."

Oil that’s too thin won't protect parts under load, leading to metal-on-metal destruction. Oil that's too thick will starve the pump, causing cavitation and overheating. It can also cause seals to swell or shrink, creating leaks you never had before.

Stick to the ISO grade specified for your Toyota 7-series. Mixing different oils is even worse, as their additives can react and form a useless sludge. Don't guess. Get the right fluid from a supplier like Flat Earth Equipment that knows your machine.

My Lift Is Jerky After Changing the Oil. What Did I Do Wrong?

Jerky movement is the classic sign of trapped air. You didn't do anything wrong, you just need to be more thorough with the bleeding process. Air compresses; oil doesn't. That compression is the sponginess you're feeling.

The fix is simple: re-bleed it.

- Start the machine, keep it at a low idle.

- Slowly cycle all hydraulic functions—lift, lower, tilt—to their absolute limits.

- Repeat this several times to push the air pockets back to the reservoir.

Shut it down, let the oil settle, and re-check your fluid level. You'll probably need to top it off now that the air is out.

How Do I Dispose of the Old Hydraulic Oil?

Don't be the guy who dumps it behind the shop. Used hydraulic oil is hazardous waste, and the fines for improper disposal are crippling.

Drain it into a sealed, labeled container. Most auto parts stores will take it for free. Your local waste facility will also have a hazardous materials drop-off. For a larger operation, get a waste oil collection service. It’s easy to do it right and it keeps the EPA off your back.

I’ve seen operations get shut down for less. Proper disposal isn't a suggestion; it's a non-negotiable part of the job. Don't get lazy on the last step.

Can I Just Top Off the Hydraulic Fluid Instead of Changing It?

Topping off is for routine checks between changes, not a substitute for them. If the fluid is low, you have to add more to prevent pump starvation. But that does nothing to remove the contaminants and sludge in the old oil.

Over time, hydraulic fluid gets saturated with metal particles, dirt, and moisture. Heat breaks down its chemical structure.

Adding new oil to old, dirty oil is like taking a shower without soap. It doesn't solve the problem. A full drain and refill is the only way to protect your system. Anything less is just kicking a very expensive can down the road.

When you do the job yourself, you need a parts supplier that works as hard as you do. Flat Earth Equipment has the right filters, seals, and technical knowledge to help you get the job done right the first time, without the dealer games. Get the parts you need shipped today from https://flatearthequipment.com.