When the job site is humming, you're making money. Simple as that. But when a JCB telehandler throws a DEF code, a Skyjack lift gets moody, or a Komatsu gets stuck in a permanent regen cycle, the silence is deafening. Every hour that 'yellow iron' sits idle is another hour you're bleeding cash.

The best diagnostic scanner for a mixed construction fleet is the one that gets you back to work now, not three weeks from now when the dealer finally decides to show up.

When Your Fleet Is Down and The Dealer Is Weeks Out

Let's cut the crap. The dealer's proprietary "Service Master" laptop isn't your friend. It's a locked box designed to keep you chained to their schedule, forcing you to call them out for even the simplest electronic gremlins. They talk about their software like it's black magic, but all it really does is hold your fleet hostage.

You know the drill. A machine goes down with an emissions fault. You call the service department, and they tell you the next available slot is weeks away. Meanwhile, your project timeline is shot, your operator is sitting on his hands, and you’re staring down a hefty bill just for them to plug in and tell you what you already suspect—a finicky sensor has failed again.

The Daily Grind of Mixed Fleet Maintenance

Managing a mixed fleet is a constant battle of whack-a-mole. One day it's a JCB backhoe with a mysterious AdBlue system error; the next, it's a Genie lift that won’t cooperate. Each brand has its own quirks, its own connectors, and its own special way of driving a technician nuts. Juggling different dealers for each piece of equipment is a logistical nightmare and a massive drain on your budget.

This is where taking control of your own diagnostics becomes non-negotiable. You need a single tool that speaks every language your iron does.

The real enemy on any job site isn't a tough patch of ground; it's unplanned downtime. Waiting for a dealer to fix a simple sensor fault is the same as setting a pile of money on fire. You need the power to diagnose and fix it yourself, right in the field.

Taking Back Control from the Dealer

The solution isn't another frustrated phone call to the service department. It's arming your own techs with a powerful, multi-brand diagnostic scanner. This isn't about pulling the basic codes you can get from a cheap reader from the auto parts store. We're talking about commanding OEM-level functions: forcing a DPF regen on a stubborn machine, calibrating a brand new NOx sensor, or resetting a transmission controller after a repair.

When your scanner tells you a DEF pressure sensor is shot, you don't have to wait and pay the dealer's markup. You can source a high-quality replacement from a supplier like Flat Earth Equipment, get it shipped overnight, and have that machine earning its keep by the next morning.

That’s the difference between being a victim of the system and being in command of your fleet's uptime.

Dealer Laptop vs. Independent Scanner Showdown

Still on the fence about bringing diagnostics in-house? Let’s break down why an independent, multi-brand scanner is a game-changer compared to relying on the dealer's proprietary tools.

| Factor | Dealer Proprietary Laptop | Independent Multi-Brand Scanner |

|---|---|---|

| Brand Coverage | Single brand only (e.g., Cat ET, John Deere Service Advisor). | Covers dozens of brands of engines, equipment, and trucks. |

| Accessibility | Locked down. Requires expensive subscriptions and dealer approval. | Open access. Your tool, your rules. |

| Cost | Extremely high initial cost plus ongoing mandatory subscriptions. | A one-time investment with optional, affordable updates. |

| Field Use | Often requires an internet connection and is not built for rough use. | Rugged, military-grade tablets designed for the job site. |

| Control | Keeps you dependent on the dealer for parts and service. | Empowers your techs to diagnose and repair on your terms. |

The choice is clear. While dealer tools are powerful for their specific brand, they're designed to keep you tethered. An independent scanner cuts the cord, giving your team the flexibility and power they need to keep a diverse fleet running.

What Actually Makes a Good Mixed Fleet Scanner

Forget the fancy touchscreens and slick sales pitches. The true test of a diagnostic scanner isn’t how it looks on a workbench—it’s how it performs when you're ankle-deep in mud, staring down a cryptic fault code on a JCB telehandler that’s holding up the entire job. A good tool is a weapon against downtime, not a toy.

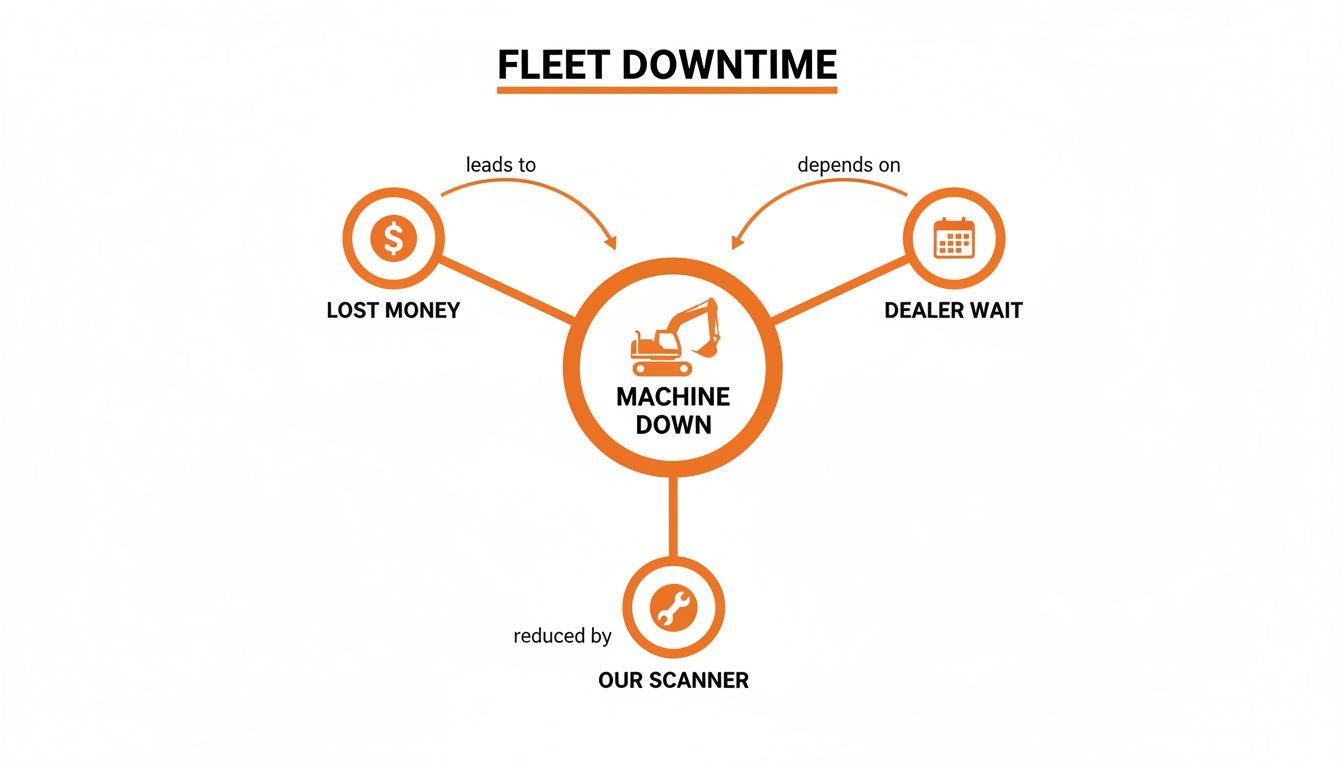

When a machine goes down, it kicks off a chain reaction: lost money, project delays, and long waits for a dealer tech to show up. A powerful scanner is what breaks that cycle.

As you can see, an independent scanner is the direct countermeasure to financial loss and dealer dependency. Let’s dig into the guts of what makes a scanner a true field asset.

Speaking the Language of Yellow Iron

Your machines don't all speak English. They communicate through a tangled mess of electronic languages called protocols, and if your scanner isn't fluent, it's basically a paperweight. This is the absolute foundation of a useful tool.

A scanner has to master the core heavy-duty protocols, no exceptions. Think of them as the different dialects spoken by your equipment.

- J1939: This is the universal language for almost all modern diesel engines in North America. From your Komatsu excavator to your Freightliner dump truck, J1939 is how the engine, transmission, and ABS systems talk.

- CAN (Controller Area Network): This is the high-speed nervous system inside your machines. It connects everything from the joystick controllers on a Skyjack to the complex hydraulic systems on a JCB backhoe.

- KWP2000 (Keyword Protocol 2000): It's an older protocol, but still critical. You'll find it on a lot of European equipment and some ancillary systems. Ignoring it means you'll have blind spots in your fleet.

A cheap scanner might read basic engine codes, but the best diagnostic scanner for a mixed construction fleet dives deep into these protocols to give you the full story.

More Than Just a 9-Pin Connector

So you can speak the language, but you still need the right plug to join the conversation. Relying on a single 9-pin Deutsch connector is like bringing only one socket to a full engine rebuild. It won't get you far.

Your fleet is a mix of different plugs. JCB loves their proprietary connectors, older equipment might have a 6-pin, and compact machines often use something else entirely. A top-tier diagnostic kit must come with a full arsenal of adapters. Without them, you’re dead in the water before you even start.

The moment you have to say, "I don't have the right adapter for that machine," is the moment you've lost the battle. You’re back to calling the dealer, and the clock on downtime starts ticking again.

The Power to Command, Not Just Read

Here's what separates the professional-grade tools from the pretenders: bi-directional controls and OEM-level functions. Reading a fault code is one thing. Forcing the machine to act is another. This is where you fight back against that dreaded "Regen" cycle that stops a machine cold.

This is the kind of functionality that truly replaces the dealer's laptop:

- Forced DPF Regeneration: Don't let a clogged Diesel Particulate Filter sideline your equipment. A good scanner lets you command a stationary regen on the spot, clearing the system and getting back to work.

- Injector Cut-Out Tests: Isolate a faulty injector without tearing the engine apart. By shutting off injectors one by one from the scanner, you can pinpoint the exact cylinder that's causing the misfire.

- AdBlue/DEF System Calibrations: A new NOx sensor on a JCB is useless until it's calibrated. This function lets you perform the electronic handshake needed to make the new part work with the ECU—a job the dealer would gladly charge you a fortune for.

When you can command these functions yourself, you're not just a technician—you're in control. You can diagnose the problem, source the needed sensor or solenoid from a place like Flat Earth Equipment, install it, and complete the electronic repair cycle yourself.

Finally, the tool itself has to survive the job site. A flimsy tablet with a cracked screen is a liability. Look for rugged, drop-tested hardware with a battery that will outlast you on a long day. Because when that critical machine goes down, your scanner needs to be as tough as the iron you're fixing.

Translating Scanner Data Into Actionable Repairs

A scanner spitting out fault codes is just a fancy paperweight if you can't turn that data into a real-world fix. Too many techs get hung up on the code itself, but that code is just the symptom. It tells you the patient has a fever; it doesn't tell you about the infection causing it.

Getting a machine back to work means moving beyond the code and diving into the live data streams. This is where you separate the guessers from the real technicians.

This shift towards in-house diagnostics is reshaping the industry. The global market for this tech is exploding, moving from USD 2.8 billion in 2025 toward a projected USD 5.77 billion by 2035. Why? Because a good scanner that handles mixed fleets can slash unplanned downtime by up to 30%, a figure that makes any fleet manager sit up and take notice.

From Fault Code to Root Cause

Let’s get practical. A JCB backhoe throws a DEF code related to low pressure. The dealer’s first move? They’ll want to sell you an entire, eye-wateringly expensive pump assembly. But with a proper scanner, you can watch the live data from the DEF pressure sensor.

Is the pressure fluctuating wildly? Is it stuck at zero? By monitoring the sensor's live output, you can tell if it's just a cheap, failed sensor—something you can get from a supplier like Flat Earth Equipment—or if the pump is genuinely failing. That's the difference between a hundred-dollar fix you do yourself and a five-thousand-dollar dealer repair that sidelines your machine for a week.

The dealer wants you to replace big, expensive modules. We want to find the single, cheap component that's causing the problem. Live data is the tool that lets us do that. It's about surgical precision, not swapping parts until the light goes off.

Chasing a hydraulic issue is another perfect example. Instead of cracking lines and making a mess, you can monitor solenoid command percentages and feedback signals directly on the scanner. You can see if the controller is telling the valve to open and if the valve is actually responding. This saves hours of greasy guesswork.

The Power of Bi-Directional Controls

Now we get to the real game-changer: bi-directional controls. This is what truly lets you leave the dealer’s "Service Master" laptop to collect dust. Bi-directional functions allow you to command the machine's components directly from your scanner.

Think of it as having a remote control for the machine’s brain. With these controls, you can:

- Cycle a Hydraulic Solenoid: Hear that satisfying click? You just confirmed the solenoid is electrically sound without ever putting a wrench on it.

- Activate the EGR Valve: Command it to open and close while watching the live data to see if it responds smoothly or gets stuck.

- Test Individual Injectors: Perform a cylinder cut-out test to isolate a weak or dead injector causing a rough idle.

This isn’t just about reading what the machine is doing; it’s about telling it what to do. You become the ECU. This is how you confirm a diagnosis with 100% certainty before you order parts. It’s also a critical part of maintaining jobsite safety protocols by testing components in a controlled manner.

This level of control is what makes the best diagnostic scanner for a mixed construction fleet an investment in uptime, not just another tool in the box. It’s how you take a cryptic code, follow the data to the source, and command the system to prove your diagnosis is correct. That's how you fix it right the first time and get that yellow iron back to making you money.

The Real Cost of Downtime vs The Price of a Scanner

Let’s do the back-of-the-napkin math every fleet manager hates but absolutely needs to see. That idle excavator isn't just a quiet machine; it's a black hole sucking revenue right out of your business. We're not talking pocket change—we're talking thousands per day in lost billing, operator wages, and project delays that make clients furious.

Then there's the dealer. Their first move is a diagnostic call-out fee that costs hundreds, and that’s before they even open a toolbox. If the machine needs to be hauled back to their shop, you can add a massive tow bill to the bleeding. This isn't a sustainable way to run a business. It's a painful cycle of dependency.

The Math That Matters

The sticker price on a quality multi-brand scanner might make you pause for a second. But when you stack that one-time investment against the crippling, recurring cost of unplanned downtime, the picture becomes crystal clear.

A single major service call that you could have prevented or fixed yourself often pays for the entire tool.

Think about it. That JCB telehandler stuck in a regen cycle? A good scanner can force it through, saving you a $500 dealer visit and getting a $2,000-a-day machine back to work in minutes. One or two of those events, and your scanner is already pure profit. It stops being an expense and becomes one of the most valuable assets in your shop.

This isn't about buying another tool to clutter up the truck. It's about buying your independence. It's an investment in uptime, self-sufficiency, and telling the dealer you don't need them to hold your hand every time a sensor throws a fit.

Unlocking Hidden Benefits

The return on investment goes far beyond avoiding a few service calls. When your technicians have the power to diagnose anything in the fleet, a ripple effect of efficiency spreads across your entire operation. They're not just parts-swappers anymore; they’re empowered problem-solvers.

This leads to some serious hidden benefits:

- Smarter Maintenance: You can schedule proactive repairs based on real data, not just a generic hours-based schedule.

- Repair Verification: After a fix, you can run diagnostics to confirm the job was done right the first time, preventing frustrating repeat failures.

- Empowered Techs: A technician who can confidently diagnose and fix a complex electronic issue is a happier, more valuable employee.

This is especially critical with finicky AdBlue/DEF systems or dead batteries that can cause a cascade of phantom electrical faults. Having the right tool to diagnose the root cause is essential—and so is having the right gear to keep your equipment charged and ready. A simple check with our guide on heavy-duty battery chargers can prevent a lot of headaches.

The Uptime Investment Case

The numbers don't lie. Unplanned downtime can devour 5-20% of a fleet's revenue, but top-tier scanners have been shown to slash that figure by half, pushing fleets toward 99%+ uptime.

With IoT diagnostics now integrated into 45% of new equipment, the ability to predict failures up to 72 hours in advance is becoming the new standard, cutting repair costs by an average of 22% per machine.

For busy service shops, this translates to faster turnarounds; scanner users report diagnosing issues 35% faster, a critical advantage for getting rentals back on the line. Read more about the trends shaping the construction equipment market to see where the industry is heading. Investing in the best diagnostic scanner for your mixed construction fleet is a direct investment in your bottom line.

Closing the Loop From Diagnosis to Done

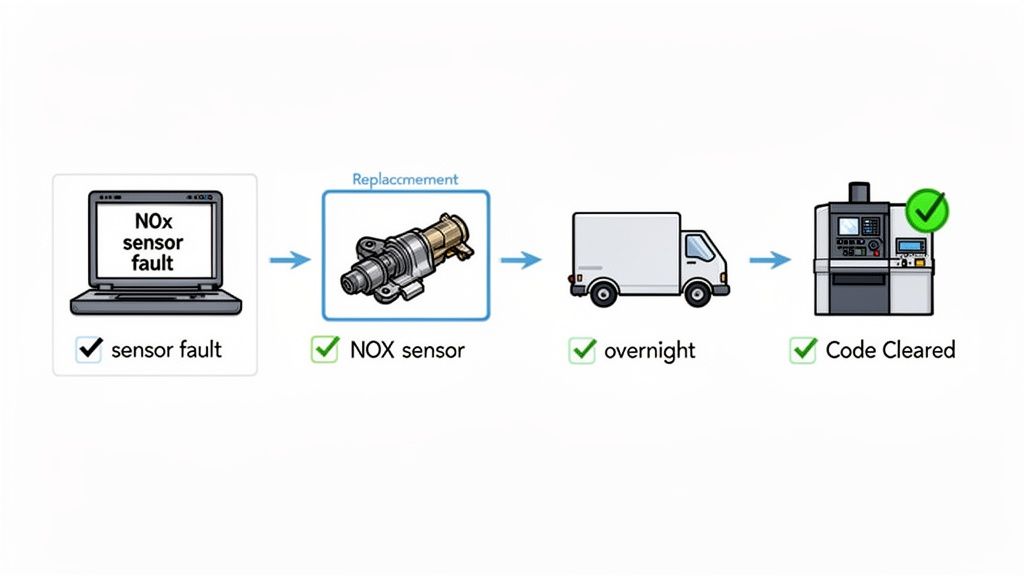

You’ve done the hard part. You wrestled with the machine, plugged in the scanner, and navigated the software. The tool confirms what your gut was telling you: a faulty NOx sensor on your JCB 540-170 Loadall. A clear diagnosis feels like a win, but it’s only half the battle.

The machine is still down, and now the clock is ticking on a new problem—getting the right part in your hand.

This is where your diagnostic strategy has to connect directly to your parts strategy. Waiting for the dealer to look up a part number, check stock, and maybe ship it out in a few days means you’re still dead in the water. You’ve lost all the uptime you gained by diagnosing it yourself.

The Anti-Dealer Model for Parts

The whole point of having the best diagnostic scanner for a mixed construction fleet is to break free from the dealer’s grip. Once that scanner gives you the exact fault and part number, you’re in the driver's seat. You don’t have to get in line behind three other shops waiting for the dealer's parts counter.

You can take that part number directly to a reliable supplier like Flat Earth Equipment. We have the precision-fit sensors, solenoids, and filters you need, ready for same-day shipping. This is how you close the loop from diagnosis to done, fast.

This model is a game-changer for fleets of all sizes. Remote diagnostic tools can detect 40% more issues before they become catastrophic breakdowns, preventing a slice of the $50 billion the industry loses annually to downtime. Data shows that fleets adopting this approach cut their diagnostic travel by 60%, freeing up techs for actual repairs.

For the small and medium-sized businesses that make up 70% of a construction firms, an affordable multi-brand scanner can deliver a full ROI in under six months. Dig deeper into the impact of telematics on the construction industry to see the full picture.

The Uptime Checklist From Diagnosis to Repair

Tired of waiting? Here’s the straightforward, no-nonsense checklist to take back control of your fleet's productivity. This is how you turn a week of downtime into an overnight fix.

You bought the scanner to get answers. Now use those answers to get parts. Don't let a slow parts department become the new bottleneck. Take the diagnosis and run with it.

Following a clear process is the fastest way to turn that fault code into a running machine. Every step is designed to eliminate guesswork and delays.

| Step | Action | Key Benefit |

|---|---|---|

| 1. Diagnose the Fault | Use your scanner to pinpoint the exact component failure. Don't guess—know. | Eliminates time wasted on incorrect repairs. |

| 2. Identify the Part Number | Get the OEM or cross-reference number directly from the scanner or your service manual. | Ensures you order the right part the first time. |

| 3. Source the Part Immediately | Call a supplier like us who understands you need it yesterday. No ticket numbers, just a tech on the other end of the line. | Bypasses dealer delays and backlogs. |

| 4. Get It Overnight | With same-day shipping, that critical part arrives at your shop or job site the next morning. | Minimizes machine downtime from days to hours. |

| 5. Install, Clear, and Run | Install the new component, use your scanner to clear the fault codes and perform any necessary calibrations. | Confirms the repair is successful and gets the machine back to earning its keep. |

This checklist isn't just a set of steps; it's a new way of operating. By connecting your diagnostic tool directly to an agile parts supplier, you create a direct line from problem to solution.

Straight Answers to Your Questions from the Field

Out in the trenches, there's no time for fluff. You need straight answers that get the machine moving again. Here are the no-nonsense responses to the questions we get every day from technicians who've had enough of the dealer runaround.

Will an Aftermarket Scanner Really Handle Finicky JCB Electronics?

Absolutely, but only if you have the right one. JCB electronics, especially their AdBlue/DEF systems, are notoriously sensitive. The best diagnostic scanner for a mixed construction fleet isn't just about reading codes; it’s about having OEM-level software that lets you command critical functions.

This is your key to bypassing the dealer's locked-down "Service Master" laptop. You need the power to force a DPF regeneration, execute a full DEF system reset after swapping a part, and calibrate new sensors right on the spot. That’s the stuff that gets you past 90% of the common electronic and emissions faults that sideline a machine. Without that, you're just reading codes—you're not solving problems.

What's More Important: Brand Coverage or Functional Depth?

Functional depth, every single time. A scanner that claims to cover 100 brands but only reads basic engine codes is totally useless when you’re staring down a complex hydraulic or emissions issue. It's a classic trap that looks great on a sales sheet but falls flat in the field.

Think about it: you need a tool with deep bi-directional controls and special functions for your core brands—the Caterpillar, Komatsu, John Deere, and JCB equipment that actually makes you money. It's far better to have total control over the 20 key brands in your fleet than to have shallow, surface-level data on 100 you’ll never even see.

Can One Scanner Handle My Whole Fleet, from Skid Steers to Excavators?

Yes, that’s the entire point. A true mixed-fleet scanner is built to be your single diagnostic solution. A top-tier kit will come with a whole briefcase of adapters for everything from the standard 9-pin Deutsch on your heavy iron to the smaller, proprietary plugs on compact equipment like skid steers and telehandlers.

The software has to be just as versatile, covering not just off-highway diesel engines but also the hydraulics, transmission controllers, and body control modules. It pulls all your diagnostic needs into one rugged, field-ready tool. If you have questions about what your specific fleet needs, our team of techs can give you the right answers—get in touch with us here.

How Do I Justify the Cost of a High-End Scanner to My Boss?

Simple, brutal math. Calculate the real cost of just one major downtime event. Add up the tow bill, the dealer's outrageous diagnostic fees, the lost revenue from that idle machine, and the operator's wage. A good scanner often pays for itself by preventing just one or two of those crippling events.

It's not an expense; it's an investment in operational independence. Every time you fix a machine in-house that would have gone to the dealer, that tool is putting money directly back into your pocket.

When you have the right diagnosis and need the part to finish the job, Flat Earth Equipment is ready. We ship the sensors, solenoids, and filters you need to get your yellow iron back to work, fast. Take back control of your uptime with a tool that works as hard as you do. Visit https://flatearthequipment.com to gear up.