A 24 volt forklift battery charger is the dedicated power supply built to safely juice up the 24V batteries in your light-to-medium duty electric forklifts—think pallet jacks, walkie stackers, and smaller riders. Getting the right one isn't just a technicality; it's a critical decision that directly impacts battery lifespan, equipment uptime, and your warehouse's bottom line.

Why Your Charger Choice Powers More Than Just Your Forklift

Think of your forklift charger as the unsung hero of your material handling operation. It’s more than just a box that plugs into a wall; it’s the heart that pumps life back into the equipment keeping your inventory moving. The right charger ensures your forklifts are ready for every shift, but the wrong one quickly becomes a bottleneck, causing costly downtime and frustrated operators.

This decision goes way beyond convenience. A mismatched charger can drastically shorten the life of an expensive battery by either overcharging or undercharging it. This leads to premature degradation, less capacity, and eventually, a big bill for a replacement. Even worse, bad charging practices can create serious safety hazards, from overheating to the release of flammable gases.

The Growing Importance of Electric Power

The shift to electric material handling equipment is happening now. As more warehouses adopt electric forklifts for their efficiency and lower emissions, the tech that supports them has become more important than ever. The numbers back this up: the global forklift battery charger market was valued at USD 1.88 billion and is projected to keep growing, highlighting its role in modern logistics. You can dig into more data on this trend at ResearchAndMarkets.com.

Choosing the right charger is an investment in your operation’s resilience. It's about protecting your assets, keeping your team safe, and maintaining the seamless flow of goods that defines a successful warehouse.

This guide is here to cut through the technical jargon and give you a clear roadmap. We'll cover everything you need to know, from charger technology to safety compliance. By the end, you'll be able to select a 24 volt forklift battery charger that not only powers your equipment but also drives your business forward. Think of this as your complete playbook for making a smart, strategic decision.

Understanding Different Charger Technologies

Not all chargers are built the same. The technology packed inside your 24 volt forklift battery charger has a huge impact on everything from your monthly power bill to how quickly your crew can get back to work. Think of it like refueling a car—some methods are like old, reliable gas pumps, while others are high-tech superchargers.

To make the right choice, you have to look past the metal box and understand what’s driving the charging process. Let's break down the three main types you'll find in any warehouse: Conventional, SCR, and High-Frequency. Each has its own place, and knowing the difference is key.

Conventional Ferroresonant Chargers: The Old-School Workhorse

Conventional chargers, which you'll often hear called Ferroresonant or just "Ferro" chargers, are the original workhorses for lead-acid batteries. They’re built around a massive transformer that regulates power, making them incredibly simple and tough. They are durable, reliable, and usually the cheapest option to buy upfront.

Imagine this charger as a basic water valve—it’s either all the way on or off. It blasts a high current into the battery at the start, which then slowly tapers off as the battery fills up. It gets the job done, but it's not very precise or efficient. A lot of the electricity it pulls from the wall is wasted as heat, which you can literally feel radiating off the unit.

Because of this brute-force approach, a Ferro charger typically has an efficiency rating of only 70-80%. That means for every dollar you spend on electricity, up to 30 cents is literally vanishing into thin air as heat.

SCR Chargers: The Smarter Successor

Silicon-Controlled Rectifier (SCR) chargers were the next big step up. They use microprocessors to gain much finer control over the charging process. It’s like upgrading from that simple on/off valve to a digitally controlled faucet that can adjust the flow perfectly.

SCR chargers constantly monitor the battery's condition and adjust the current to match. This "smarter" charging cycle is much healthier for your battery, helping it last longer. They're also a good bit more efficient than the old Ferro models, usually operating at around 85-90% efficiency.

The real win with SCR technology is its tailored charge. By managing the current so precisely, it cuts down on overcharging and excess heat—two of the biggest enemies of battery life.

That jump in efficiency translates directly into lower utility bills. For any facility running multiple shifts or managing even a small fleet, the energy savings from an SCR charger can add up fast.

High-Frequency Chargers: The Modern Standard

High-Frequency (HF) chargers are the most advanced and efficient technology on the market today. If Ferro chargers are the old gas pumps, HF chargers are the EV superchargers of the forklift world. They are small, light, and use sophisticated software to deliver a precise, multi-stage charge that’s perfectly matched to the battery’s needs.

Instead of a giant, heavy transformer, HF chargers use modern electronics to convert AC power to DC at a much higher frequency. This process is incredibly efficient, with ratings that often top 93%. Less wasted electricity means lower energy costs and a charger that runs much cooler.

The advantages are hard to ignore:

- Faster Charging: High-frequency chargers can top off a battery much faster than older tech without causing heat damage.

- Versatility: Many HF units are programmable, allowing them to charge different battery types like lead-acid, AGM, or even Lithium-ion with the right settings.

- Reduced Gassing: The precise control minimizes the gassing phase in lead-acid batteries, which means a safer charging area and less time spent watering batteries.

With their blend of efficiency and advanced features, High-Frequency chargers have become the go-to for any operation looking to boost productivity and lower their total cost of ownership. If you're looking for the best, you'll find plenty of advanced 24 volt forklift battery charger models in this category. They are a smart investment that quickly pays for itself in energy savings and longer-lasting batteries.

Matching Charger Amperage to Battery Capacity

Of all the decisions you'll make, picking the right amperage for your 24 volt forklift battery charger is probably the most important one for your battery's health and performance. It's a bit like filling a swimming pool. Use a tiny garden hose, and you'll be there forever. Use a fire hose, and you’ll just make a damaging mess.

The same idea applies directly to your forklift battery. Amperage—or amps (A)—is just the speed at which electricity flows into the battery. Get the speed right, and you get a safe, efficient charge that helps the battery last. Get it wrong, and you're asking for trouble.

The Dangers of a Mismatched Charger

Undercharging is a slow death for a battery. If your charger's amperage is too low for the battery's capacity, it might never actually reach a 100% full charge. When that happens, lead sulfate crystals start to harden on the battery plates in a process called sulfation. Over time, this permanently cripples the battery's ability to hold a charge, stealing runtime from your operations.

Overcharging is much faster and more destructive. Shoving too much current into the battery too quickly makes it overheat and gas like crazy. This literally boils away the electrolyte, damages the internal components, and creates a serious safety hazard. It’s an expensive mistake that will drastically shorten your battery's life.

Calculating the Perfect Charge Rate

Thankfully, finding the right amperage isn't just guesswork. The industry has a straightforward rule of thumb based on the battery's Amp-hour (Ah) rating, which is simply a measure of its total energy storage.

The sweet spot for a lead-acid forklift battery is a charge rate between 16% and 20% of its total Amp-hour capacity. This range strikes the perfect balance between charging speed and long-term battery health.

Let's look at a common example. Say you have a 24-volt battery rated for 500 Amp-hours (Ah).

- Minimum Amperage (16%): 500 Ah x 0.16 = 80 Amps

- Maximum Amperage (20%): 500 Ah x 0.20 = 100 Amps

For that 500Ah battery, you'd want a charger that puts out somewhere between 80A and 100A. Sticking to this range ensures the battery charges efficiently without being damaged by too much heat or gassing. A quality 24 volt forklift battery charger like the Green4 24V 40A model, for instance, would be a great fit for a smaller 200-250 Ah battery.

To help you quickly find the right charger for your battery, we've put together this handy reference table. Just find your battery's Ah rating to see the recommended charger size.

Recommended Charger Amperage for Common 24V Batteries

| Battery Amp-Hour (Ah) Rating | Recommended Charger Amperage (16-20%) | Typical Full Charge Time (Hours) |

|---|---|---|

| 200 Ah | 32A - 40A | 6-8 |

| 400 Ah | 64A - 80A | 6-8 |

| 600 Ah | 96A - 120A | 6-8 |

| 800 Ah | 128A - 160A | 6-8 |

| 1000 Ah | 160A - 200A | 6-8 |

This table makes it easy to match your equipment, but always double-check your battery's specific documentation for any unique manufacturer recommendations.

This chart shows the different types of charger technologies that deliver these amperage ratings.

As you can see, while older Conventional chargers still exist, modern High-Frequency technology gives you the most precise and efficient control over the charging process.

How Battery Chemistry Changes the Game

The rise of different battery types adds another layer to this. The global forklift battery market, currently valued around $2.26 billion, is in the middle of a major shift. While traditional flooded lead-acid batteries still command about 77.2% of the market, lithium-ion is gaining ground fast.

Here's the key difference: lithium-ion batteries can often handle much faster charge rates than their lead-acid cousins—sometimes up to 100% of their Ah capacity (known as a 1C rate). You absolutely must check the battery manufacturer's specs. Using a standard lead-acid charger on a lithium battery without the right profile can cause severe, irreversible damage. Sizing your charger amperage correctly is the first and most important step to keeping your fleet running smoothly.

Making Sure Everything Plays Together: Full System Compatibility

True compatibility for a 24 volt forklift battery charger is about more than just matching volts and amps. Two other factors are just as vital for keeping your equipment safe and running efficiently: the battery's internal chemistry and the physical connector that links the charger to the battery.

Think of it like this: a charger has a specific "recipe" for refilling a battery. But different battery types, like old-school lead-acid and modern lithium-ion, need completely different recipes. Using the wrong one is like pumping diesel into a gasoline engine—it might fit, but the result is going to be a serious, expensive mess.

The global market for industrial battery chargers is already valued at USD 2.52 billion and climbing. Why? Because these chargers are the critical link in the entire industrial power chain. As more facilities bring in different battery technologies, getting these compatibility details right is the only way to protect that massive investment. You can learn more about the industrial battery charger market and its growth here.

Matching the Charger to the Battery Chemistry

Every type of battery has its own unique "charge profile"—a specific sequence of voltage and current it needs to recharge safely and completely. A charger built for a classic flooded lead-acid battery uses a totally different approach than one made for a sealed AGM or a high-tech lithium-ion battery.

- Flooded Lead-Acid: These workhorses need a multi-stage charge that includes an "equalization" phase to stir up the internal chemistry and prevent damage. A charger that skips this step will kill the battery's lifespan.

- AGM (Absorbent Glass Mat): While still lead-acid, these sealed batteries are much touchier about being overcharged. They demand a very precise, voltage-controlled profile that avoids the high-voltage equalization stage, which would wreck their sealed cells.

- Lithium-ion (Li-ion): Lithium batteries are a different beast entirely. They require a "constant current/constant voltage" (CC/CV) profile and can't be float-charged like lead-acid types. Using a standard lead-acid charger on a lithium battery is a recipe for disaster, potentially pushing it into a dangerous over-voltage state.

Using the wrong charge profile isn't just inefficient; it actively destroys the battery. It can lead to overheating, permanent capacity loss, and in a worst-case scenario, a major safety incident.

This is where modern smart chargers, especially the high-frequency models, really shine. Many can be programmed for different battery chemistries, giving you the flexibility to handle a mixed fleet with a single unit. Just be absolutely sure the charger is set to the correct profile before you plug it in.

The Physical Handshake: Connectors and Fitment

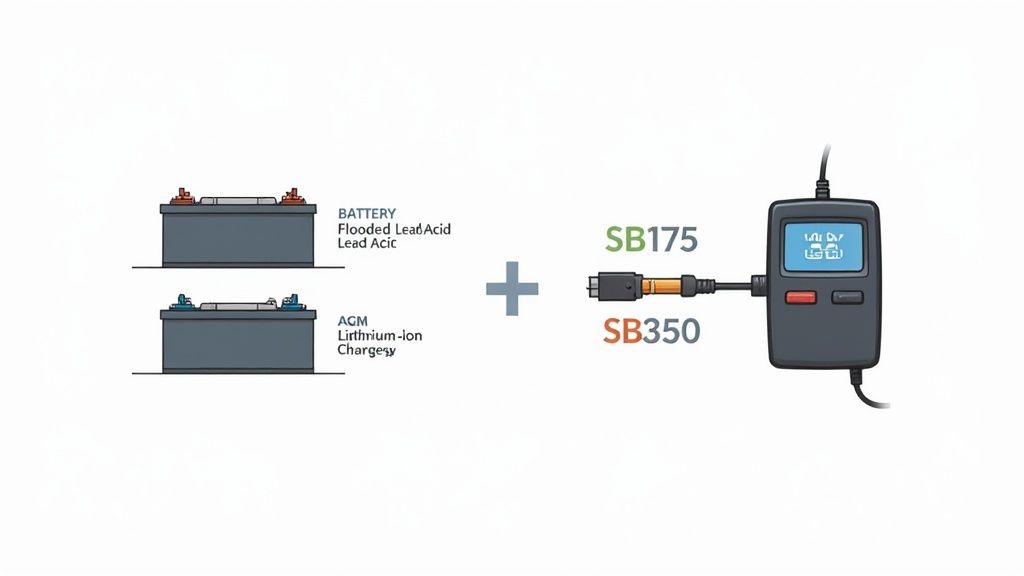

Once you've got the chemistry matched up, the last piece of the puzzle is the physical connection. That big plastic connector is more than just a plug; it's a brilliant safety feature designed to prevent costly mix-ups. For a 24 volt forklift battery charger, the most common connectors you'll see are the SB175 and SB350.

These connectors use a simple but genius safety system: color-coding. The color of the connector housing tells you its voltage rating.

- Red: Almost always for 24-volt systems.

- Gray: The standard for 36-volt systems.

- Blue: Typically used for 48-volt systems.

This isn't just for looks. The plastic housings are keyed differently based on color, making it physically impossible to plug a red 24V connector into a gray 36V one. It's a simple, foolproof design that prevents someone from accidentally connecting a high-voltage charger to a low-voltage battery—an error that could cause immediate and catastrophic failure. Always, always check that the colors on the battery and charger connectors match.

Creating a Safe and Compliant Charging Station

A dedicated battery charging area is an absolute must, but if you don't plan it right, it can quickly become one of the most dangerous spots in your entire facility. Think of it like a refueling station—it demands specific safety measures to keep accidents from happening. Setting up a safe, OSHA-compliant charging station isn't just about checking boxes; it's about protecting your team and your expensive equipment.

This goes way beyond just plugging in your 24 volt forklift battery charger. It requires a thoughtful layout that considers proper ventilation, the risk of spills, and what to do in an emergency. Getting this right from the start is the best way to reduce risk and create a secure, efficient workflow for your operators.

Core Safety Components for Every Charging Station

To build a genuinely safe charging area, several safety features are completely non-negotiable. These components all work together to tackle the main hazards of industrial batteries, especially the flammable gas and corrosive acid you find in traditional lead-acid models.

Here are the essentials your station must have:

- Adequate Ventilation: During charging, lead-acid batteries vent hydrogen gas, which is highly flammable. Your station needs enough ventilation to stop this gas from building up to explosive levels. The goal is to keep concentrations below 1%.

- Emergency Eye Wash and Shower Station: If an acid splash occurs, every second counts. An OSHA-compliant eye wash and shower station must be within 25 feet and have a clear, unobstructed path for immediate use.

- Spill Containment Kits: Accidents are going to happen. You're required to have a spill kit handy with neutralizing agents, absorbent materials, and the right disposal bags to manage acid spills safely.

- Fire Extinguisher: A Class ABC fire extinguisher should be mounted close by to handle any potential electrical or chemical fires. Make sure every operator knows exactly where it is and how to use it.

These items are the foundation of a safe charging environment. For a deeper look into day-to-day operational safety, our guide on forklift safety protocols has more valuable insights and best practices.

Personal Protective Equipment (PPE) is Non-Negotiable

Beyond the station's physical setup, personal safety is everything. Anyone handling or charging batteries must be wearing the correct Personal Protective Equipment (PPE). This is their last line of defense against a serious injury.

OSHA standard 1910.178(g)(2) is crystal clear: facilities are required to provide protective equipment for workers who handle batteries. This isn't a suggestion; it's a federal rule designed to prevent chemical burns and other injuries.

Your team’s standard PPE kit for battery handling should always include:

- Chemical-Resistant Gloves: Forget standard work gloves. You need rubber or neoprene gloves that can actually stand up to sulfuric acid.

- Safety Goggles and a Face Shield: Using both goggles and a full face shield gives you the best possible protection against acid splashing into the eyes or onto the face.

- Acid-Resistant Apron: This protects an operator's torso and legs from corrosive drips and splashes that can happen during battery watering or cleaning.

By putting these environmental and personal safety measures in place, you turn a potentially hazardous area into a controlled, compliant, and secure part of your operation. This proactive mindset doesn't just protect your employees—it also protects your investment in your fleet and your facility.

Essential Maintenance and Troubleshooting Tips

Your 24 volt forklift battery charger is one of the most hardworking pieces of equipment in your facility. Like any mission-critical asset, it needs a little proactive care to keep it running safely and efficiently for its entire lifespan. Think of it as a pre-flight check for your power system.

A simple, consistent maintenance routine is the best defense against unexpected failures and the costly downtime that follows. Spending just a few minutes on these checks each week can help you catch small issues before they snowball into major headaches, protecting your investment and keeping your fleet ready for the next shift.

Your Simple Maintenance Checklist

A well-maintained charger is a reliable one. Integrating these quick inspections into your weekly routine will pay huge dividends in uptime and equipment longevity.

- Inspect All Cables and Connectors: Give the AC input cord and the DC output cable a good look-over. You're searching for any signs of cracking, fraying, or exposed wires. Check the connector housing itself for cracks, and make sure the metal contacts are clean and free of pitting or corrosion.

- Keep It Clean and Clear: Dust and debris are the enemies of electronics. Grab a can of compressed air and gently blow out the charger’s vents and cooling fans. A clean charger runs cooler, which is key to preventing heat-related damage to its internal components.

- Ensure a Secure Installation: Give the charger a gentle push. Is it securely mounted to the wall or its stand? Over time, vibrations from a loose unit can wreak havoc on sensitive internal electronics.

- Verify Indicator Lights: The moment a charge cycle kicks off, confirm the indicator lights are doing their job. If they don't light up or immediately flash an error code, that's your first clue that something's off.

Proactive maintenance isn’t just about cleaning; it’s about preventing downtime. A five-minute check that spots a frayed cable can save you from a full day of lost productivity and a surprise repair bill.

Common Troubleshooting Steps

Even with perfect maintenance, things can go wrong. When your 24 volt forklift battery charger starts acting up, running through a few basic troubleshooting steps can often get you back online without a service call, saving you valuable time and money.

Problem 1: The Charger Won't Turn On

If the unit is completely dead, don't assume the worst just yet. Start with the most obvious culprits first.

- Check the AC Power Source: Is the charger actually plugged into a live outlet? It sounds simple, but you'd be surprised. Head over to the panel and verify the circuit breaker hasn’t tripped.

- Inspect the AC Input Cord: Make sure the cord is seated firmly in both the wall outlet and the charger itself. A loose connection is a common problem. While you're there, check for any visible damage.

- Examine Internal Fuses: Some chargers have fuses that are accessible to users. If you are qualified and comfortable doing so, check if a fuse has blown. If it has, replace it with one of the correct rating.

Problem 2: The Charge Cycle Never Finishes

When a charge cycle seems to run forever, it often points to a communication breakdown between the battery and the charger.

- Poor Connection: A dirty or damaged connector can prevent the charger from getting an accurate voltage reading. This can trick it into thinking the battery isn't full, causing it to keep pumping power indefinitely.

- Battery Health: An old or damaged battery might not be able to reach the proper finishing voltage. The charger keeps waiting for a signal that the battery simply can't send anymore.

- Incorrect Settings: If you’re using a programmable charger, double-check that it’s set to the correct profile for your battery’s specific voltage and chemistry. The wrong setting can lead to all sorts of charging issues.

Frequently Asked Questions About 24V Chargers

When it comes to the nitty-gritty of a 24 volt forklift battery charger, a few questions pop up time and time again. Whether you’re managing a whole fleet or just getting started, clear answers are what you need to make the right call and keep everything running smoothly and safely. Let's tackle some of the most common ones we hear from the field.

Can I Use a 24 Volt Charger on a 12 Volt Battery?

No, you absolutely cannot. This is one of the most important—and dangerous—mistakes you can make with batteries. Hooking a 24-volt charger up to a 12-volt battery is like trying to fill a bicycle tire with an industrial air compressor; it's going to end badly, and fast.

The massive voltage mismatch instantly and violently overcharges the battery. This will cause it to overheat, boil the electrolyte, vent dangerous gases, and could easily lead to an explosion. Always, always match the charger's voltage to the battery's voltage. No exceptions.

How Do I Know When My 24V Forklift Battery Is Fully Charged?

Thankfully, modern chargers make this pretty foolproof. Most will have a simple indicator, usually a solid green light, telling you the charging cycle is done and the battery is good to go.

If you want to double-check a lead-acid battery or don't trust the indicator, you can get a more precise reading with a couple of tools:

- A hydrometer: This tool measures the specific gravity of the battery's electrolyte. A reading around 1.275 is the classic sign of a full charge.

- A multimeter: Check the voltage after the battery has had a little time to rest post-charge. A healthy, fully charged 24V battery should read somewhere between 25.4 and 26.4 volts.

What Is the Difference Between a Single Phase and a Three Phase Charger?

This question is all about the kind of power your building supplies. It's about what you can plug the charger into.

A single-phase charger is the simpler of the two. It runs on the standard 120V or 240V AC power you find in most commercial buildings and workshops. These are great for smaller operations that don't have specialized, heavy-duty electrical wiring.

On the other hand, a three-phase charger needs a more powerful and efficient electrical supply, the kind typically found in large industrial plants and distribution centers. These chargers can handle much higher amperage, which means they can charge batteries significantly faster. They are the go-to choice for demanding, multi-shift operations where getting forklifts back in service quickly is critical.

When you need the right 24 volt forklift battery charger and the expertise to go with it, Flat Earth Equipment has your back. We provide precision-fit components and technician-led support to make sure your fleet gets exactly what it needs. See our complete lineup of charging solutions at https://flatearthequipment.com.